Method for preparing nano-scale graphene structure

A nanoscale, graphene technology, applied in nanotechnology, microlithography exposure equipment, semiconductor/solid-state device manufacturing, etc., can solve problems such as difficult to remove, unreachable, and affect the performance of graphene devices, so as to avoid direct contact, The effect of eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

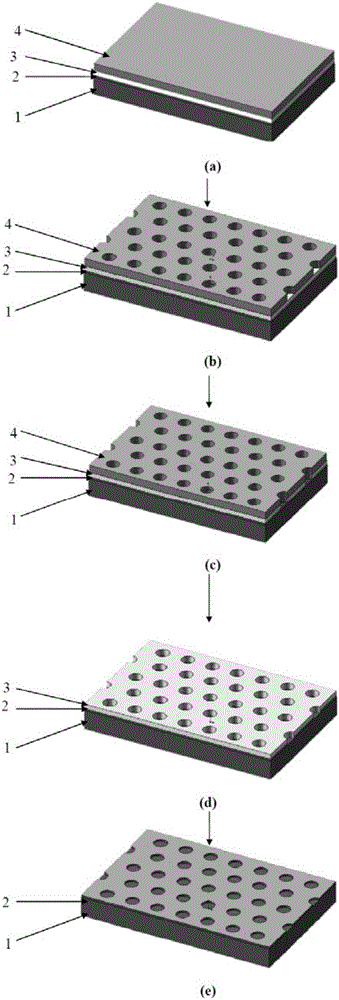

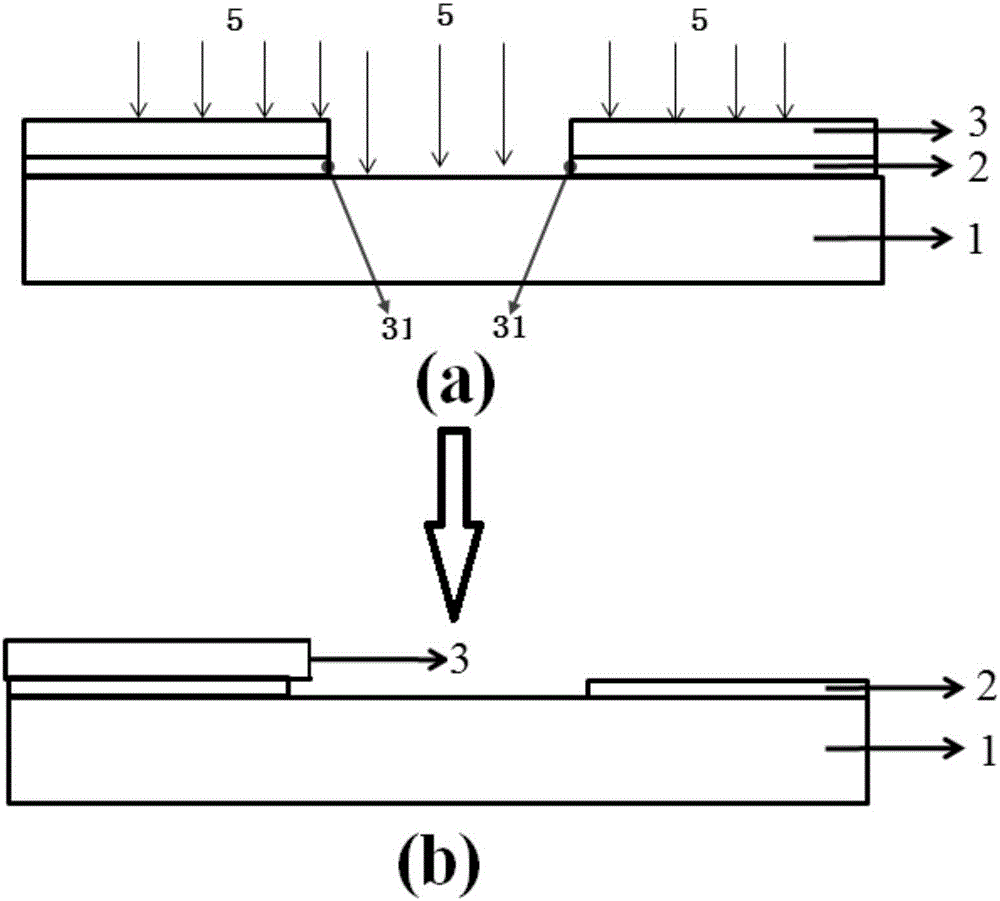

[0036] figure 1 It is a preparation flowchart of a method for preparing a nanoscale graphene structure according to an embodiment of the present invention. see figure 1 , the invention provides a kind of method for preparing the graphene structure of nanoscale, concrete steps comprise:

[0037] Step S1, selecting a substrate 1 and transferring graphene 2 on the substrate 1, or growing graphene 2 on the substrate 1;

[0038] Step S2, vapor-depositing a metal chromium film 3 with a certain thickness on the surface of the graphene 2;

[0039] Step S3, spin-coating an electron beam resist 4 with a certain thickness on the surface of the metal chromium film 3;

[0040] Step S4, using electron beam exposure technology to expose corresponding patterns on the electron beam resist 4, and after developing and fixing, forming nanoscale structural patterns on the electron beam resist 4;

[0041] Step S5, using the electron beam resist 4 with a nanoscale structure pattern as the first ...

