Patents

Literature

124 results about "Electron beam resist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

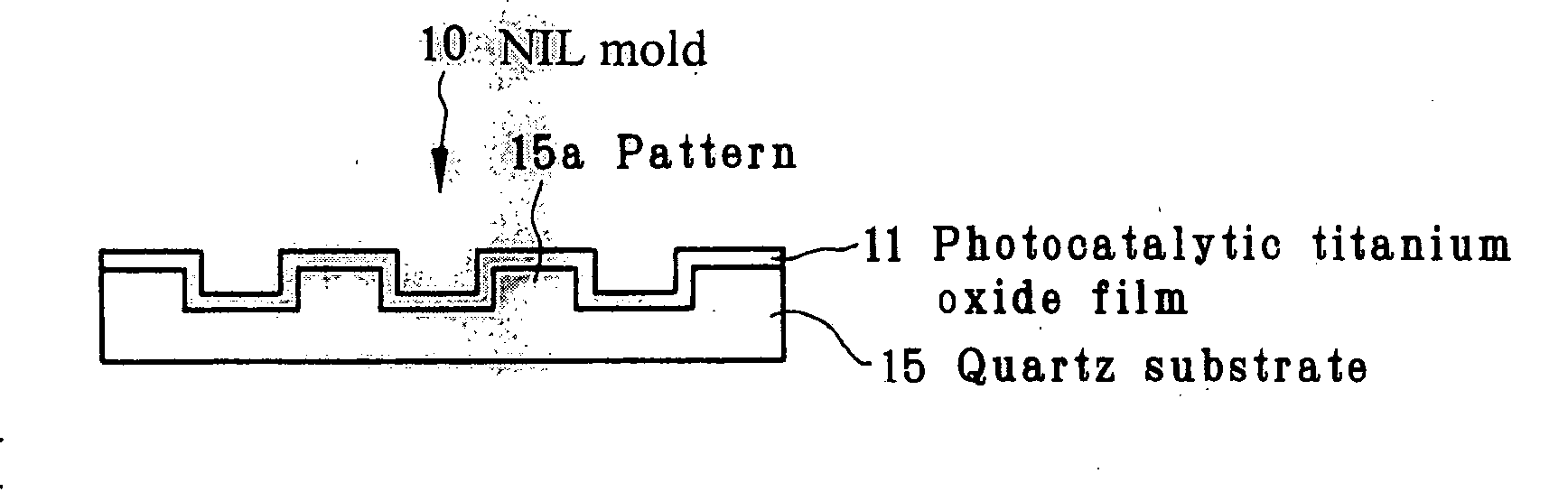

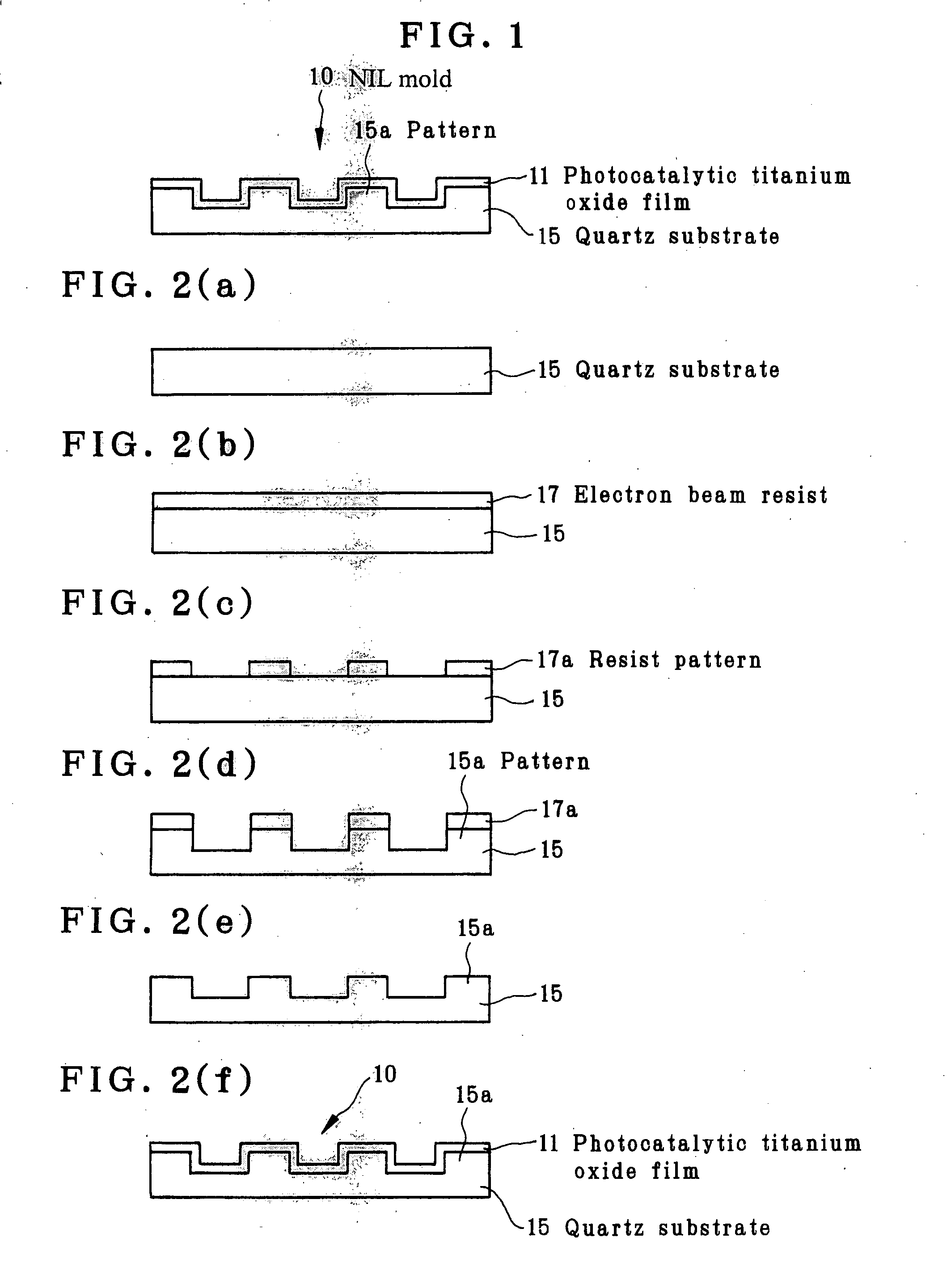

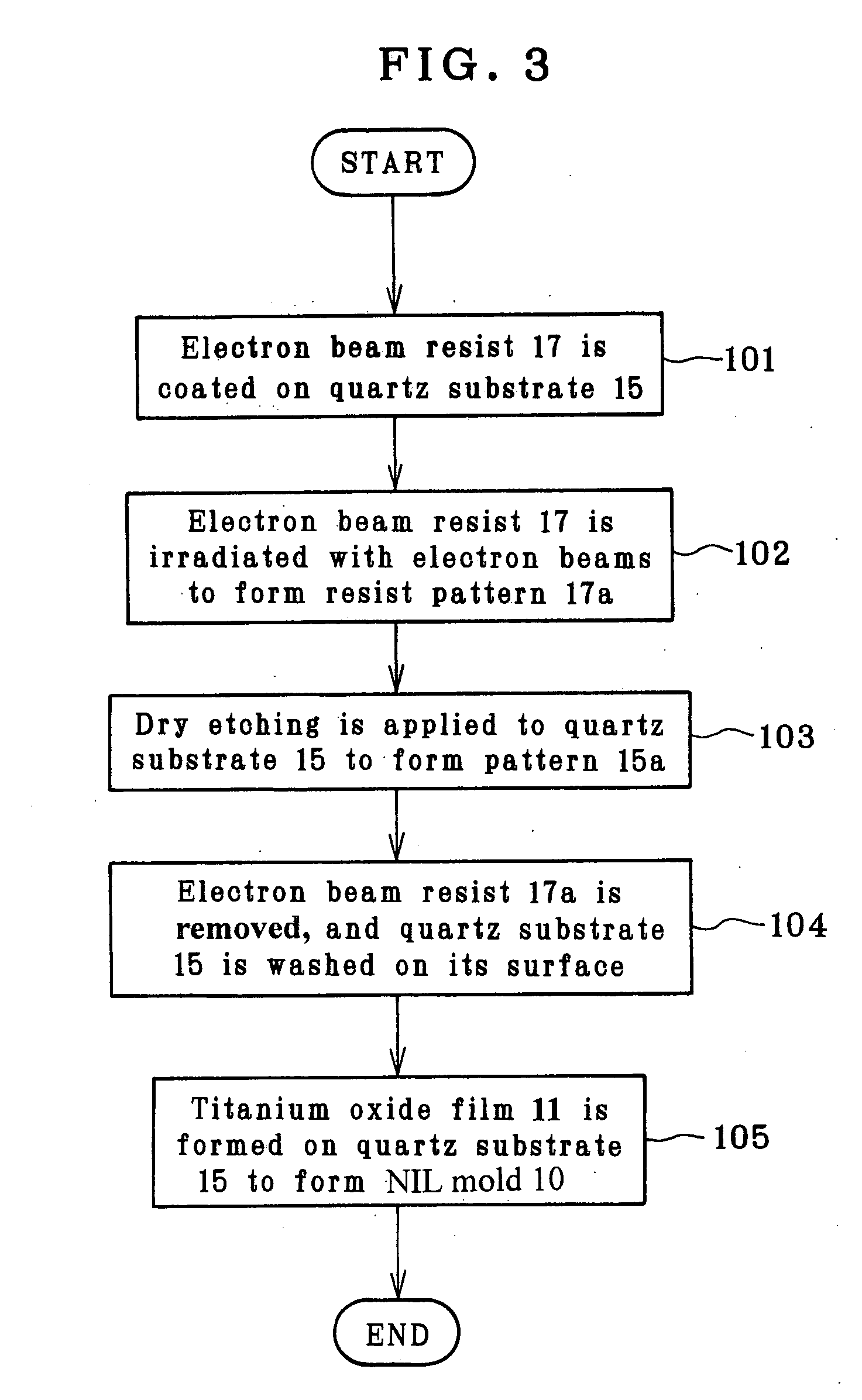

Mold for photocuring nano-imprint and its fabrication process

InactiveUS20070267764A1Improve reliabilityImprove robustnessNanoinformaticsFoundry mouldsCarbon monofluorideUltraviolet lights

The invention relates to a mold that has an improved releasability for a photocured resin and an improved robustness. First, an electron beam resist 17 is coated on a quartz substrate 15 having the nature of being transmissive to ultraviolet light. A resist pattern 17a is formed by irradiation with electron beams. Thereafter, the quartz substrate is dry etched using etching gas such as carbon tetrafluoride to form a pattern 15a on the quartz substrate 15. A photocatalytic titanium oxide film 11 is formed as by sputtering on the surface of the quartz substrate 15 with the pattern 15a formed on it to fabricate an NIL mold 10.

Owner:DAI NIPPON PRINTING CO LTD

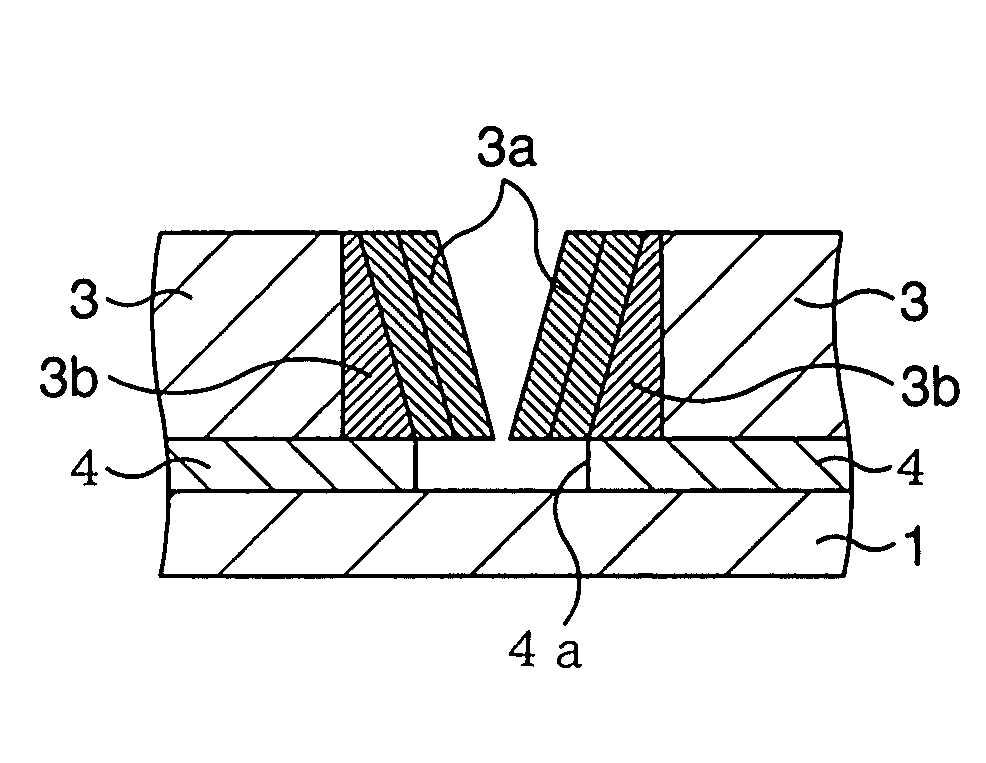

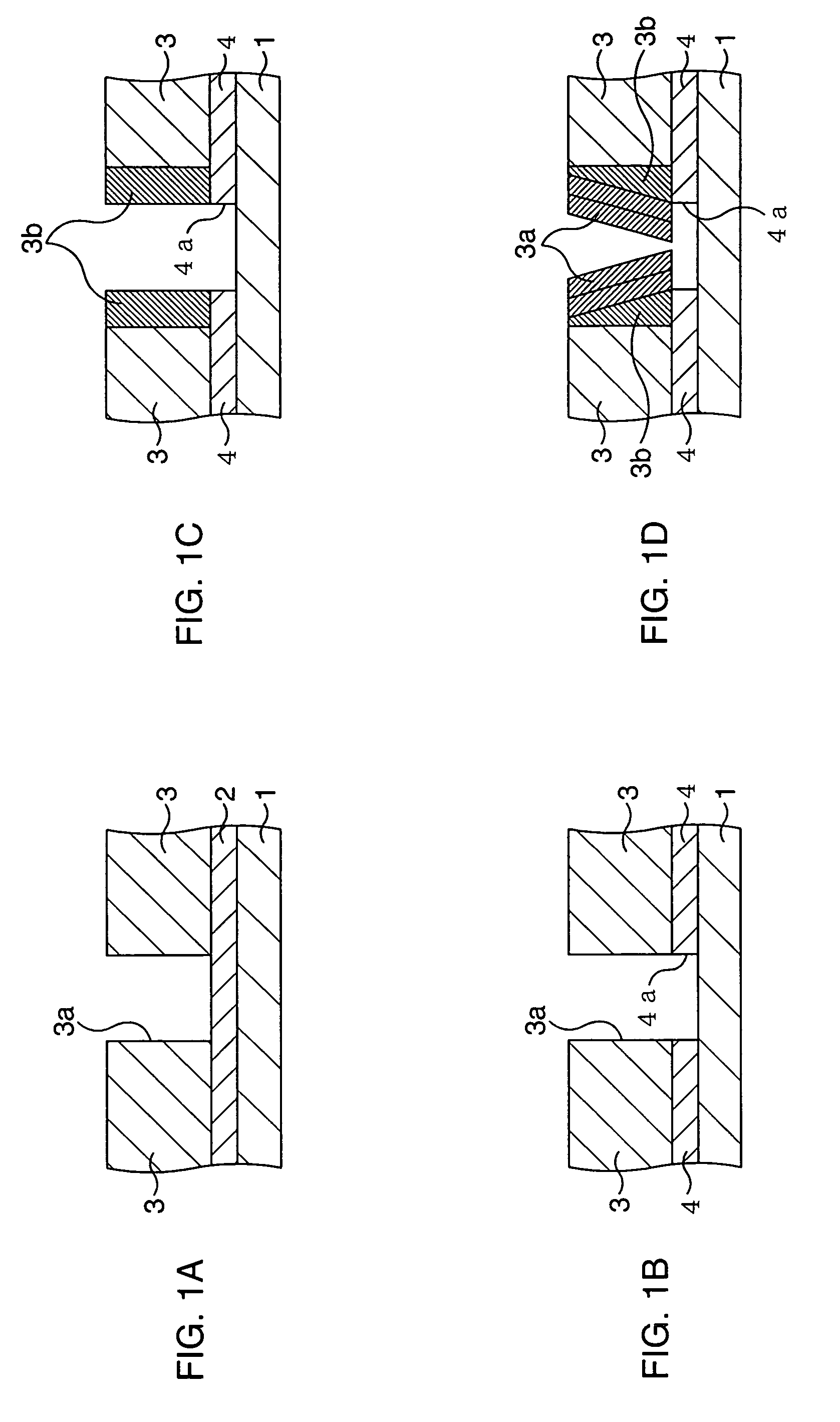

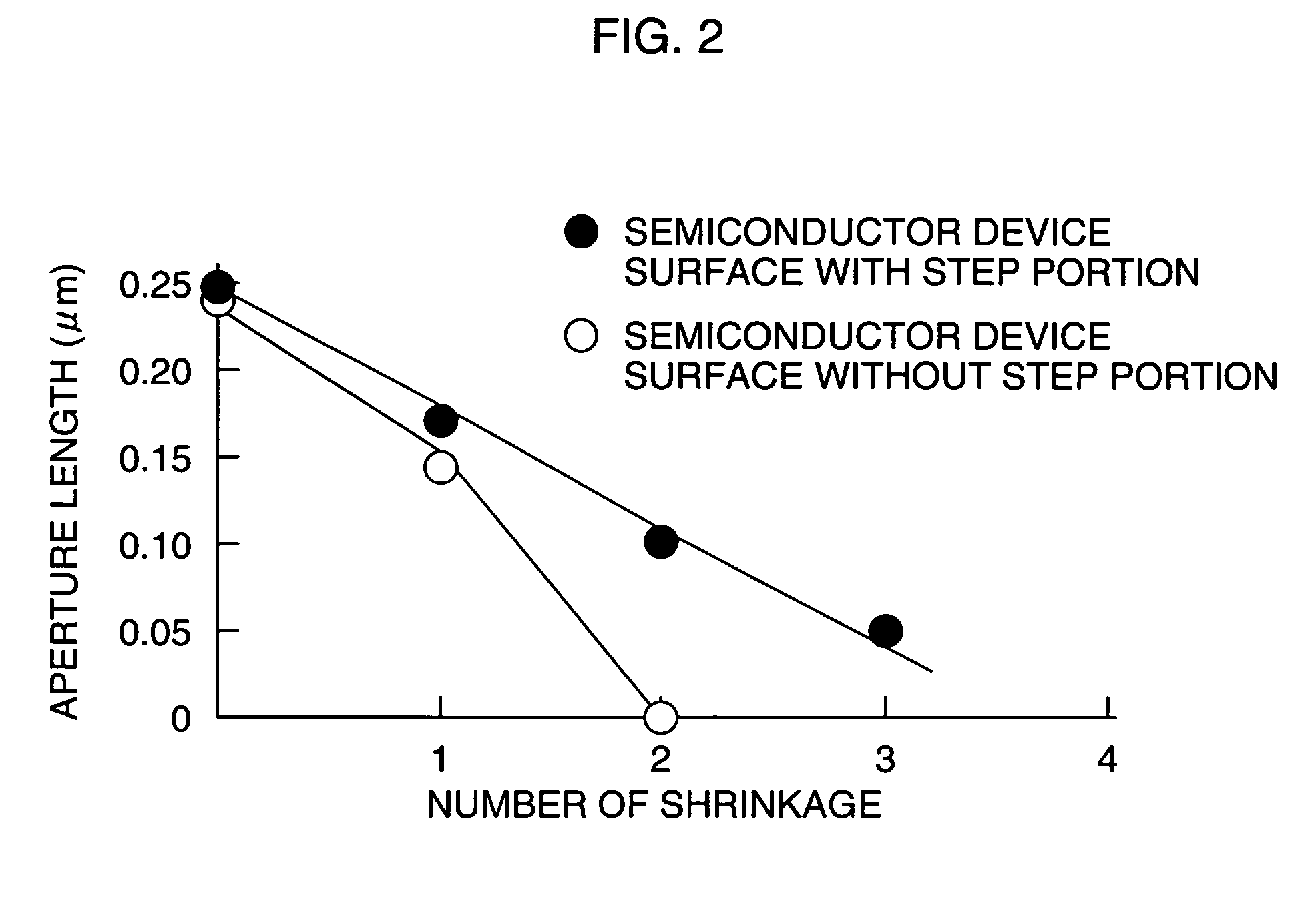

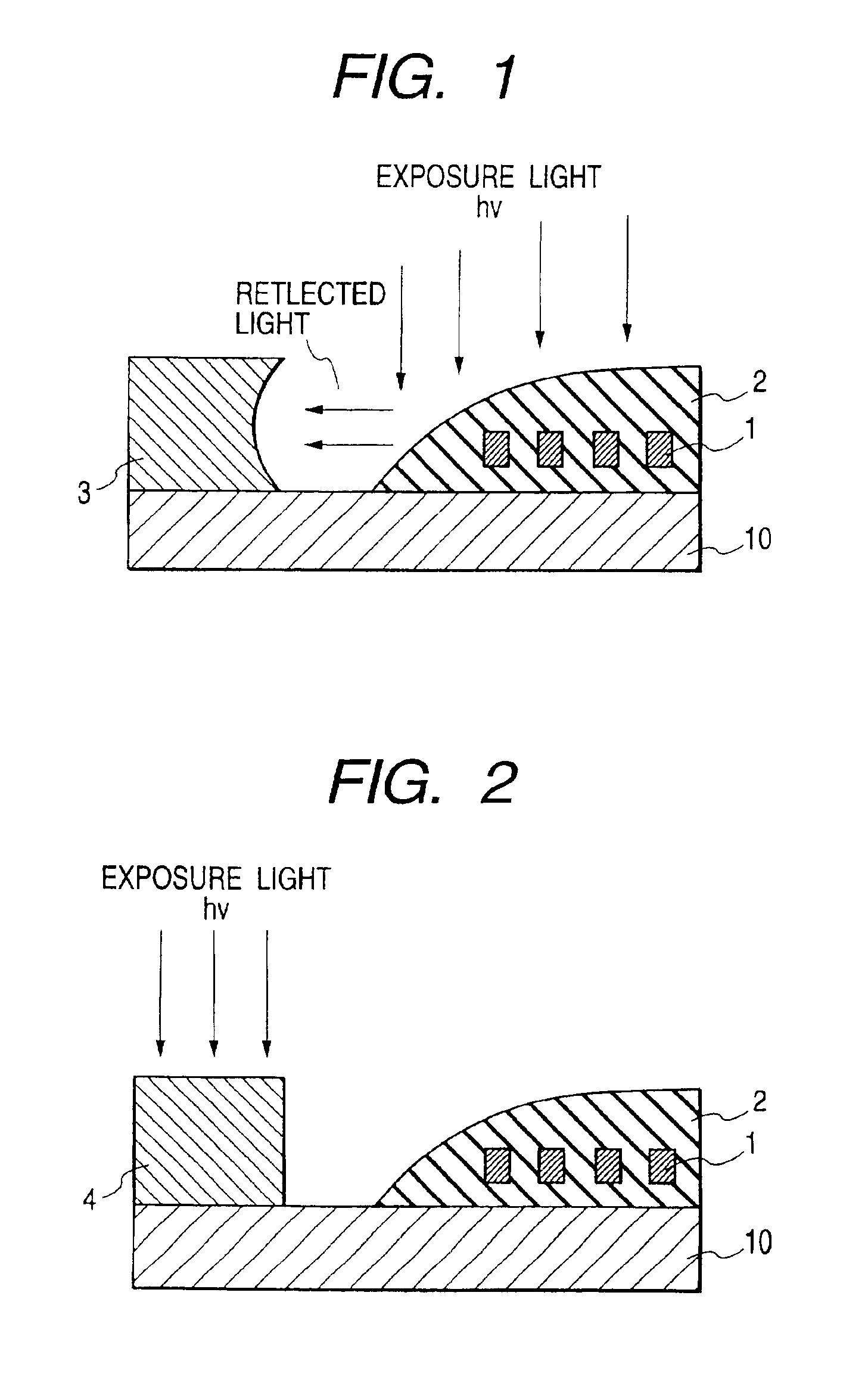

Method of processing resist, semiconductor device, and method of producing the same

A surface component film (2) is etched using a resist (3) as a mask, and the surface component film (2) is patterned according to the shape of an aperture (3a). This results in a step portion (4) having the same shape as the aperture (3a), with the sidewall (4a) of the step portion (4) exposed through the aperture (3a). The aperture (3a) is spin-coated with a shrink agent, reacted at a first temperature, and developed to shrink the aperture (3a). To control the shrinkage with high accuracy, in the first round of reaction, the aperture is shrunk by, for example, about half of the desired shrinkage. The aperture (3a) is further spin-coated with a shrink agent, reacted at a second temperature, and developed to shrink the aperture (3a). In this embodiment, the second-round shrink process will result in the desired aperture length. The second temperature is adjusted based on the shrinkage in the first round. With respect to a resist using short-wavelength light (short-wavelength resist) or a resist using electron beam (electron beam resist), a minute aperture can be obtained with stable shrink effect and accurate control of the length thereof.

Owner:FUJITSU LTD

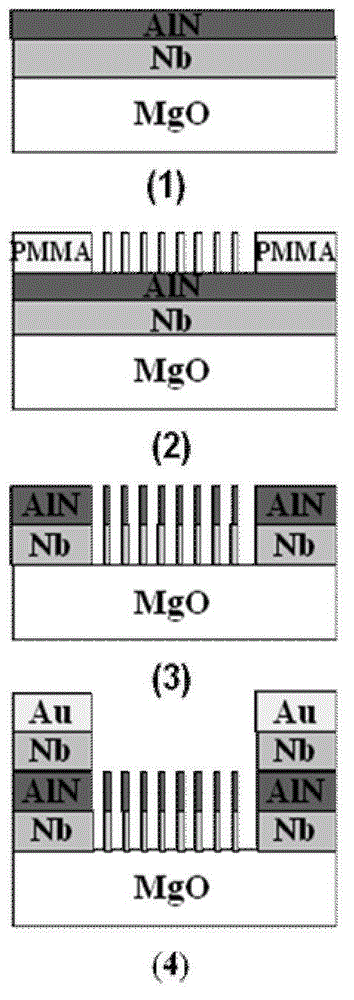

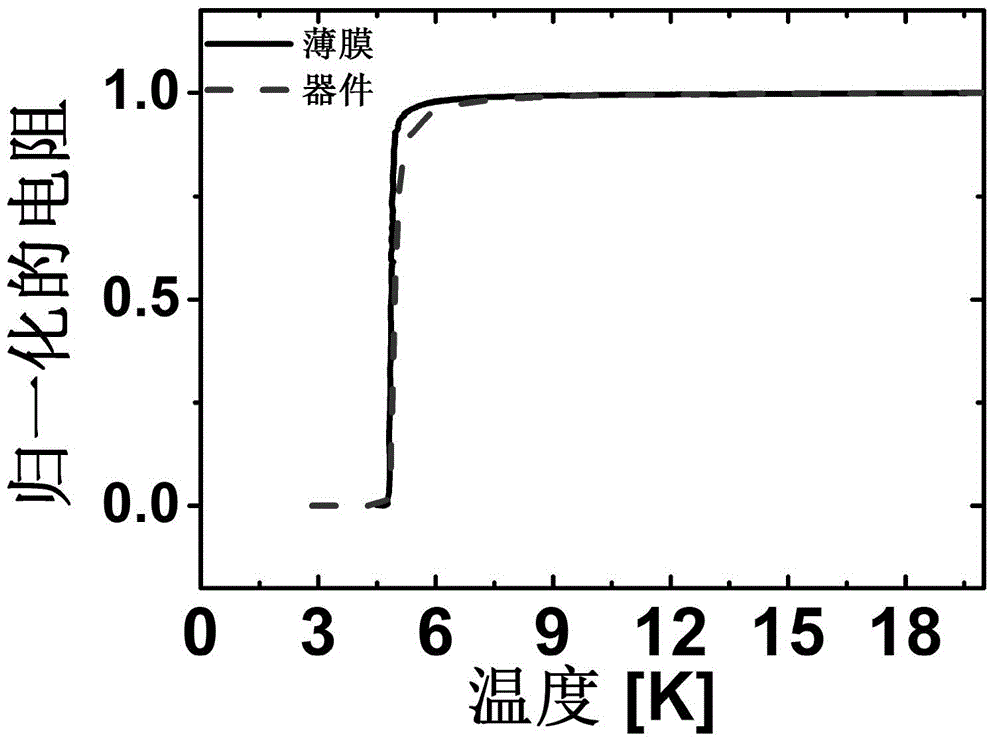

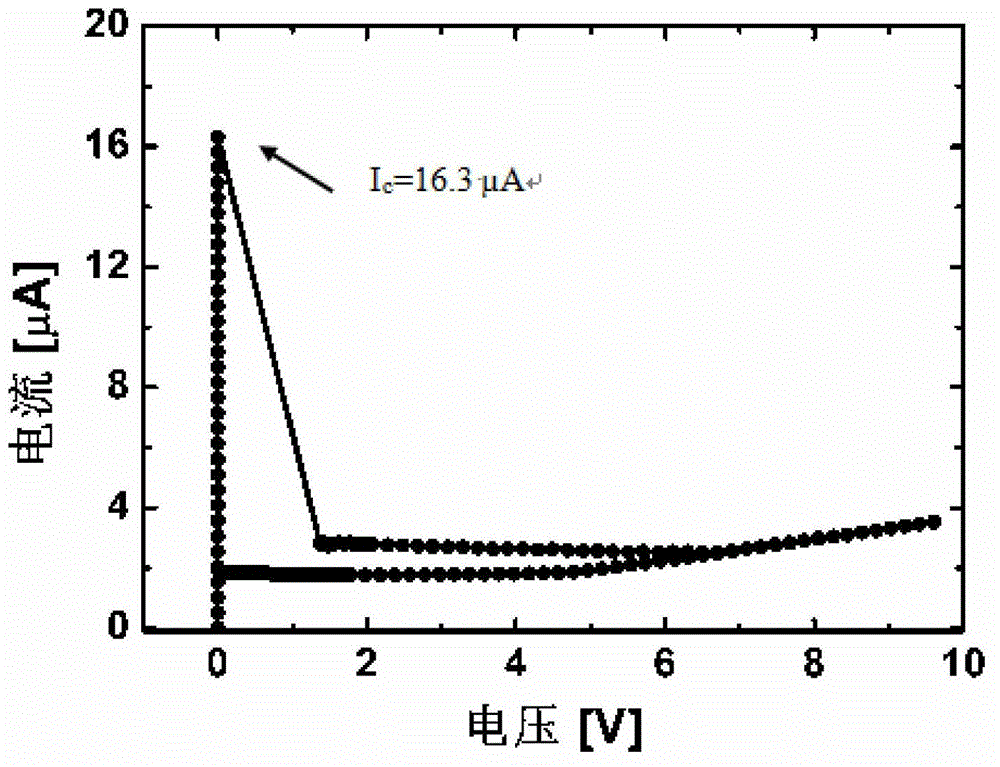

Manufacturing method for nanowire single-photon detector based on specially doped superconducting niobium film material

ActiveCN102916083AProtected superconducting propertiesIncrease the critical current densityVacuum evaporation coatingSputtering coatingNanowireNiobium

The invention discloses a manufacturing method for a nanowire single-photon detector based on a specially doped superconducting niobium film material. The manufacturing method comprises the following steps: carrying out ultrasonic cleaning and blow-drying on a substrate; carrying out Ar ion cleaning; growing a specially doped superconducting Nb film in a direct current magnetron sputtering way; carrying out spin-coating on an electron beam resist, carrying out electron beam lithography on the electron beam resist, and drawing a wire pattern with the width not more than 100nm on the electron beam resist; etching in a reaction ion etching way, and transferring the line pattern onto the Nb film to form a Nb nanowire; cleaning the residual electron beam resist, carrying out spin-coating on a photoresist on the surface of a sample, and forming an electrode pattern on the photoresist in a deep ultraviolet exposure way; and growing an electrode. According to the manufacturing method, the difficult problems of low superconducting transition temperature, low critical current density and short photoresponse wavelength of an SNSPD (Superconducting Nanowire Single Photon Detector) manufactured by the conventional Nb material are solved.

