A low-pressure casting method of an aluminum alloy motor casing with a built-in spiral coil water channel

A technology of spiral coil and low-pressure casting, which is applied in the field of new energy motor shell production, can solve the problems of spiral water-cooling cycle through holes, difficulty in cleaning residual sand, and easy fracture of spiral sand core, so as to save casting auxiliary process and auxiliary The time, production cycle and production efficiency are improved, and the processing technology is simple and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

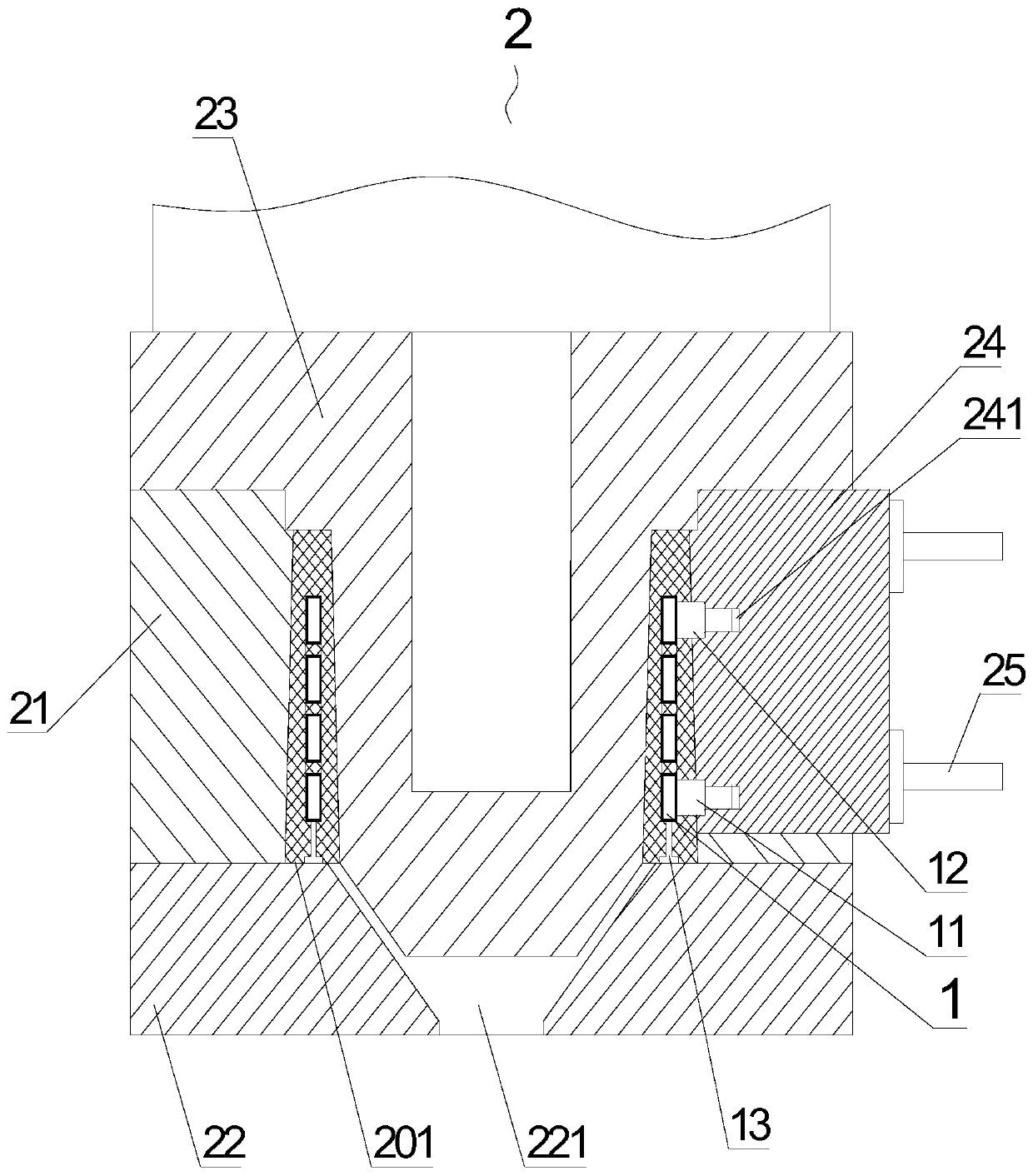

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following describes in detail in conjunction with the embodiments and accompanying drawings.