Embodiment 1

[0055] Step 1. Select and clean a silicon substrate or a silicon dioxide substrate, and transfer graphene 2 grown by chemical vapor deposition (CVD) on the silicon substrate or silicon dioxide substrate.

[0056] Step 2, using thermal evaporation equipment to grow a metal chromium film 3 with a thickness of 50 nm on the surface of the graphene 2 .

[0057] Step 3: Spin-coat PMMA electron beam resist with a thickness of 200 nm on the surface of the metal chromium film 3 , and bake at 180° C. for 1 minute with a hot plate.

[0058] Step 4, using electron beam exposure equipment to prepare a circular hole array structure with a diameter of 250 nm and a period of 290 nm on the PMMA electron beam resist through exposure, development and fixing.

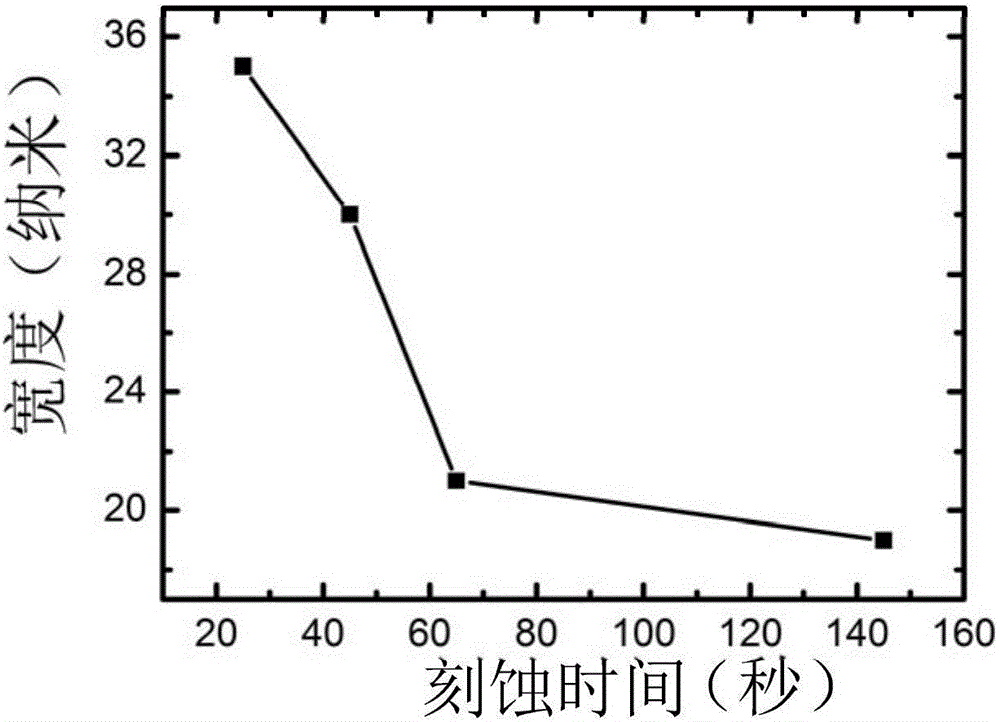

[0059] Step 5. Etching the metal chromium film 3 by using ion beam etching and using the PMMA electron beam resist with a circular hole array structure as the first mask. Among them, the etching beam density is 50mA / cm 3 , the ion energy...

Embodiment 2

[0063] Step 1, select a silicon substrate and wash it, and grow graphene 2 on the silicon substrate by mechanical exfoliation;

[0064] Step 2, using electron beam evaporation equipment to grow a metal chromium film 3 with a thickness of 10 nm on the surface of the graphene 2 .

[0065] Step 3: Spin-coat ZEP520 electron beam resist with a thickness of 50 nm on the surface of the metal chromium film 3, and bake at 180° C. for 2 minutes with a hot plate.

[0066] Step 4. Using electron beam exposure equipment, a circular hole array structure with a diameter of 150 nm and a period of 190 nm can be prepared on the ZEP520 electron beam resist through exposure, development and fixing.

[0067] Step 5, using ion beam etching technology, and using the ZEP520 electron beam resist with a circular hole array structure as the first mask to etch the metal chromium film 3 . Among them, the etching beam density is 100mA / cm 3 , the ion energy is 300eV, and the circular hole array structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com