Owner:NANJING UNIV

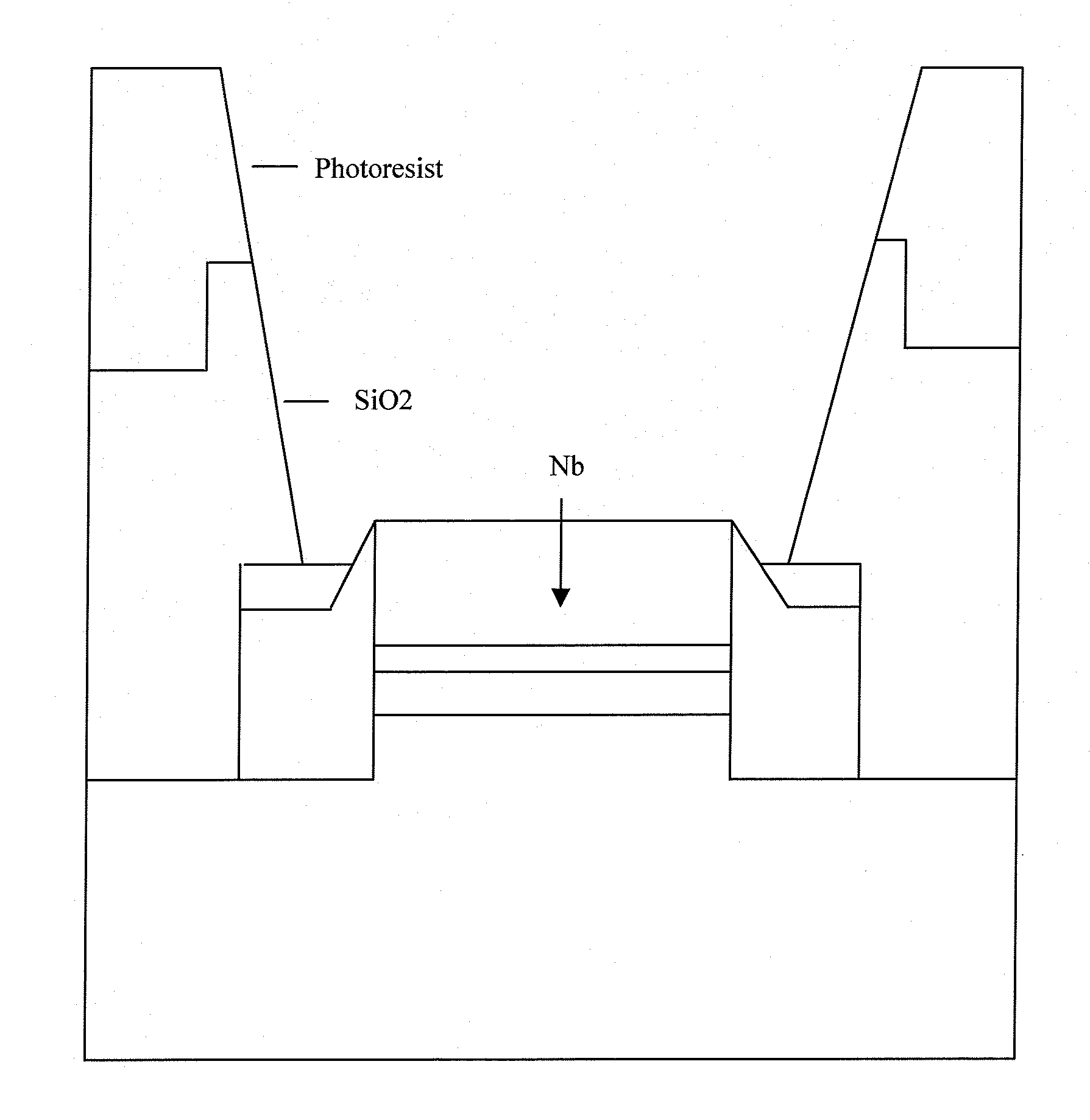

Double-Masking Technique for Increasing Fabrication Yield in Superconducting Electronics

ActiveUS20080070325A1Improve reliabilityHigh yieldSemiconductor/solid-state device manufacturingSuperconductor devicesResistNiobium

Owner:SEEQC INC

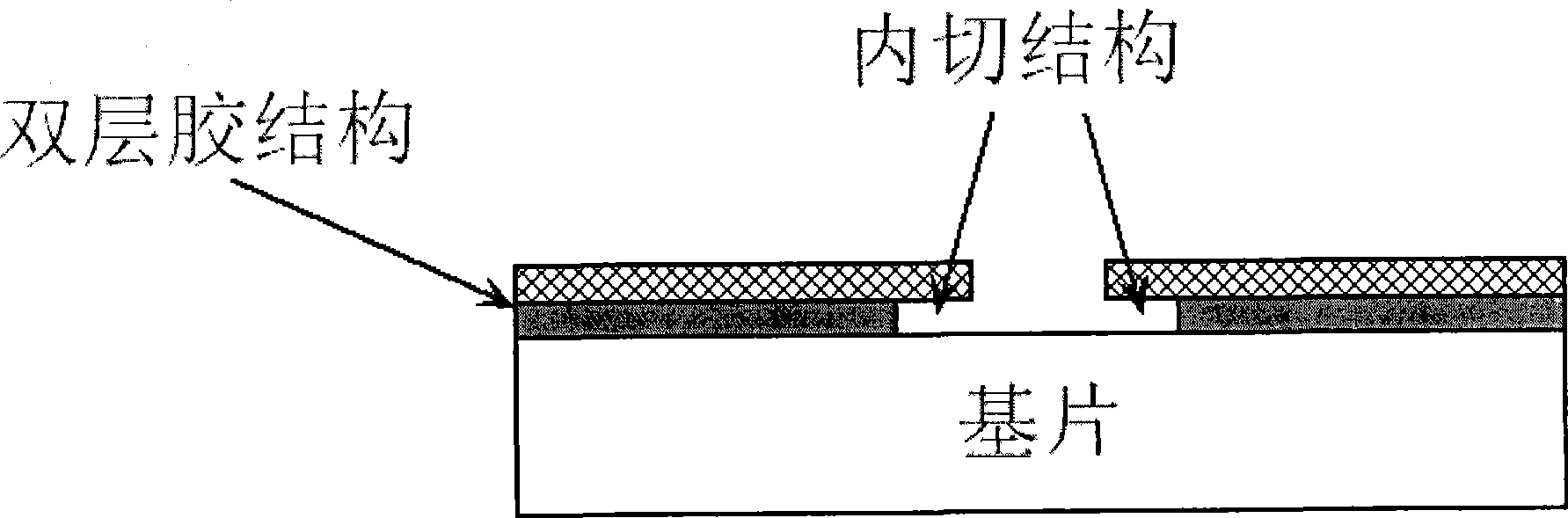

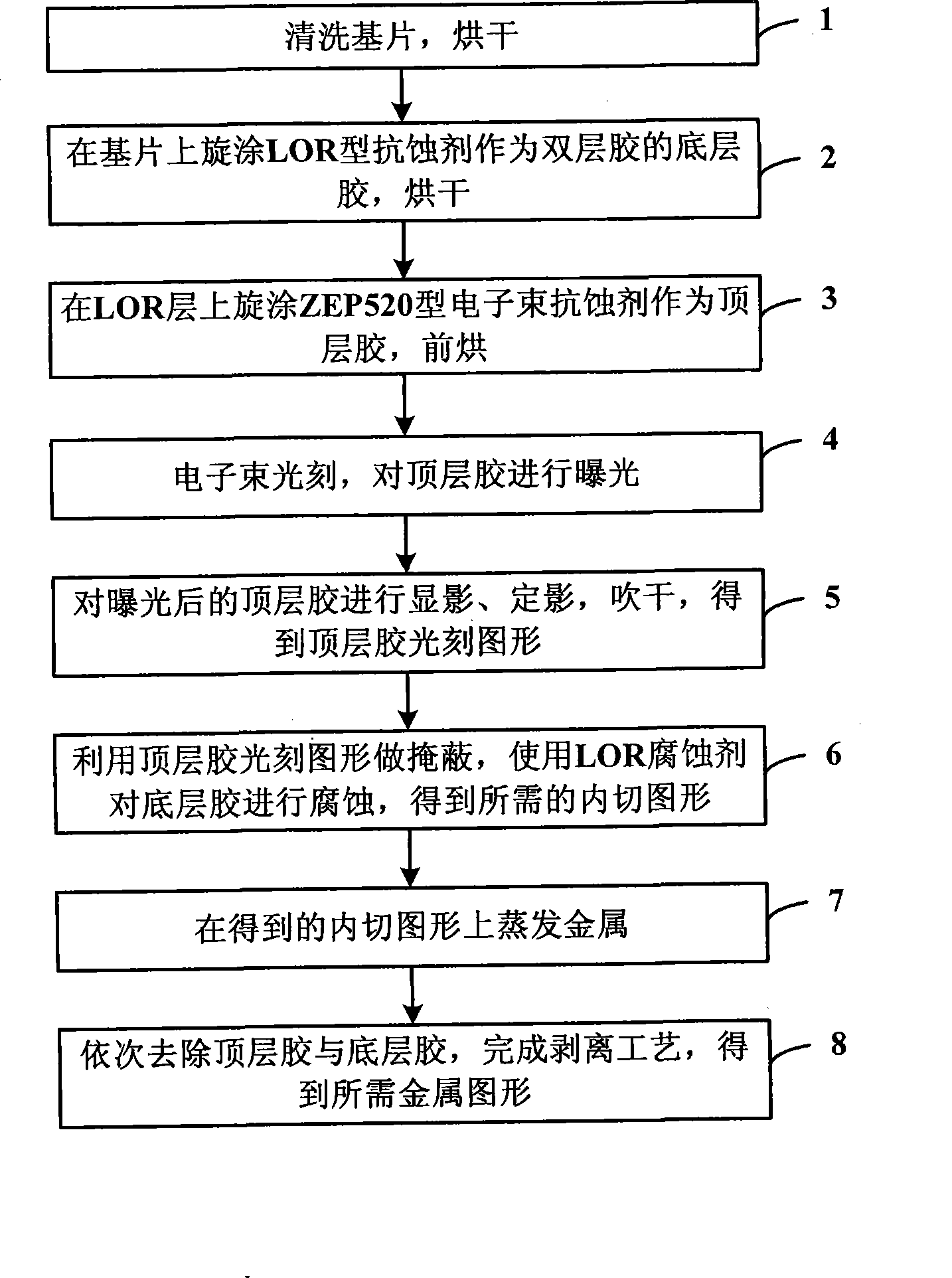

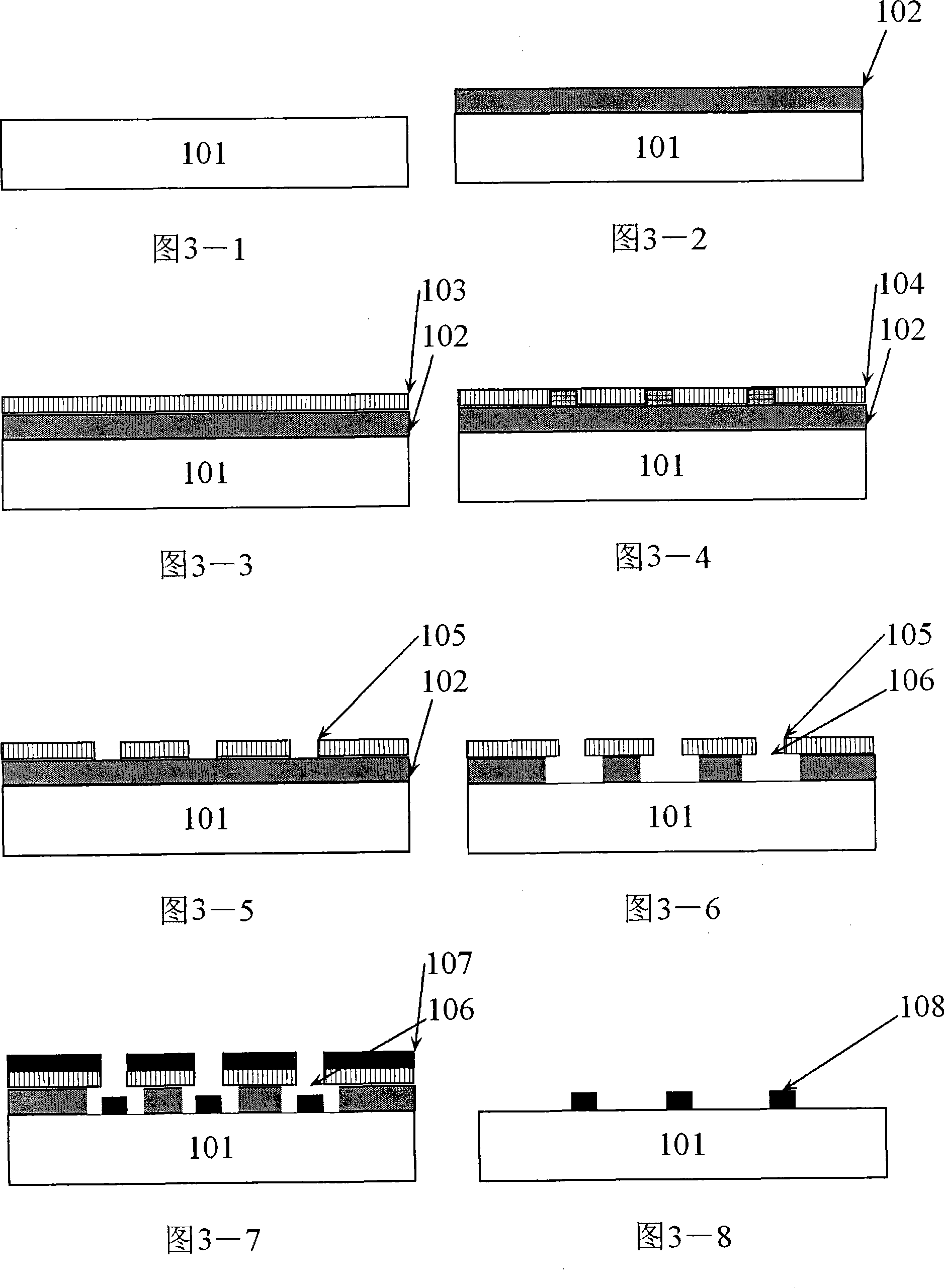

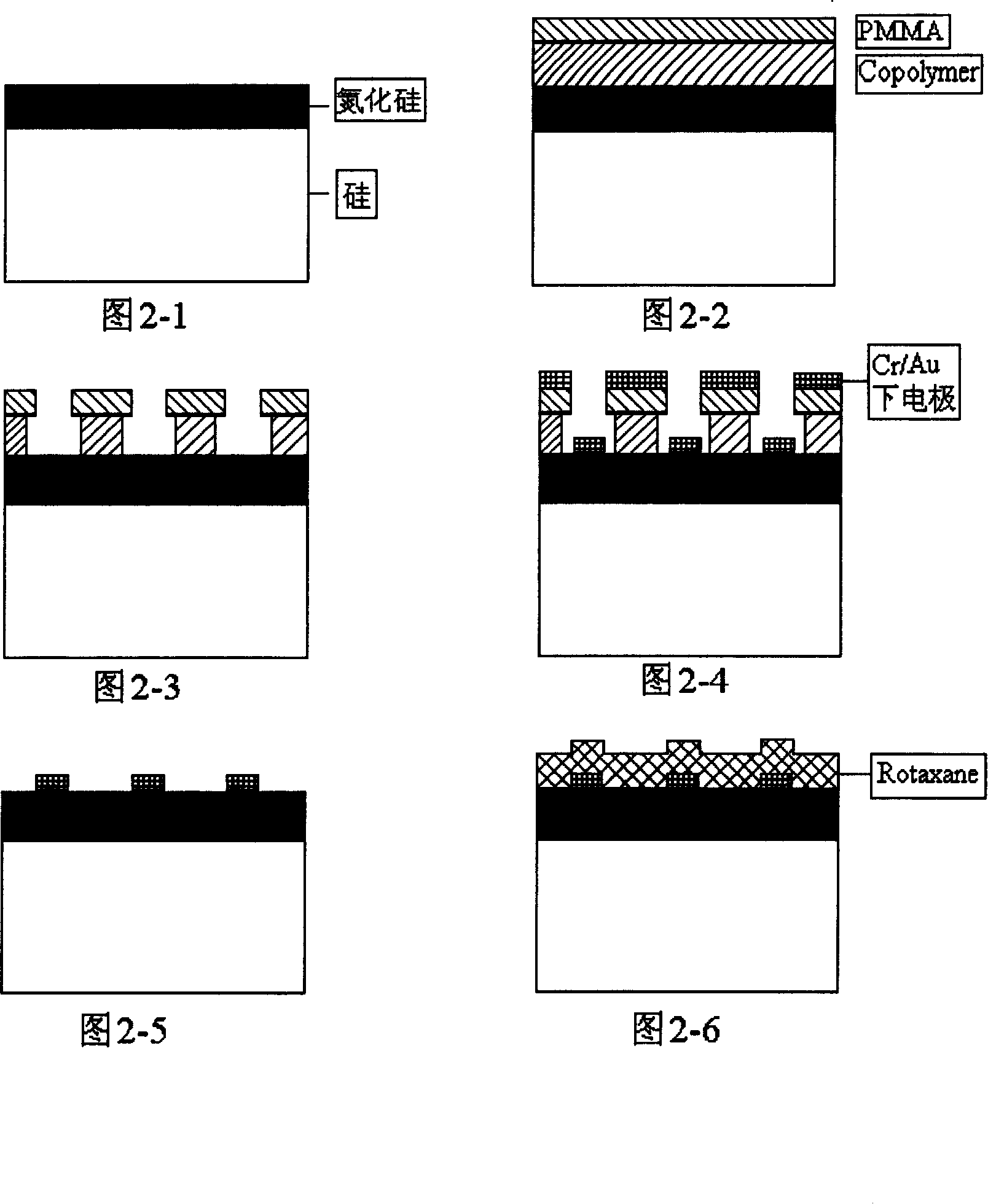

Double-layer glue removing method used for electron beam lithography stripping

ActiveCN101430503AClear and controllable incision structureReduce the difficulty of stripping processVacuum evaporation coatingSemiconductor/solid-state device manufacturingResistImage resolution

The invention discloses a method for removing double layered glue in electron bean lithography lift off, which comprises that a substrate is cleaned and dried; an LOR type resist is coated on the substrate in a pin way to be as the under layer glue of the double layered glue and is dried; a ZEP520 type electron beam resist is coated on an LOR layer in a pin way to be as the top layer glue and is prebaked; electron beam lithography exposes the top layer glue. The exposed top layer glue is developed, fixed and dried to obtain the etching graph of the top layer glue; an LOR corrosive erodes the under layer glue by using the top layer glue as masking to obtain a required interior contact graph; metal is evaporated on the obtained interior contact graph; the top layer glue and the under layer glue are sequentially removed to finish the peeling procedure and obtain the required metal graph. By using the method, the problem that the interior contact structure of the double layered glue becomes vague is solved; the method has the advantages of high resolution, high reliability, good repeatability and the like and has wide application prospect in the preparation of nano electronic devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

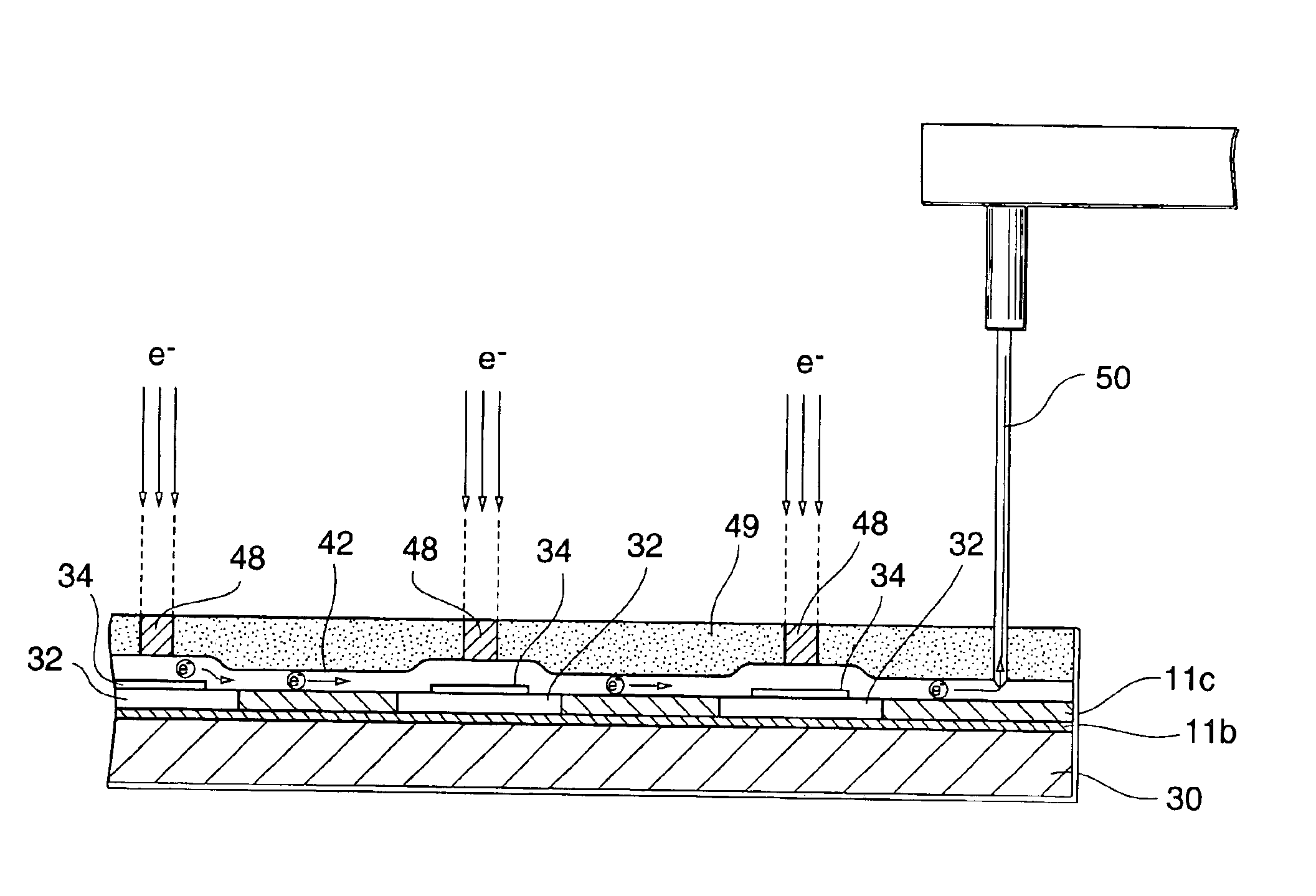

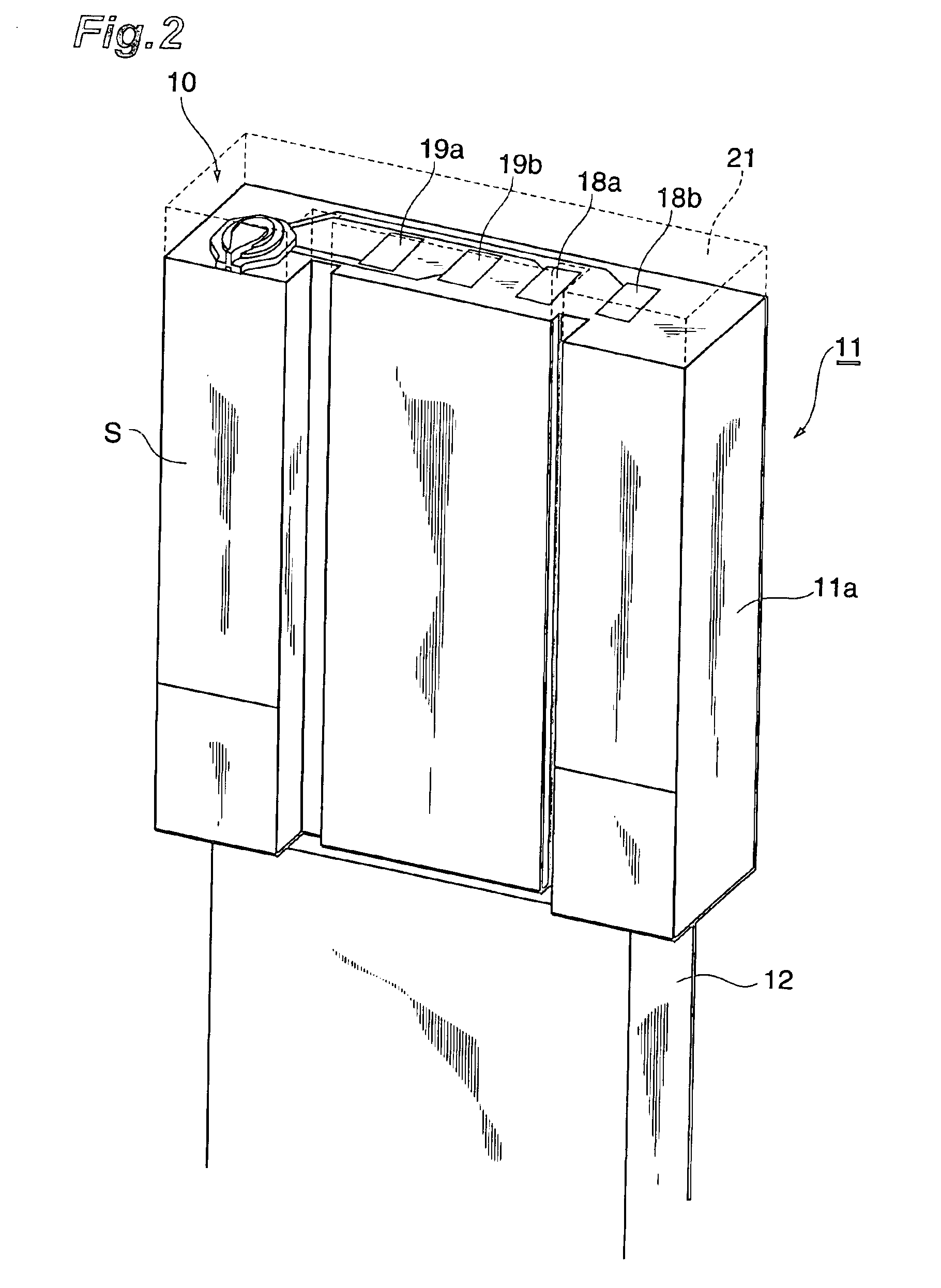

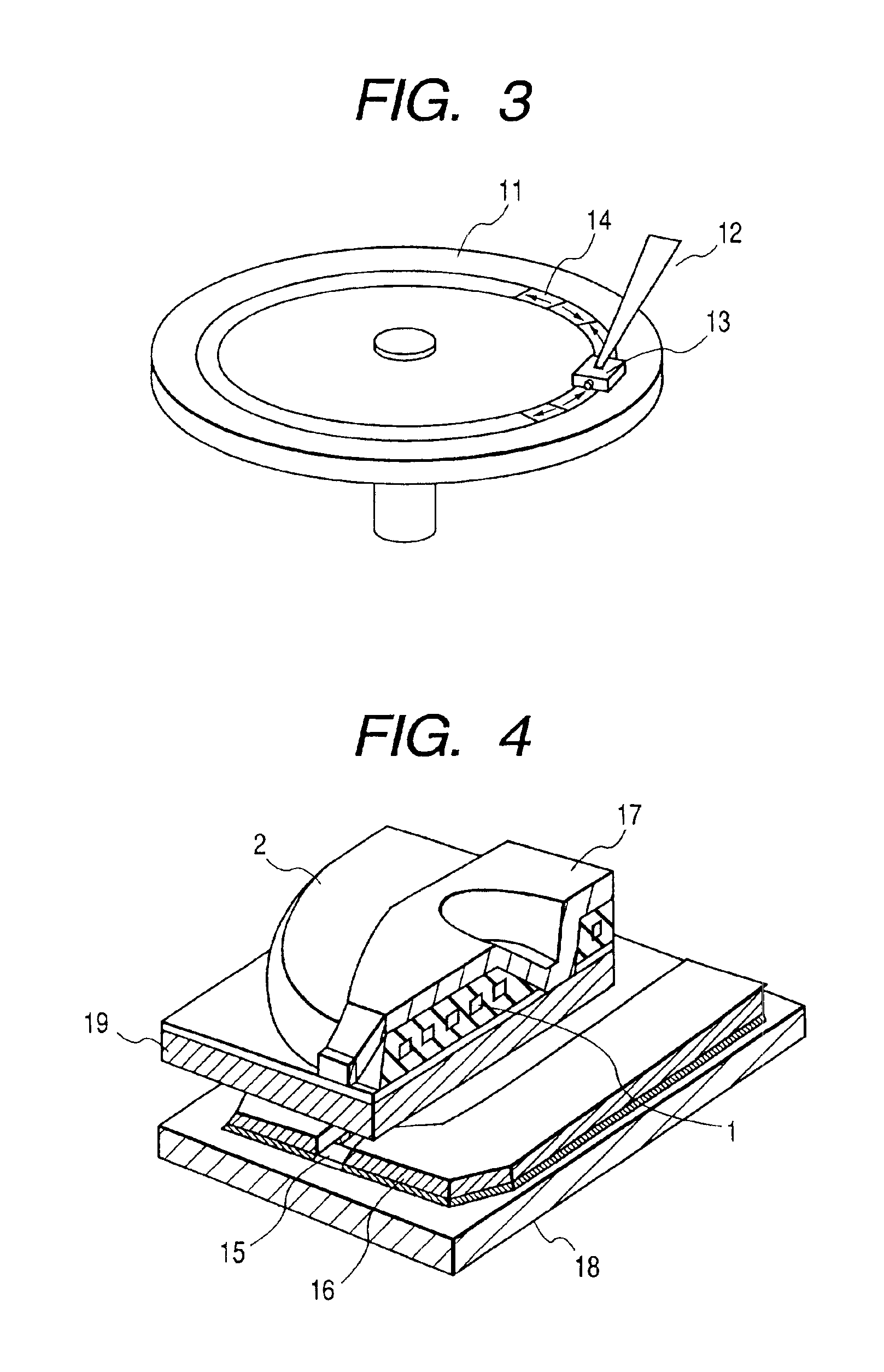

Method of making a thin-film magnetic head having a magnetoresistive device

InactiveUS6886239B2Forming accuratelyHigh precisionElectrical transducersHeads using thin filmsIrradiationElectron

In the method of making a thin-film magnetic head in accordance with the present invention, an electron beam resist is irradiated with electron beams in a state where an electrically conductive member is in contact with a magnetoresistive film. Since the magnetoresistive film electrically connects individual forming positions to be formed with magnetoresistive devices, charges stored near the forming positions upon irradiation with the electron beams can be drawn to the outside by way of the electrically conductive member. As a consequence, the electron beams are less likely to lose their rectilinearity, whereby the writing precision for patterning the magnetoresistive film by electron beam lithography can be improved.