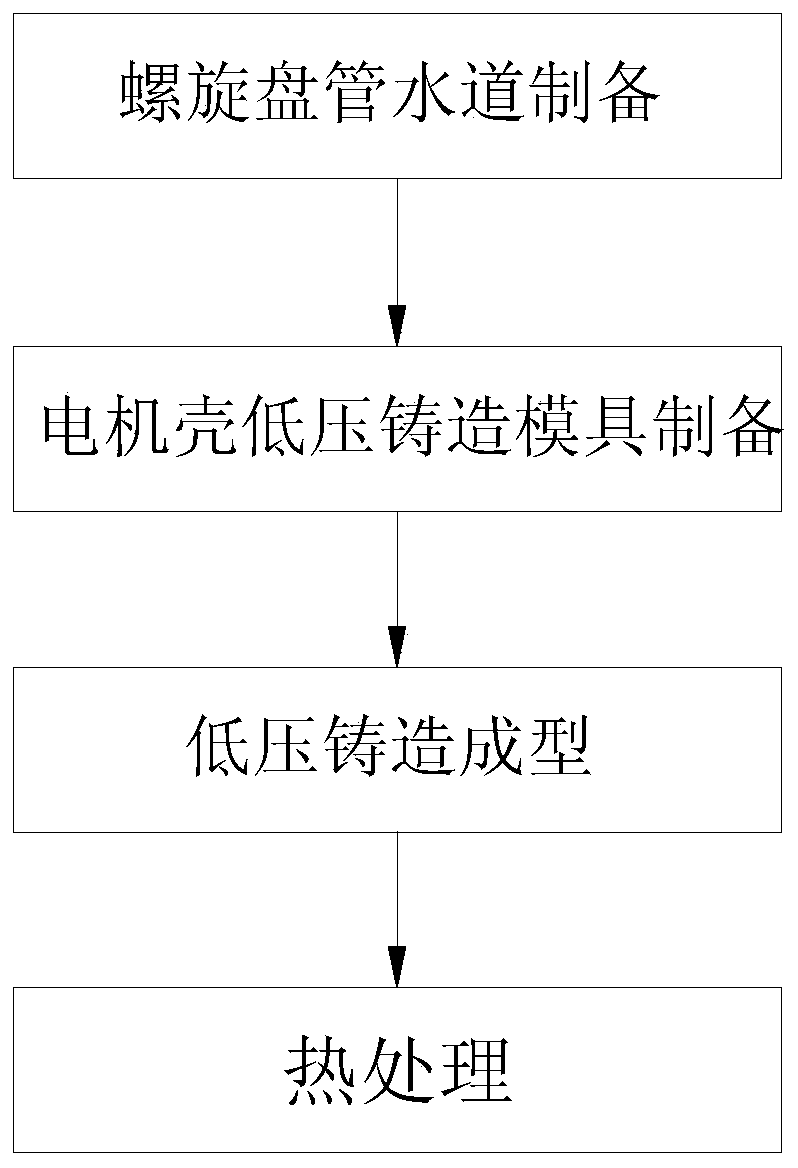

[0033] see figure 1 As shown, the low-pressure casting method of aluminum alloy motor housing with built-in coil water channel of the present invention comprises the following steps:

