Rod-like connector, thermal-insulation wall and construction method thereof

A connecting piece and rod-shaped technology, which is applied in the field of rod-shaped connecting piece, thermal insulation wall and its construction, can solve the problems of poor anchoring performance, difficult processing, complex structure, etc., and achieve high durability, reliable processing technology and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

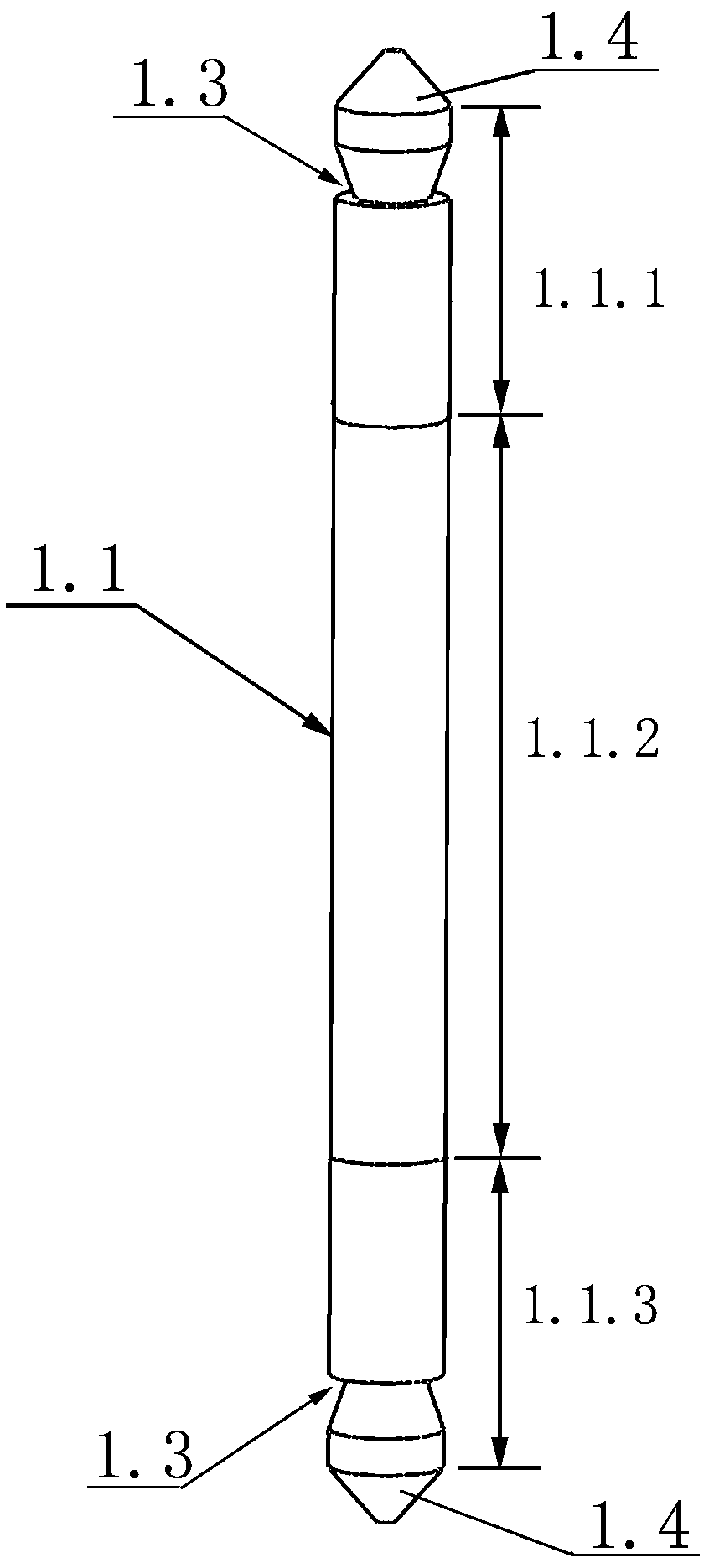

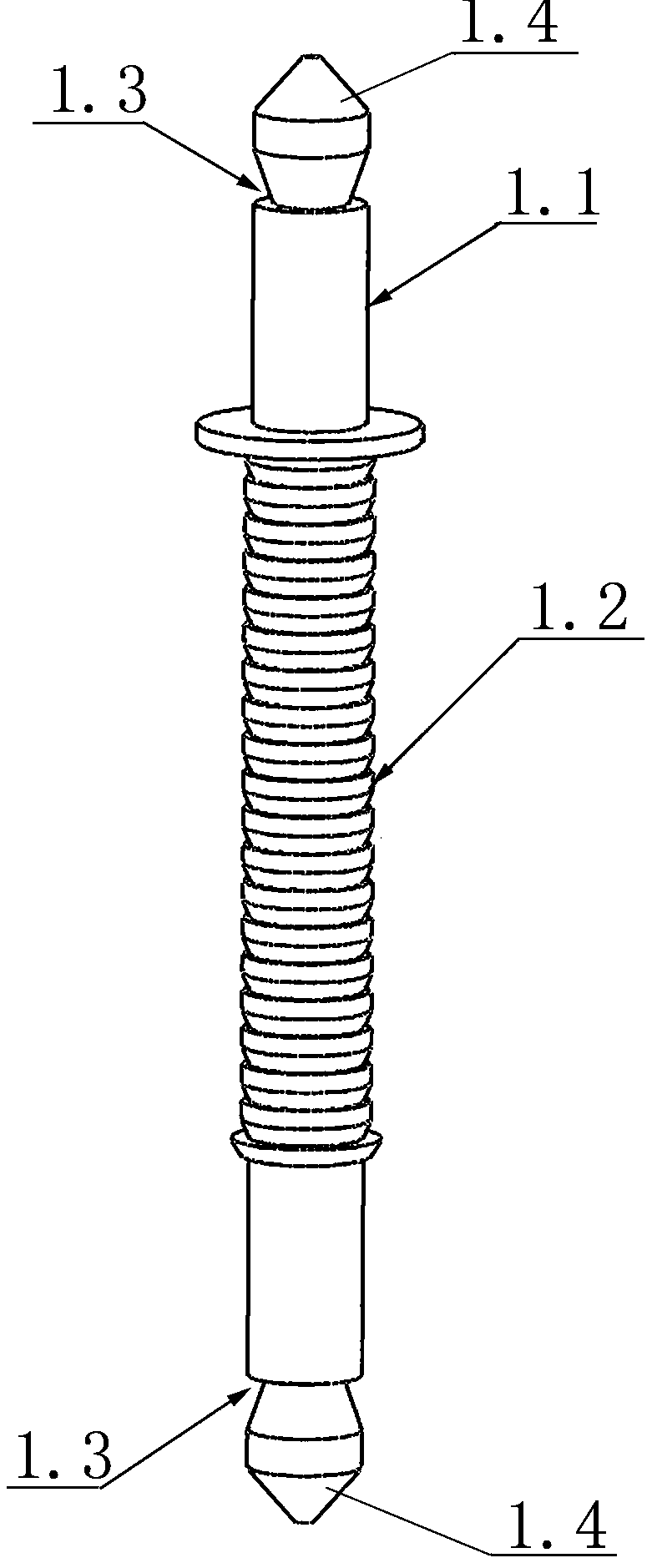

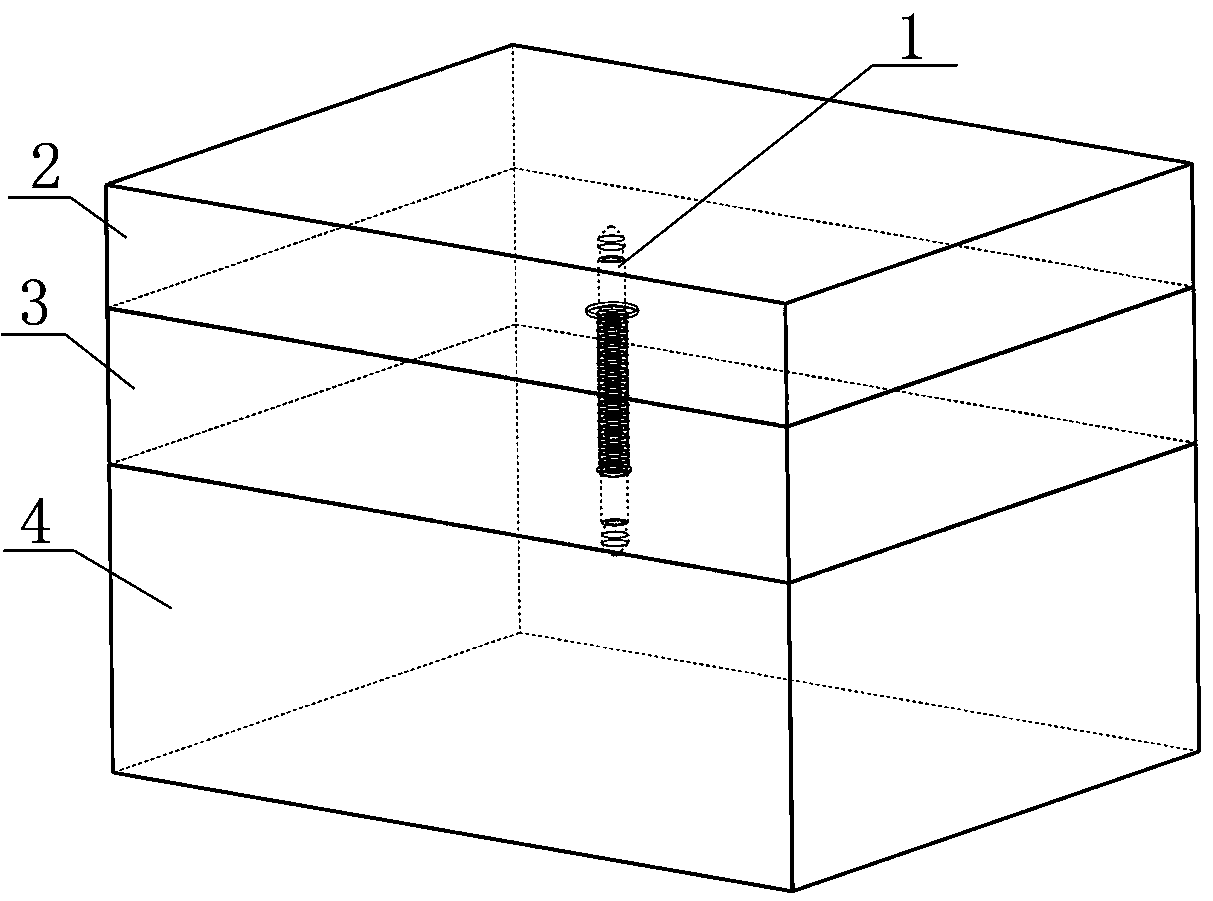

[0069] Example 1, such as Figure 1-2 , 5-6, 26-27 and 30-31, the rod-shaped connecting piece includes a rod-shaped rod 1.1 and a sleeve 1.2 sleeved on the outside of the rod-shaped rod 1.1; the rod-shaped rod 1.1 is made of FRP material Wherein, the FRP material is made of reinforced fiber and resin; the rod-shaped rod 1.1 is divided into the upper section 1.1.1, the middle section 1.1.2 and the lower section 1.1.3; the upper section 1.1.1 of the rod-shaped rod 1.1 is the outer side wall and the lower section 1.1.3 The outer side walls are respectively provided with notches 1.3 to enhance the anchoring performance of the rod-shaped