Owner:TDK CORPARATION

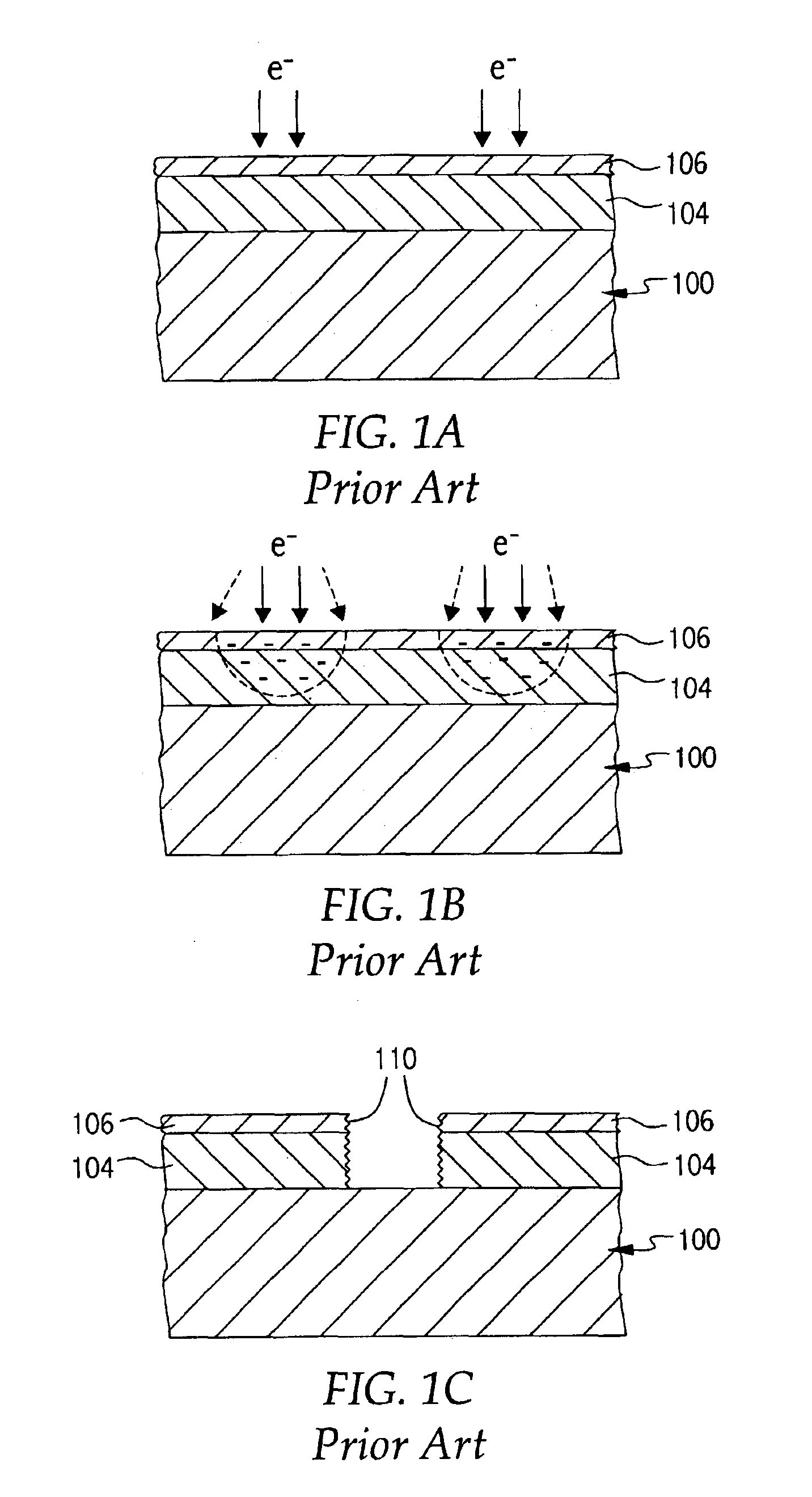

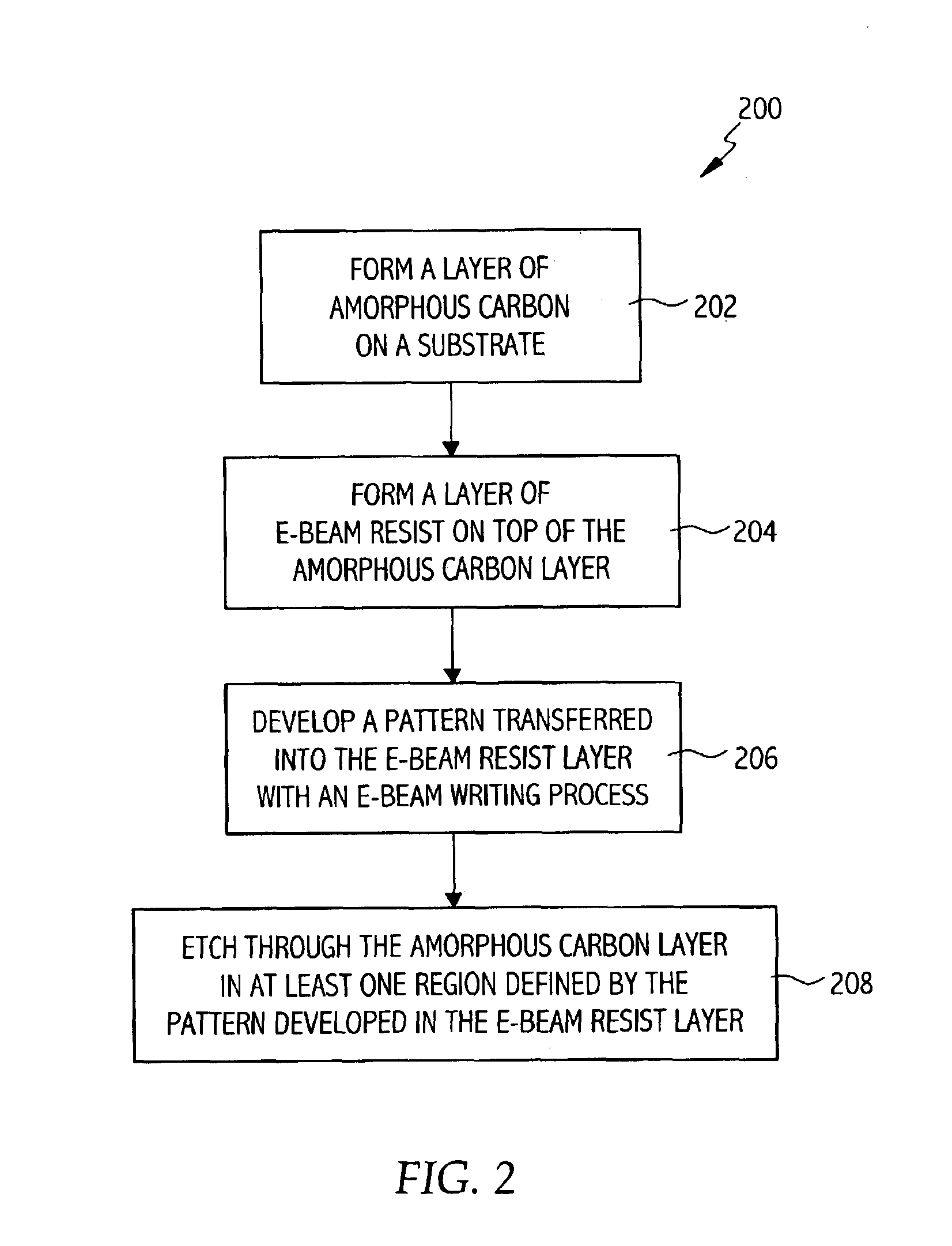

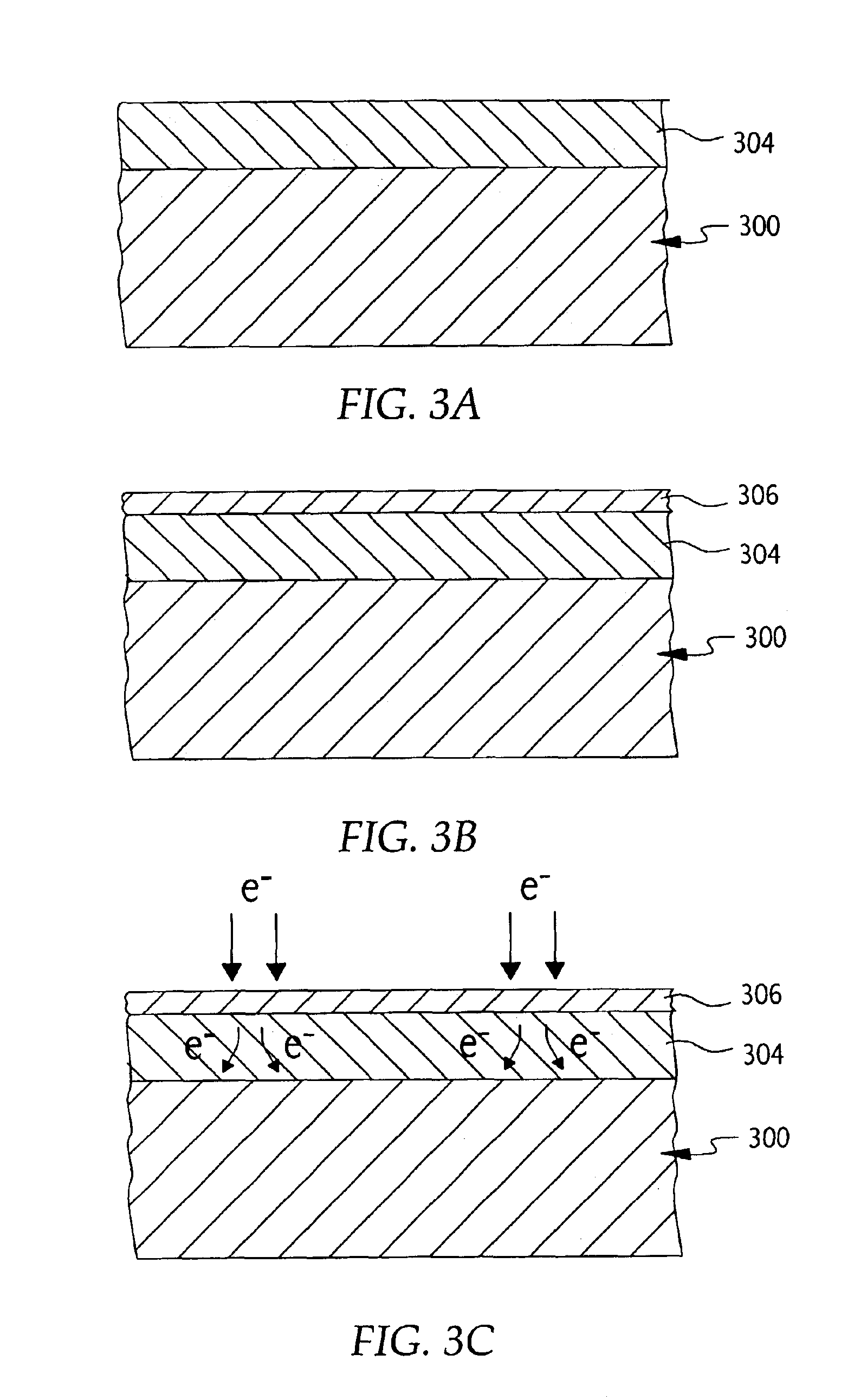

Conductive bi-layer e-beam resist with amorphous carbon

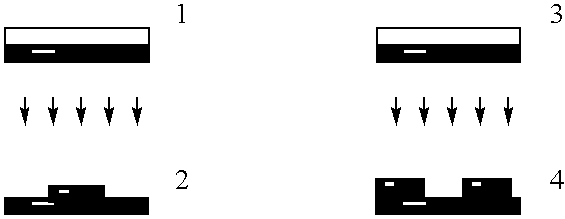

Methods for forming a patterned layer of amorphous carbon on a substrate are described. A layer of amorphous carbon may be formed on the substrate. A layer of electron sensitive resist may be formed on top of the amorphous carbon layer. A pattern transferred into the electron sensitive resist layer with an electron beam writing process is developed. During the electron beam writing process, electrons may be conducted away from the writing area through the amorphous carbon layer. The amorphous carbon layer may be etched through in at least one region defined by the pattern developed into the layer of electron sensitive resist material. For some embodiments, the amorphous carbon layer may be formed by chemical vapor deposition. For some embodiments, the layer of electron sensitive resist may be hydrogen silsesquioxane (HSQ).

Owner:APPLIED MATERIALS INC

Method for deep-UV lithography making T type gate

The invention discloses a method for manufacturing a T-shaped grate by utilization of deep-UV lithography, comprising the following steps that: a substrate is cleaned and dried and then coated by chemical amplifying deep-UV photoresist; contraposition, alignment, exposure and development are performed by adoption of a deep-UV exposure machine, and a grate root photoresist window graph is formed initially; the photoresist window graph which is formed by exposure is shrunk by adoption of chemical shrinking solution; electron beam slushing compounds are coated; chemical amplifying deep-UV photoresist is coated; contraposition, alignment, exposure and development are performed by adoption of the deep-UV exposure machine; exposure and development are performed by adoption of deep-UV electron beam slushing compounds, and a grate cap photoresist window graph is formed; grate electrode metals are deposited by adoption of the metal evaporation method; the metals are peeled off and the photoresist is stripped, and then manufacture of the T-shaped grate is finished. The method makes a grate root of the T-shaped grate break through the manufacturing limit of superfine lines of a photoetching plate, saves the manufacturing cost of the photoetching plate and simultaneously can realize large-scale deep-submicron processing of compound semiconductor devices.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

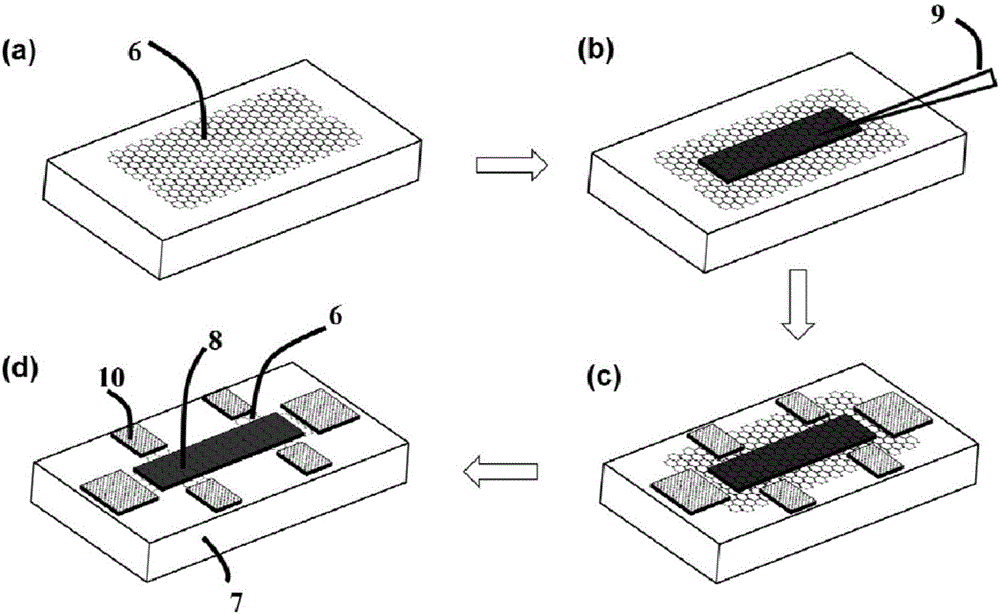

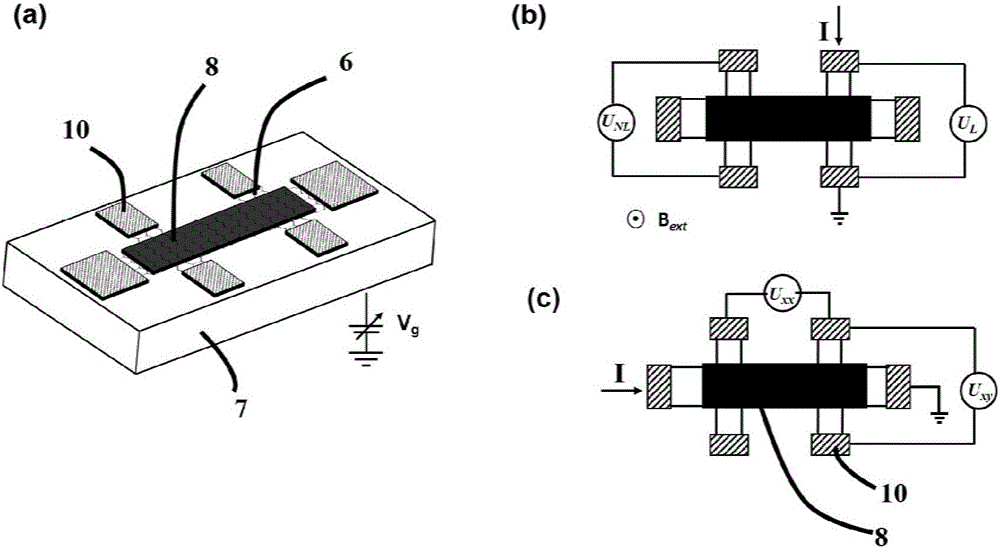

Graphene device capable of realizing spin polarization and preparation method thereof

ActiveCN106449968AFavors spin polarizationAvoid breakingGalvano-magnetic hall-effect devicesGalvano-magnetic device manufacture/treatmentElectron resistsSingle layer graphene

The invention discloses a graphene device capable of realizing spin polarization and a preparation method thereof. According to the graphene device and the preparation method thereof, single-layer graphene is prepared by adopting a micromechanical cleavage method, and a magnetic insulator nanosheet is selected according to the horizontal dimension of the single-layer graphene, and is transferred onto the single-layer graphene to form a magnetic insulator nanosheet / graphene heterogeneous structure through a glass needle of a nanometer micromechanical micromanipulation platform; an electron resist sheet is pressed above the magnetic insulator nanosheet, so that the magnetic insulator nanosheet can be combined with the single-layer graphene more closely, spin polarization of the graphene is facilitated, graphene breakage caused by spin coating can also be prevented, and the yield is improved; the advantages of a nanometer material are combined, so that the coupling effect of the single-layer graphene and the magnetic insulator nanosheet can be conveniently regulated and controlled, and the spin polarization efficiency of the graphene is improved; in addition, the device has the advantages of low cost, high yield and easiness for popularization, and the aim of convenient, efficient and flexible operation is fulfilled.

Owner:PEKING UNIV

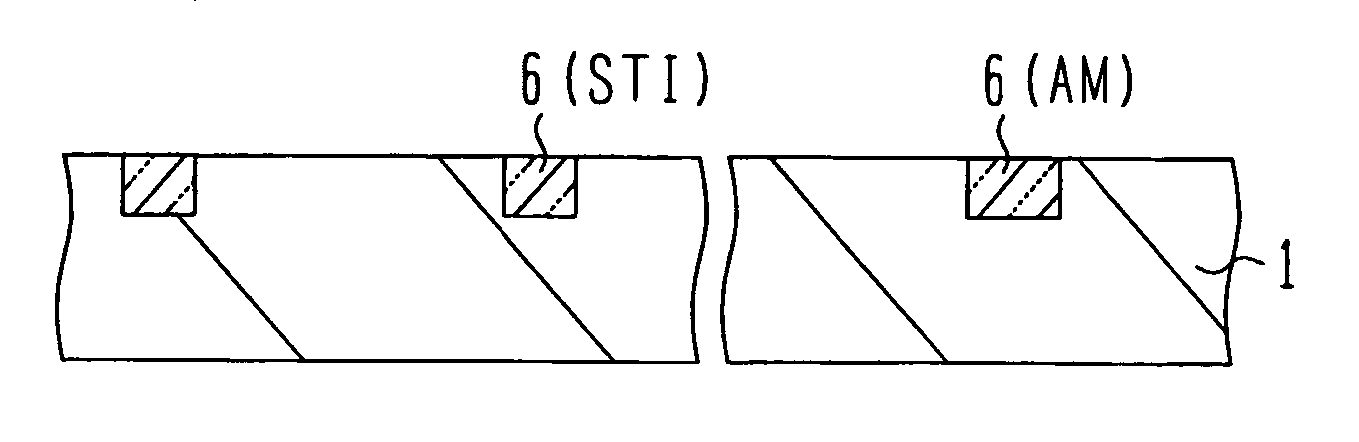

Semiconductor manufacture method

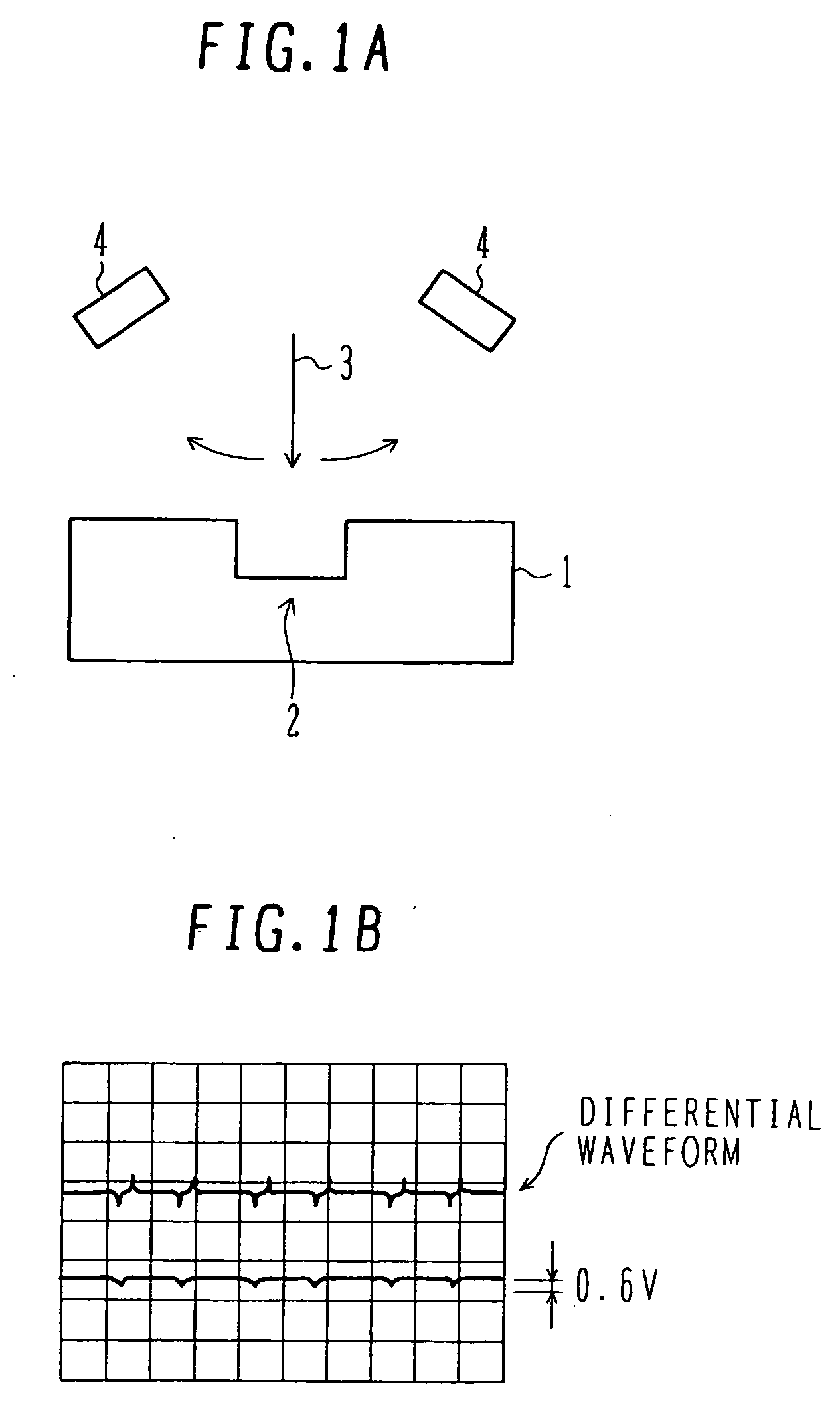

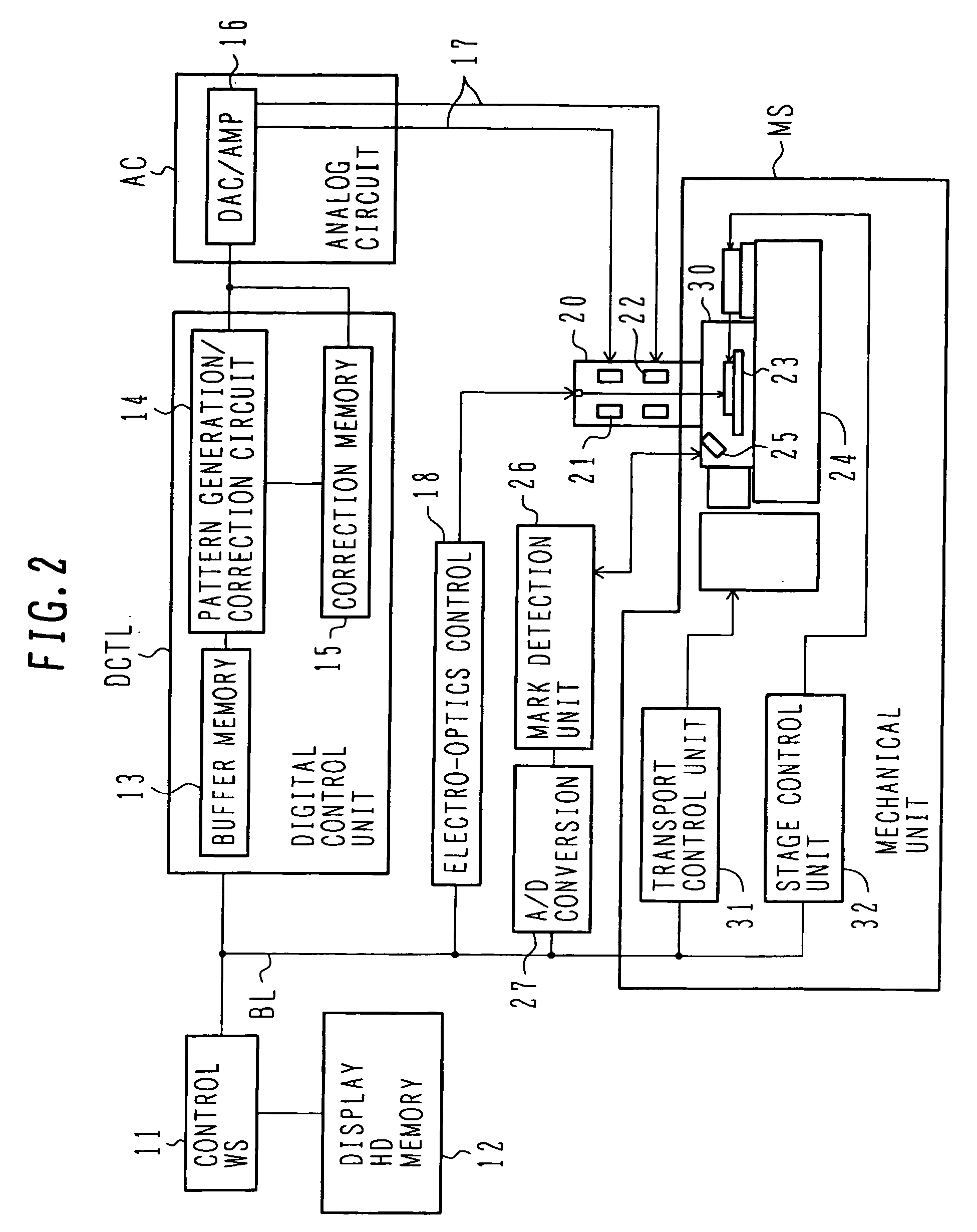

InactiveUS20060223200A1Remove outliersPrecise positioningSemiconductor/solid-state device testing/measurementElectric discharge tubesDevice materialSemiconductor

A semiconductor device manufacture method has the steps of: (a) forming a semiconductor device structure in a chip and alignment marks, respectively in a semiconductor wafer; (b) forming a workpiece layer above the semiconductor wafer; (c) exposing the alignment marks; (d) coating an electron beam resist film on the workpiece layer; (e) scanning the alignment marks with an electron beam to obtain plural position information on the alignment marks and obtaining differences between the plural position information; (f) removing abnormal values of position information in accordance with the difference between the plural position information; and (g) performing an electron beam exposure in accordance with plural position information of the alignment marks with the abnormal value being removed. An alignment mark detection precision can be improved in electron beam exposure.

Owner:FUJITSU SEMICON LTD

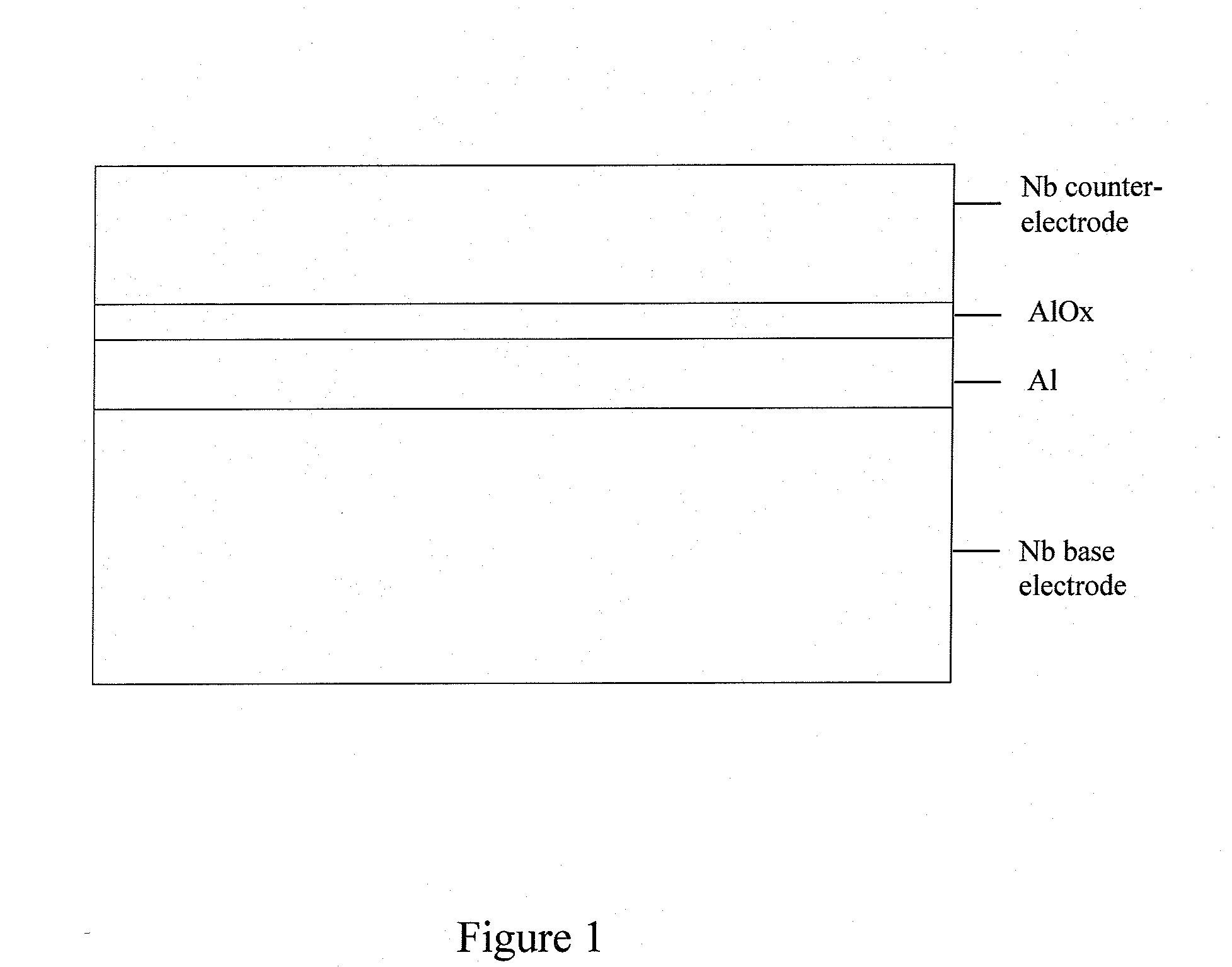

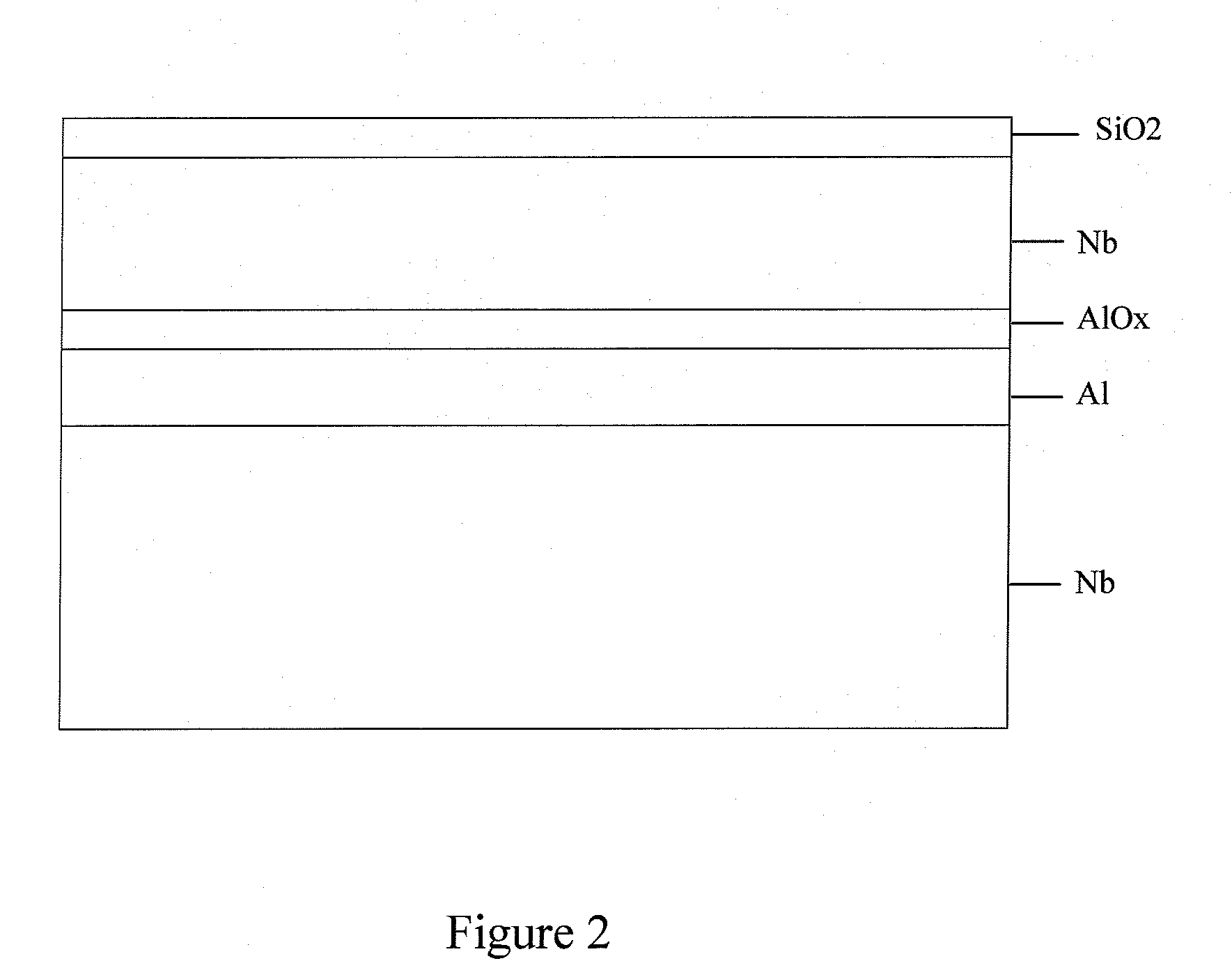

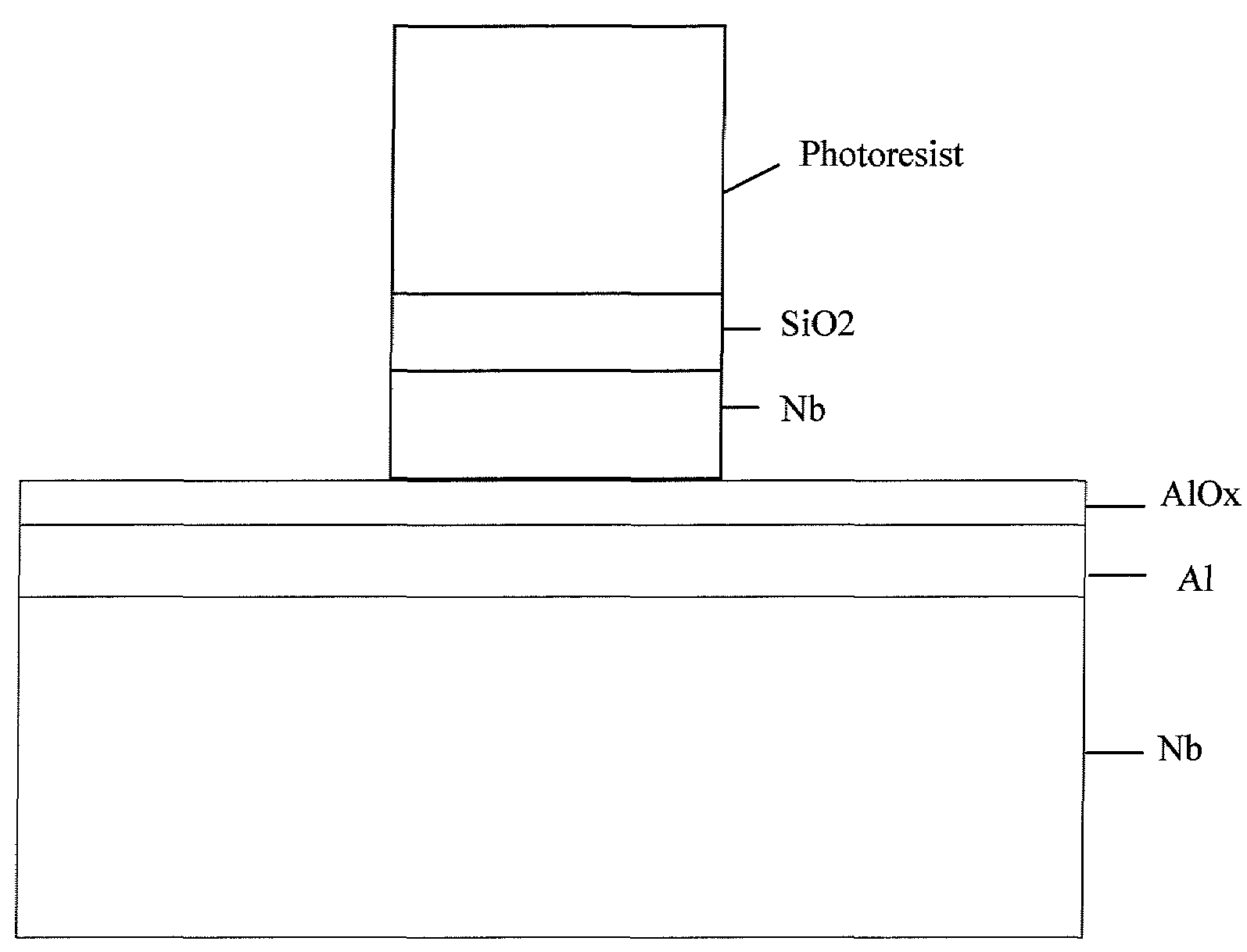

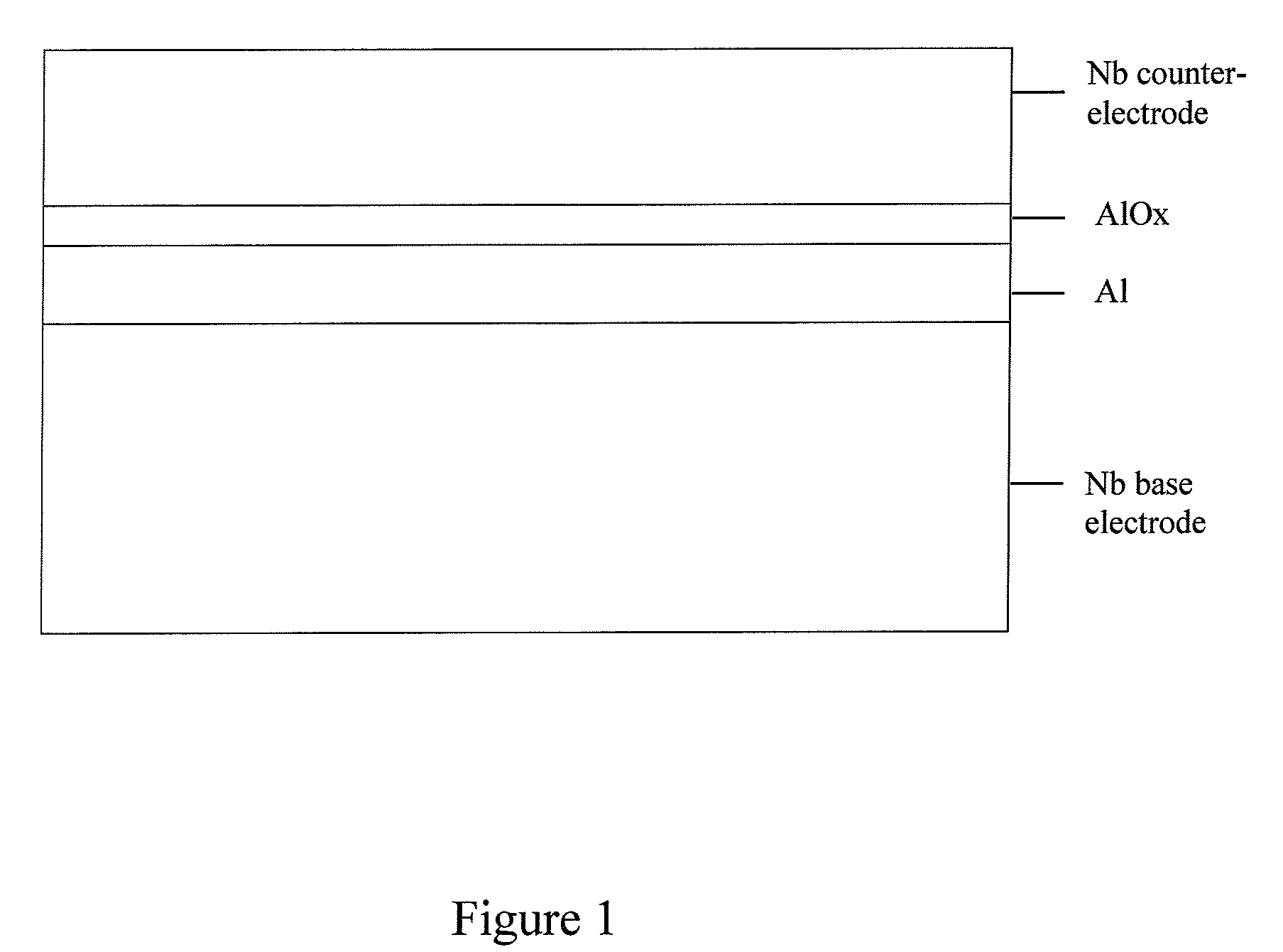

Double-masking technique for increasing fabrication yield in superconducting electronics