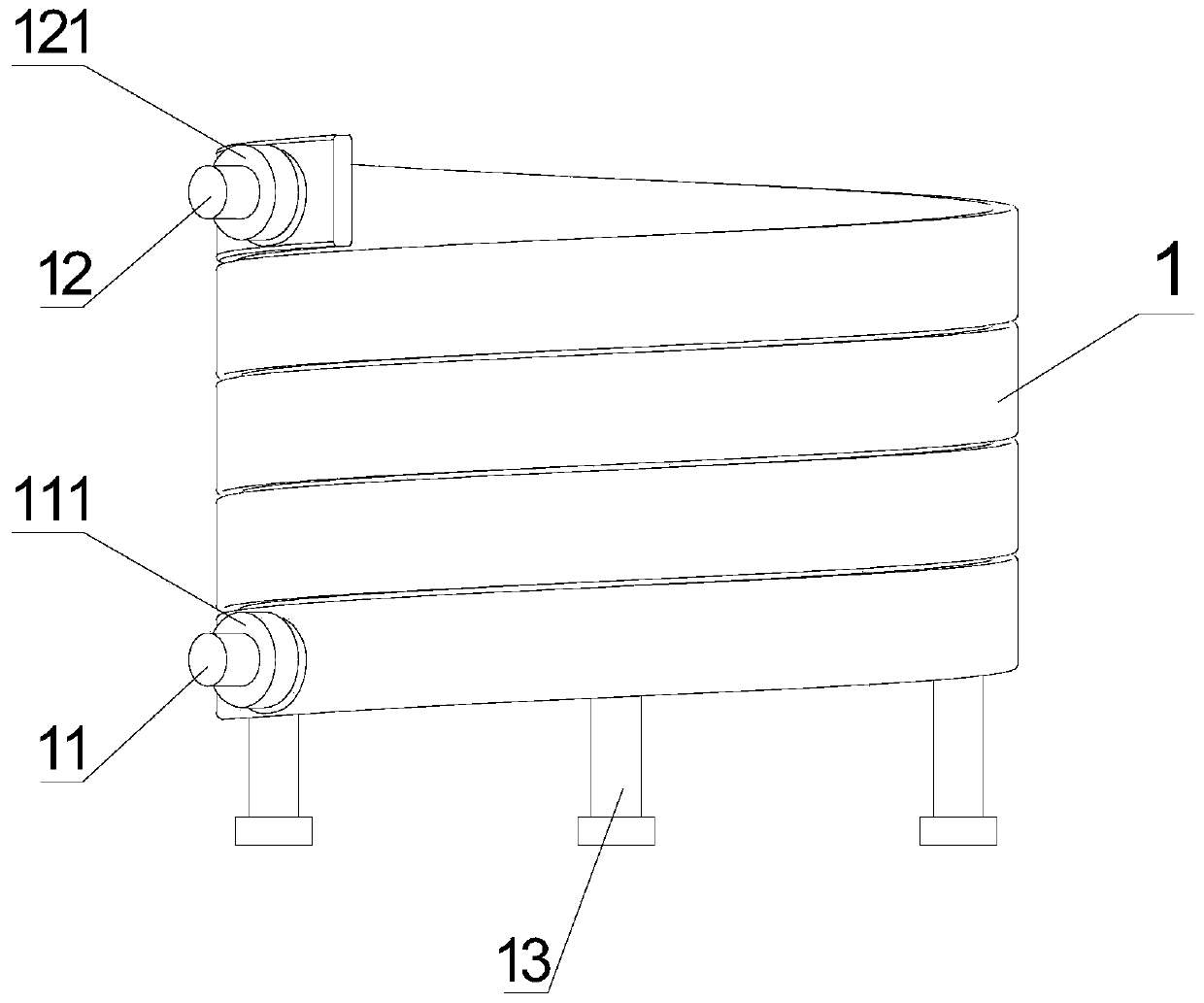

[0034]Step 01: Preparation of the spiral coil water channel: According to the product structure, a rigid spiral coil water channel 1 is wound with a flat tube or a round tube, and the sides of the upper and lower ends of the spiral coil water channel 1 are respectively provided with a water inlet 11 and a water outlet 12. The water inlet 11 and the water outlet 12 are respectively provided with bosses 111 and 121 for positioning, and the bottom of the spiral coil water channel 1 is provided with three or four fixed support rods 13; the spiral coil water channel 1 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com