Plate type static-indeterminant combination bearing beam oversize vibration screen

An ultra-statically indeterminate, load-bearing beam technology, applied in the direction of screens, solid separation, grids, etc., can solve the problem that the reliability and life of extra-large vibrating screens cannot be satisfied, there is no major breakthrough in the structure technology of large-scale vibrating screens, and the vibrating screen body It is difficult to increase the width of the cross-section to achieve the effect of improving comprehensive mechanical properties and reliability life, simple and reliable screen structure, and improving comprehensive mechanical properties and reliability life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

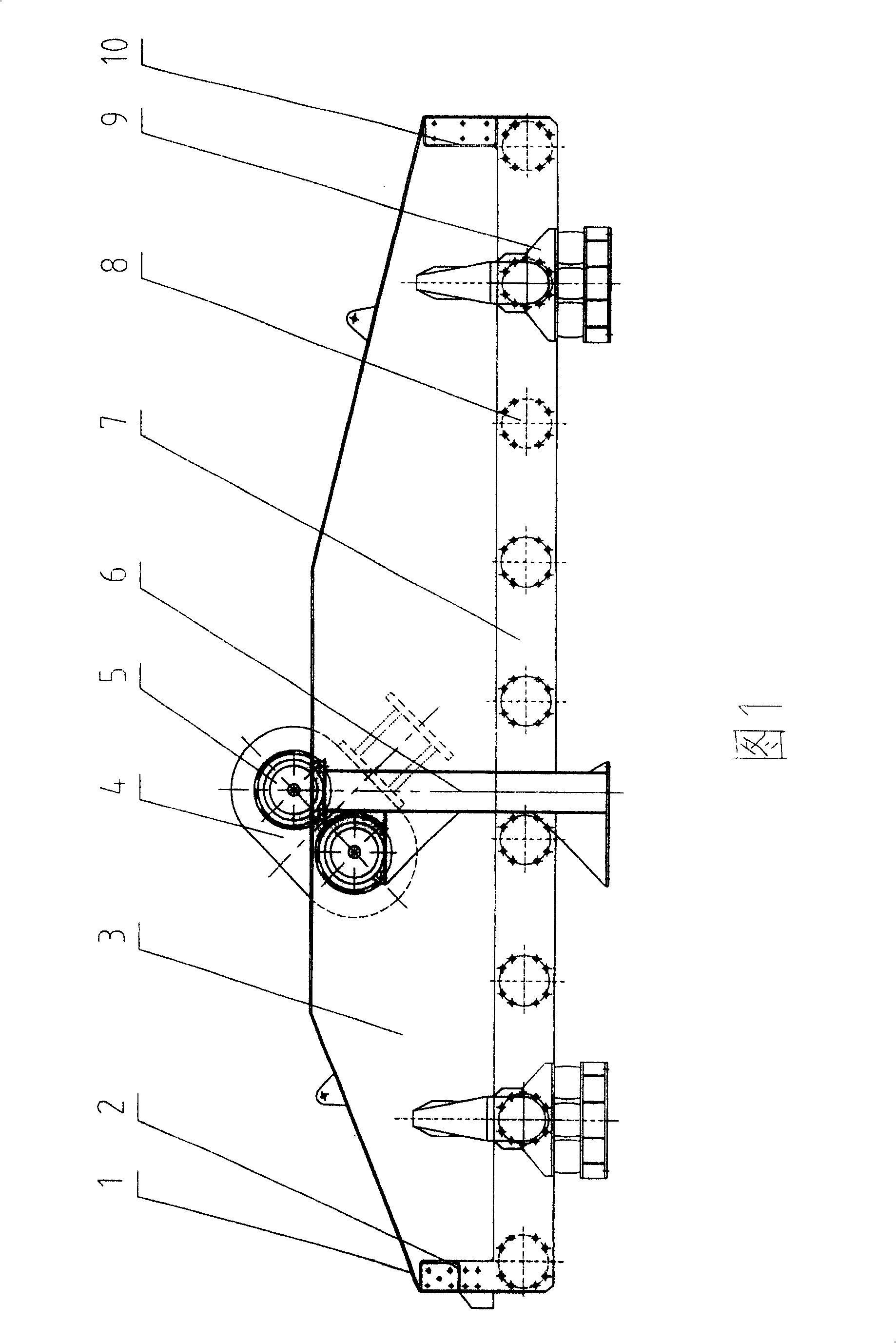

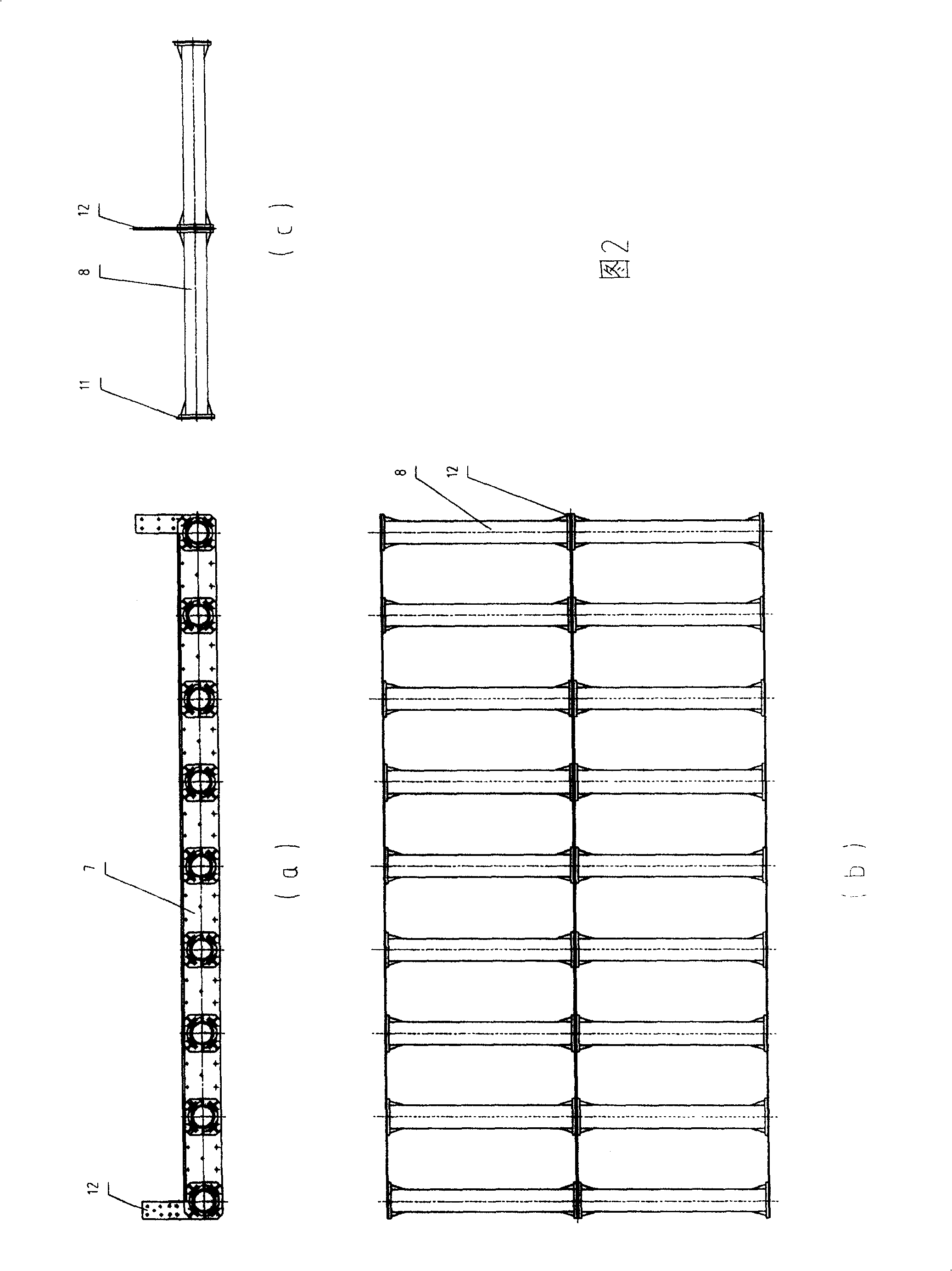

[0010] As shown in Fig. 1, the plate-type ultra-static combined load-bearing beam super-large vibrating screen mainly consists of side plates 3, sieve plates, rectangular closed beams 2 at the discharge end, rectangular closed beams 10 at the feed end, vibrators 4, and plate-type vibrating screens. The sieve box 1 composed of super-static combined load-bearing beam 7; the sieve body is composed of spring upper seat, rubber spring, and elastic support body 9 composed of spring base; Composed of universal joints, the motor 5 is arranged on the motor base 6, and according to the width of the screen box, the motor 5 can be provided with single or double parts. The screen box 1 is equipped with a plate-type ultra-static combination load-bearing beam 7, which is connected with the screen box by high-strength hinged bolts. Constitute a closed large rigid containm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com