ActiveUS7615385B2Improve reliabilityHigh yieldSemiconductor/solid-state device manufacturingSuperconductor devicesResistNiobium

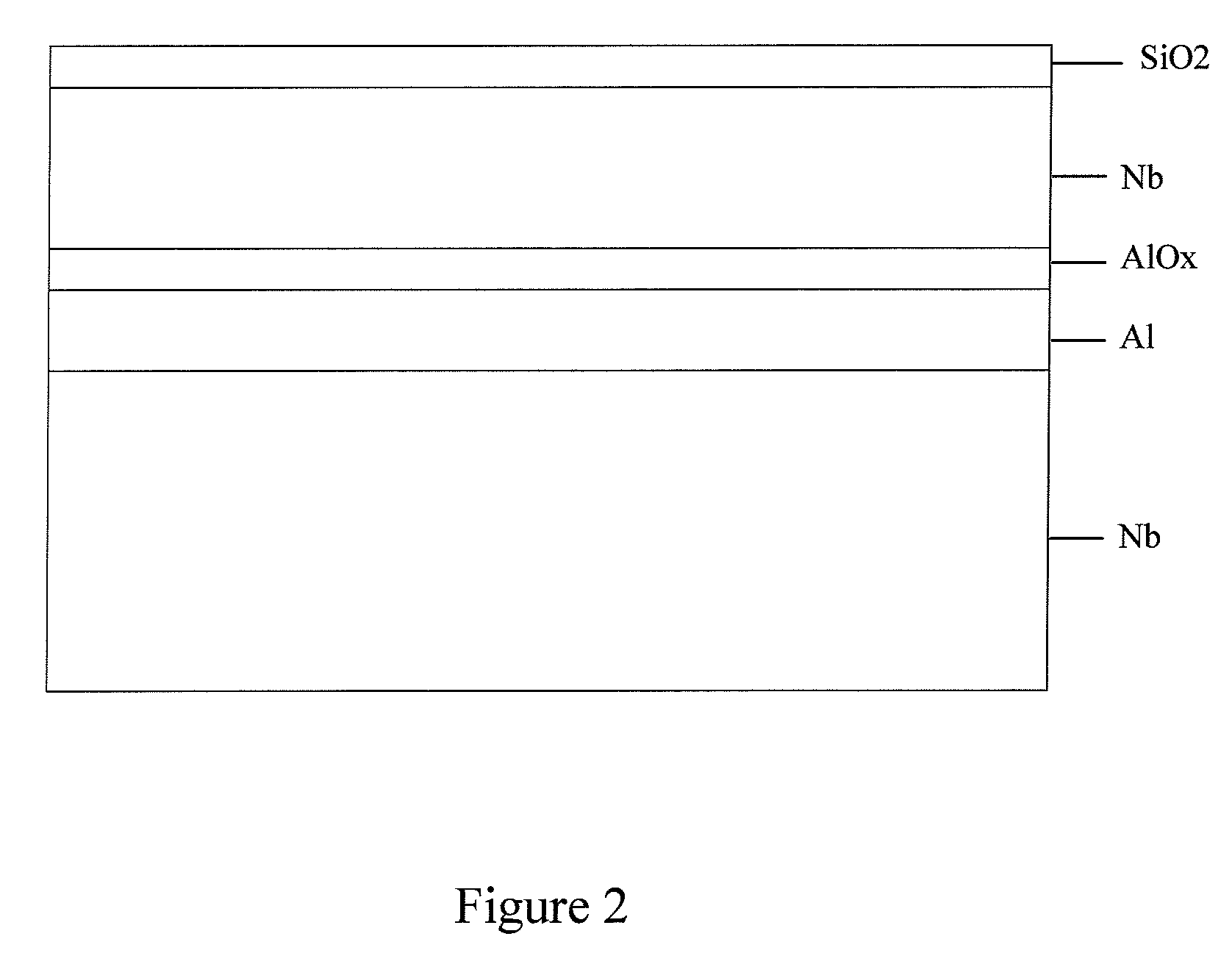

A new technique is presented for improving the microfabrication yield of Josephson junctions in superconducting integrated circuits. This is based on the use of a double-layer lithographic mask for partial anodization of the side-walls and base electrode of the junctions. The top layer of the mask is a resist material, and the bottom layer is a dielectric material chosen so as to a) maximize adhesion between the resist and the underlying superconducting layer, b) be etch-compatible with the underlying superconducting layer, and c) be insoluble in the resist and anodization processing chemistries. In a preferred embodiment of the invention, the superconductor is niobium, the material on top of this is silicon dioxide, and the top layer is conventional photoresist or electron-beam resist. The use of this combination results in a substantial increase in the fabrication yield of high-density superconducting integrated circuits due to increase in junction uniformity and reduction in defect density. An additional improvement over the prior art involves the replacement of a wet-etch step with a dry etch more compatible with microlithography.

Owner:SEEQC INC

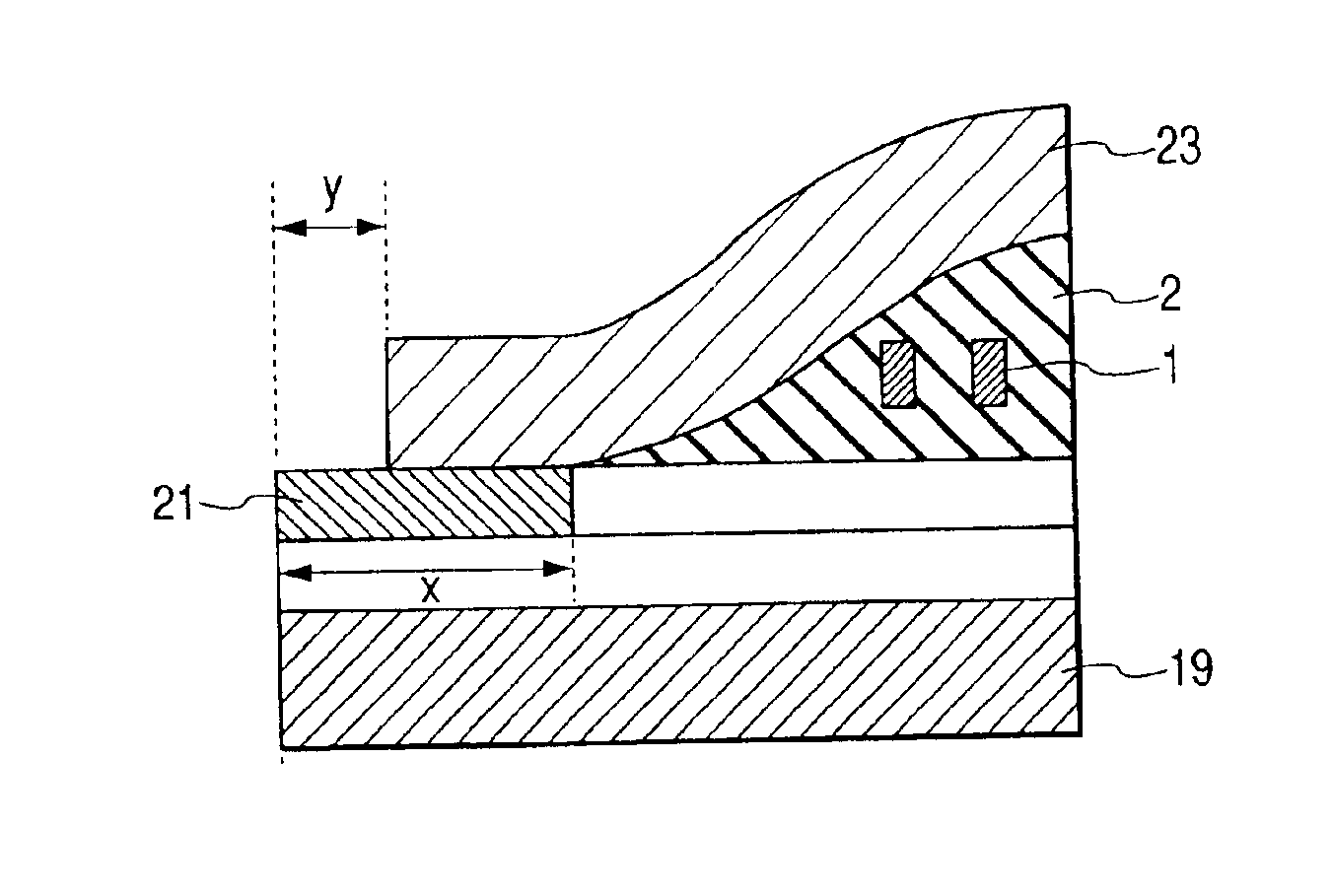

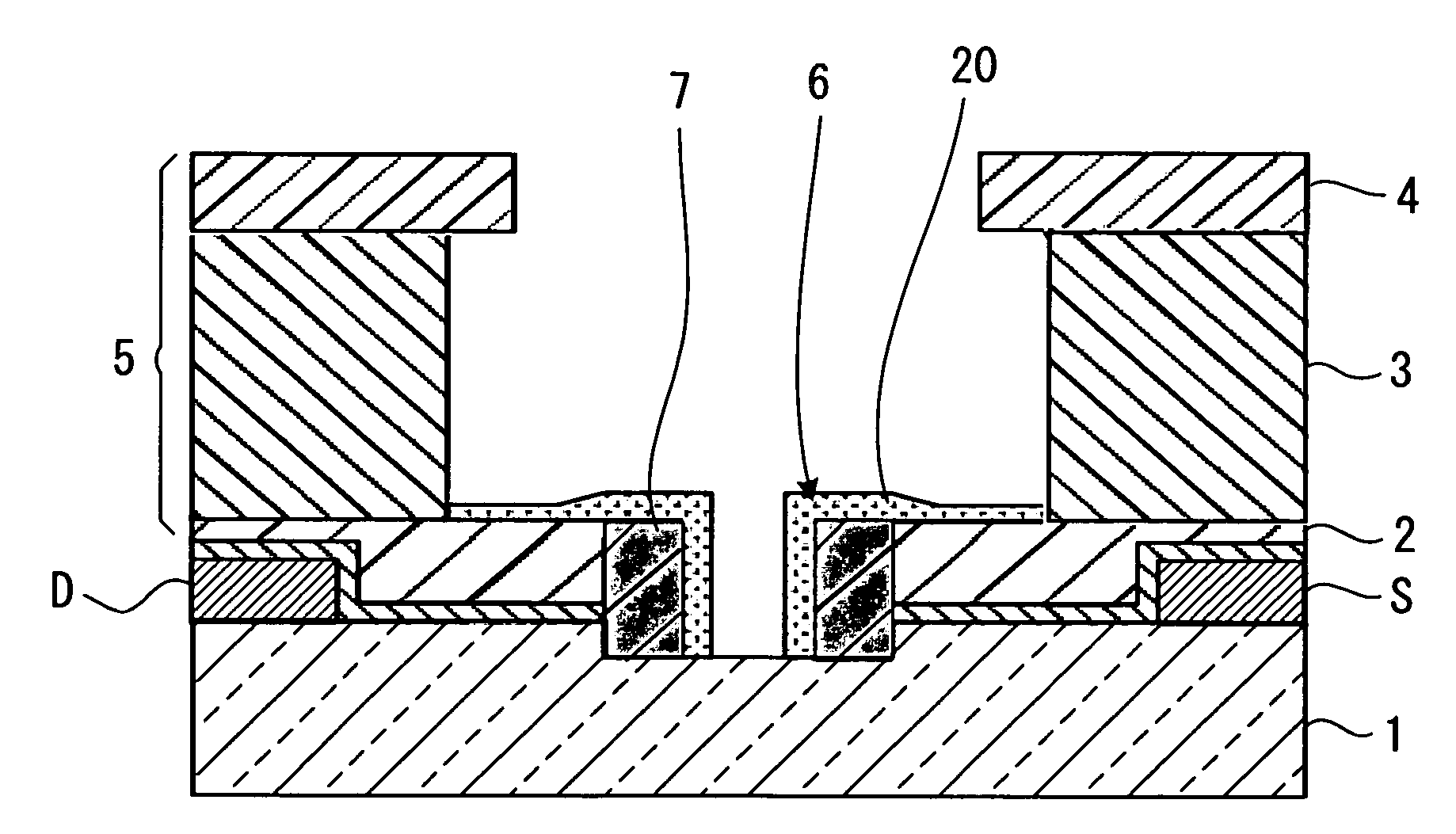

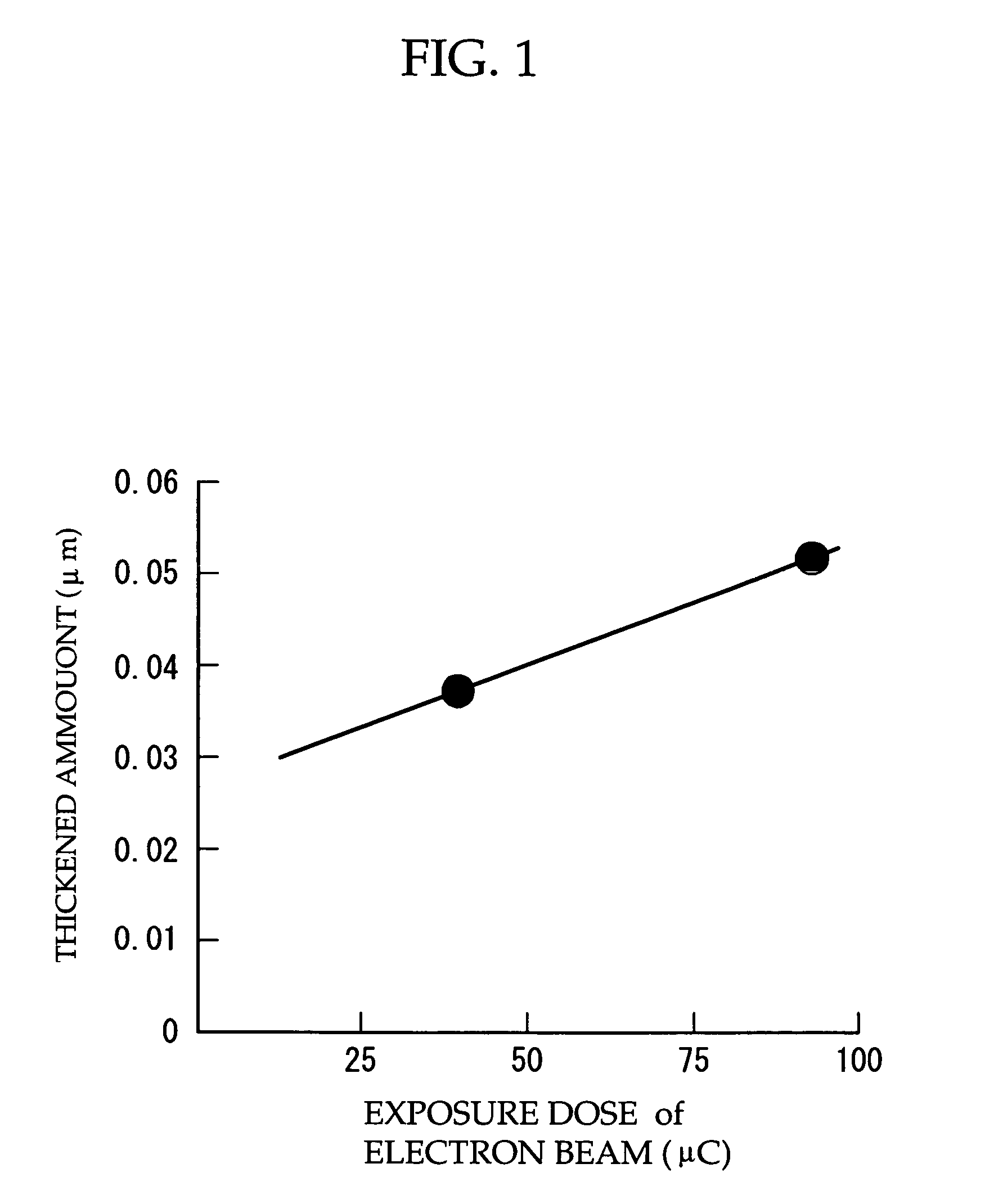

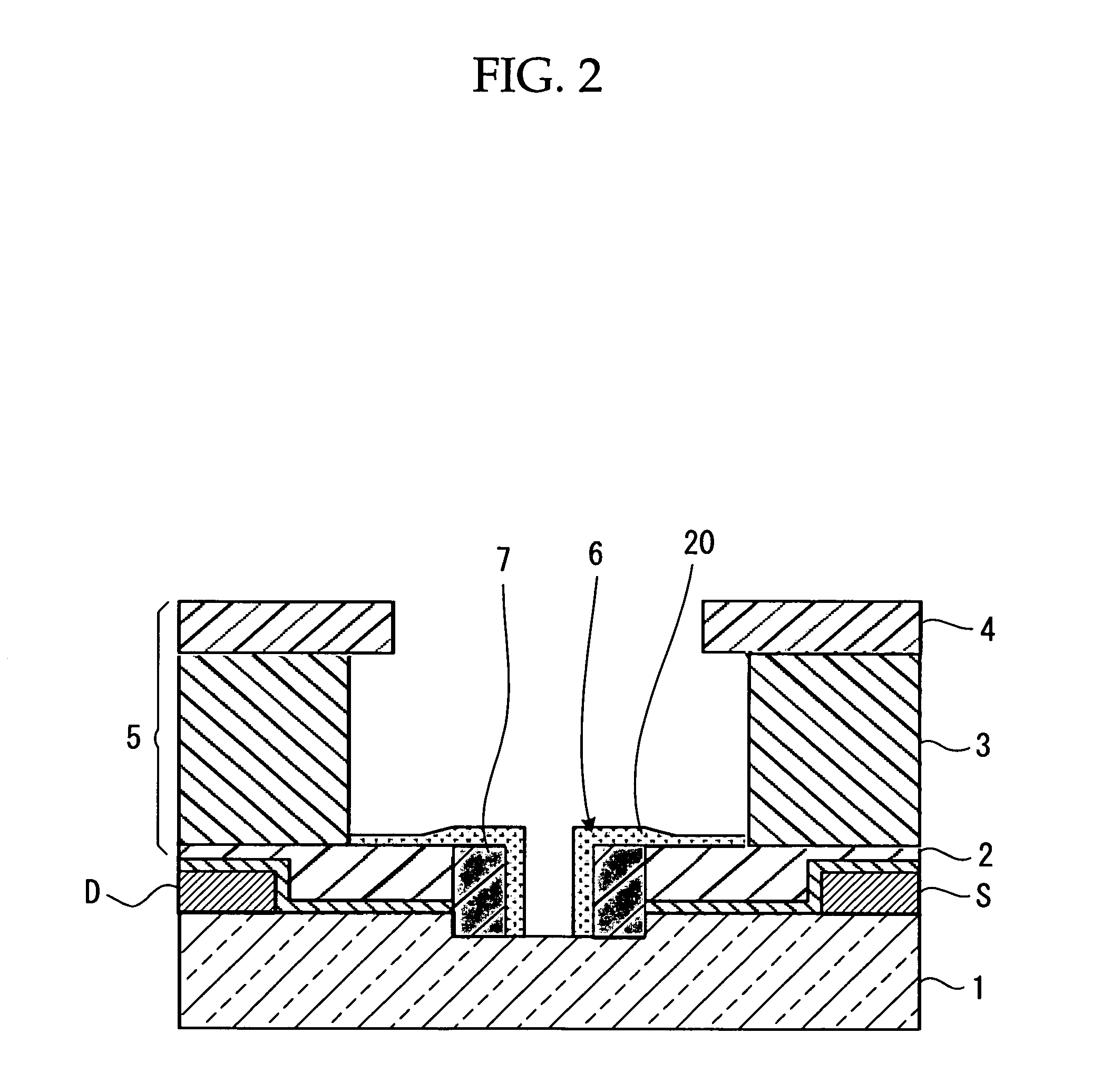

Gate electrode and manufacturing method thereof, and semiconductor device and manufacturing method thereof

ActiveUS20050159009A1Reduce selection requirementsWell formedSemiconductor/solid-state device manufacturingSemiconductor devicesResistDevice material

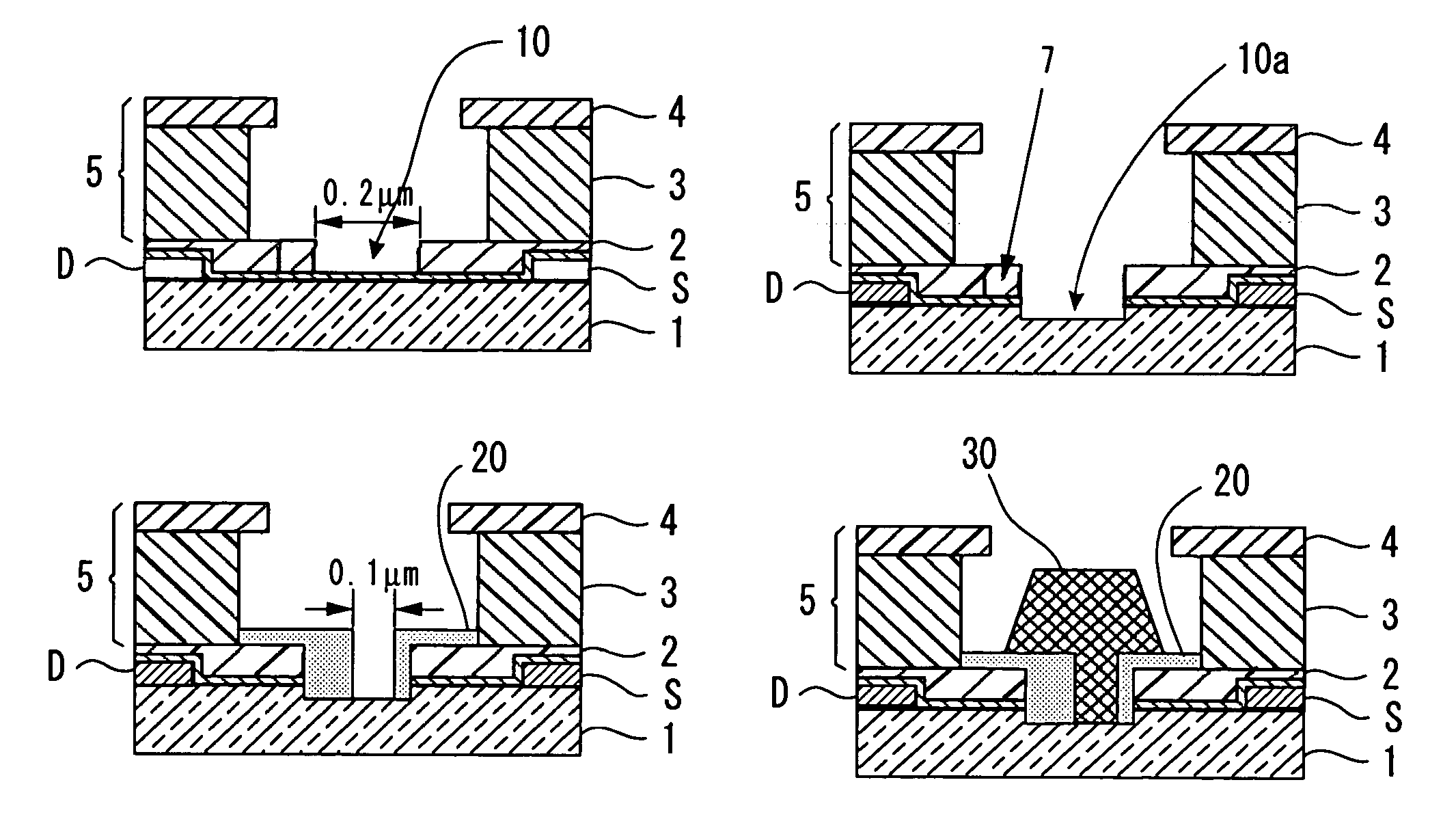

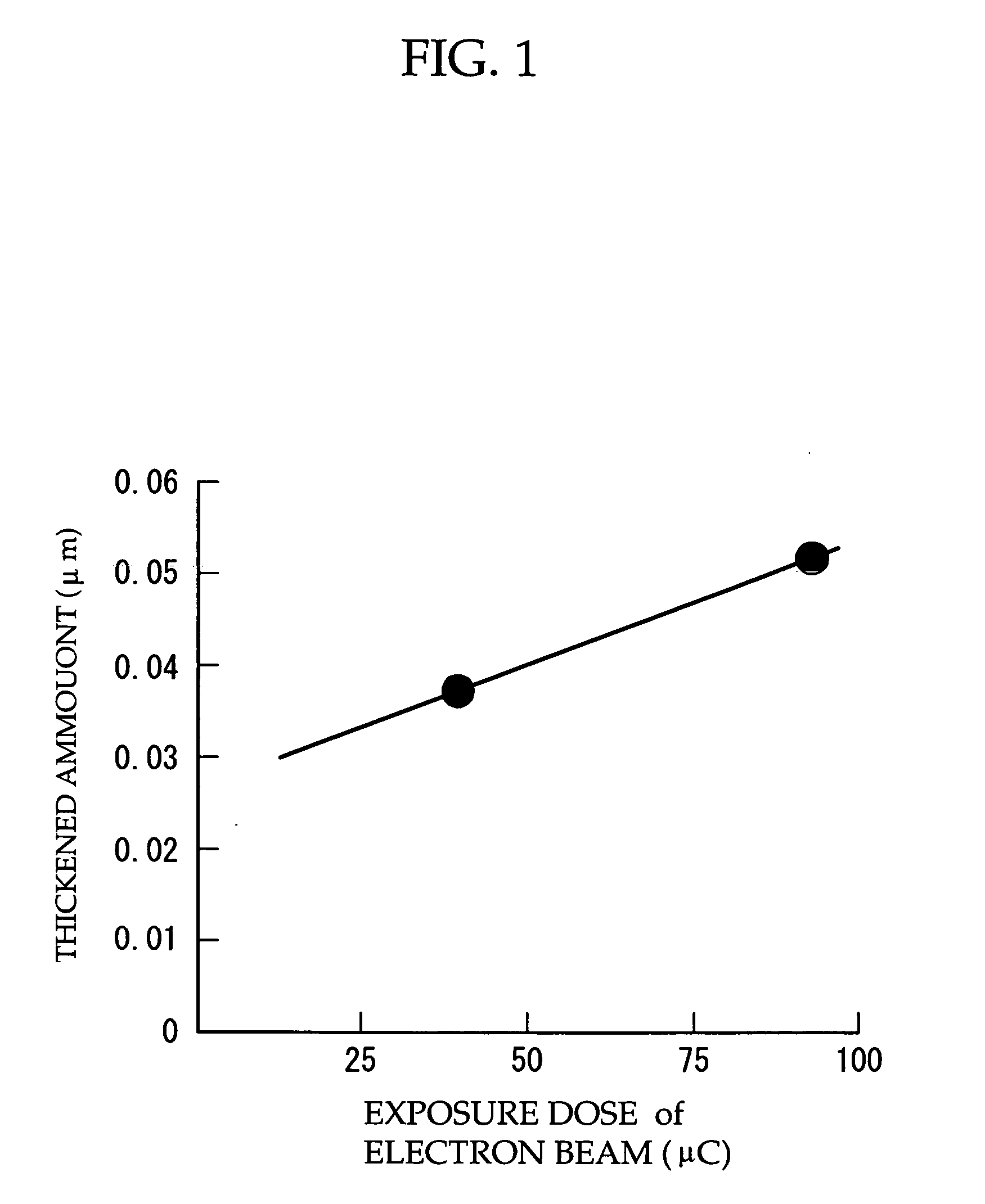

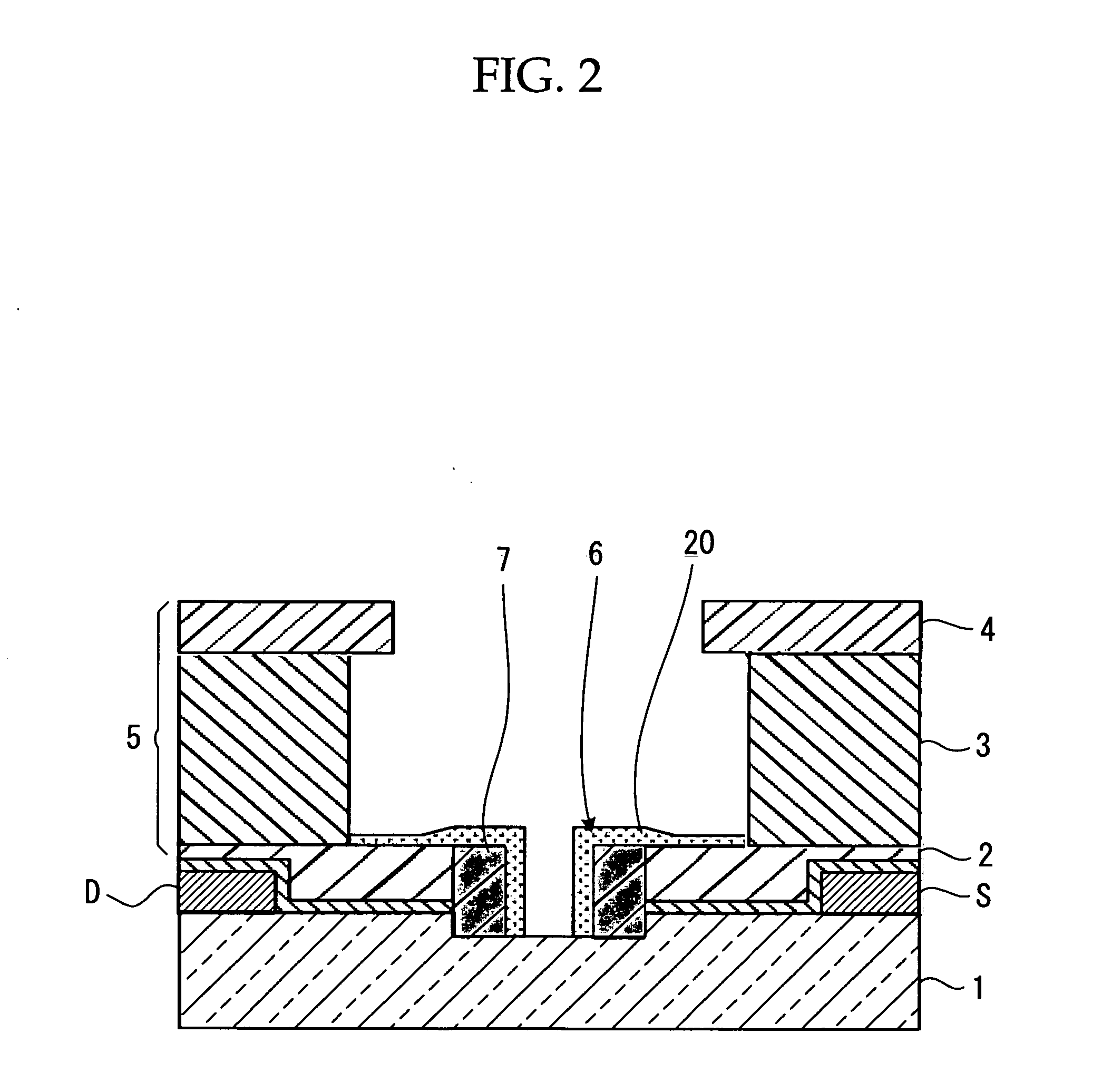

The present invention provides a method of manufacturing a gate electrode in which a fine gate electrode can effectively be manufactured by thickening a resist opening for gate electrodes formed by ordinary electron beam lithography so as to reduce opening dimensions. The method of manufacturing a gate electrode of the present invention includes a step of forming a laminated resist including at least an electron beam resist layer as a lowermost layer on a surface where a gate electrode is to be formed; a step of forming an opening in layer(s) other than the lowermost layer; a step of forming a gate electrode opening on the lowermost layer exposed from the opening; a step of reducing the gate electrode opening selectively; and a step of forming a gate electrode in the gate electrode opening.

Owner:FUJITSU LTD

Plastic male mold for fabricating microstructures and nanostructures using imprint lithography

Known electron beam lithography used for manufacturing male molds is cost-intensive and very time consuming. As a result, conventional highly sensitive electron beam resists have an insufficient plasma etching resistance and galvanic molding makes special demands on the structural profile and the thermal stability and solubility of the resist structures. The novel production and use of lithographically produced resist structures as male mold material for use in imprint lithography for producing microstructures and nanostructures should thus overcome the drawbacks associated with the conventional procedure for producing male molds. To this end, a negative resist system is used whose lithographically produced structures correspond to the demands made on a male mold for molding thin polymer layers. Lithographically produced structures comprised of curable materials are thus used for molding, preferably those based on photo-reactive epoxy resins. The invention, in turn, enables an economical and thereby low-cost production of male mold material.

