Cast aluminum alloy motor casing with built-in stainless steel spiral coiled pipe water channel

A technology of casting aluminum alloy and spiral coils, which is applied in the direction of casings/covers/supports, electromechanical devices, electrical components, etc., can solve the problems of easy fracture of spiral sand cores, high labor costs, and difficulty in mass-manufacturing products, and achieve The processing technology is simple and reliable, the production cycle is shortened, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following describes in detail in conjunction with the embodiments and accompanying drawings.

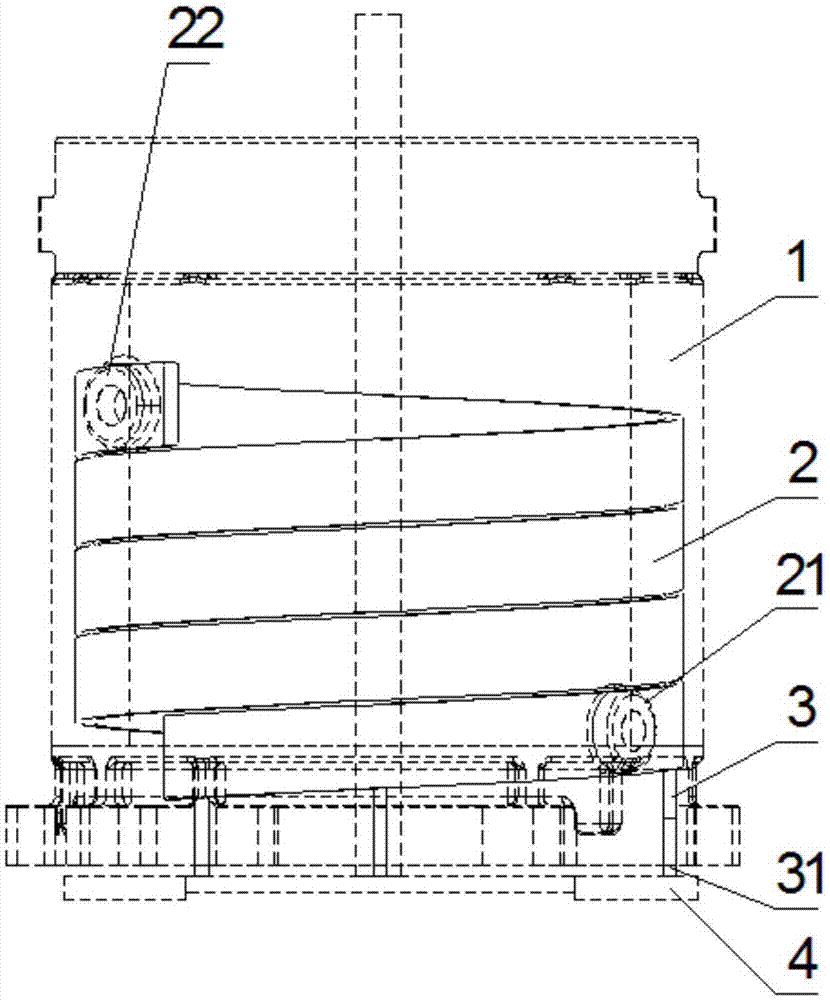

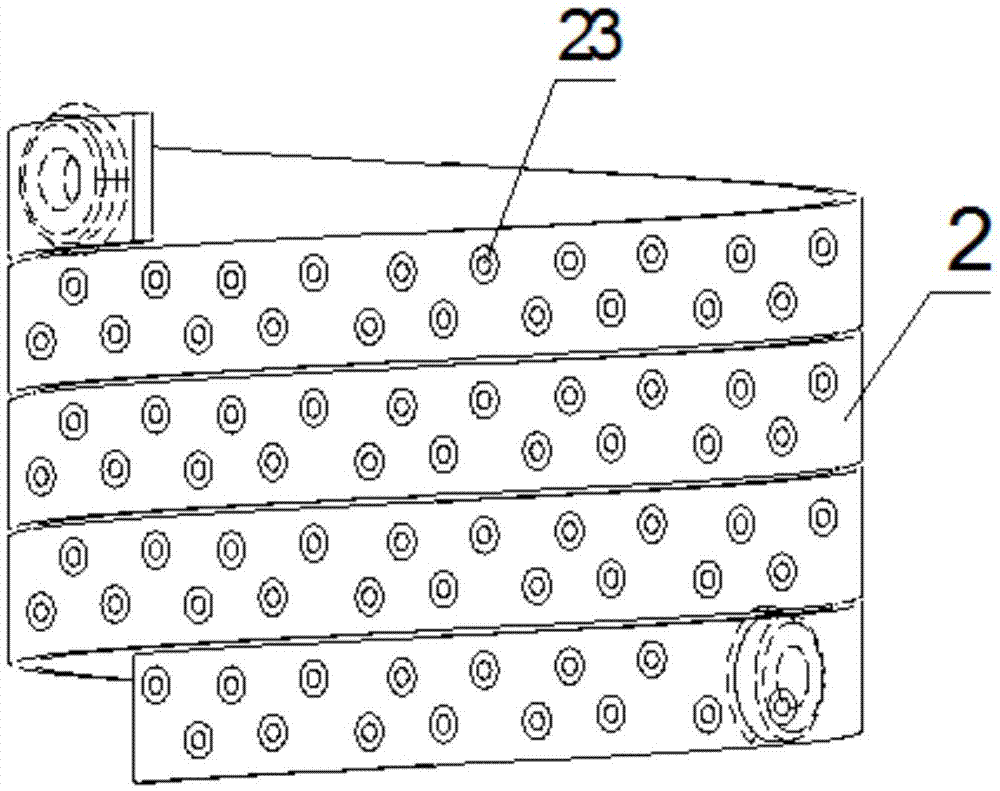

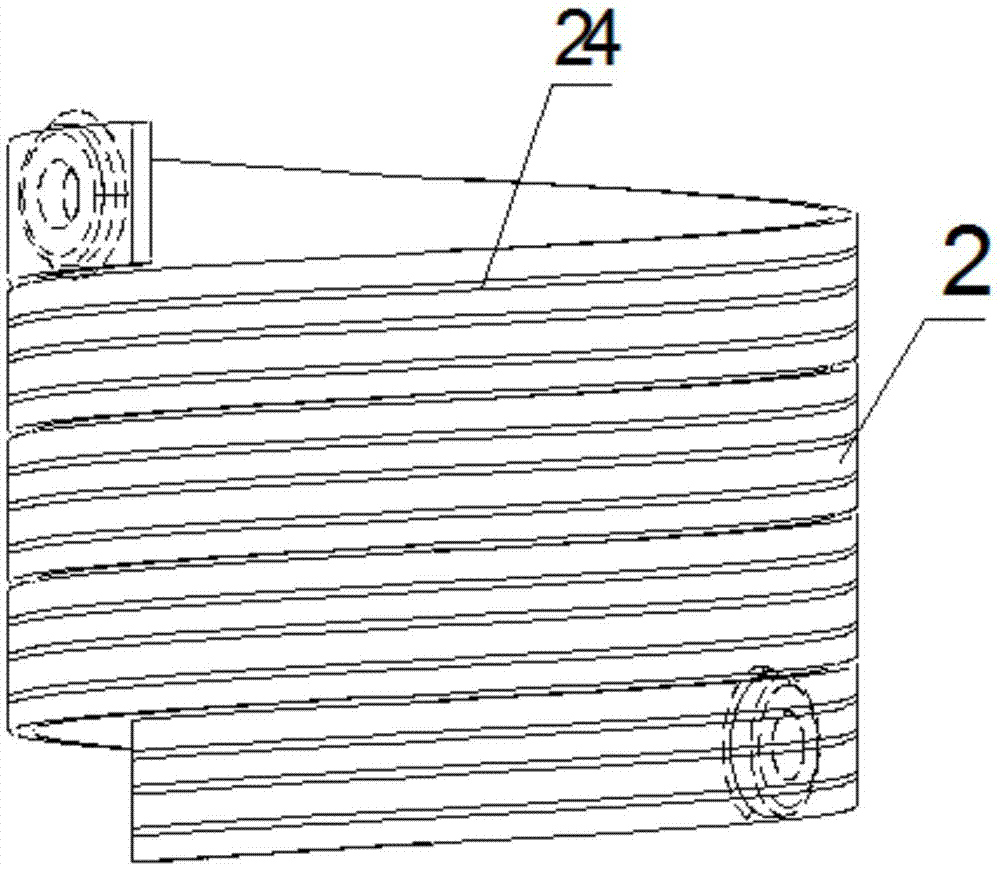

[0033] see figure 1As shown, the cast aluminum alloy motor casing with a built-in stainless steel spiral coil waterway in the present invention includes an aluminum alloy cast motor casing 1, and a stainless steel spiral coil waterway 2 is inlaid and cast in the motor casing 1, so that The upper and lower sides of the stainless steel spiral water channel 2 are respectively provided with a water inlet 21 and a water outlet 22, and the water inlet 21 and the water outlet 22 protrude from the cylindrical surface of the motor housing 1 respectively. Both the water inlet 21 and the water outlet 22 are provided with threaded joints that can be connected to the water-cooling circulation system. One end of the stainless steel spiral water channel 2 is als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com