rod 1.1; the sleeve 1.2 is sleeved on the middle section 1.1.2 of the rod-shaped rod 1.1; and the upper end of the sleeve 1.2 is provided with a horizontal The plugging disk 1.2.1, the middle of the plugging disk 1.2.1 is provided with a hole through the rod-shaped rod 1.1, and the shape of the hole is compatible with the horizontal section shape of ...

Embodiment 2

[0077] Example 2, such as Figure 9-10 , 13-14, 18-19 and 22-23, the rod-shaped connecting piece includes a rod-shaped rod 1.1 and a sleeve 1.2 sleeved on the outside of the rod-shaped rod 1.1; the rod-shaped rod 1.1 is made of FRP material ; Among them, the FRP material is made of reinforced fiber and resin; the rod-shaped rod 1.1 is divided into the upper section 1.1.1, the middle section 1.1.2 and the lower section 1.1.3; in the upper section 1.1.1 of the rod-shaped rod 1.1 outer side wall and lower section 1.1.3 The outer side walls are respectively provided with notches 1.3 to enhance the anchoring performance of the rod-shaped rod 1.1; the sleeve 1.2 is sleeved on the middle section 1.1.2 of the rod-shaped rod 1.1; and the upper end of the sleeve 1.2 is provided with a horizontal The plugging disk 1.2.1, the middle of the plugging disk 1.2.1 is provided with a hole through the rod-shaped rod 1.1, and the shape of the hole is compatible with the horizontal section shape of ...

Embodiment 3

[0084] Example 3, such as Figure 34-35 The rod-shaped connector shown in and 38-39 includes a rod-shaped rod 1.1 and a sleeve 1.2 sleeved on the outside of the rod-shaped rod 1.1; the rod-shaped rod 1.1 is made of FRP material; wherein, the FRP material is reinforced fiber And resin; the rod-shaped rod 1.1 is divided into an upper section 1.1.1, a middle section 1.1.2 and a lower section 1.1.3; the upper section 1.1.1 outer side wall and the lower section 1.1.3 outer side wall of the rod-shaped rod 1.1 are respectively provided with useful The notch 1.3 to enhance the anchoring performance of the rod-shaped rod 1.1; the sleeve 1.2 is sleeved on the middle section 1.1.2 of the rod-shaped rod 1.1; the upper end of the sleeve 1.2 is provided with a horizontal plugging disc 1.2.1, so The middle of the plugging disc 1.2.1 is provided with a hole passing through the rod-shaped rod 1.1, and the shape of the hole is compatible with the shape of the horizontal section of the middle sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com