One-step molding process of double-layer plastic vehicle shell

A molding process and plastic technology, applied in coatings, household components, household appliances, etc., can solve the problems of increasing the cost of raw materials, the weight of the body shell, the uneven wall thickness of the inner and outer plastic sheets, and the high manufacturing cost, so as to achieve simplification The production process and mold structure, uniform and stable wall thickness, and the effect of reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

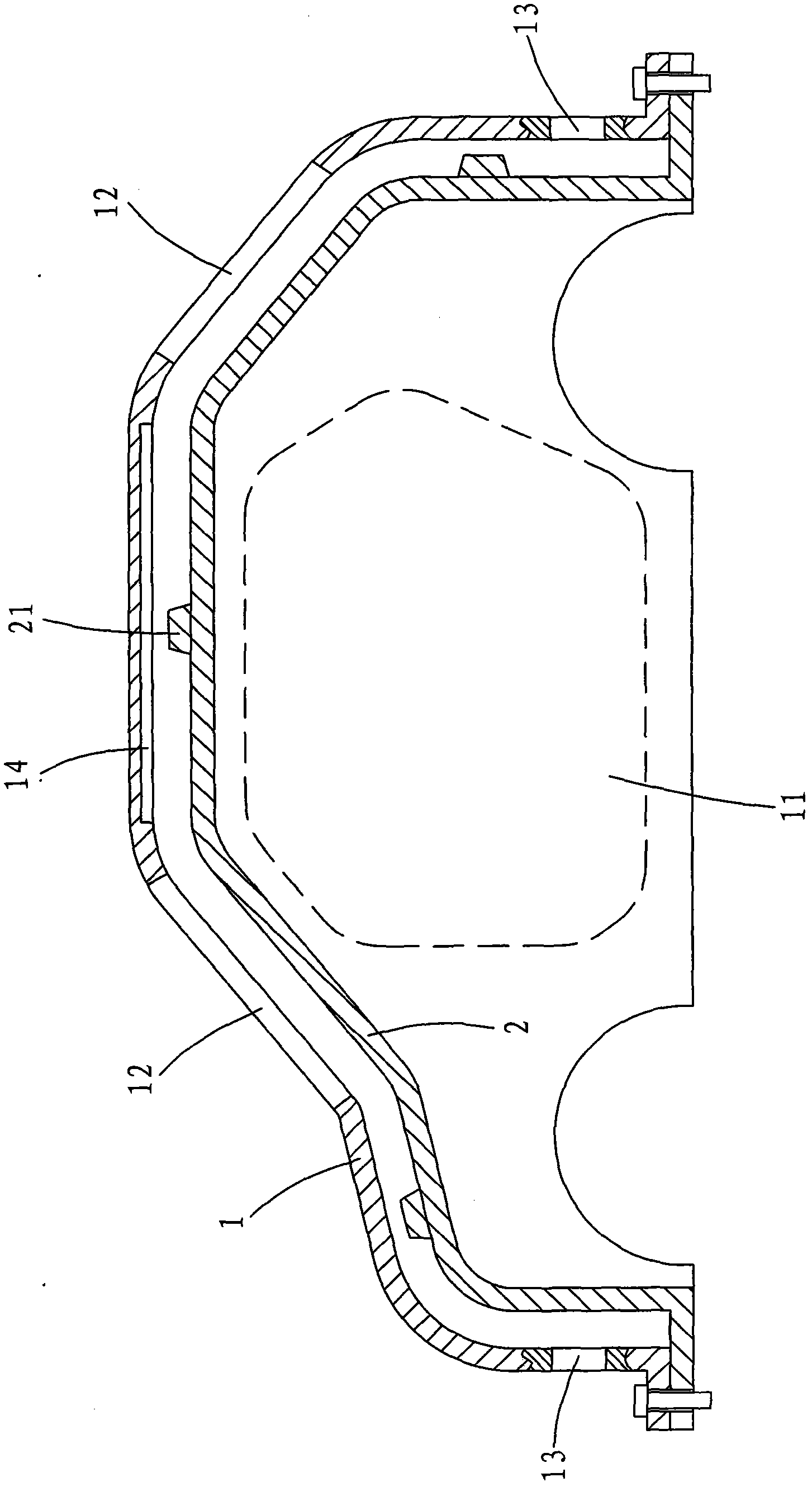

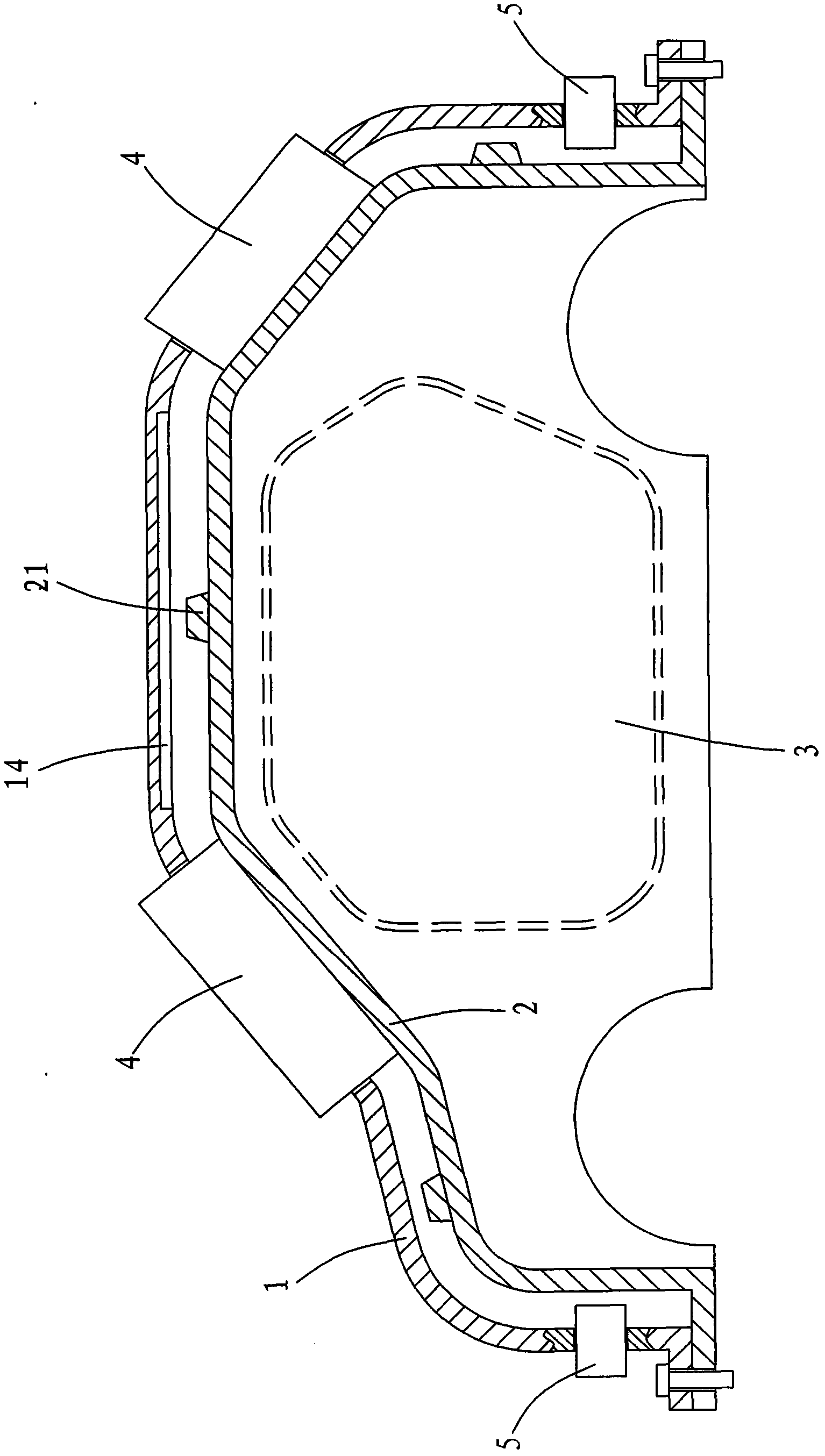

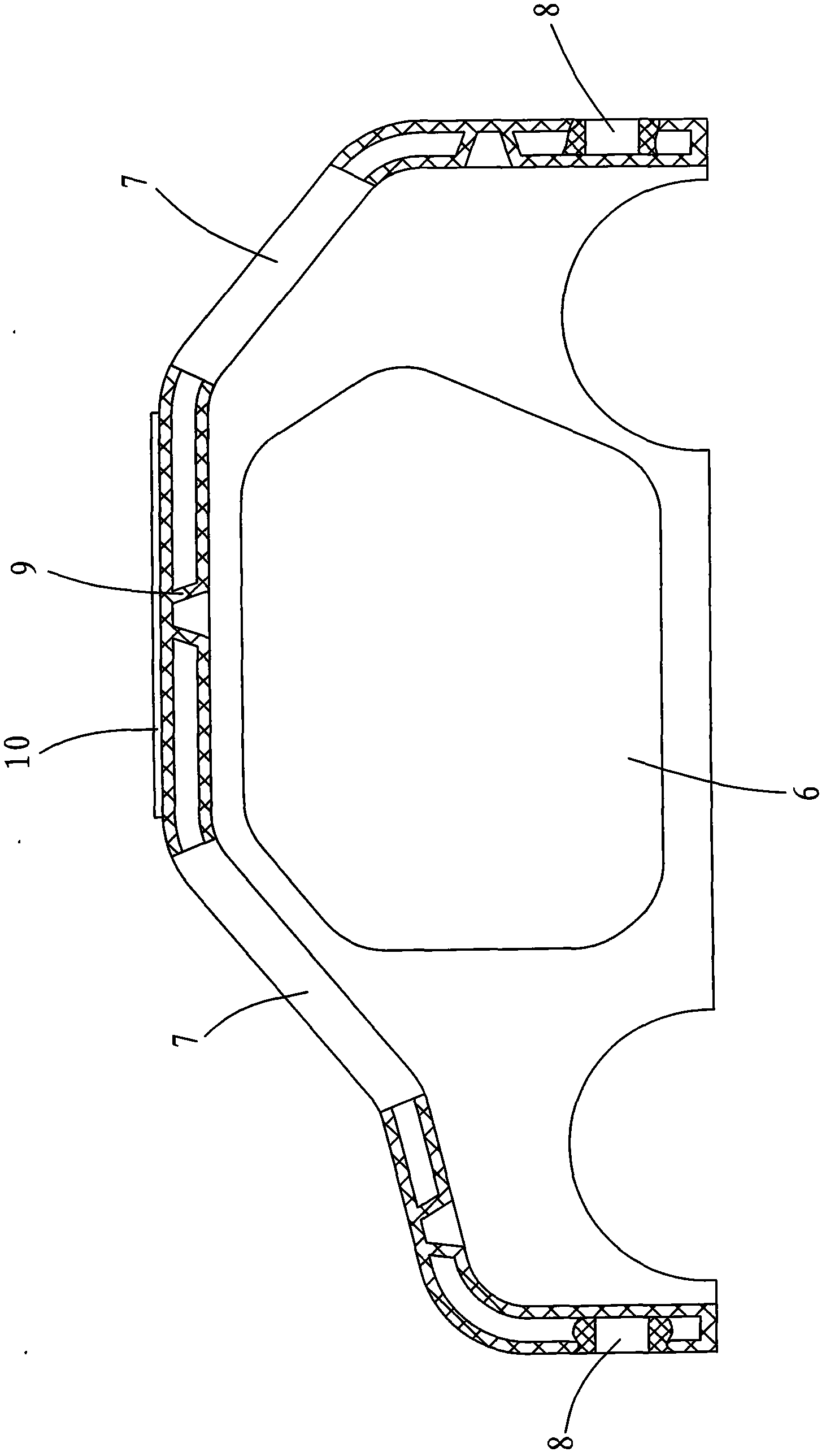

[0029] see figure 1 , figure 2 and image 3 , taking the body shell of an electric vehicle as an example, the one-time molding process of the double-layer plastic car shell provided by the present invention comprises the following steps:

[0030] ① Make a die 1 and a punch 2 according to the outline of the car shell, and make the door core 3, the window core 4, and the lamp core 5 respectively according to the outline of the car door, car window, and lamps. Among them, the die 1 is provided with core-pulling insertion holes 11, 12, 13 corresponding to various core-pulling.

[0031] ② Insert the door core 3, the window core 4, and the lamp core 5 into the die 1, and add powdered plastic raw materials into the die 1 and the punch 2.

[0032] ③Close the mold, and make the inner surface of the door core 3 and the window core 4 against the inner wall of the punch 2 to form the through-hole structure of the door mounting hole 6 and the window mounting hole 7, and the inner surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com