Method for preparing high-density super sharp silicon probe array

A probe array, high-density technology, applied in the field of semiconductor silicon material manufacturing process

Inactive Publication Date: 2010-09-01

SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI +2

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, almost all existing technologies require an oxide layer as a mask for secondary pattern transfer, and can only produce probe arrays with a period of more than a micron. It is still a challenge to prepare a high-density probe array with a submicron period.

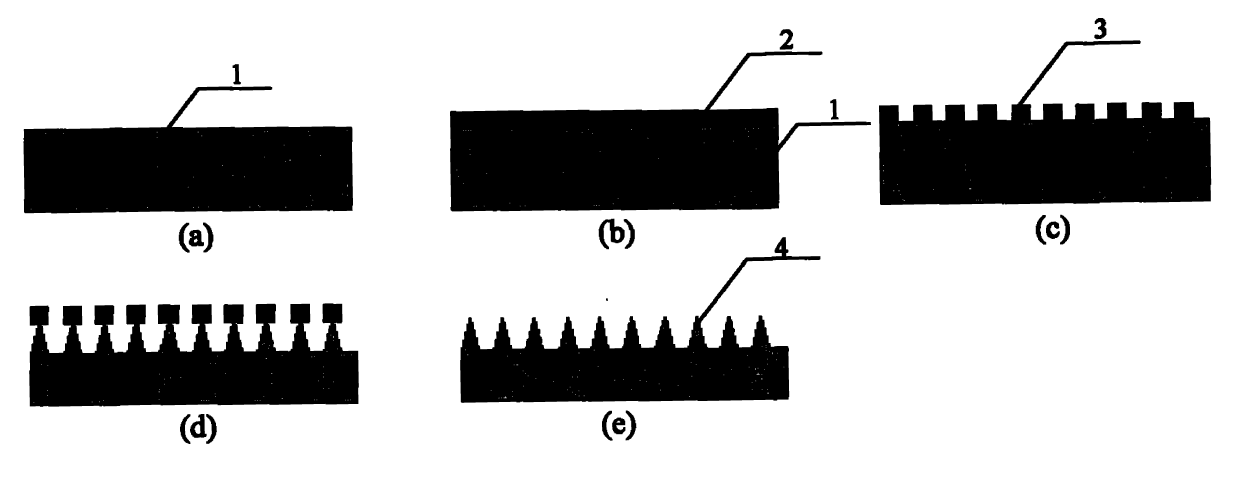

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

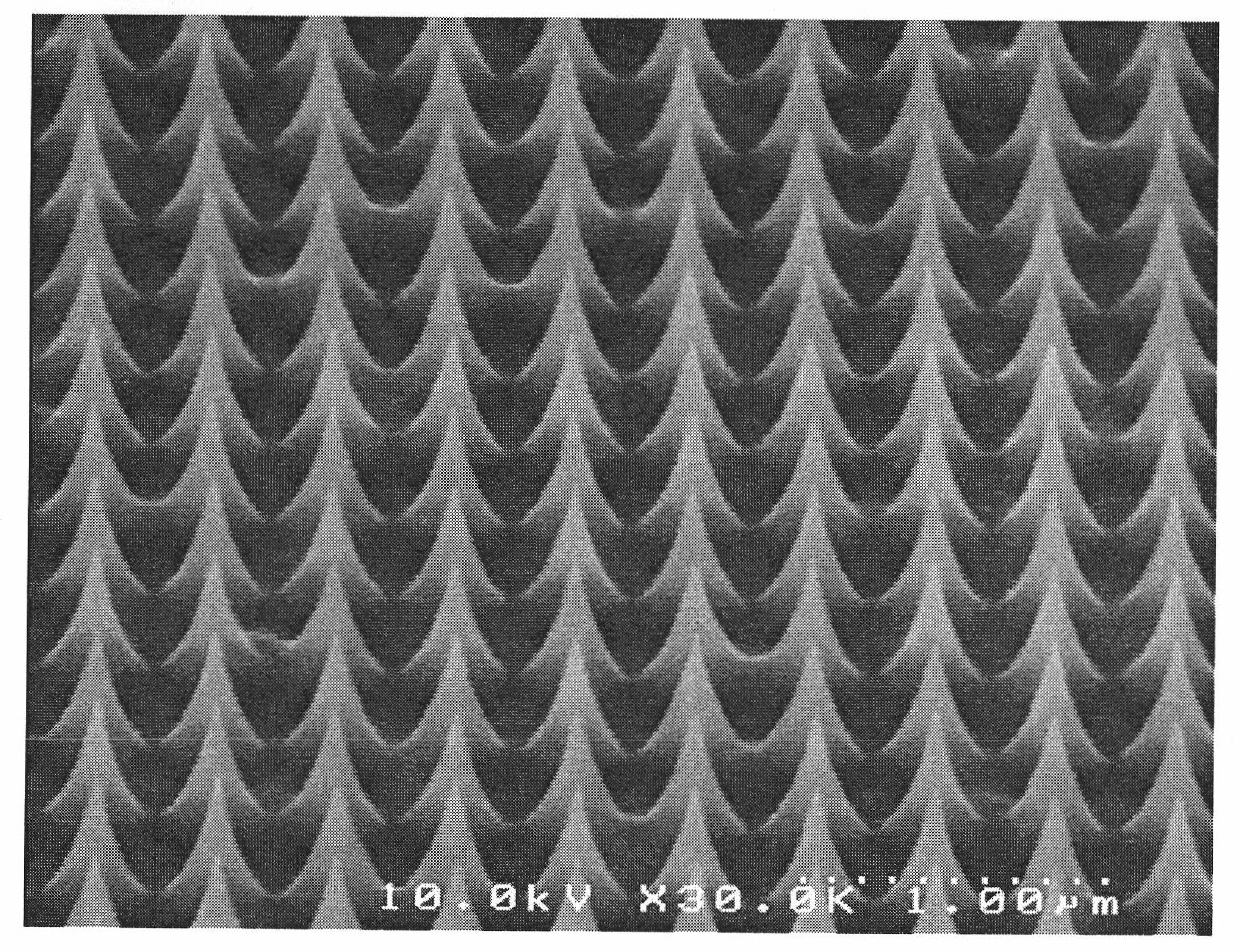

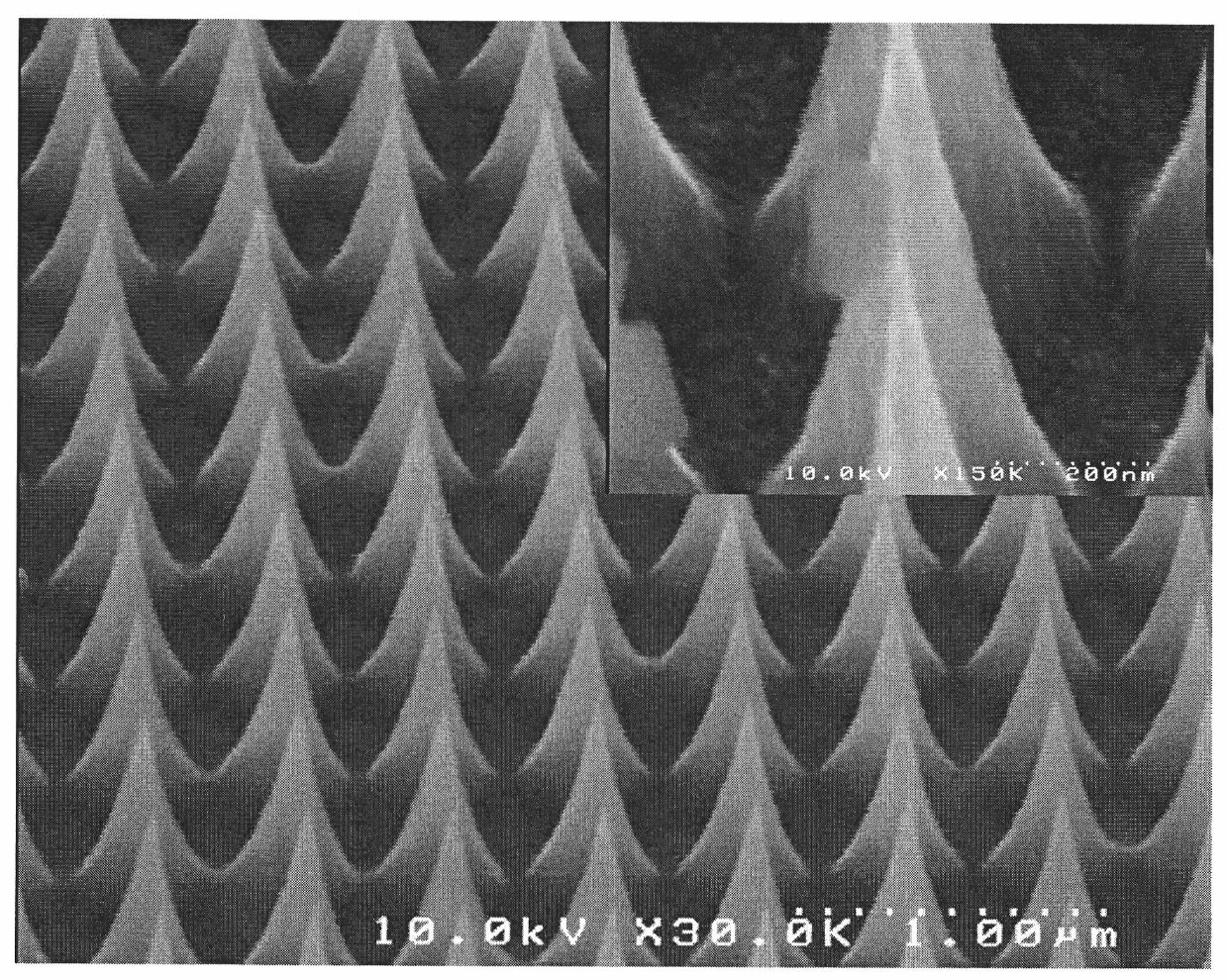

Login to View More Abstract

The invention provides a method for preparing a high-density super sharp silicon probe (tip) array by directly taking a hydrogen silsesquioxane (HSQ) electron beam resist as an etching mask. The hydrogen silsesquioxane (HSQ) electron