Double-layer glue removing method used for electron beam lithography stripping

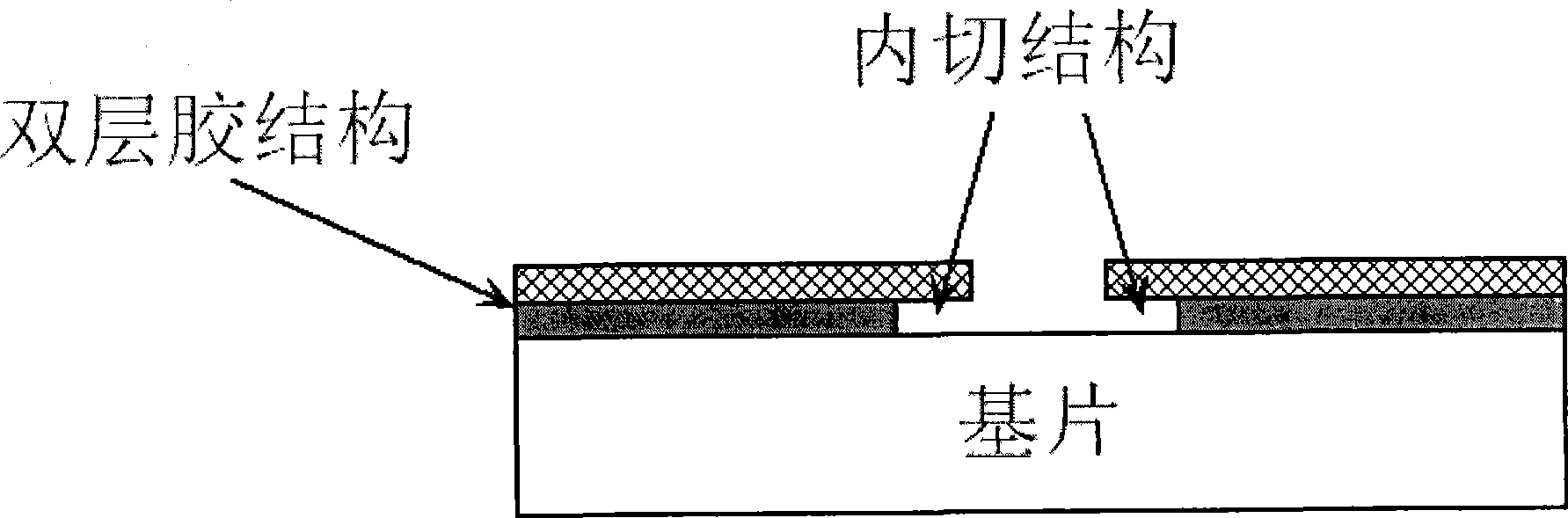

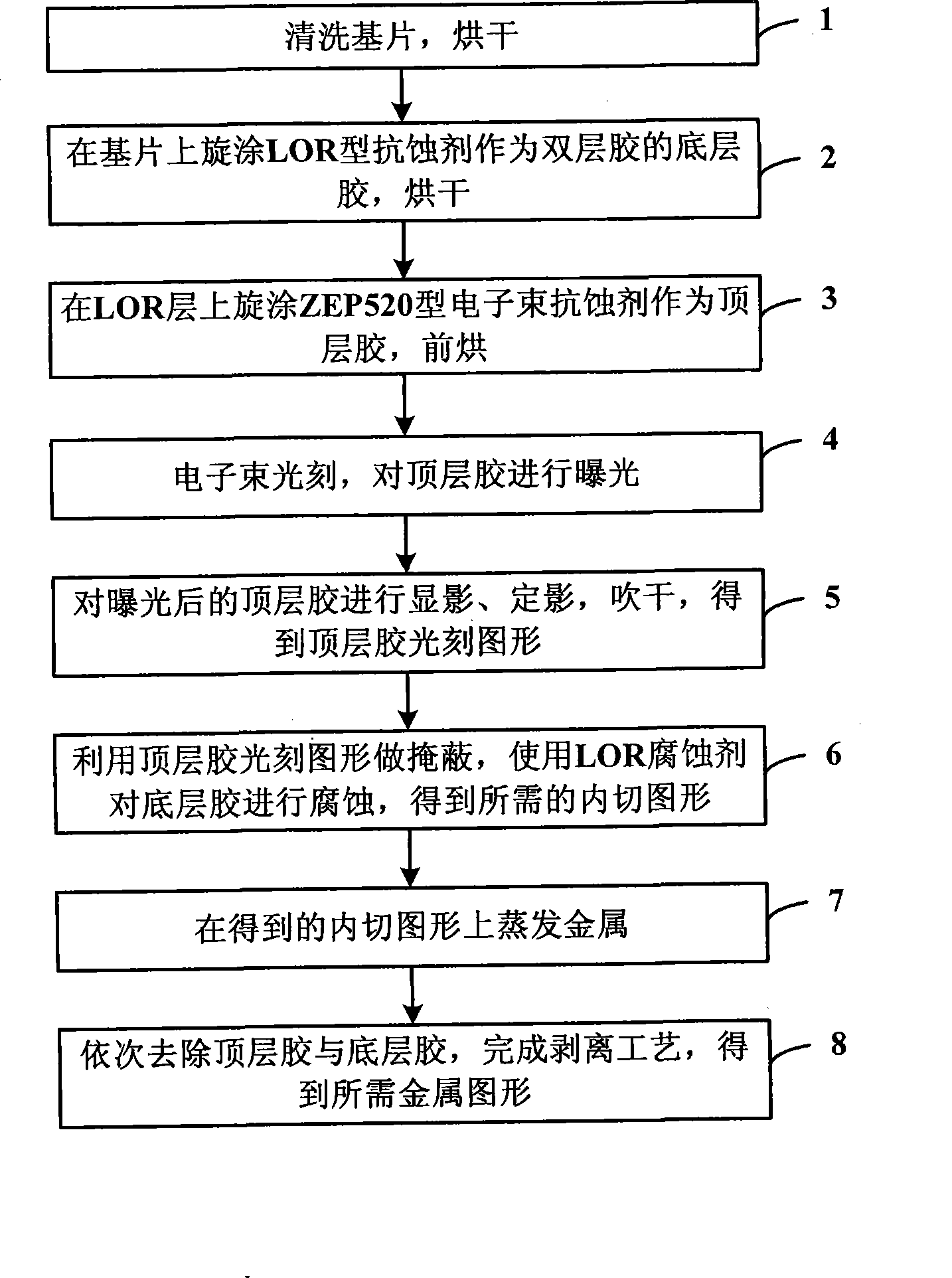

An electron beam lithography, double-layer adhesive technology, applied in coating, optics, circuits, etc., can solve the problem of blurred internal cutting structure of double-layer adhesive, improve the peeling yield, reduce the difficulty of peeling process, and widely The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

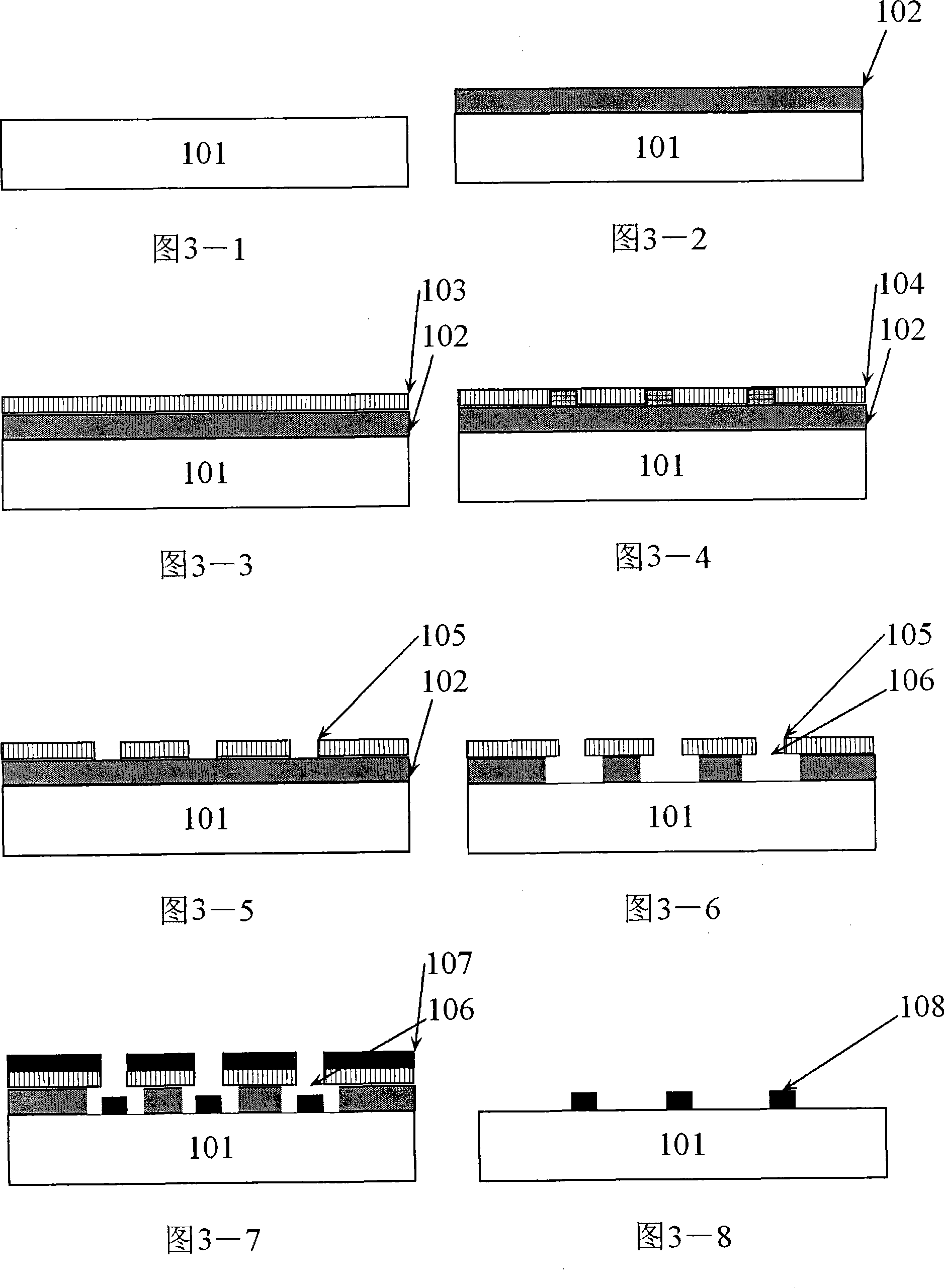

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0035] LOR (Micro Chem.Corp.) is not sensitive to electron beams, and is insoluble in PMMA / ZEP520 commonly used developer and fixer. It is an ideal choice for the bottom layer of electron beam double-layer adhesives. Therefore, the present invention uses ZEP520 as the top glue and LOR as the bottom glue, which has high innovative significance and practical value. Moreover, at present, there is no patent application for the double-layer adhesive process applied to electron beam lithography. The patent applied for (Chinese patent application number: 02123171.0) is a double-layer adhesive process for optical lithography, and the method of etching the bottom layer adhesive with O2 / HBr gas is complicated and different from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com