Tubular channel-type heat exchange method for sewage or surface water

A surface water, dredging type technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the retention of suspended solids and impurities in the interior, pipe structure pipe mouth blockage, casing structure The problem of large steel consumption, etc., achieves the effect of simple and reliable processing technology, guaranteeing reliability, and solving the clogging problem of suspended solids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

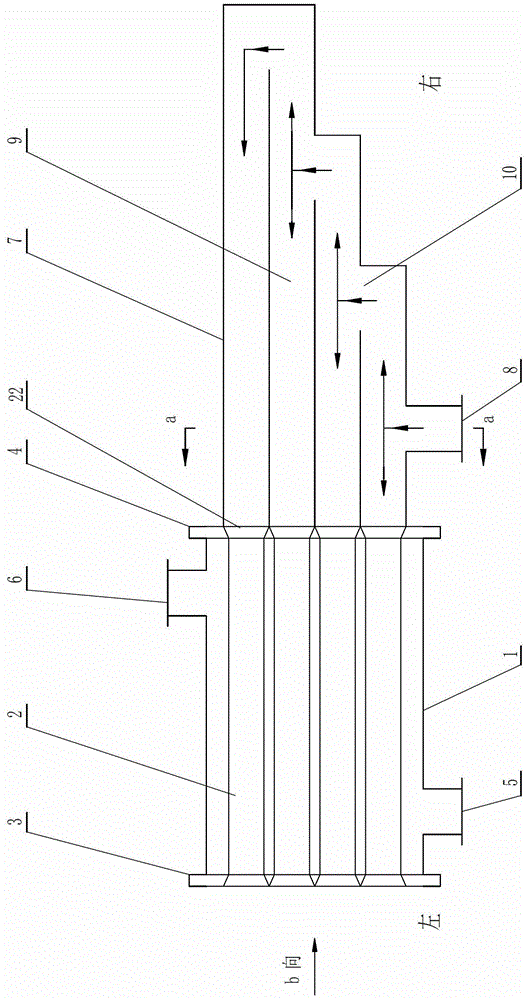

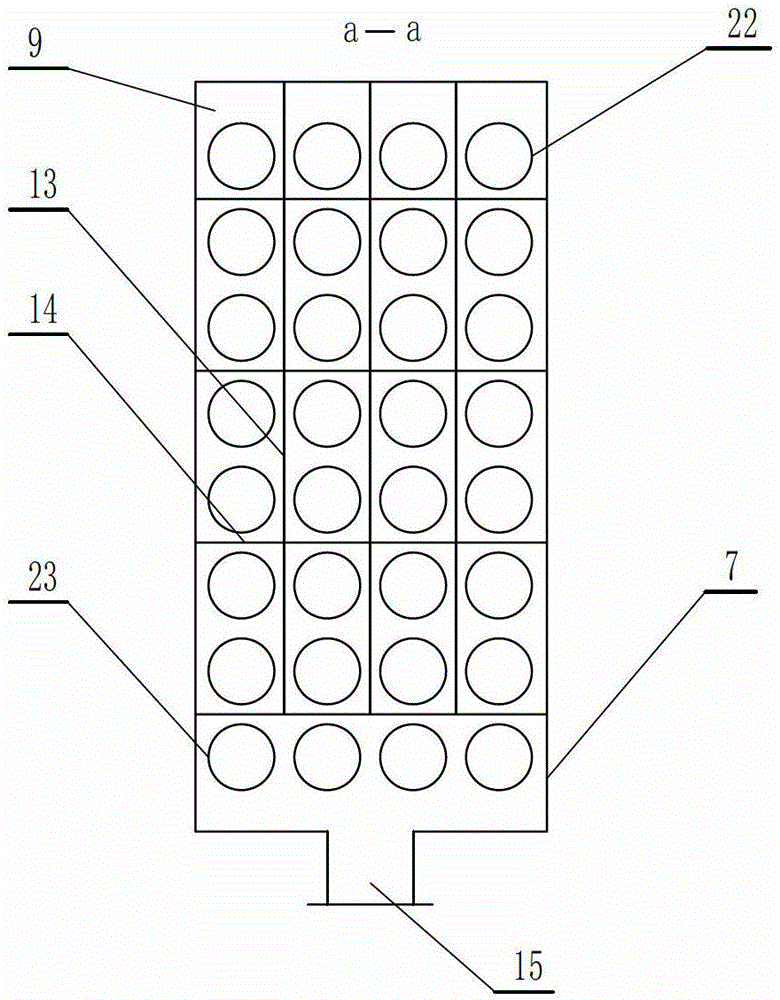

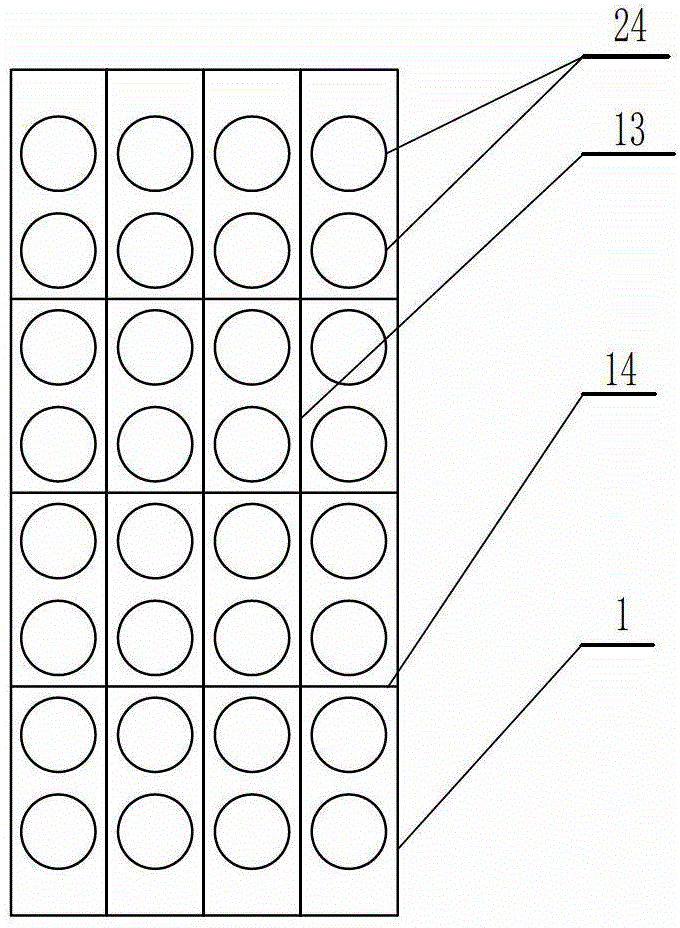

[0042] Specific implementation mode one: as Figure 1 ~ Figure 3 , Figure 5 and Image 6 As shown, the pipe-type dredging heat exchange method for sewage or surface water in this embodiment includes the following steps:

[0043] Step 1: Multilayer heat exchange tubes 2 are arranged in the heat exchange shell 1, the left end of the multilayer heat exchange tubes 2 is fixedly connected to the left tube plate 3, the right end of the multilayer heat exchange tubes 2 is fixedly connected to the right tube plate 4, and the The heat shell 1 is respectively provided with a medium inlet 5 and a medium outlet 6, the left end of the dredging shell 7 is an open end, the open end of the dredging shell 7 is fixedly connected with the right tube plate 4, and the dredging shell 7 One or two sewage or surface water inlets 8 are arranged on the top, and a plurality of parallel flow channels are arranged in the dredging type shell 7. The numbers are one-to-one corresponding and connected, an...

specific Embodiment approach 2

[0046] Specific implementation mode two: as figure 1 As shown, in the specific embodiment 1 of the pipe-type dredging heat exchange method for sewage or surface water, in step 1, the number of sewage or surface water inlet 8 is one, and it is arranged on the side of the shortest separation channel. on the side wall.

specific Embodiment approach 3

[0047] Specific implementation mode three: as Figure 5 As shown, in the first embodiment of the pipe-type dredging heat exchange method for sewage or surface water, in step 1, the number of sewage or surface water inlets 8 is two, and two sewage or surface water inlets 8 It is arranged symmetrically with respect to the central axis of the length direction of the dredging shell 7, and the two sewage or surface water inlets 8 are arranged on the side walls of the two shortest separated flow channels of the dredging shell 7, and each sewage or surface water The inlet 8 communicates with an adjacent separation channel with the shortest length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com