beam resist is exposed by an electron beam photoetching method, and then developed to form a raster graphics of the HSQ; the silicon is subjected to isotropic etching by directly taking the HSQ as the mask; by controlling the etching conditions, the probe tip can be sharpest and the HSQ is about to fall off or automatically falls off simultaneously; the probe tip can reach several nanometers; and the additional oxidation, corrosion and other sharpening process are not needed, so the method is very simple. The method overcomes the inconvenience that the traditional preparation method needs an oxide layer to serve as a mask for secondary graphic transfer and requires additional oxidation and etching processes to sharpen the probe, and overcomes the difficulty in preparing submicron-period high-density silicon probe array, and can easily prepare the silicon probe array with the density more than 2.5*107 / mm<2>.

Description

technical field The invention relates to a semiconductor silicon material manufacturing process technology, in particular to a method for preparing a high-density, ultra-sharp silicon tip array directly using silsesquioxide hydride (HSQ) as an etching mask. Background technique Silicon probes are widely used in field emitters and probes for atomic force microscopy (AFM), scanning probe microscopy (SPM) and related probe scanning techniques (see literature [1]), and are also used as carbon nanotubes, GaN Coatings, nanoscale diamond particles and growth templates for diamond-like films (see literature [2], [3]). There is a growing demand for supertip silicon with tip size on the order of nanometers in the above fields (see literature [4]). However, almost all existing technologies require an oxide layer as a mask for secondary pattern transfer, and can only produce probe arrays with a period of more than a micron, and it is still a challenge to prepare a high-density probe a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01Q60/38

Inventor 王少伟陆卫陈效双俞立明

Owner SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com