Combined exterior structural heat pipe for vertical heat-pipe condensers and manufacturing method thereof

The technology of a heat pipe condenser and a manufacturing method is applied in the field of composite outer structure heat pipe and its manufacturing, which can solve the problem that evaporation, condensation and reflux do not have a good strengthening effect, reduce the heat transfer coefficient of steam in the condenser, and adversely affect the overall performance of the condenser. and other problems, to achieve the effect of simple and reliable processing technology, reducing reflux resistance, and strengthening condensation heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

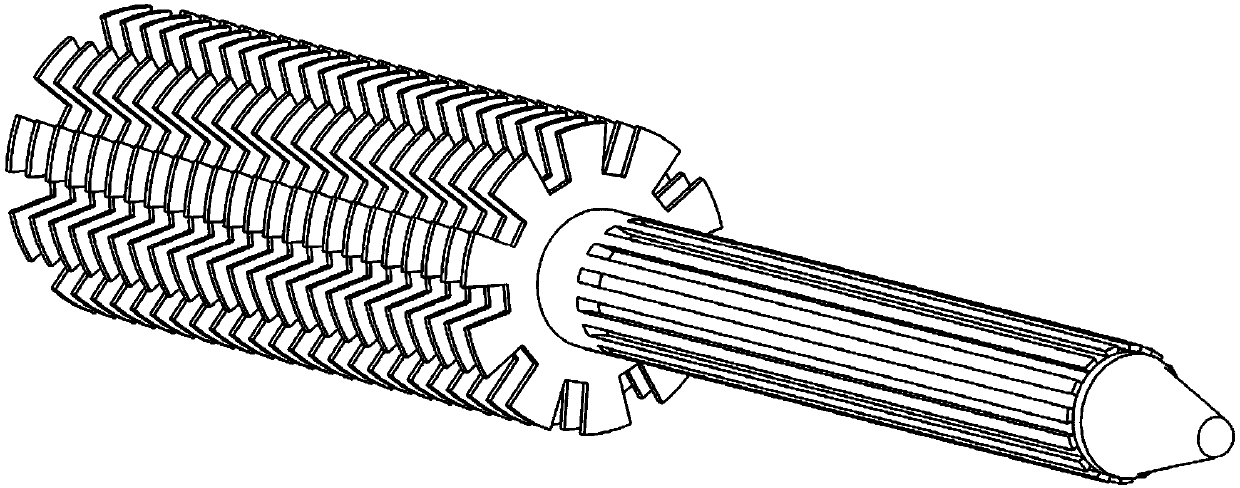

[0028] The specific implementation manners of the present invention will be described in further detail below in conjunction with the drawings and examples, but the implementation manners of the present invention are not limited thereto.

[0029] In this embodiment, the cross-sectional shape of the outer groove is rectangular; the liquid-absorbing core is copper powder sintered core, and the particle size is about 200 mesh branch-shaped copper powder; the size of each part of the composite outer structure heat pipe can be determined according to the specific situation.

