Nanoscale non-volatile resistive random access memory unit and preparation method thereof

A technology of resistive variable memory and memory unit, which is applied in the direction of static memory, digital memory information, information storage, etc. It can solve the problems of large device size, large dispersion of resistive variable performance, and poor stability, and achieve easy integration and easy device performance. control, good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

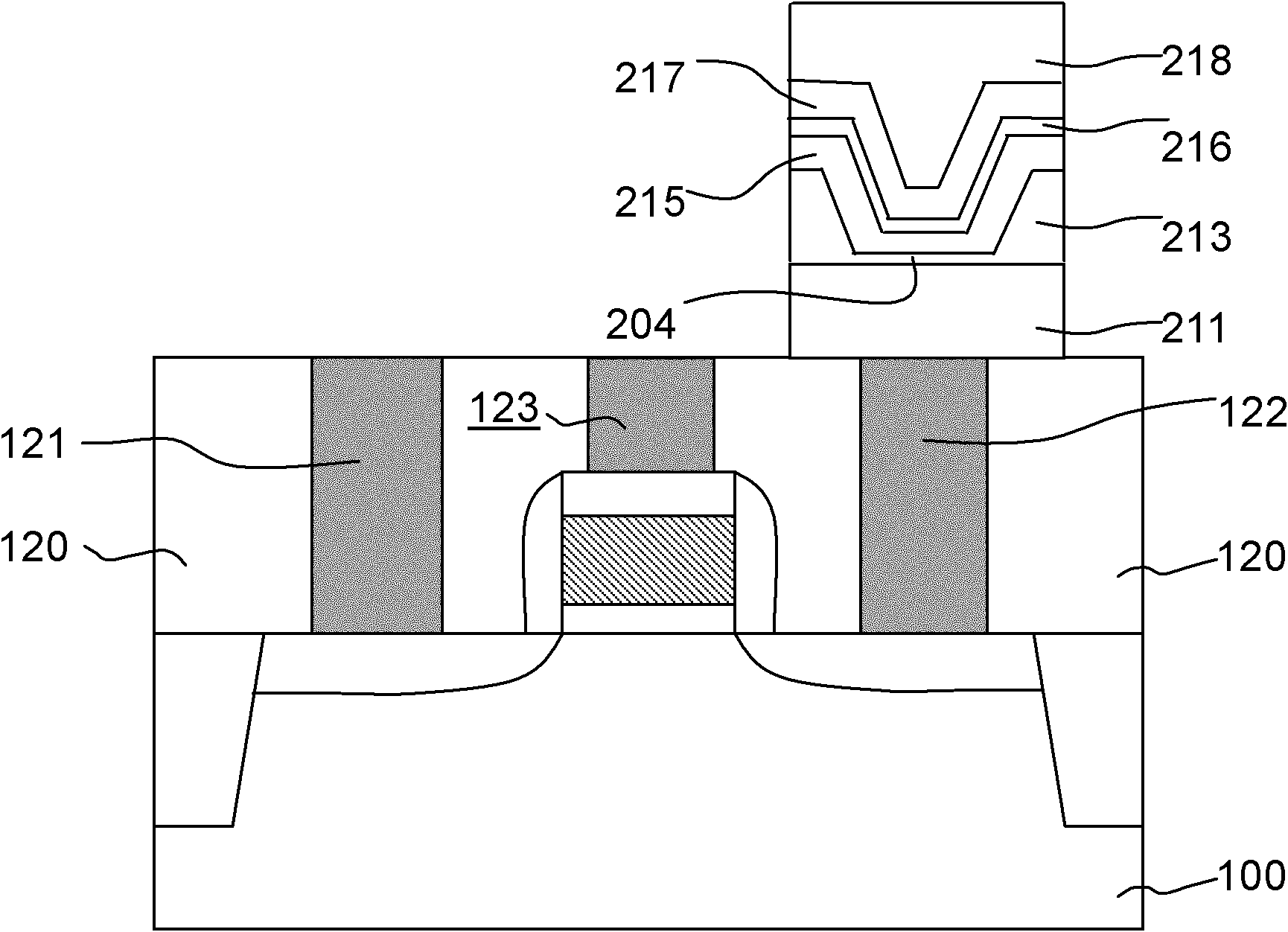

[0105] In one embodiment of the present invention, the plugs 121, 122, and 123 all use tungsten plugs ( Figure 4 ); Magnetron sputtering deposits 20 nanometers thick platinum as the first conductive electrode material 201 ( Figure 5 ); Coating a layer of HSQ negative electron beam resist 202 ( Figure 5 ); using the JEOLJBX-6300FS electron beam lithography system at an accelerating voltage of 100KeV and a beam current of 100pA Figure 6 The pattern shown in the left figure is subjected to electron beam exposure; developing, forming a circular electron beam resist pattern with a diameter of 50 nanometers, i.e. a through hole 203 ( Figure 7 ); Atomic layer deposition of 15 nanometers thick hafnium oxide resistive thin film 205 ( Figure 9 ); Magnetron sputtering deposits 2 nanometers thick copper as the second metal nanolayer film 206 ( Figure 9 ); Atomic layer deposition of 15 nanometers thick hafnium oxide resistive thin film 207 ( Figure 9 ); Magnetron sputtering dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com