Owner:MICRO RESIST TECH

Method of synthesizing ITO electron-beam resist and method of forming ITO pattern using the same

ActiveUS20100035179A1Eliminate the problemHigh light transmittanceTin compoundsPhotosensitive materialsAtomic physicsElectron beam resist

Provided is a method of synthesizing an ITO electron beam resist and a method of forming an ITO pattern. The ITO electron beam resist is synthesized by dissolving indium chloride tetrahydrate and tin chloride dihydrate in 2-ethoxy ethanol. The method of forming an ITO pattern includes: forming an ITO electron beam resist film on a substrate, forming an ITO electron beam resist pattern by patterning the ITO electron beam resist film, and forming an ITO pattern by annealing the ITO electron beam resist pattern.

Owner:ELECTRONICS & TELECOMM RES INST

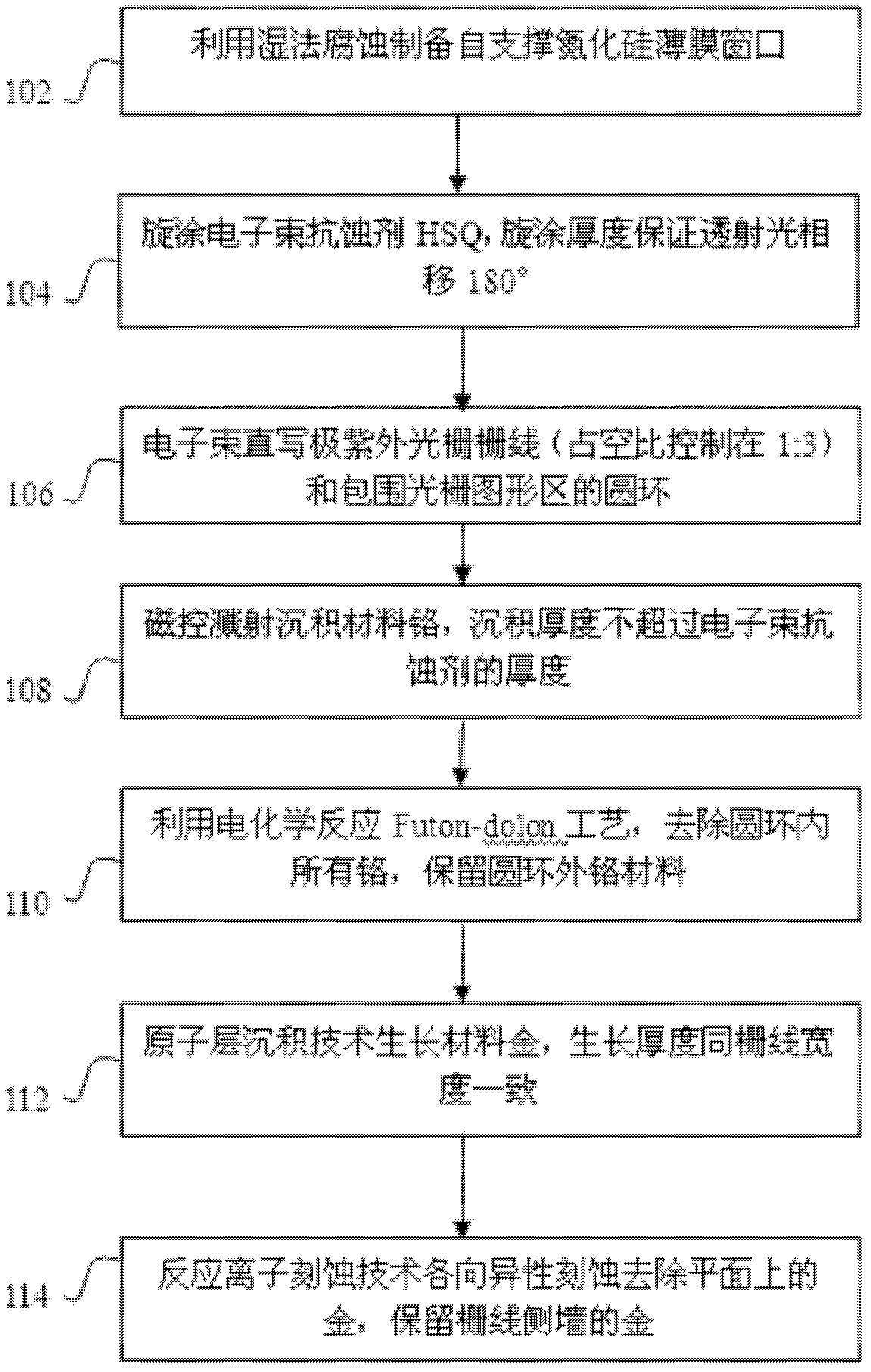

Method for manufacturing chromium sidewall attenuation type phase-shifting mask used in extreme ultra-violet lithography

InactiveCN103163726AReduce diffraction effectsIncrease contrastOriginals for photomechanical treatmentMicro nanoDiffraction effect

The invention discloses a method for manufacturing a chromium sidewall attenuation type phase-shifting mask used in extreme ultra-violet lithography. Firstly, a plurality of multilayer reflectors are manufactured according to a manufacturing method for a conventional extreme ultra-violet lithography mask; then a phase-shifting layer structure is manufactured on an electron beam resist by using a micro-nano machining technology, and an absorber material chromium is deposited on a large area; and finally, the absorber material chromium is anisotropically etched, only leaving the attenuation type phase-shifting layer chromium sidewalls, so that the chromium sidewall attenuation type phase-shifting mask used in the extreme ultra-violet lithography can be obtained. The chromium sidewall attenuation type phase-shifting mask is obtained by one time of electron beam exposure, two times of magnetron sputtering deposition of multilayer reflecting layers and the phase-shifting layer, one time of atomic layer deposition of the chromium material on a large area, and one time of anisotropic etching of the chromium material. The chromium sidewall is added in two sides of the attenuation type phase-shifting mask, and the exposure shadow and the diffraction effect in the extreme ultra-violet lithography are depressed by the chromium sidewalls, so that a more efficient function of resolution enhancement than that of a conventional attenuation type phase-shifting mask is obtained.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

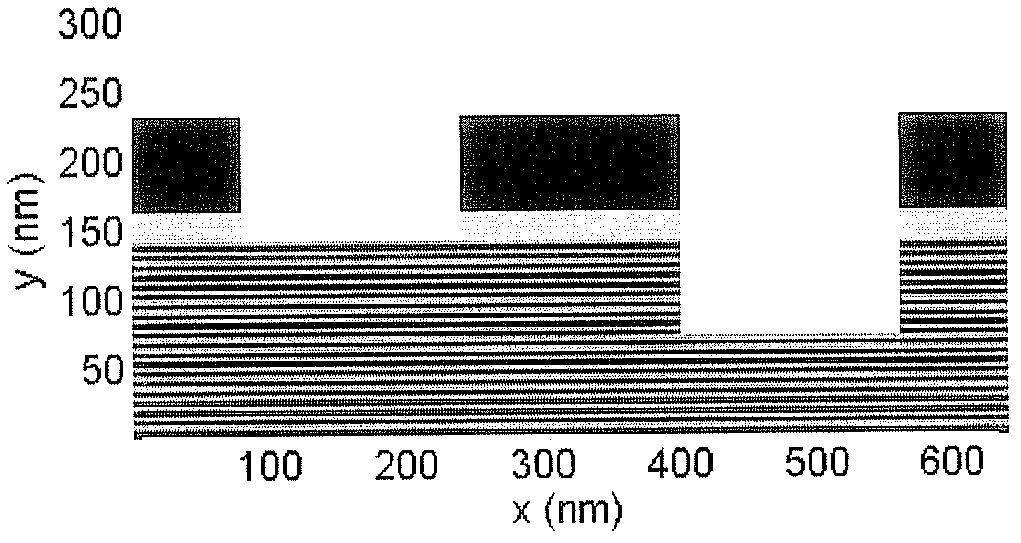

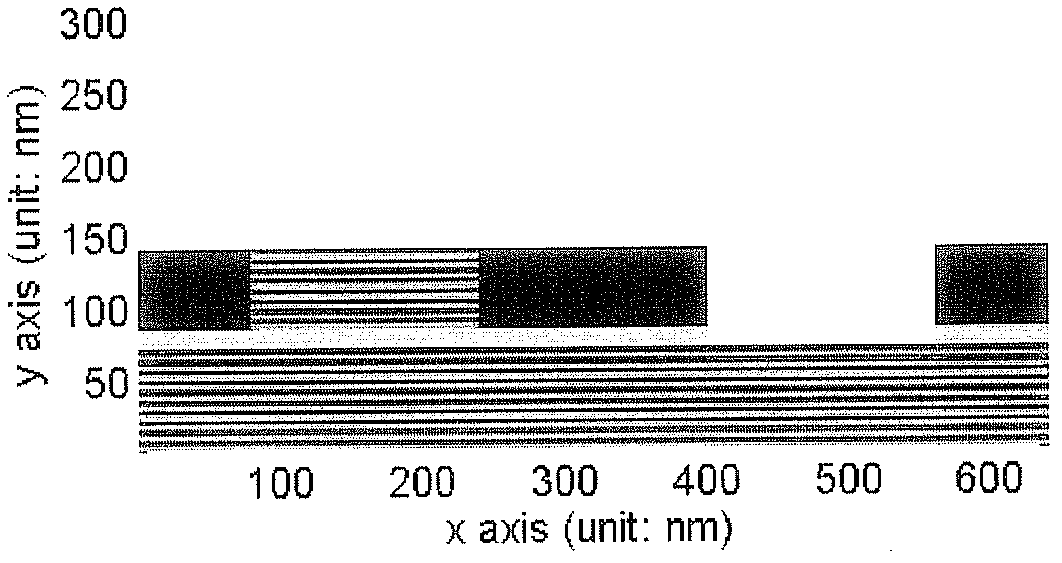

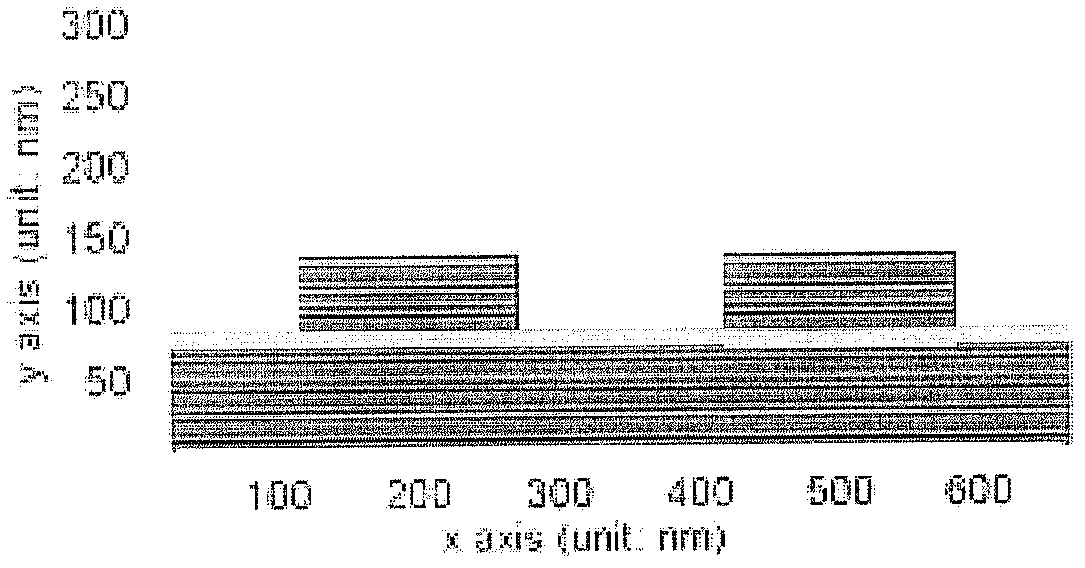

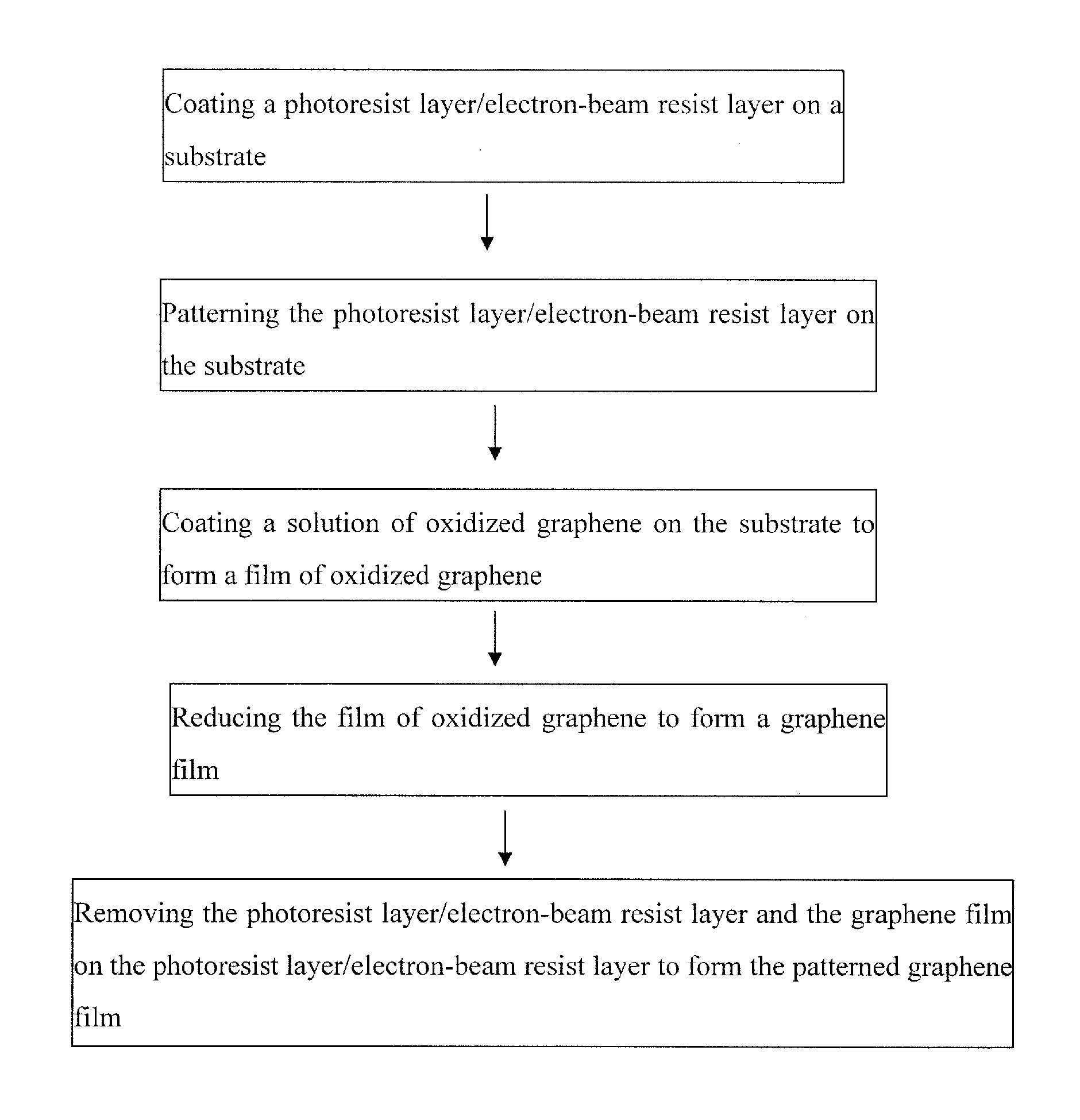

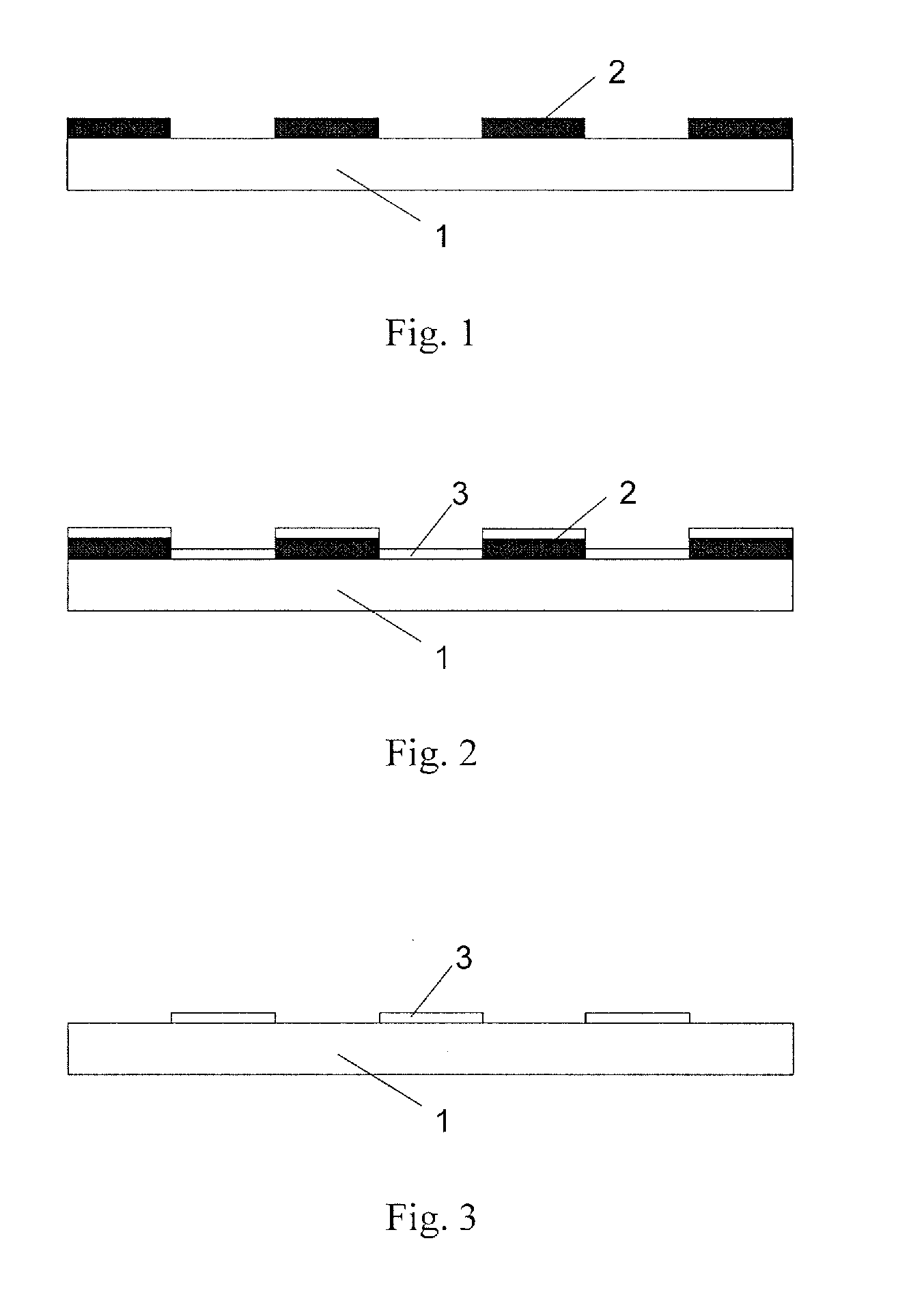

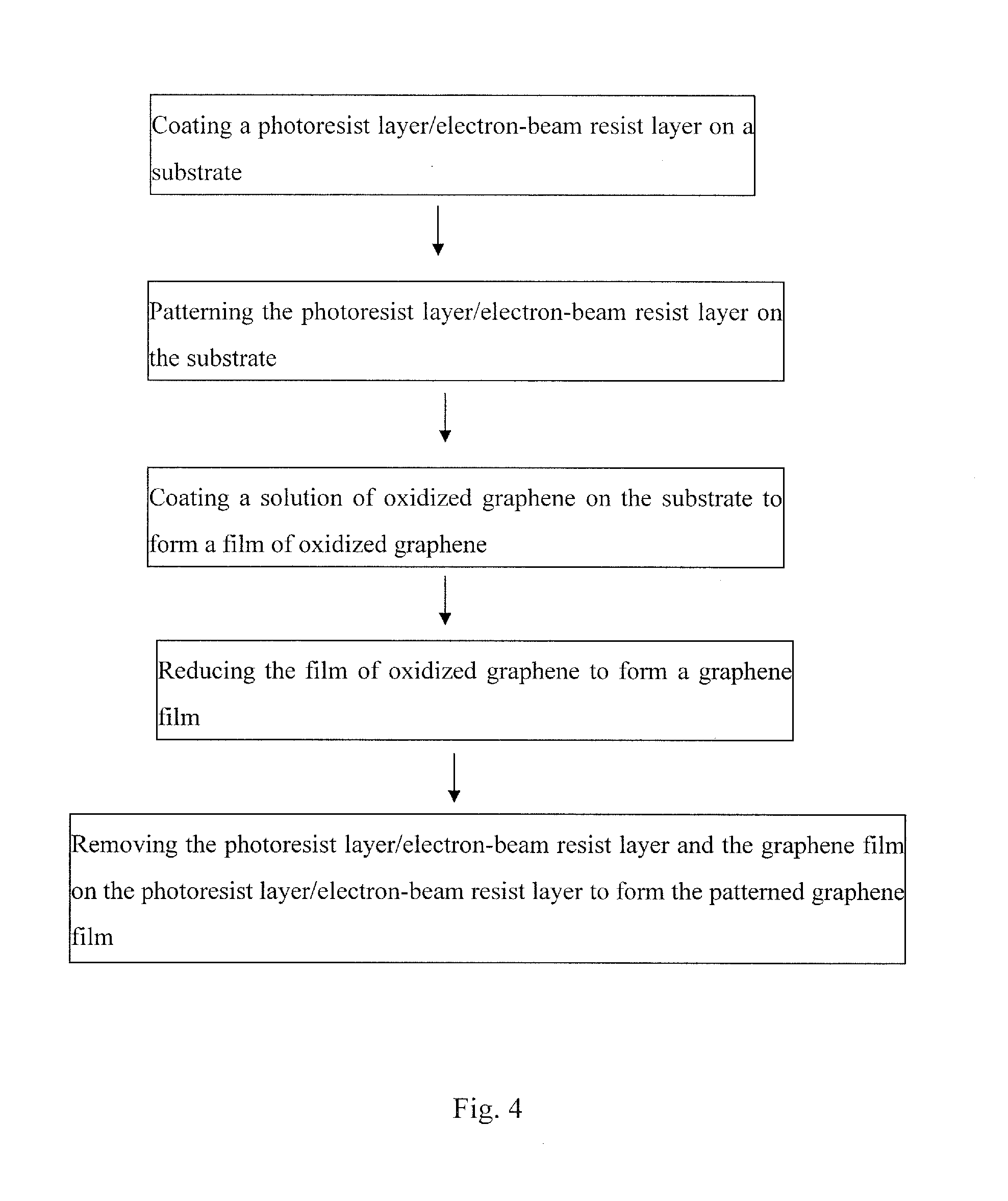

Method of manufacturing patterned graphene film

InactiveUS20130149463A1Simple procedureLow costMaterial nanotechnologyRadiation applicationsResistHydrazine compound

Embodiments of the invention provide a method of manufacturing a patterned graphene film. The method comprises the following steps: Step 1: a photoresist layer / electron-beam resist layer is coated on a substrate and patterned, the photoresist layer / electron-beam resist layer in a region for forming the patterned graphene film is removed; Step 2: a solution of oxidized graphene is coated on the substrate formed with the photoresist layer / electro-beam resist layer patterned in Step 1, so that a film of oxidized graphene is formed; Step 3: the substrate obtained in Step 2 is placed in a hydrazine steam, so that the film of oxidized graphene formed in Step 2 is reduced and a graphene film is obtained; and Step 4: the photoresist layer / electron-beam resist layer and the graphene film on the photoresist layer / electrone-beam resist layer are removed, so that the patterned graphene film is obtained.

Owner:BOE TECH GRP CO LTD

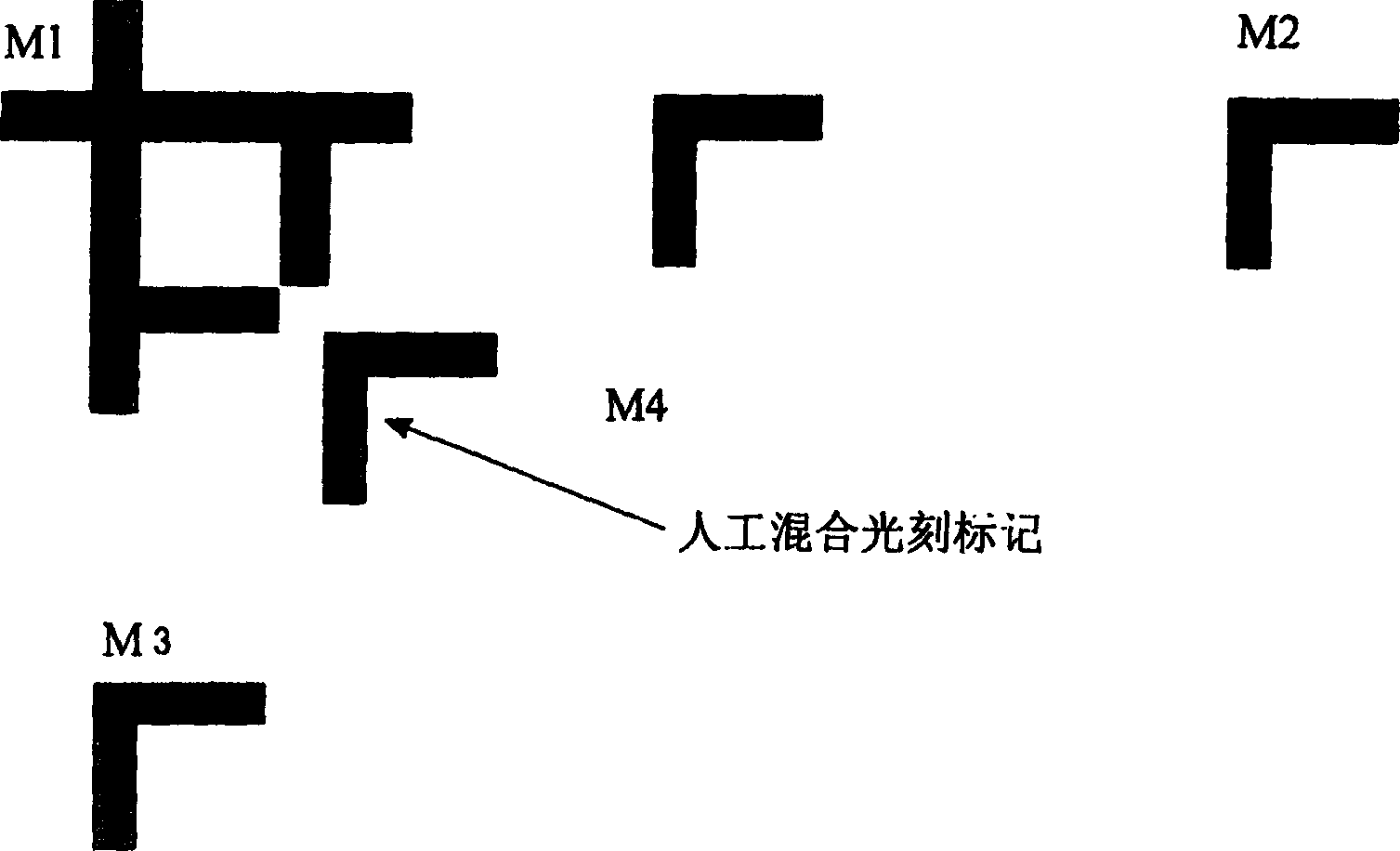

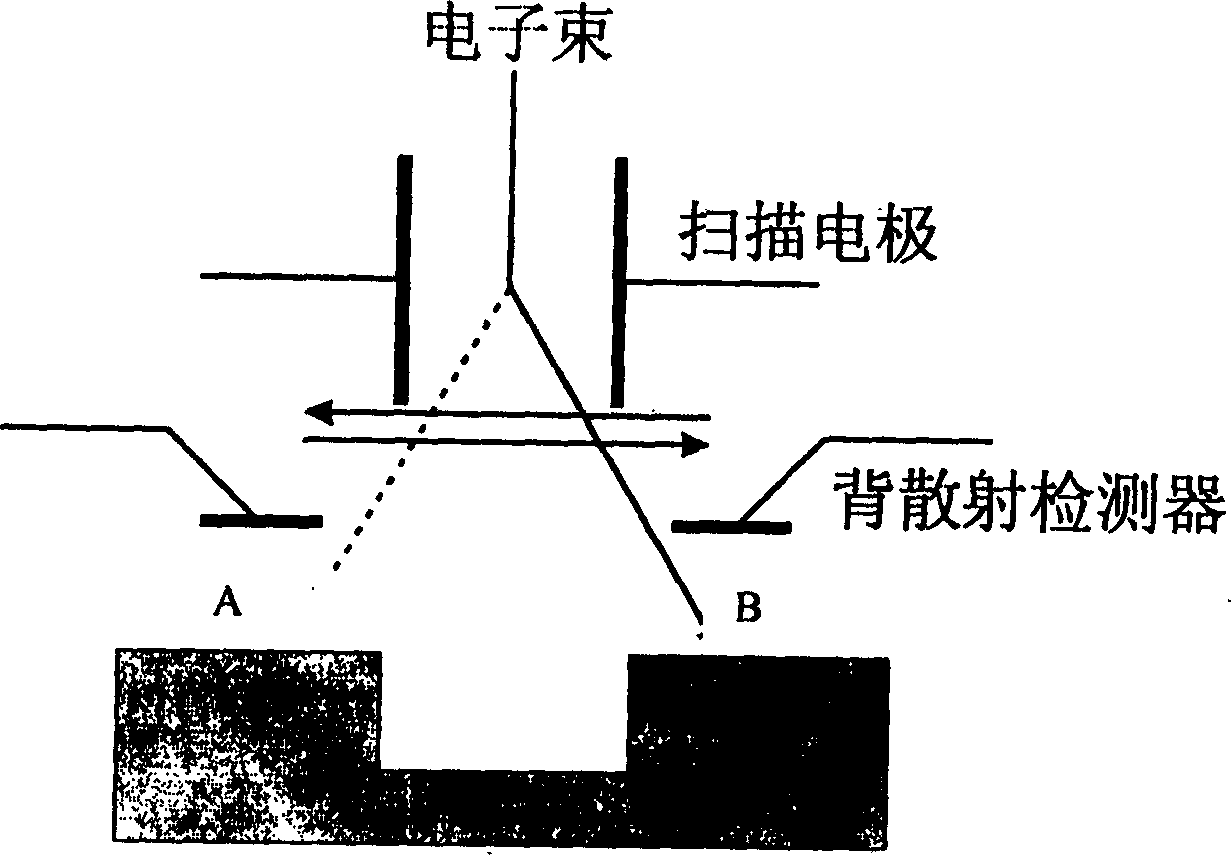

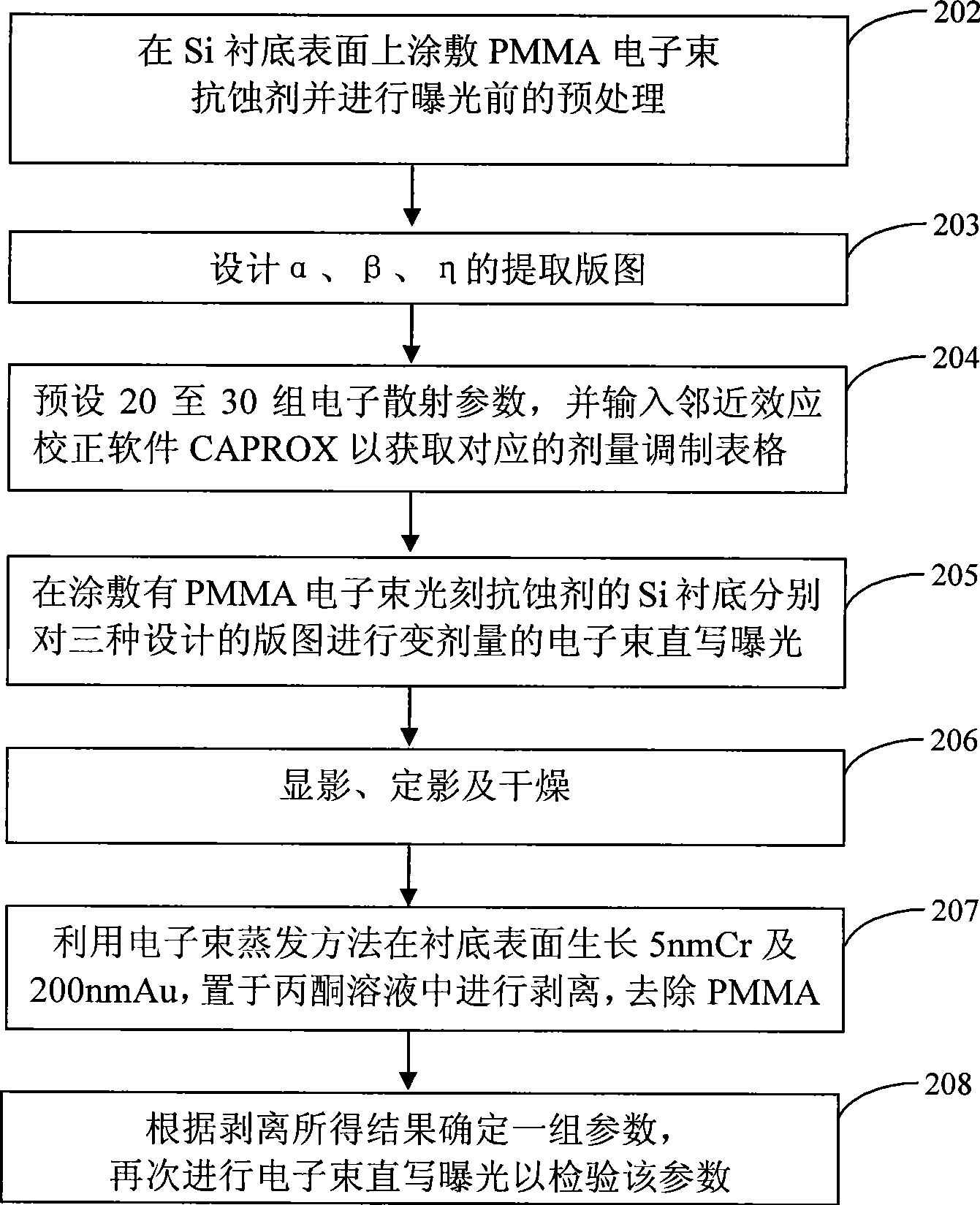

Method for making nano device

The present invention relates to a method for making nano device. The method includes the following steps: preparing overlay detection mark mask plate of electron-beam and optical exposure machine; applying PMMA resist on substrate, prebaking, electron-beam exposure, developing MIBK:IPA=1:3, time is 1 min, fixing for 30 sec. in IPA solution, evaporation or sputtering metal, stripping in acetone solution, applying secondary electron-beam resist, thickness is 200-250 nm, prebaking, utilizing the method for detecting back scattered electron of mark edge by using electron-beam to detect whole mark on the substrate and small mark of every die, correcting according to measured value, secondary electron-beam exposure, accelerating voltage 50KV, dose 500 u C / sq.cm, beam current 100 Pa, developing MIBK:IPA=1:3, time is 1 min, fixing for 30 sec in IPA solution, optically exposing other pattern for making device, finally forming nano-grade device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