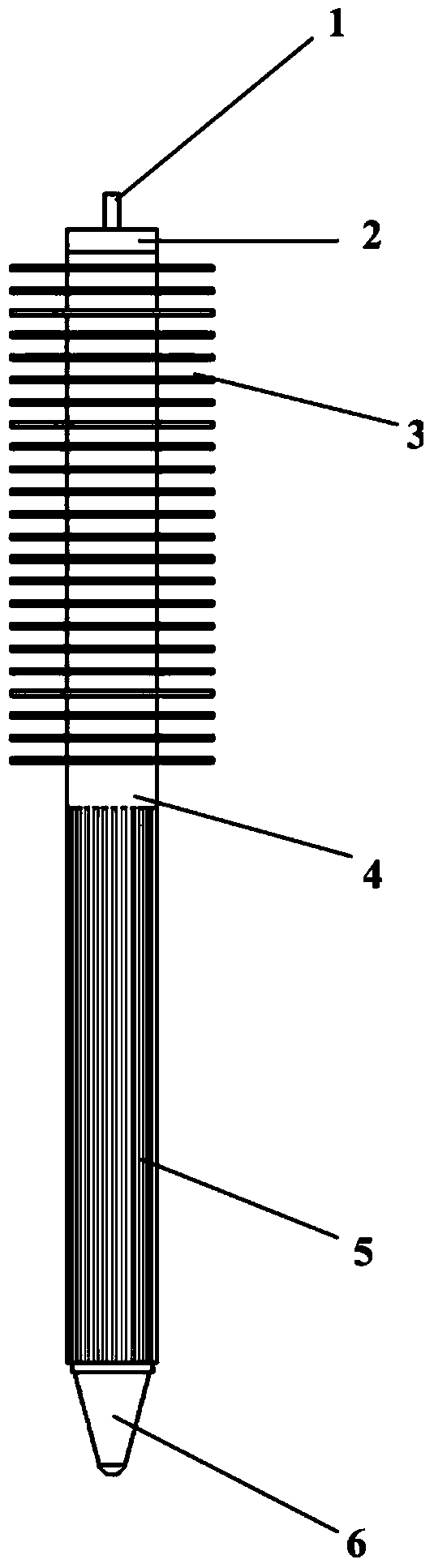

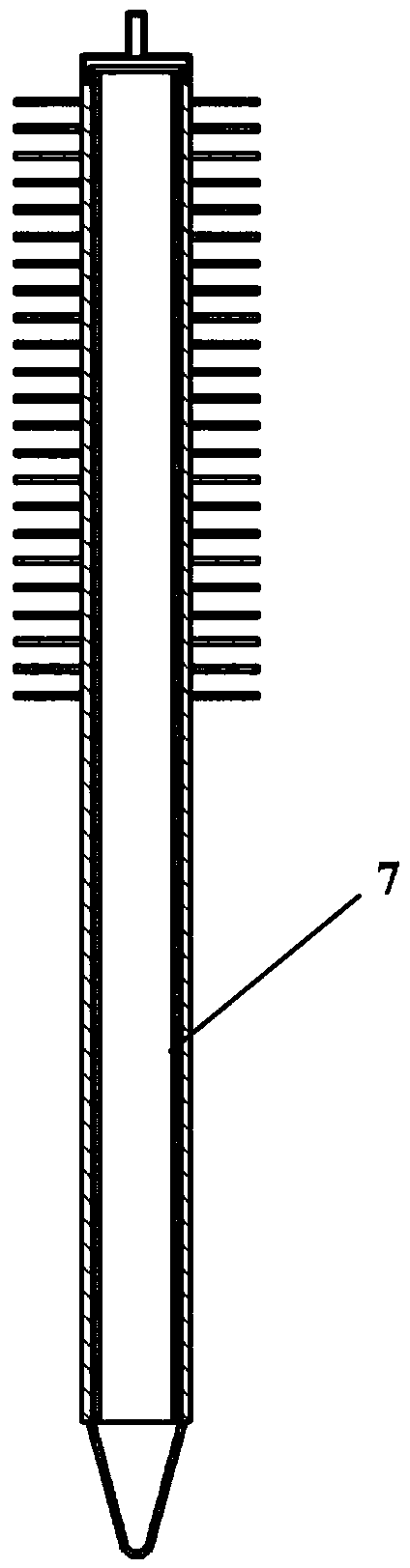

[0030] A heat pipe with a composite outer structure for a vertical heat pipe condenser, comprising: an upper end cover, a tube body, a lower end cover, an outer fin unit, a liquid-absorbing core, a vacuum tube and a liquid working fluid. The upper end cover is inserted into the outer stepped opening at the top of the pipe body, and is sealed with the outer wall of the pipe body. The liquid-absorbing core fits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com