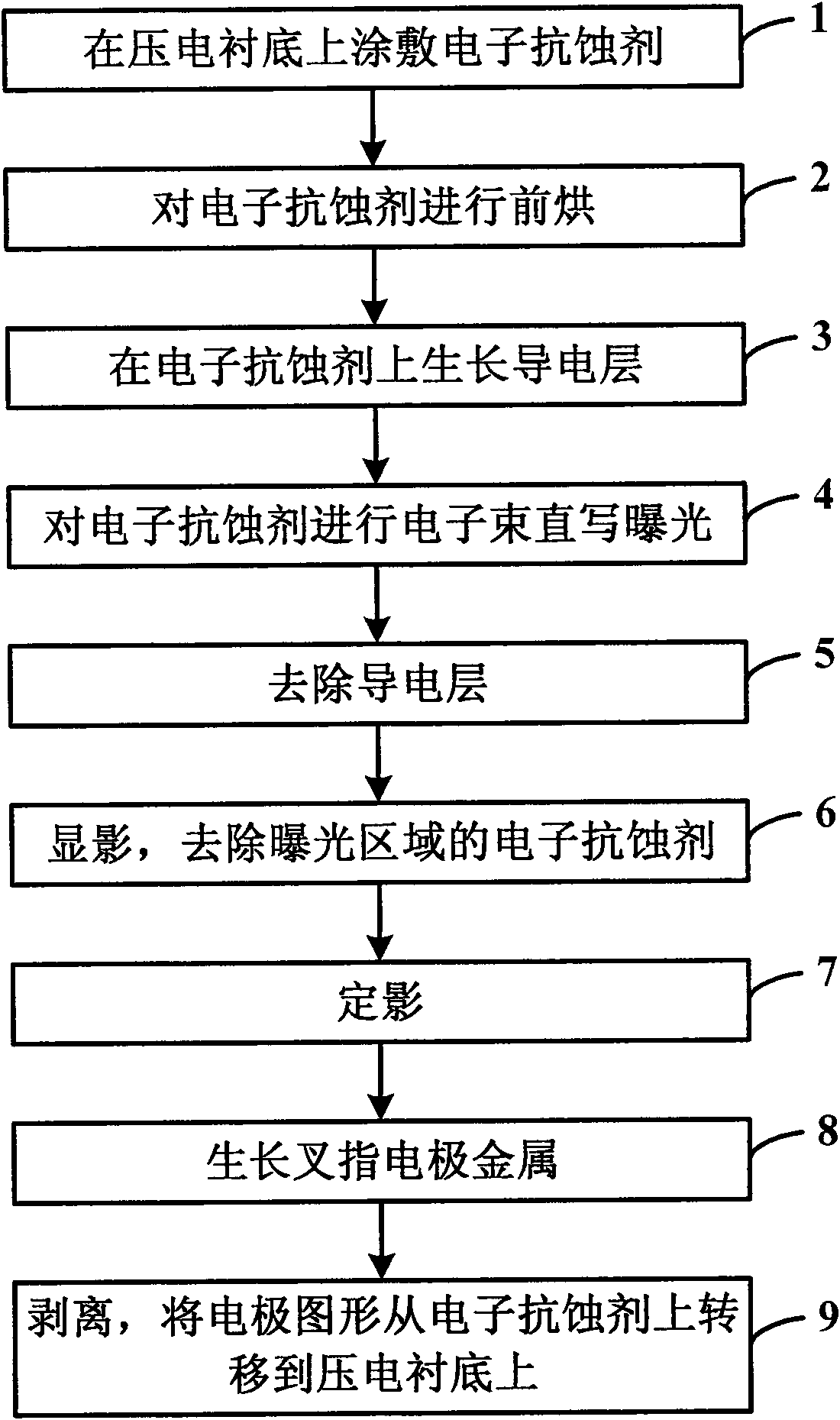

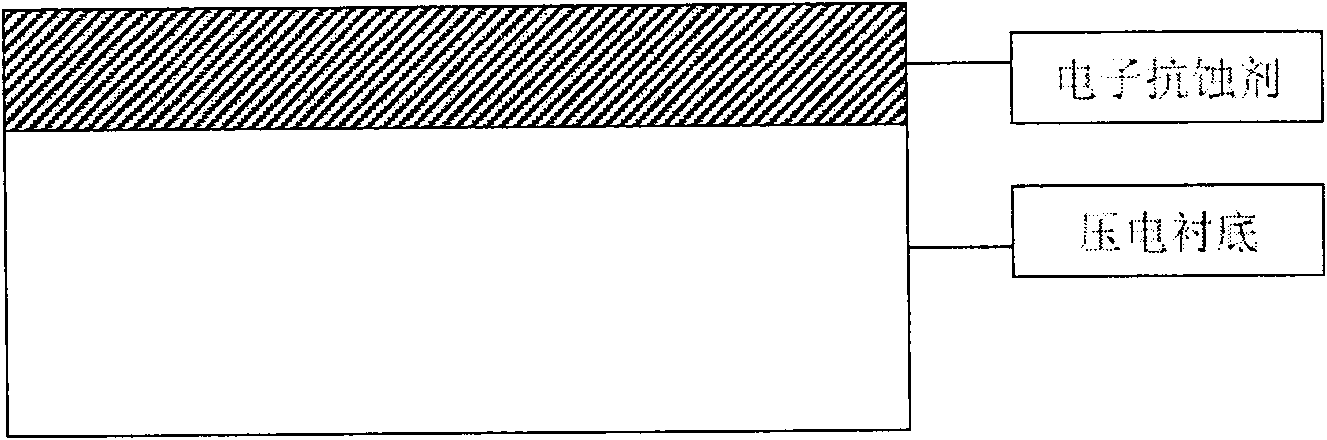

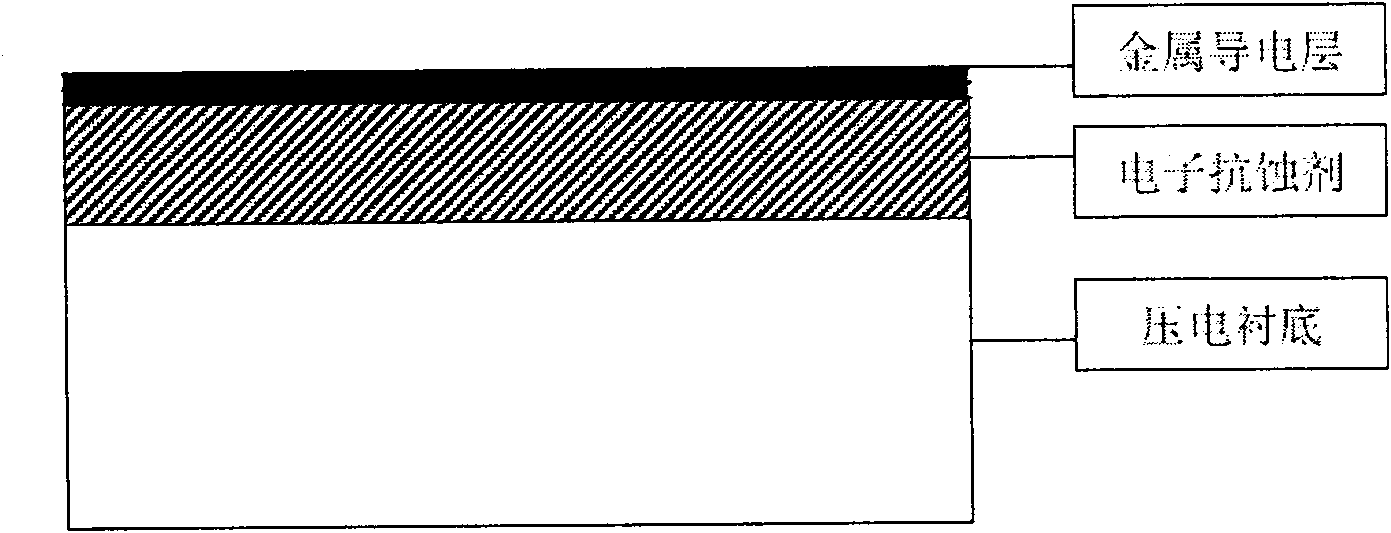

Method of producing surface acoustic wave devices by exposing X-rays in a direct writing way

ActiveCN101676797ASteep edgeGood width controlPhotomechanical exposure apparatusPhotosensitive material processingResistElectron resists

The invention discloses a method of producing surface acoustic wave devices by exposing X-rays in a direct writing way. Electron beam resist concave solid figures of an interdigital transducer are obtained by photoetching electron beams on a piezoelectric substrate, and various surface acoustic wave devices are produced with the stripping technology. The method of producing surface acoustic wave devices by exposing X-rays in a direct writing way comprises the following concrete steps: spreading the electron beam resist on the piezoelectric substrate; prebaking the electron beam resist; growingmetal material which has weak back scattering effect on the electron beam exposure; exposing the electron beams in a direct writing way; removing the metal layer; developing the electron beam resist;fixing the electron beam resist; growing interdigital electrode metal and stripping a beam resist masking film. An interdigital electrode produced with the method has steep and straight edges and good width control, and the method can be used for producing the surface acoustic wave devices which have the characteristic linewidth of less than 500nm. The method needs less process steps and is simple, stable and reliable.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

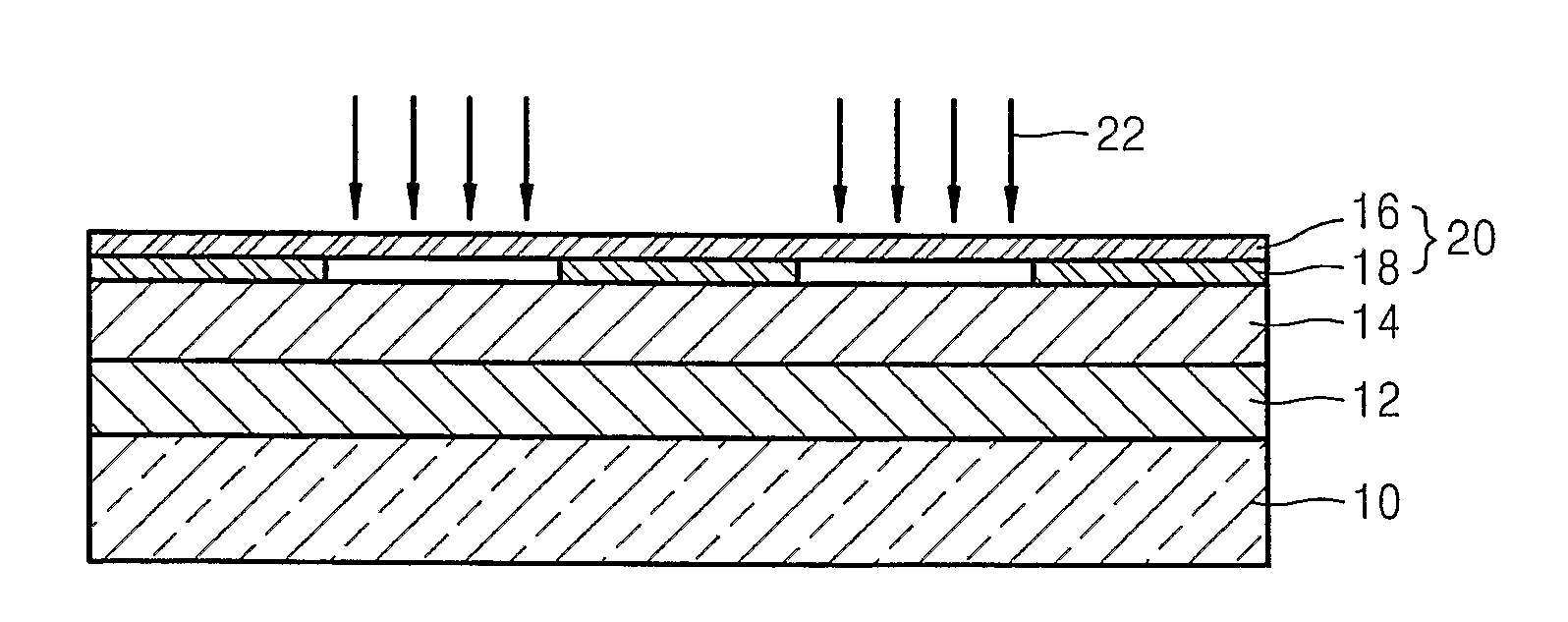

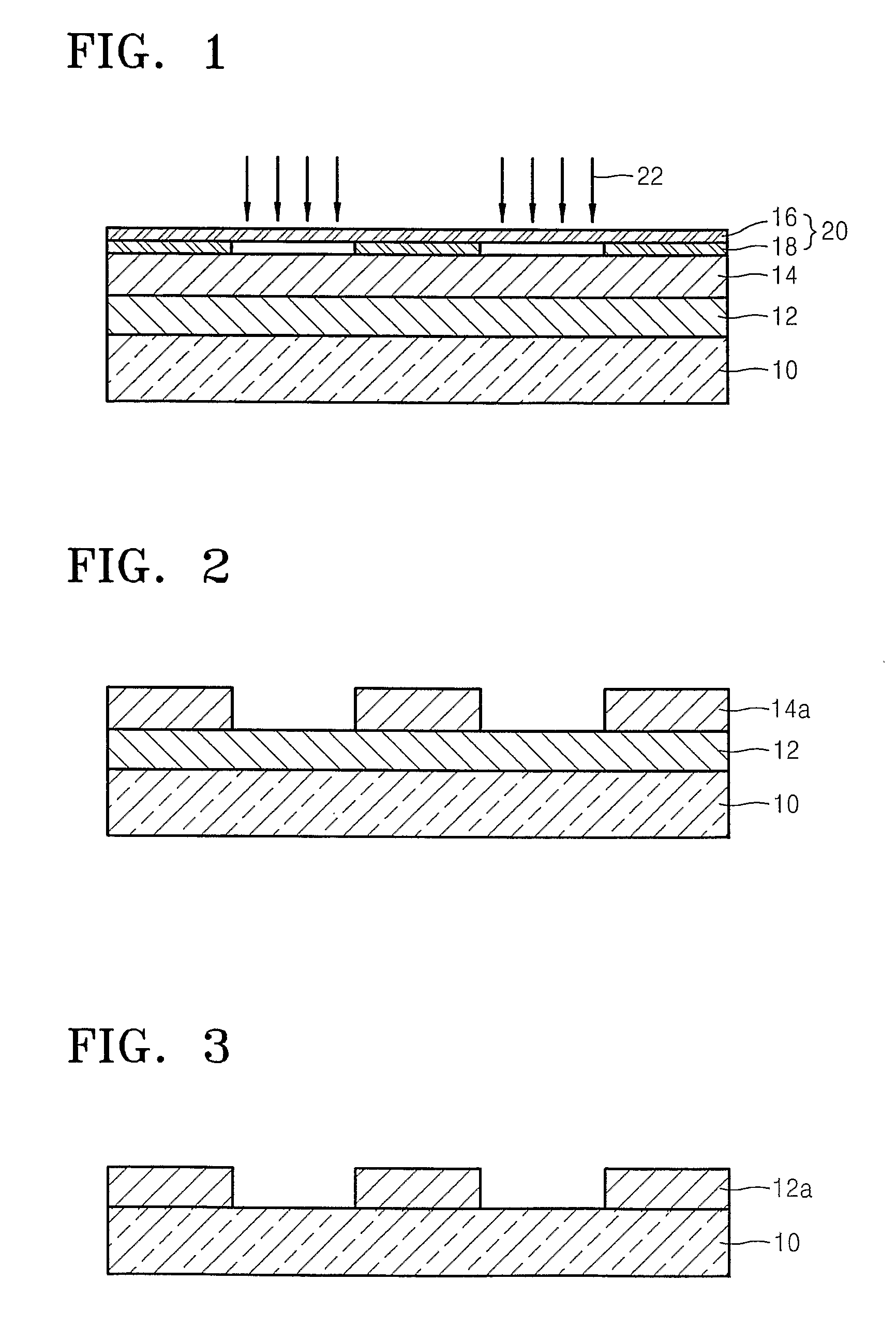

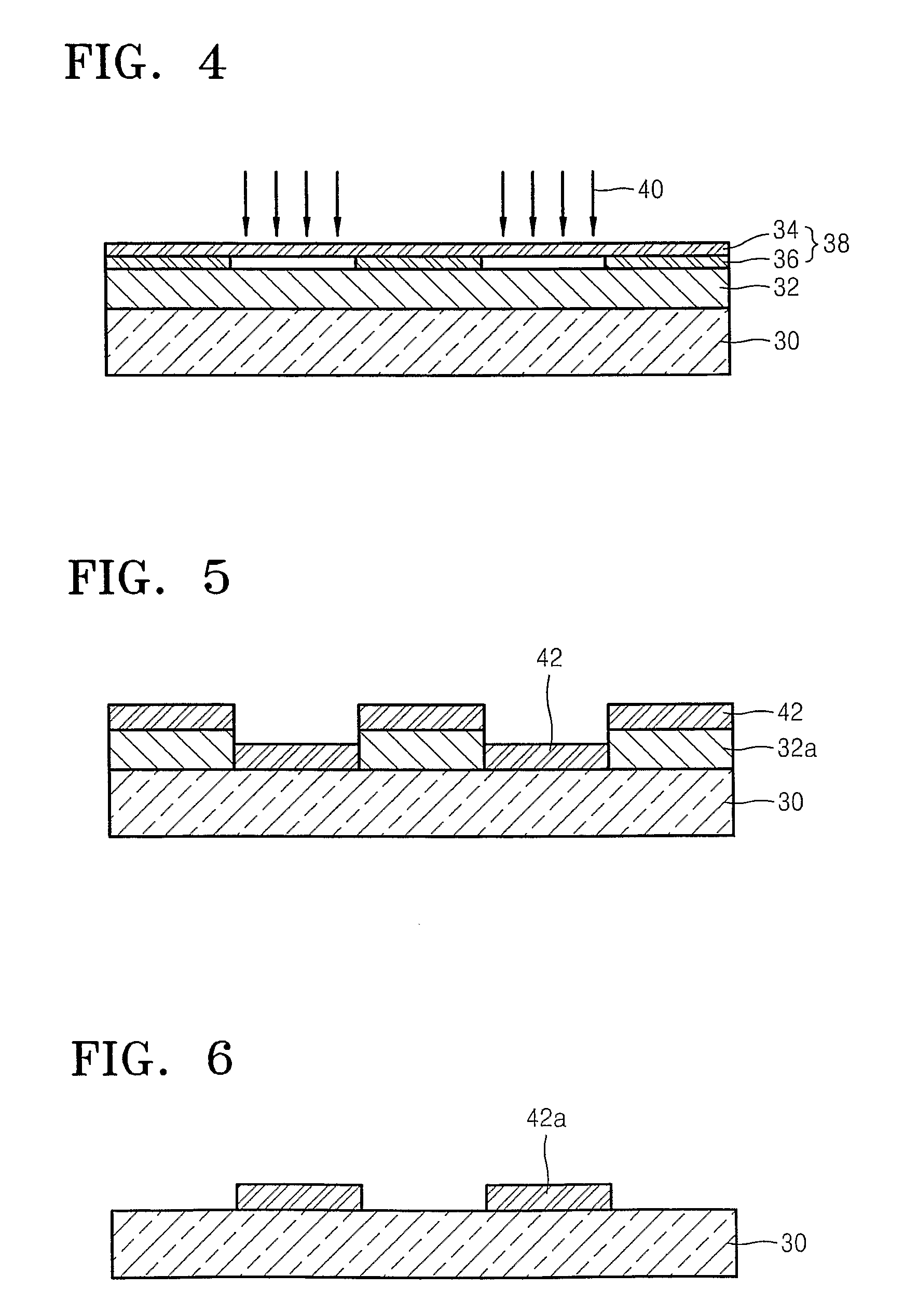

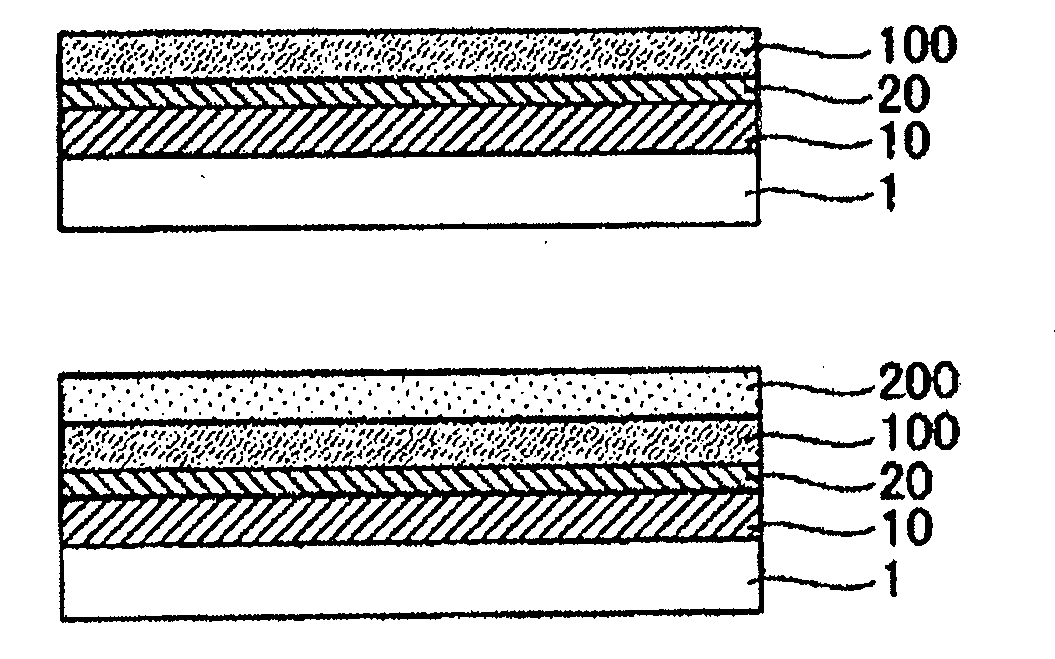

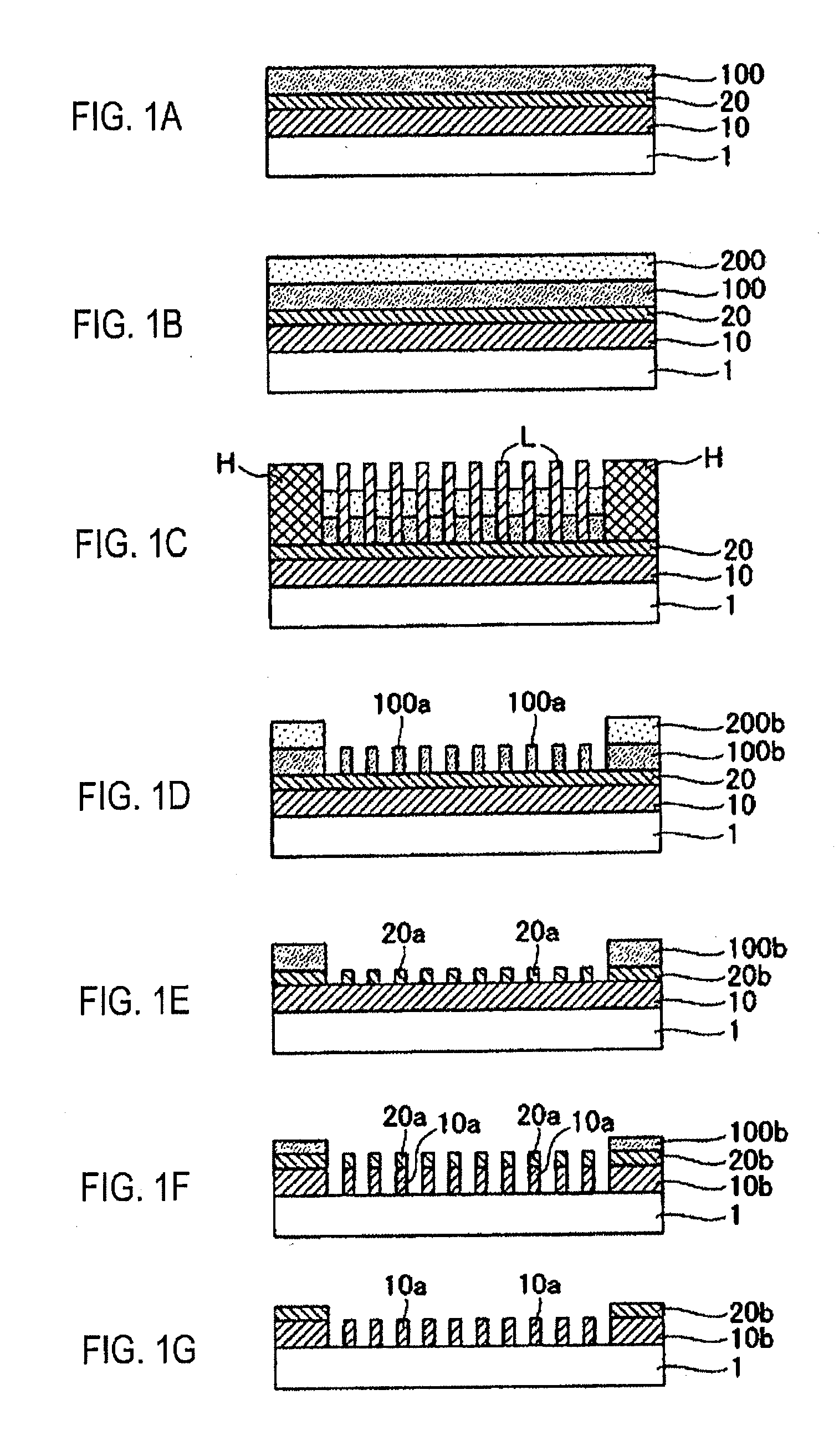

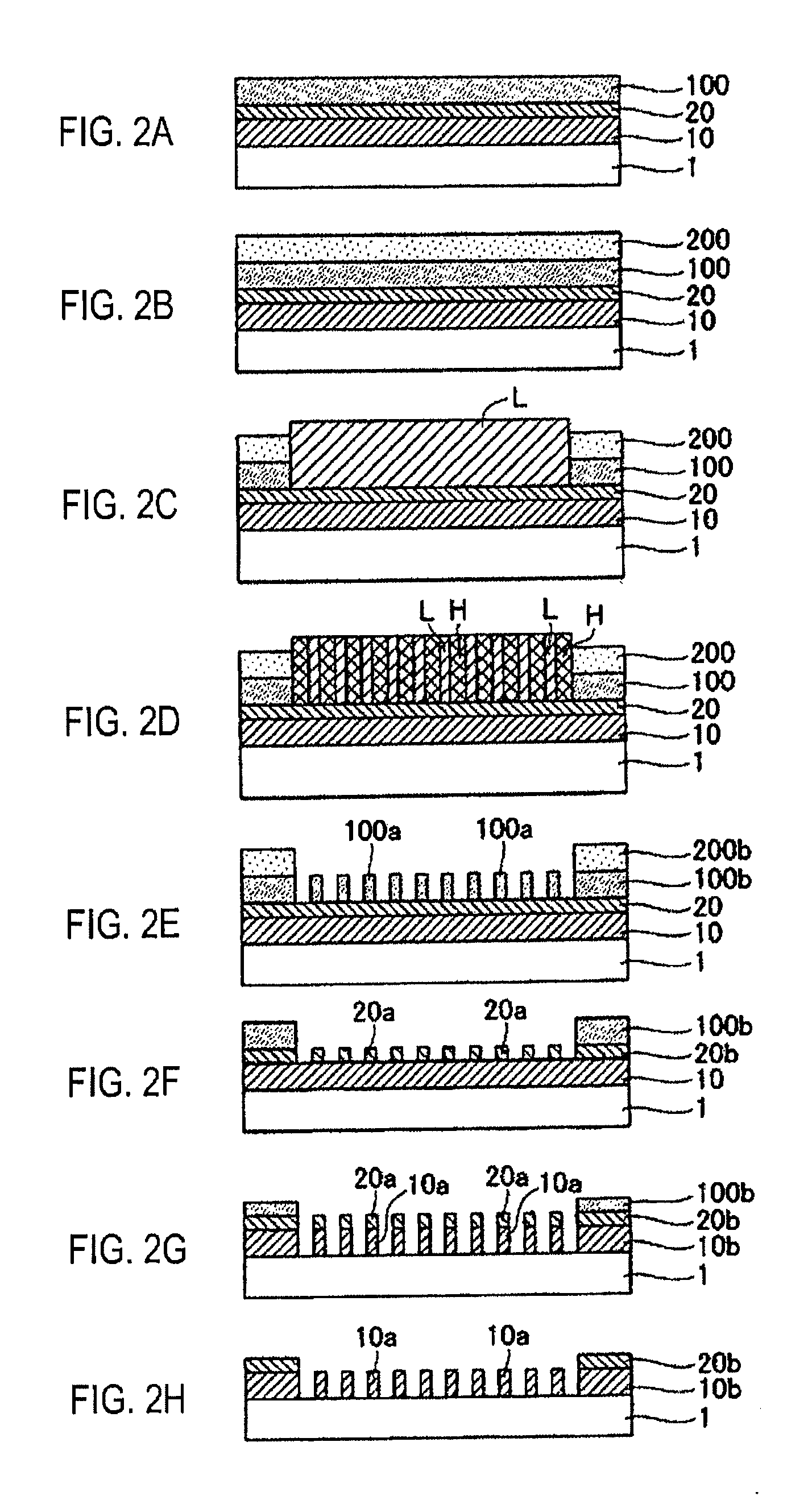

Mask blank, mask blank manufacturing method, transfer mask, and transfer mask manufacturing method

ActiveUS20110183240A1Prevent removalReduce production processElectric discharge tubesSemiconductor/solid-state device manufacturingResistElectron

According to certain embodiments, a mask blank for an electron beam writing is provided, capable of forming a resist pattern of a 3-dimensional topology through an one-time writing. The mask blank includes a substrate, a thin film formed on the substrate, and an electron beam resist film formed on the thin film. The electron beam resist film is made of a laminated film including at least a lower resist film and an upper resist film. The lower resist film and the upper resist film have different resist sensitivities with respect to an electron beam.

Owner:HOYA CORP

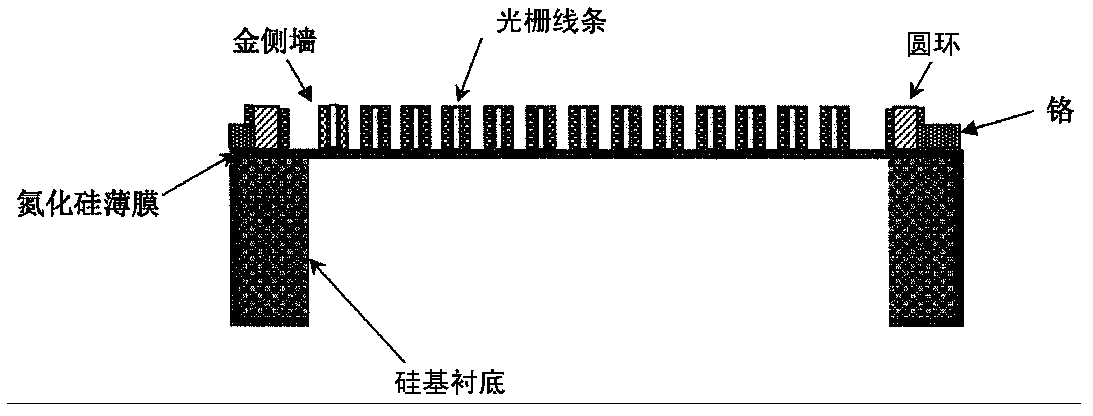

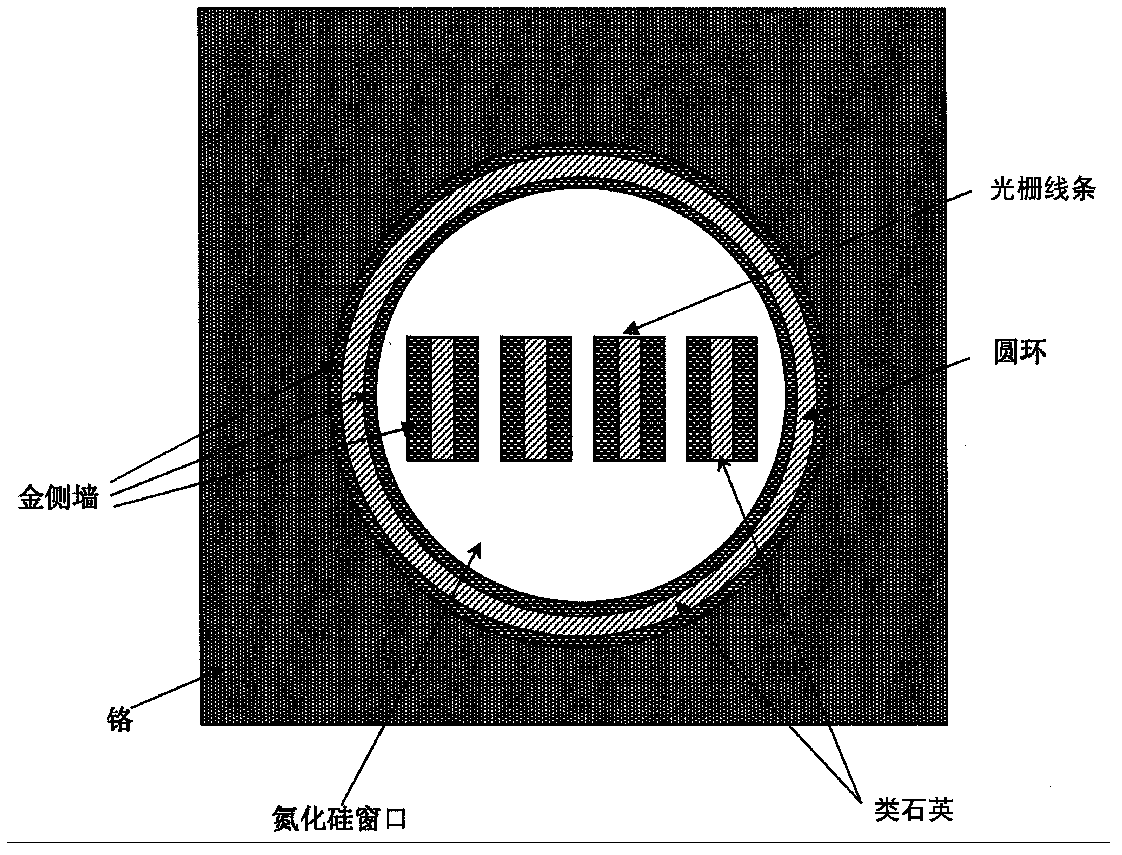

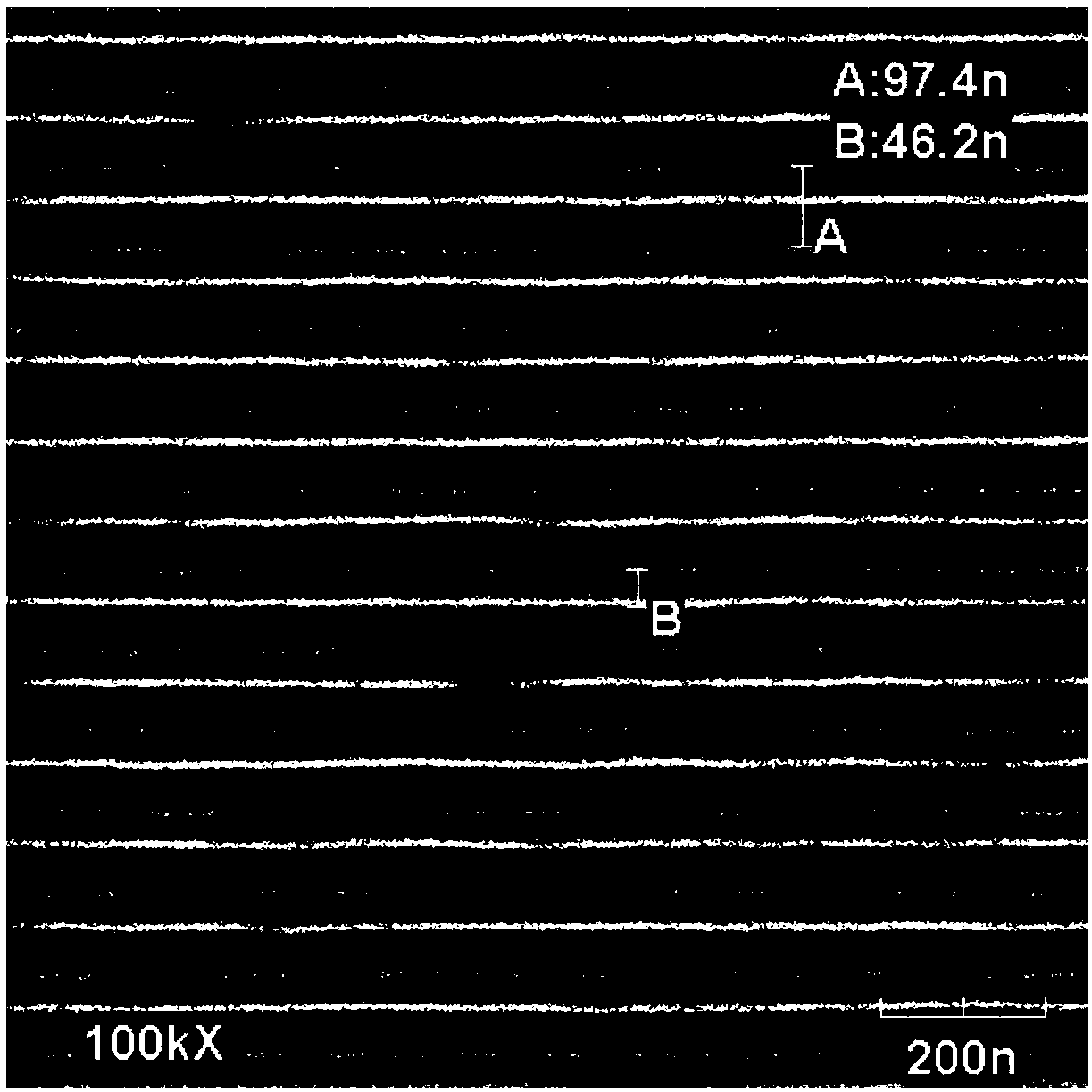

Sub-wavelength extreme ultraviolet metal transmission grating and manufacture method thereof

ActiveCN103018806AReduce backscattering problemsReduce the risk of collapsePhotomechanical apparatusDiffraction gratingsGratingDirect writing

The invention discloses a sub-wavelength extreme ultraviolet metal transmission grating and a manufacture method of the sub-wavelength extreme ultraviolet metal transmission grating. The manufacture method of the sub-wavelength extreme ultraviolet metal transmission grating comprises the steps of manufacturing a silicon nitride self-supporting film window on the back of a double-sided polishing silicon substrate, coating an electron beam resist HSQ (polyhedral octahydridospherosiloxane) on a silicon nitride film on the front side of the silicon substrate in a rotating mode, carrying out electron beam direct-writing lithography to HSQ, forming grating lines and a ring surrounding the grating lines, and fixing photography to obtain graphs of grating lines graph and the ring after the development; depositing a chromium material on the front side of the silicon substrate by the silicon substrate magnetron sputtering to be used as light blocking layers on around the graphs of the grating lines and the ring, eliminating the chromium material in the graph of the ring, and only maintaining the chromium material outside the graph of the ring to be used as an absorbent for absorbing stray light; generating a metal material on the front side of the silicon substrate by adopting an atomic layer deposition technology; and eliminating the metal material deposited on the chromium material outside the graph of the ring, among the graphs of the grating lines, and on the graphs of the grating lines, and maintaining the metal material on the side wall of the graphs of the grating lines.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

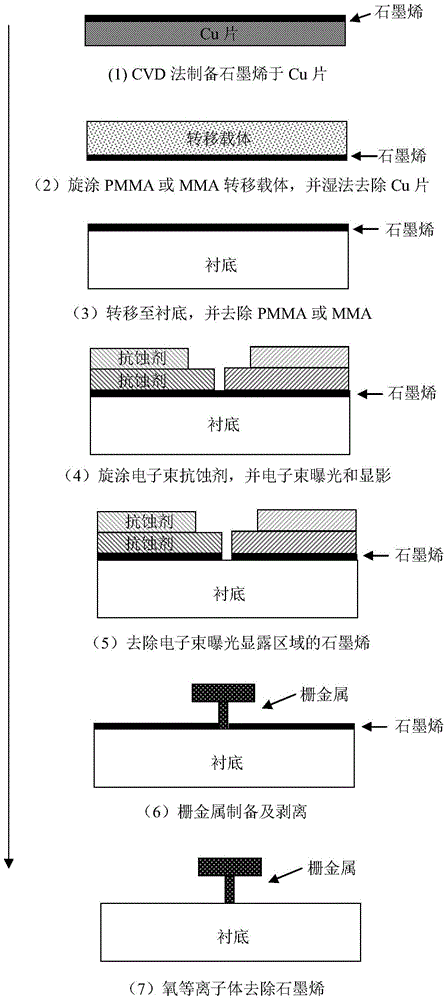

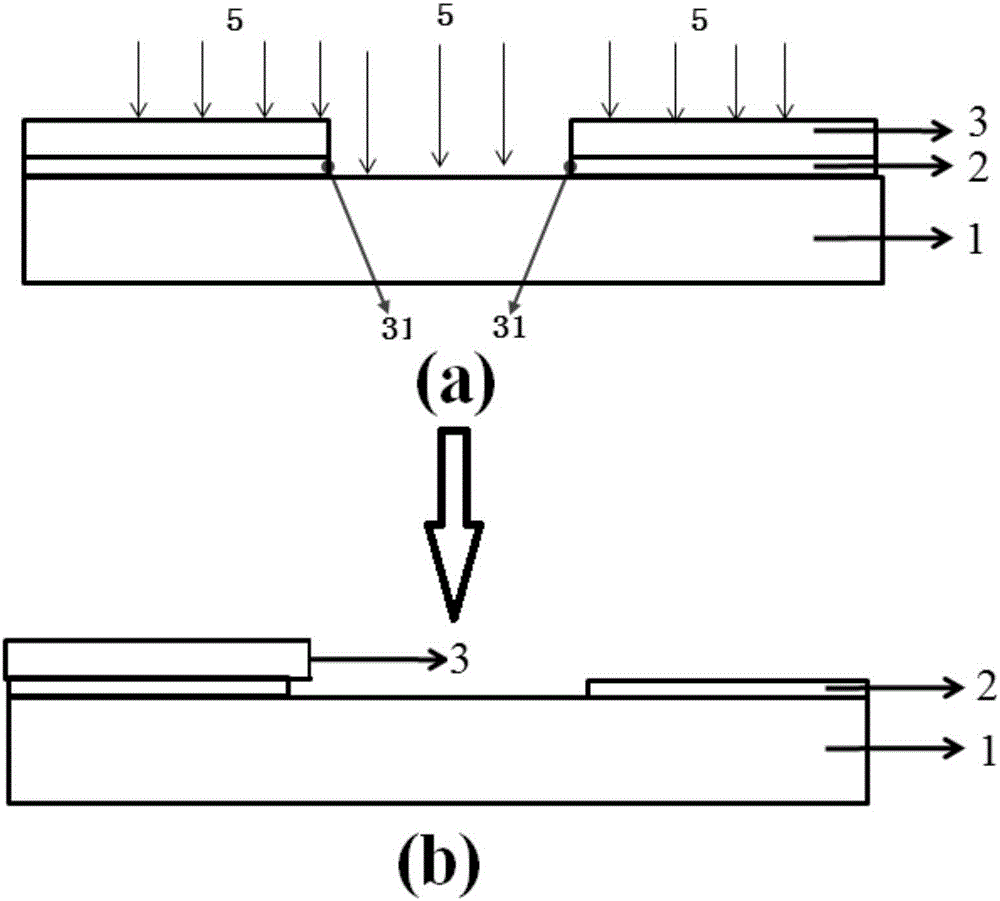

Method of adopting two-dimensional graphene thin film to improve conductivity of substrate during electron beam nano gate writing

ActiveCN105551949AGood removal effectReduce the impactSemiconductor/solid-state device manufacturingSemiconductor devicesResistOxygen

The invention discloses a method of adopting a two-dimensional graphene thin film to improve the conductivity of a substrate during electron beam nano gate writing. The method comprises the following steps: a CVD method is used for preparing graphene on a Cu substrate; spin coating of PMMA or MMA transfer vectors is carried out; a wet method is used for removing the Cu substrate and a sample is transferred to a substrate; the PMMA or the MMA is removed; spin coating of an electron beam resist is carried out; electron beam exposure and development are carried out; the graphene in an electron beam exposure area is removed; preparation and exfoliation of the gate metal are carried out; and oxygen plasmas are used for removing the graphene. The high conductivity of the two-dimensional graphene thin film is used for improving the conductivity of the surface of the substrate, the problems that an identifier can not be recognized and overlay has large errors caused due to poor conductivity of the substrate during the electron beam nano gate writing process can be solved, and the electron beam overlay accuracy is improved; and as the graphene thin film is below the electron beam resist, the graphene thin film has the advantages of being super thin and being well attached to the resist, the exposure and the development of the electron beam resist are not influenced, and removal of the graphene later is simple.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

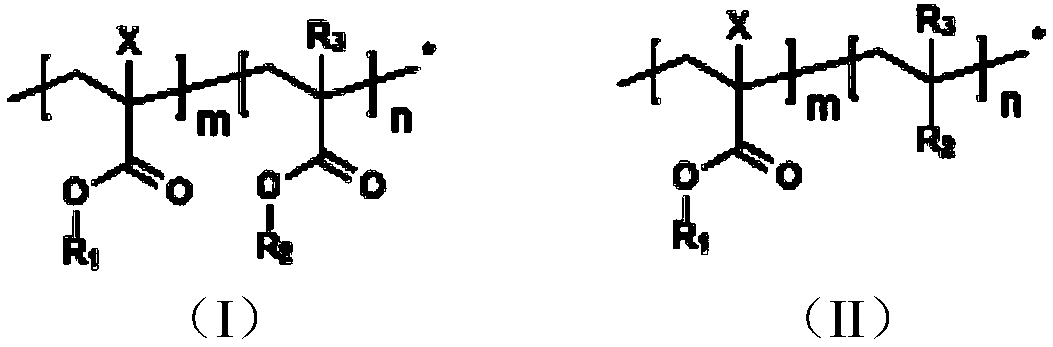

Electron beam resist composition and preparation method

The invention provides an electron beam resist composition. Main components of the electron beam resist composition comprise a halogenated acrylate copolymer and a photo-acid generator, wherein the halogenated acrylate copolymer is a copolymer of a halogenated acrylate monomer unit and an aromatic acrylate or aromatic alkene monomer unit. Side chain-substituted halogen atoms and rigid aromatic rings are introduced and a proper combination of monomer units is selected. The copolymer in the composition provided by the invention has higher sensitivity and corrosion resistance. Besides, the composition also contains the photo-acid generator which can accelerate the pyrolysis of the copolymer in the composition, effectively improves exposure efficiency and further improves the sensitivity of the electron beam resist.

Owner:儒芯微电子材料(上海)有限公司

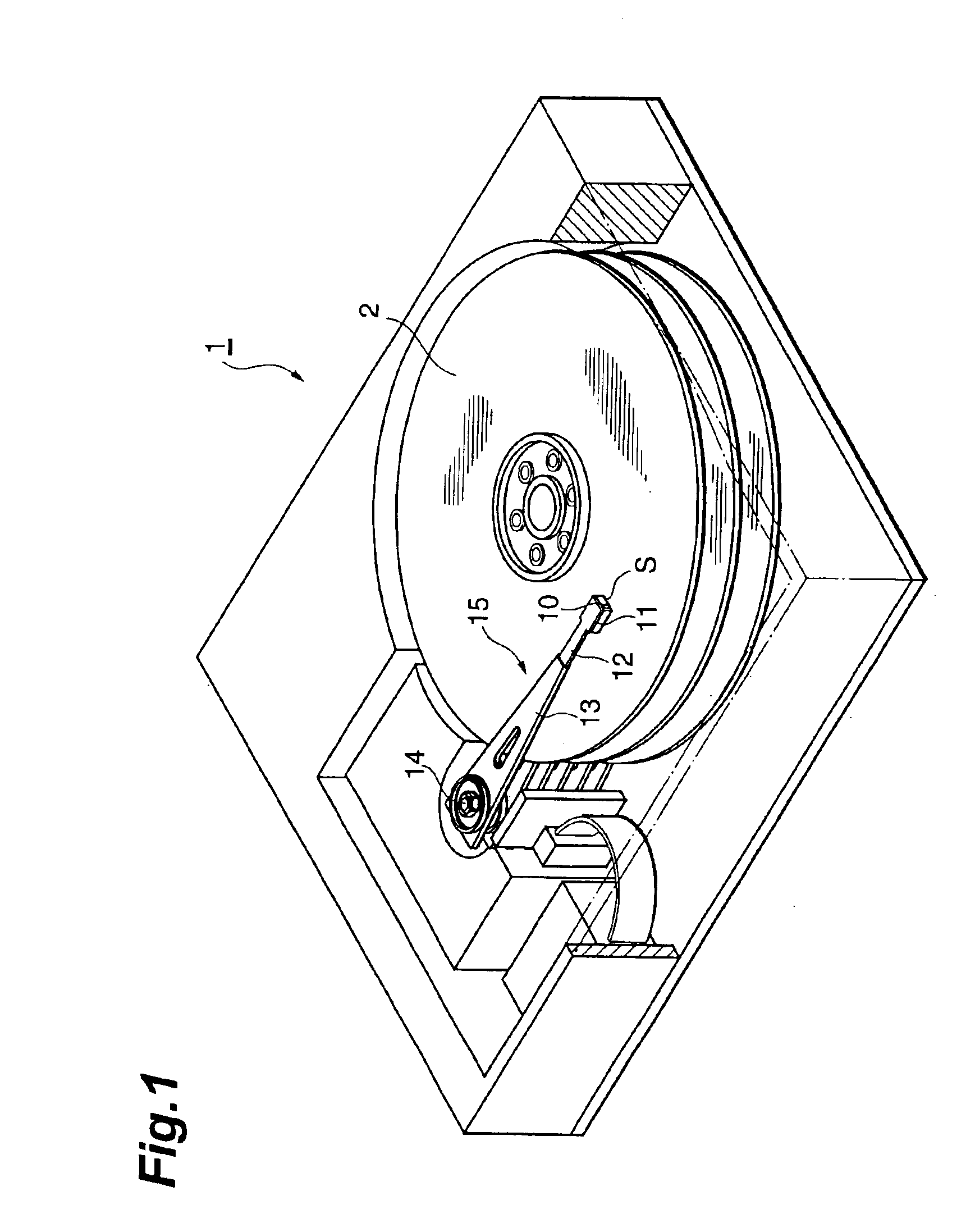

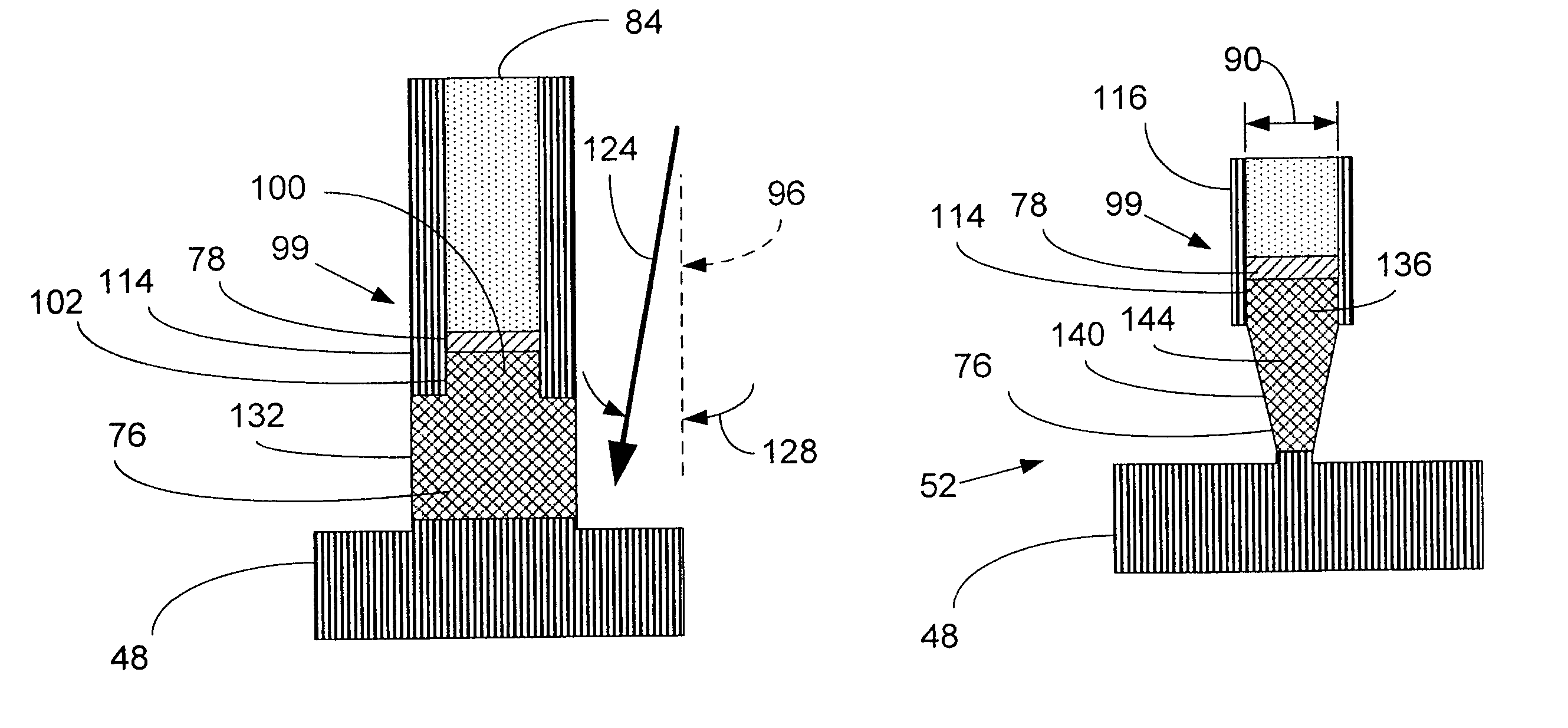

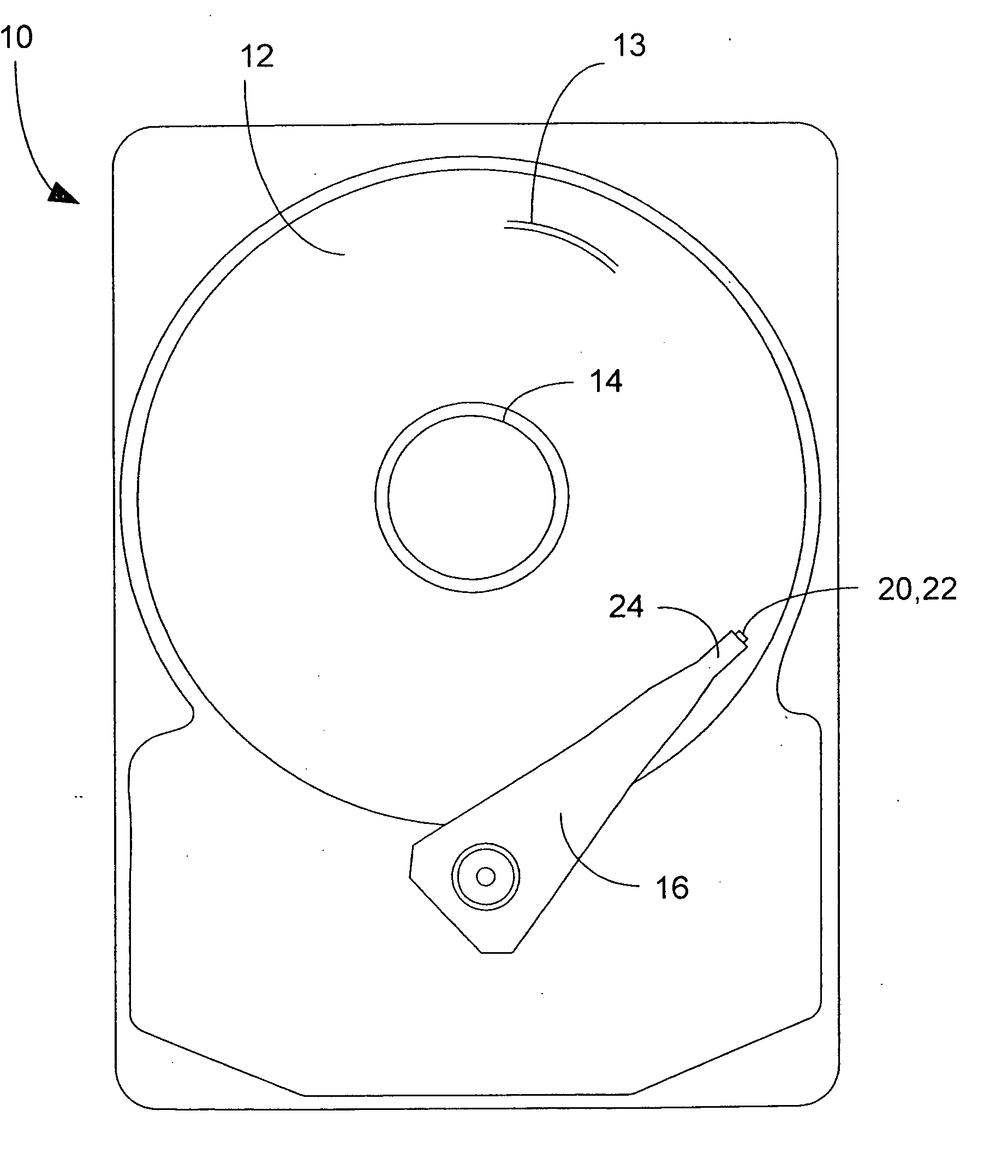

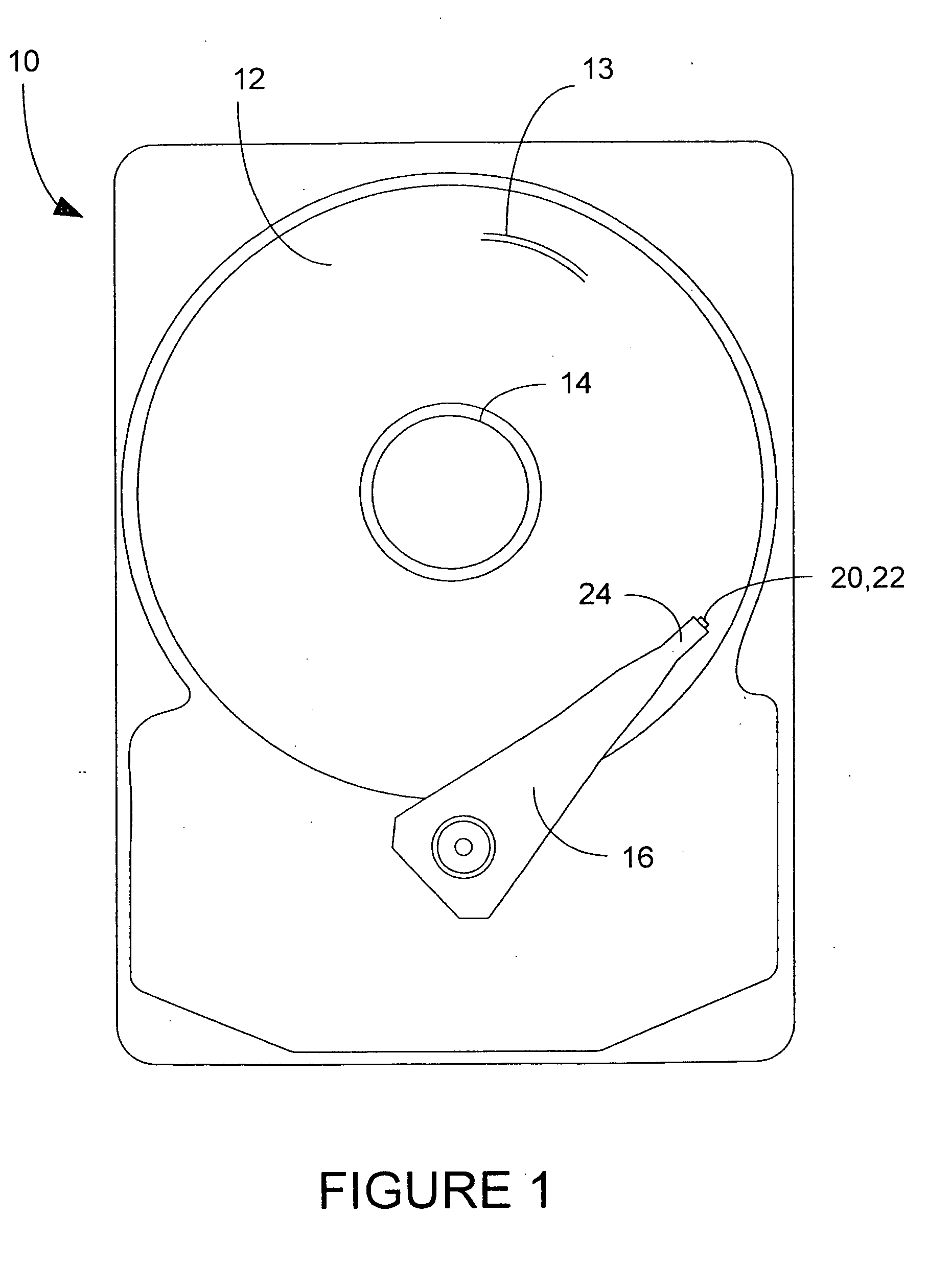

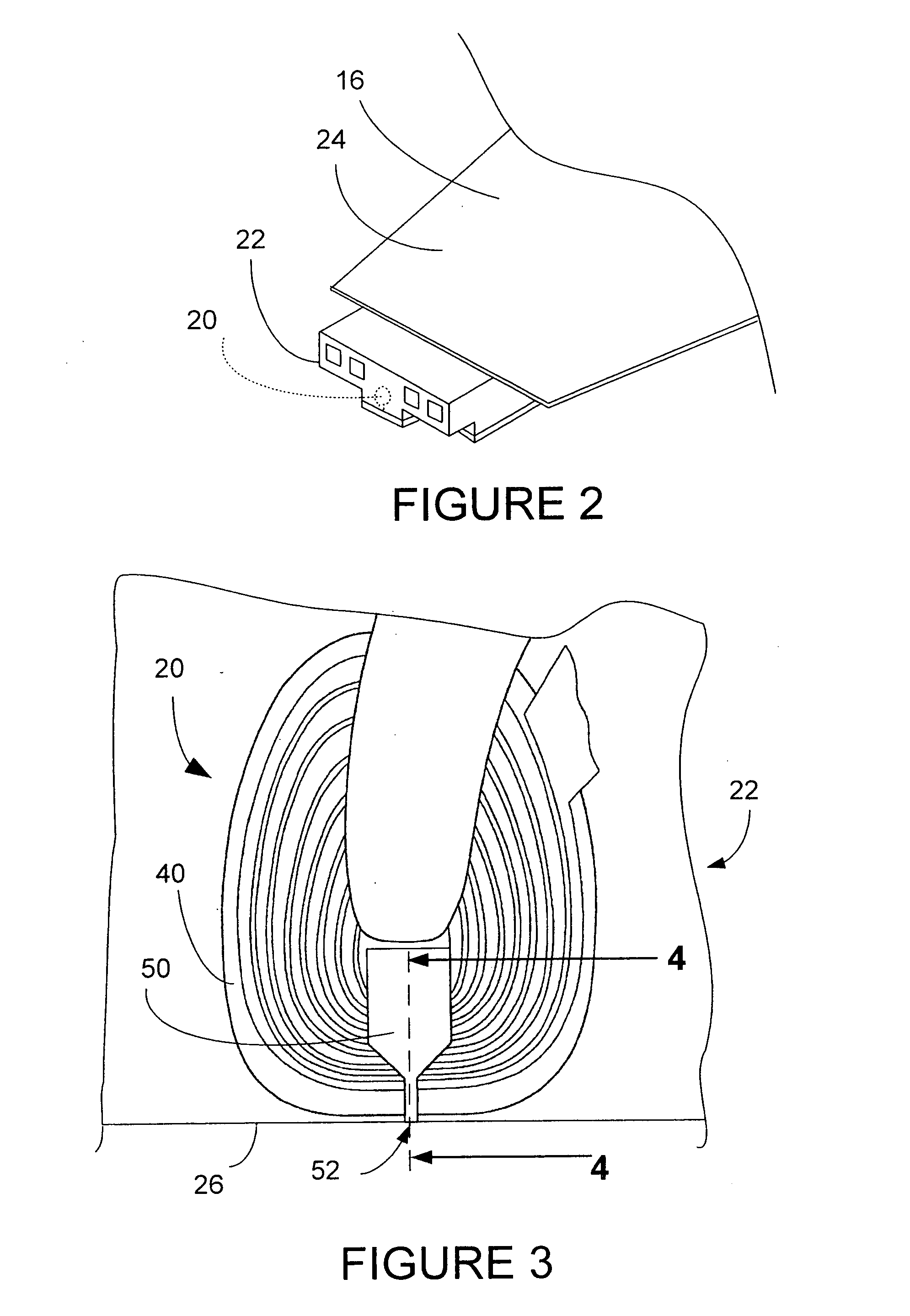

Method for fabricating magnetic write pole for a magnetic head using an E-beam resist mask

InactiveUS7716813B2Made preciselyAccurately establishedManufacture head surfaceElectrical transducersResistElectron

A method is disclosed for independently controlling track width and bevel angle of a write pole tip of a magnetic recording head. The method includes establishing the track width in the pole tip layer material utilizing E-beam lithography. A portion of this pole tip material having the established track width is protected by providing a temporary masking material to make a protected portion. At least one unprotected portion is left exposed to be shaped. This unprotected portion is then beveled to produce at least one beveled portion. The protected portion produces an upper pole tip portion which together with the beveled portion produce an improved pole tip. Also disclosed is a magnetic head having the improved pole tip, and a disk drive having a magnetic head having the improved pole tip.

Owner:WESTERN DIGITAL TECH INC

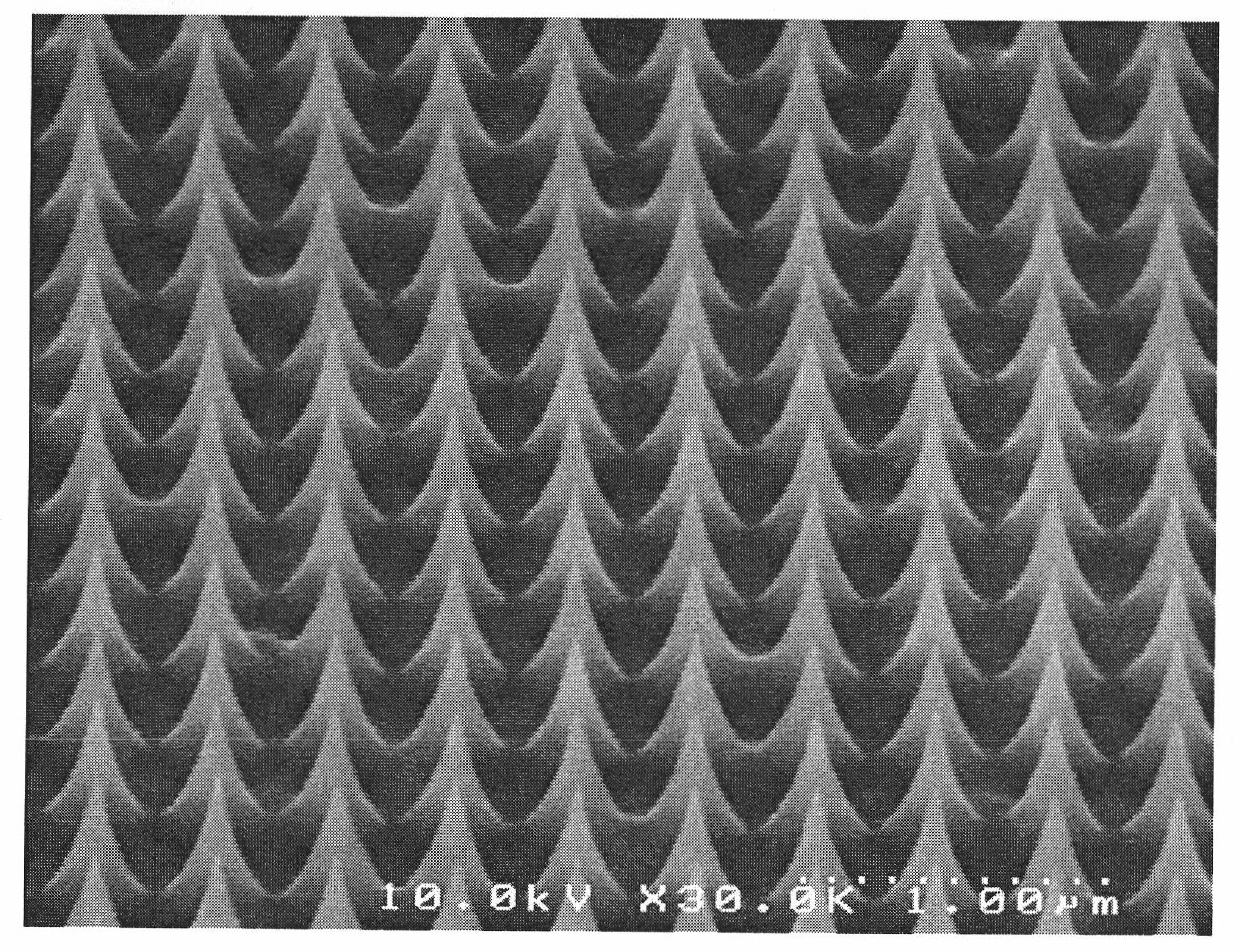

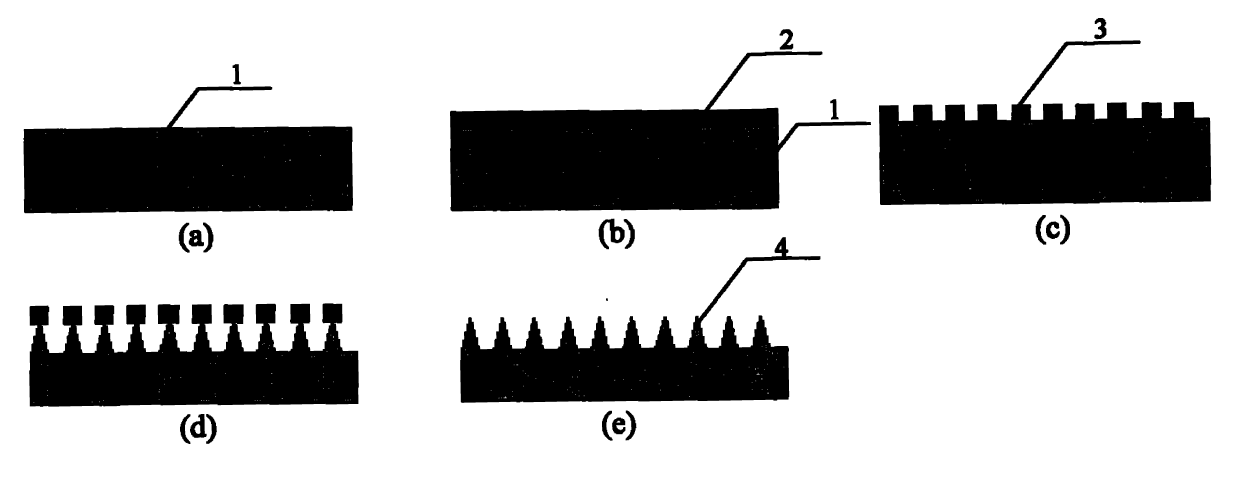

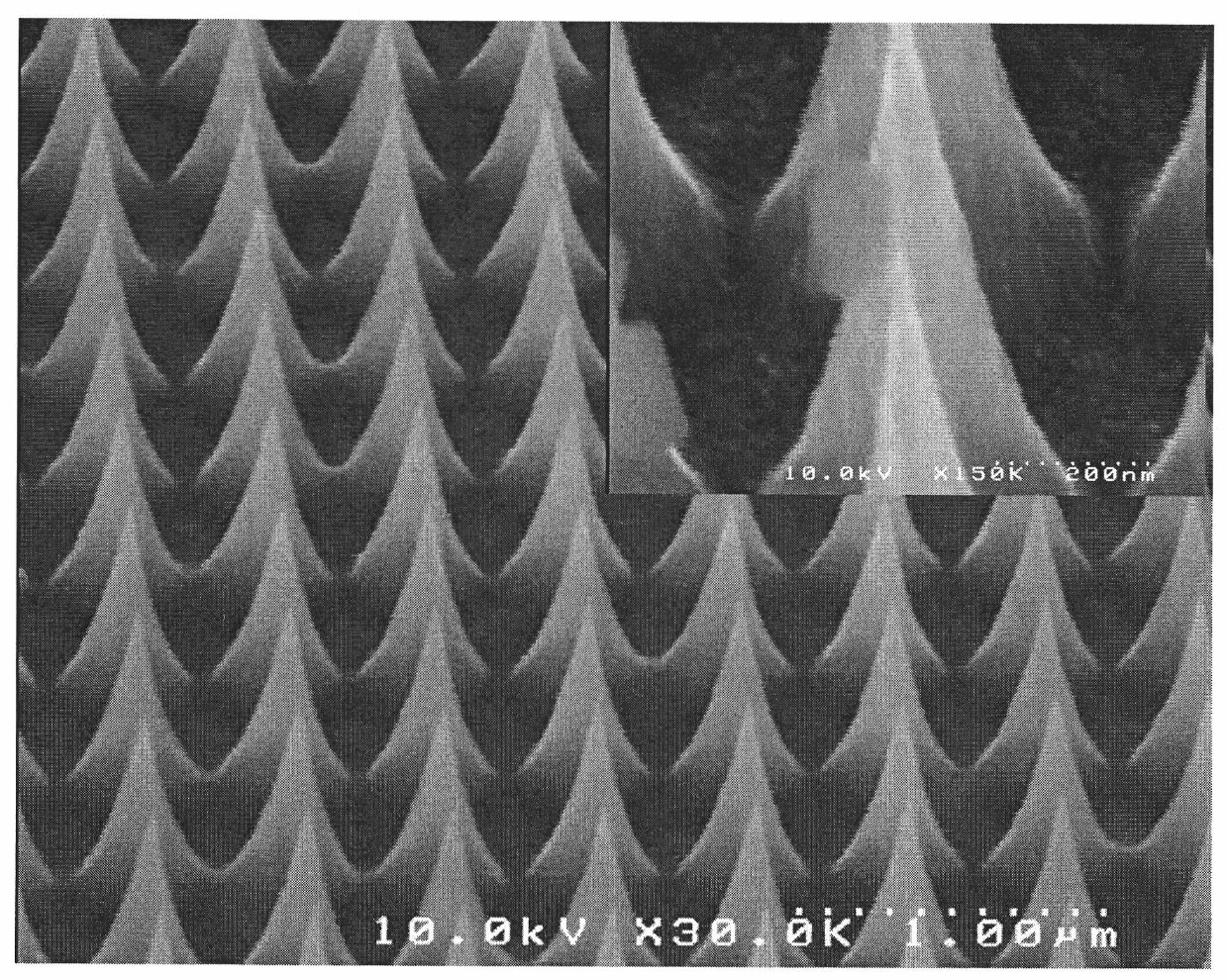

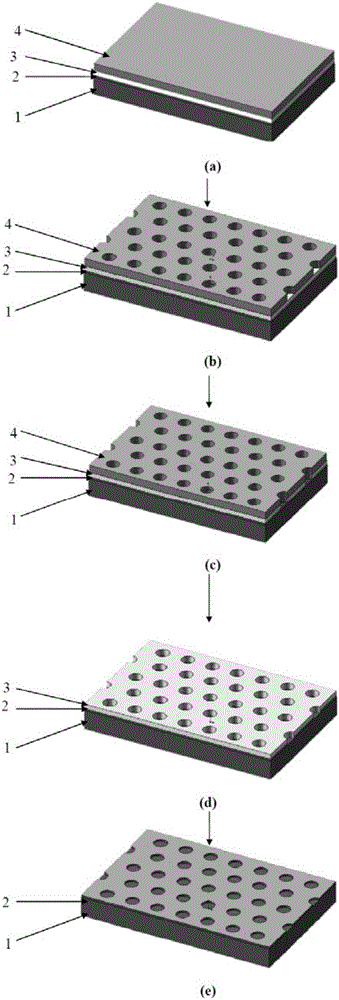

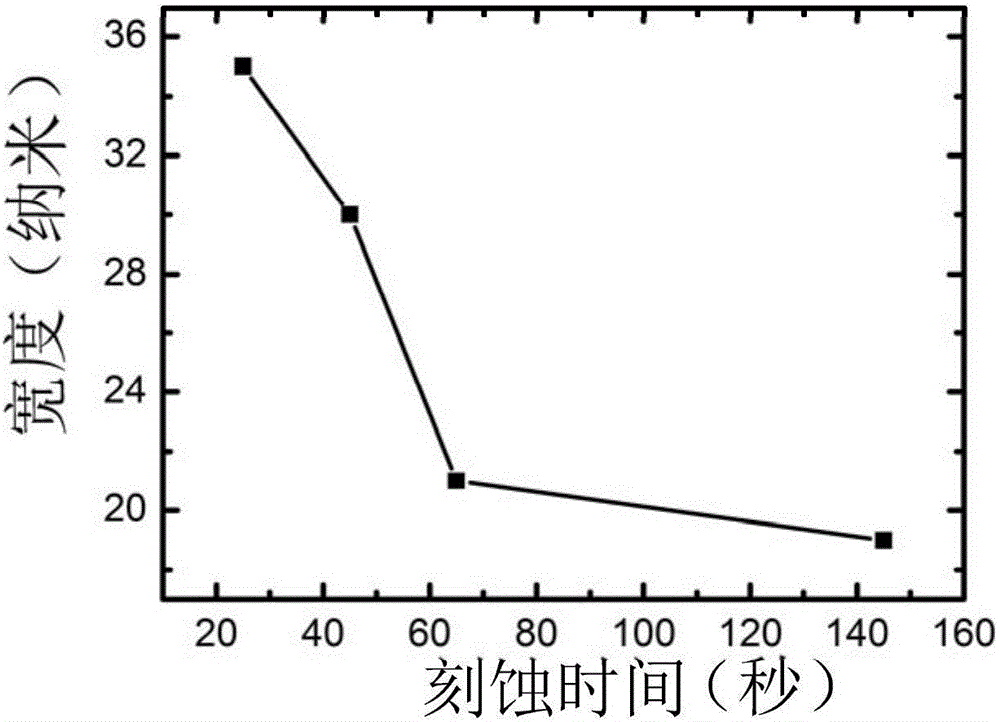

Method for preparing high-density super sharp silicon probe array

The invention provides a method for preparing a high-density super sharp silicon probe (tip) array by directly taking a hydrogen silsesquioxane (HSQ) electron beam resist as an etching mask. The hydrogen silsesquioxane (HSQ) electron beam resist is exposed by an electron beam photoetching method, and then developed to form a raster graphics of the HSQ; the silicon is subjected to isotropic etching by directly taking the HSQ as the mask; by controlling the etching conditions, the probe tip can be sharpest and the HSQ is about to fall off or automatically falls off simultaneously; the probe tip can reach several nanometers; and the additional oxidation, corrosion and other sharpening process are not needed, so the method is very simple. The method overcomes the inconvenience that the traditional preparation method needs an oxide layer to serve as a mask for secondary graphic transfer and requires additional oxidation and etching processes to sharpen the probe, and overcomes the difficulty in preparing submicron-period high-density silicon probe array, and can easily prepare the silicon probe array with the density more than 2.5*107 / mm<2>.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI +2

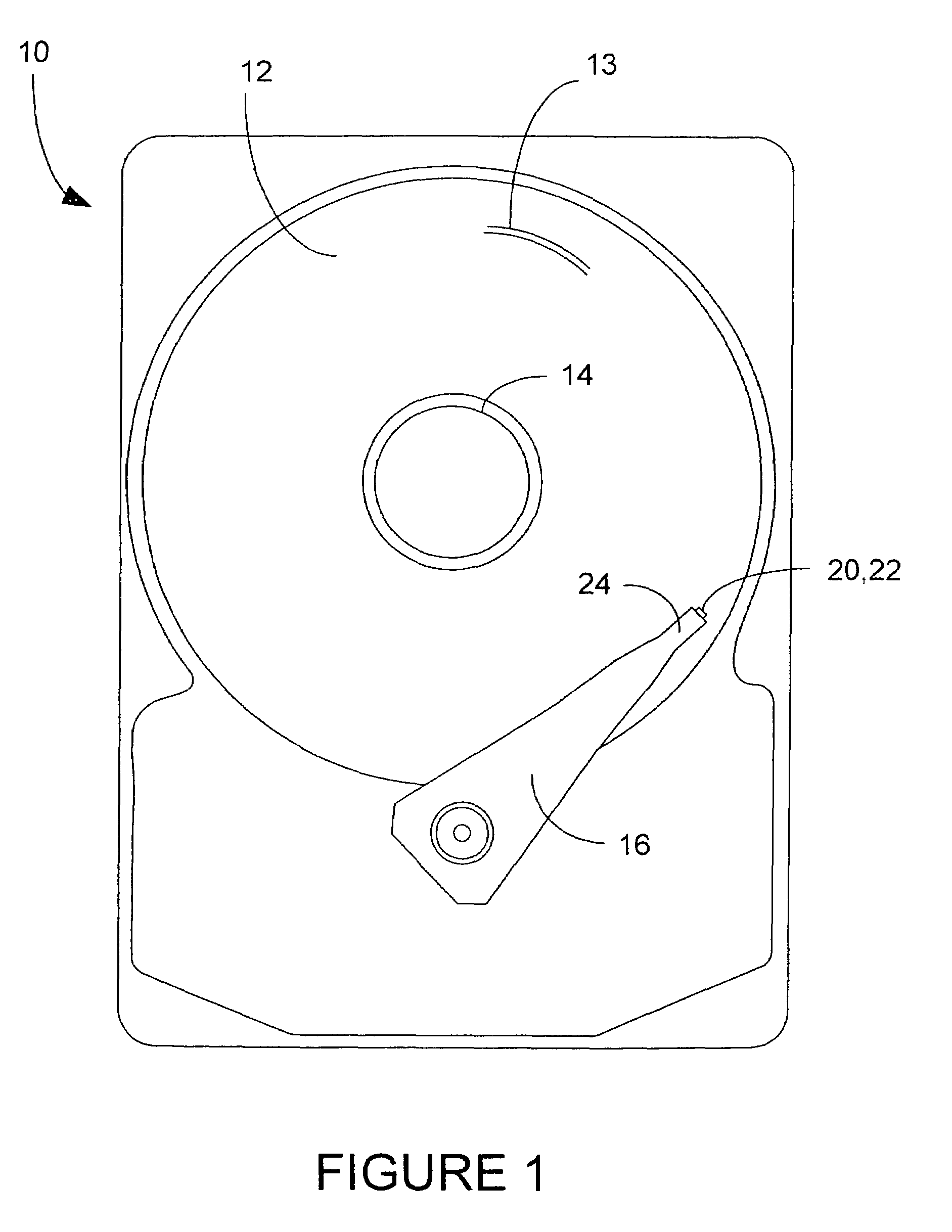

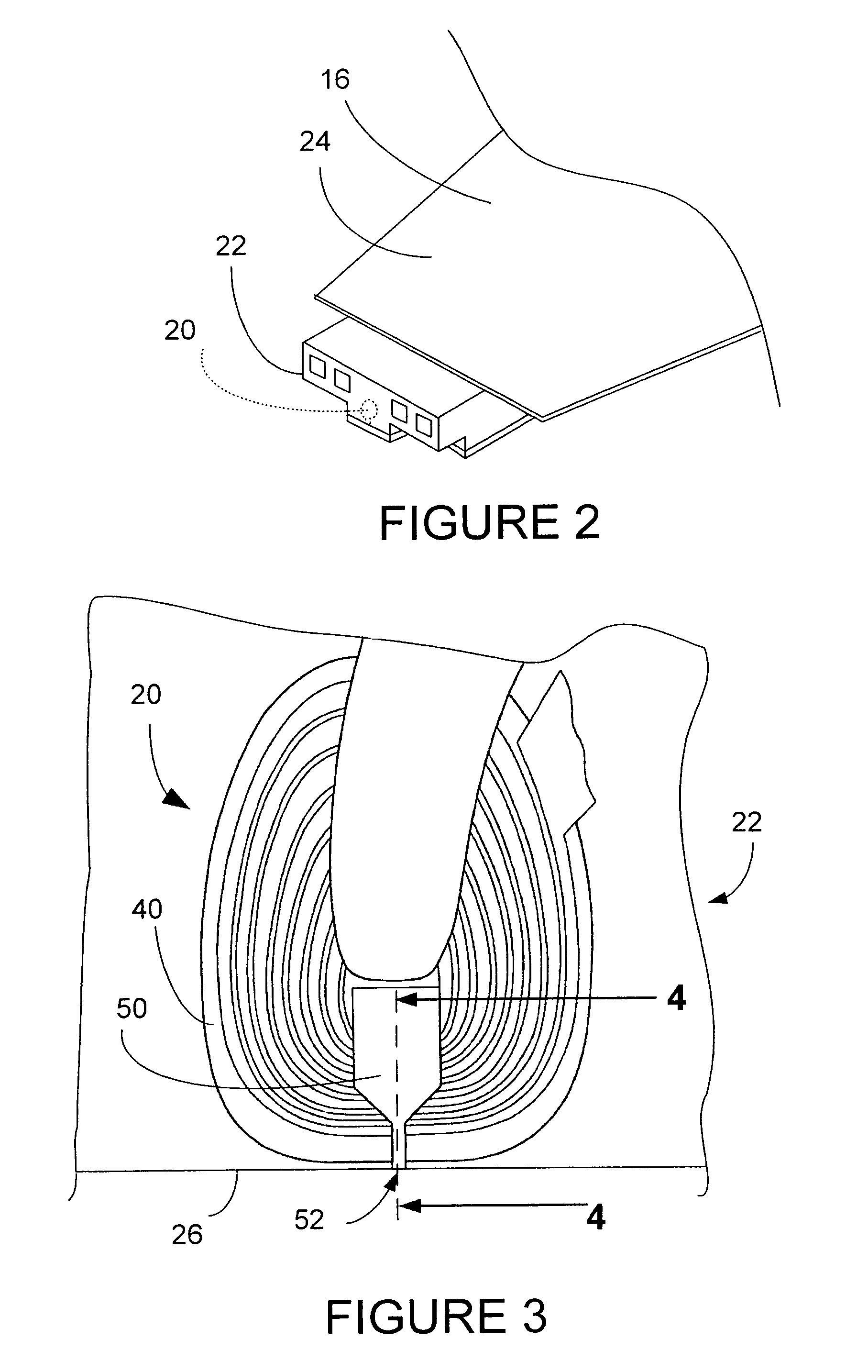

Manufacturing method of a thin film magnetic head

A magnetic disk apparatus includes a magnetic reproducing head portion, and a magnetic recording head including a lower magnetic core and an upper magnetic core having a end portion and a rear portion. The rear portion is formed using a negative resist or an electron beam resist to form a frame for plating above the end portion of the upper magnetic core head.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

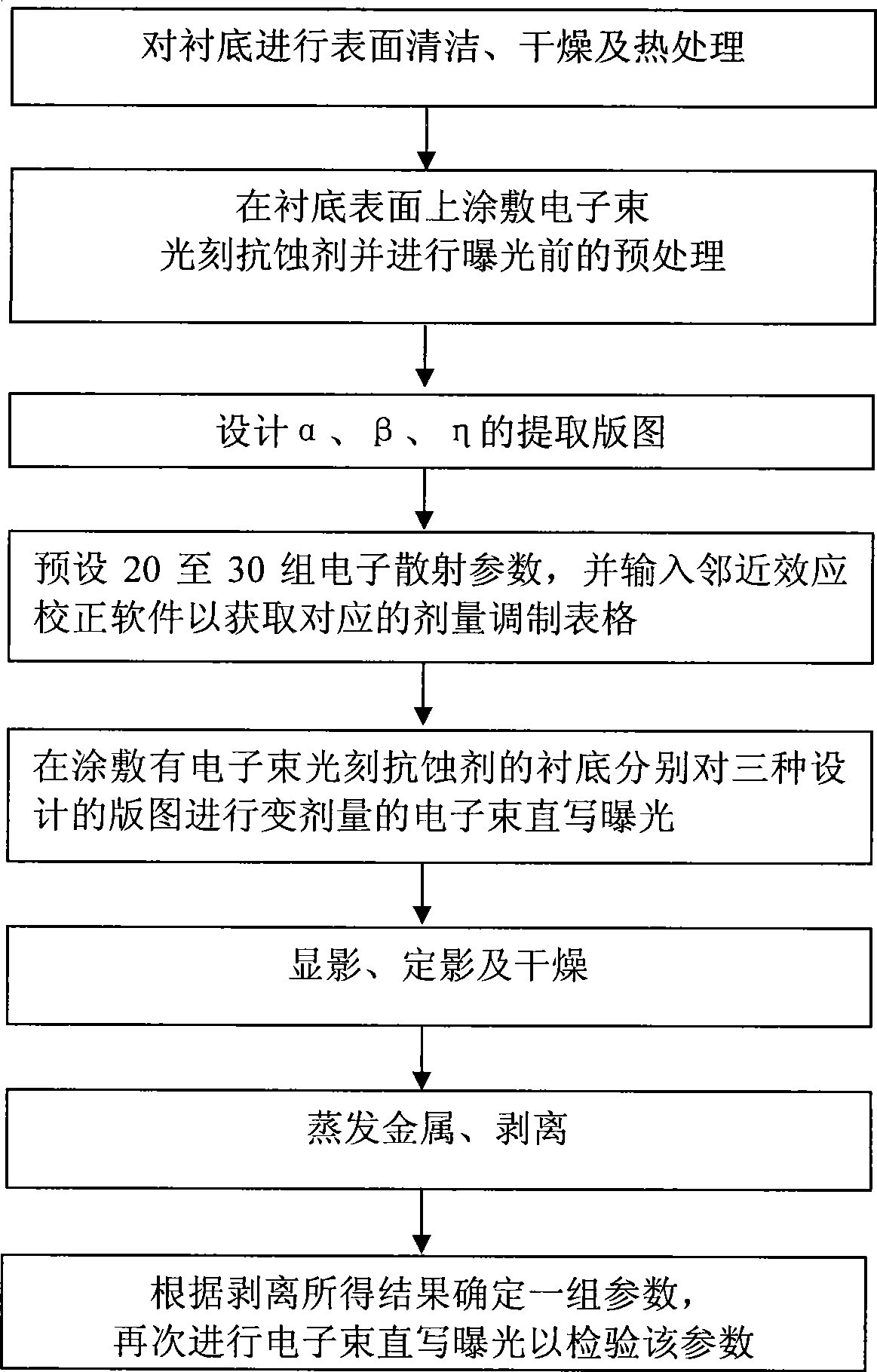

Method for extracting electron-beam exposure scattering parameter

ActiveCN101510050AExtraction is accurate and easyReduce mistakesSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusObservational errorElectron resists

The invention relates to a method for extracting an electron beam lithography scattering parameter. In order to solve the problems of complex operation and difficult guarantee for the accuracy in the existing method for extracting the electron beam lithography scattering parameter, the invention provides the method for extracting the electron beam lithography scattering parameter. According to the electron beam resist agent for parameter extraction and the substrate structure characteristics, the method designs a suitable front-scattering parameter Alpha, a back-scattering parameter Beta, and an extracting version map of Gama which is the ratio of the back-scattering deposition energy and the front-scattering deposition energy; and then electron beam direct writing lithography of variable doses for three types of design version maps is carried out on the electron beam resist agent and the substrate structure; and finally, according to a plurality of groups of different parameter lithography, development and the stripped graph structure features, a group of suitable scattering parameters are determined. The invention does not need large amount of complex measurement, therefore, no measurement error exists, the error caused by mathematical treatment is reduced, and the parameter extraction is led to be accurate, simple and feasible.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for preparing nano-scale graphene structure

ActiveCN105668546AAvoid direct contactEliminate the effects ofSemiconductor/solid-state device manufacturingNanotechnologyNanoscopic scaleCvd graphene

The invention provides a method for preparing a nano-scale graphene structure and relates to the field of graphene semi-conductor devices. The method comprises specific steps as follows: a metal chromium film is evaporated on the surface of graphene with a substrate; the surface of the metal chromium film is spin-coated with an electron beam resist; an electron beam lithography technique is adopted, a corresponding pattern is exposed on the electron beam resist, and a nano-scale structural pattern is formed on the electron beam resist through developing and fixation; the metal chromium film is etched with the electron beam resist used as a first mask, and a corresponding nano-scale structural pattern is formed on the metal chromium film; the graphene is etched with the metal chromium film used as a second mask, and the size of the graphene can be controlled by controlling etching parameters; the remaining metal chromium film is removed by means of a chromium corrosive liquid, and accordingly, the clean nano-scale graphene structure without impurities is obtained. With the adoption of the method, the feature size of the graphene structure can be controlled under 10 nm, and direct contact of the graphene with the electron beam resist can be avoided.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

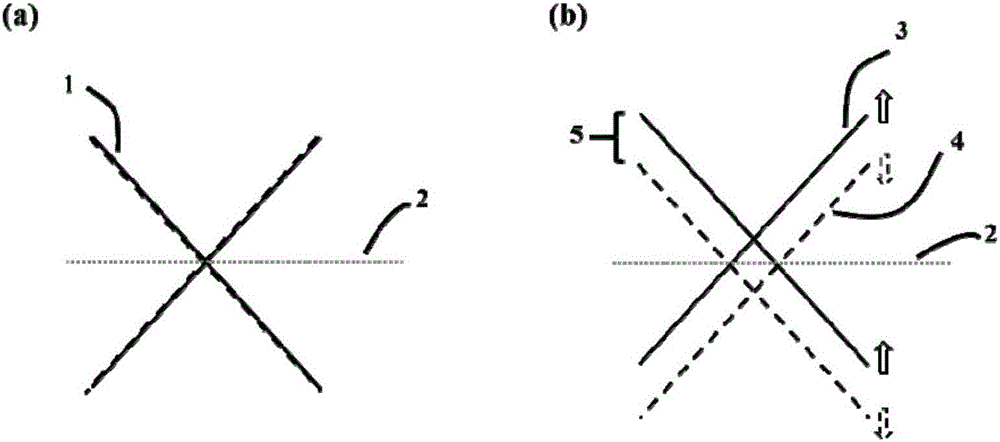

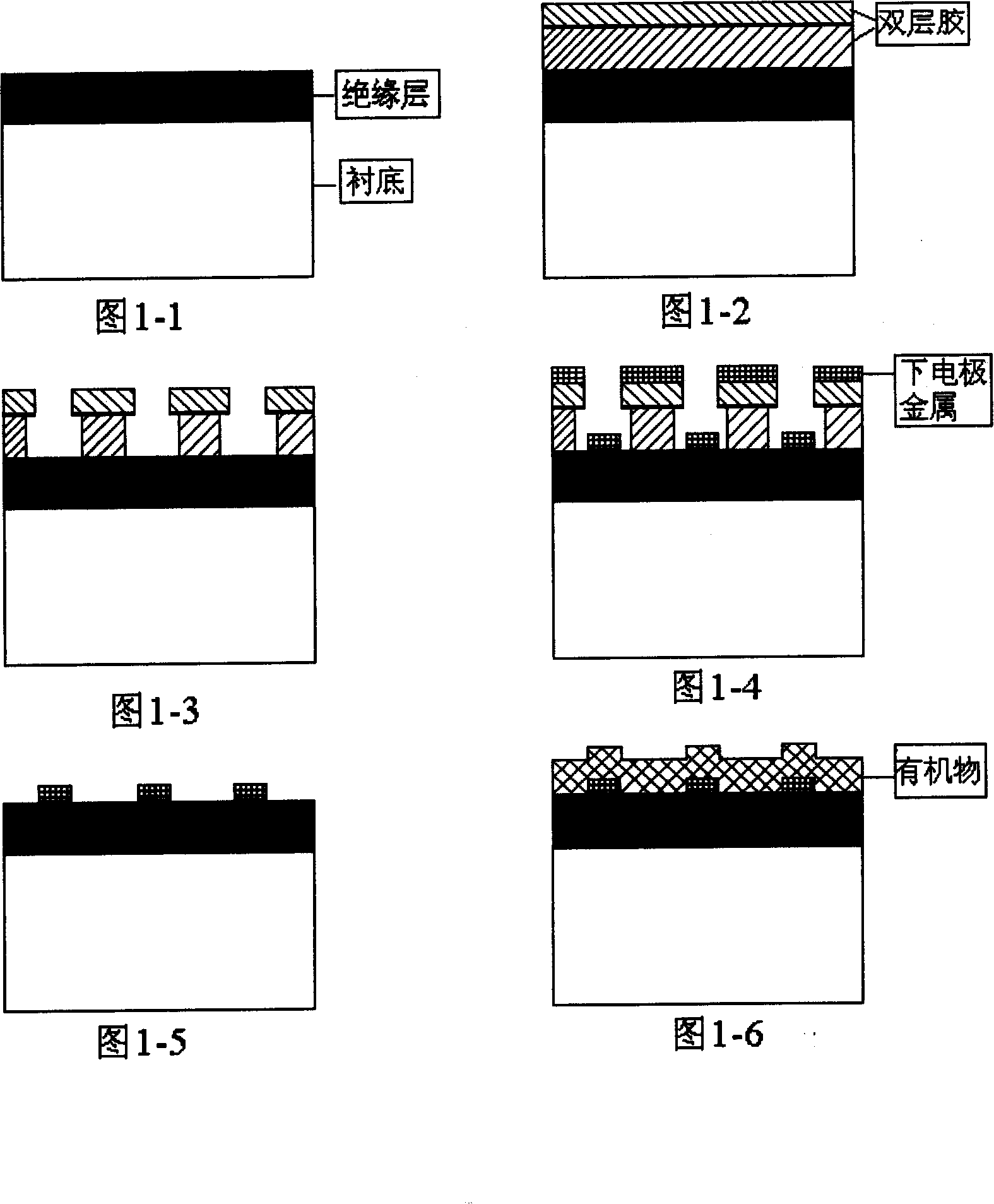

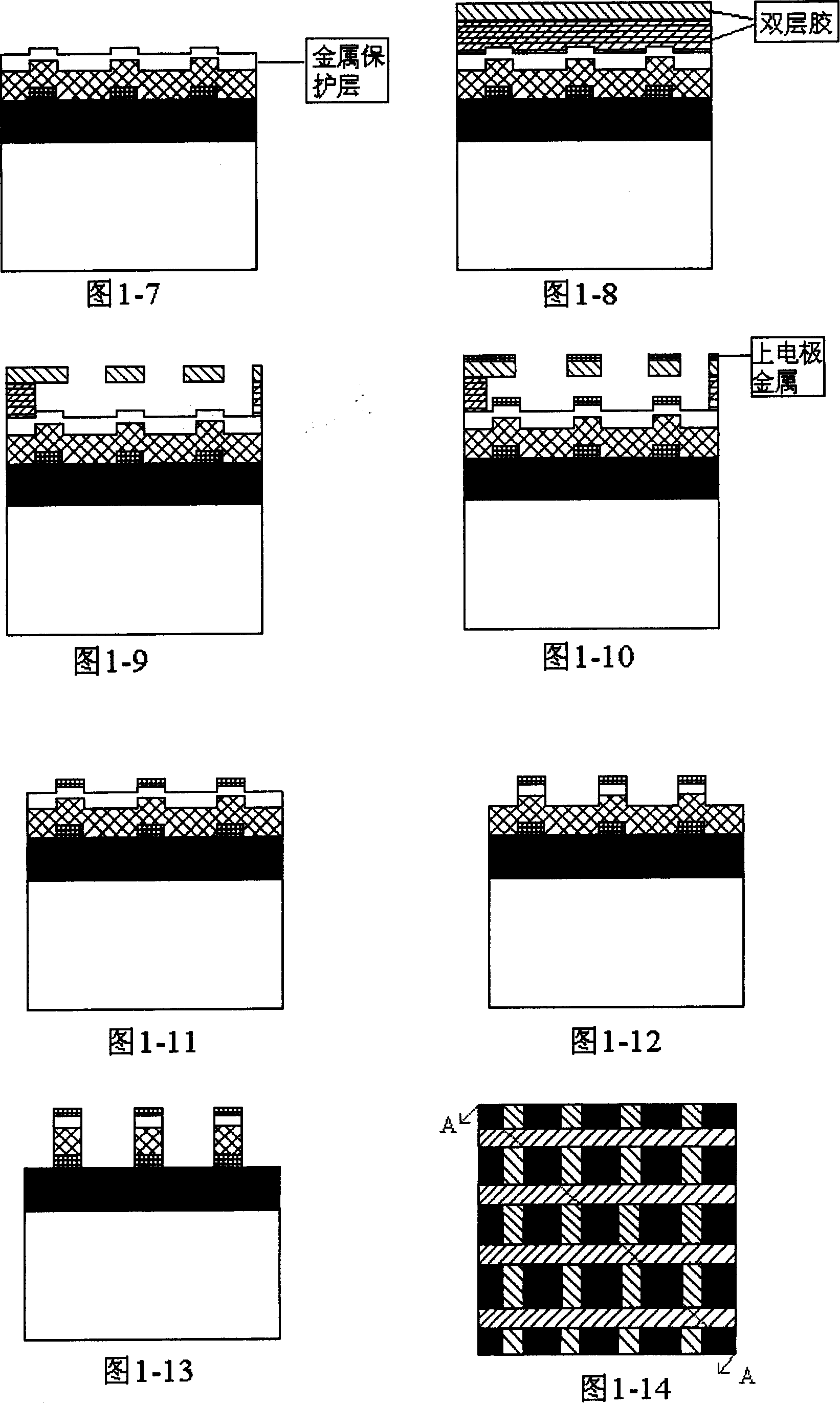

Process for producing nano-scale cross lines array structure organic molecule device

ActiveCN101083301AAvoid damageImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingProtection layerMolecular electronics

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for fabricating magnetic write pole for a magnetic head using an E-beam resist mask

InactiveUS20080127481A1Made preciselyAccurately track widthManufacture head surfaceElectrical transducersResistLithographic artist

A method is disclosed for independently controlling track width and bevel angle of a write pole tip of a magnetic recording head. The method includes establishing the track width in the pole tip layer material utilizing E-beam lithography. A portion of this pole tip material having the established track width is protected by providing a temporary masking material to make a protected portion. At least one unprotected portion is left exposed to be shaped. This unprotected portion is then beveled to produce at least one beveled portion. The protected portion produces an upper pole tip portion which together with the beveled portion produce an improved pole tip. Also disclosed is a magnetic head having the improved pole tip, and a disk drive having a magnetic head having the improved pole tip.

Owner:WESTERN DIGITAL TECH INC

Gate electrode and manufacturing method thereof, and semiconductor device and manufacturing method thereof

ActiveUS7419894B2Reduce selection requirementsWell formedSemiconductor/solid-state device manufacturingSemiconductor devicesResistEngineering

The present invention provides a method of manufacturing a gate electrode in which a fine gate electrode can effectively be manufactured by thickening a resist opening for gate electrodes formed by ordinary electron beam lithography so as to reduce opening dimensions. The method of manufacturing a gate electrode of the present invention includes a step of forming a laminated resist including at least an electron beam resist layer as a lowermost layer on a surface where a gate electrode is to be formed; a step of forming an opening in layer(s) other than the lowermost layer; a step of forming a gate electrode opening on the lowermost layer exposed from the opening; a step of reducing the gate electrode opening selectively; and a step of forming a gate electrode in the gate electrode opening.

Owner:FUJITSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com