Method for manufacturing chromium sidewall attenuation type phase-shifting mask used in extreme ultra-violet lithography

A technology of extreme ultraviolet lithography and phase shift mask, which is applied in the field of making chromium sidewall attenuation type phase shift mask for extreme ultraviolet lithography, and can solve the problems of complex manufacturing, lower resolution, lower contrast of exposure results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

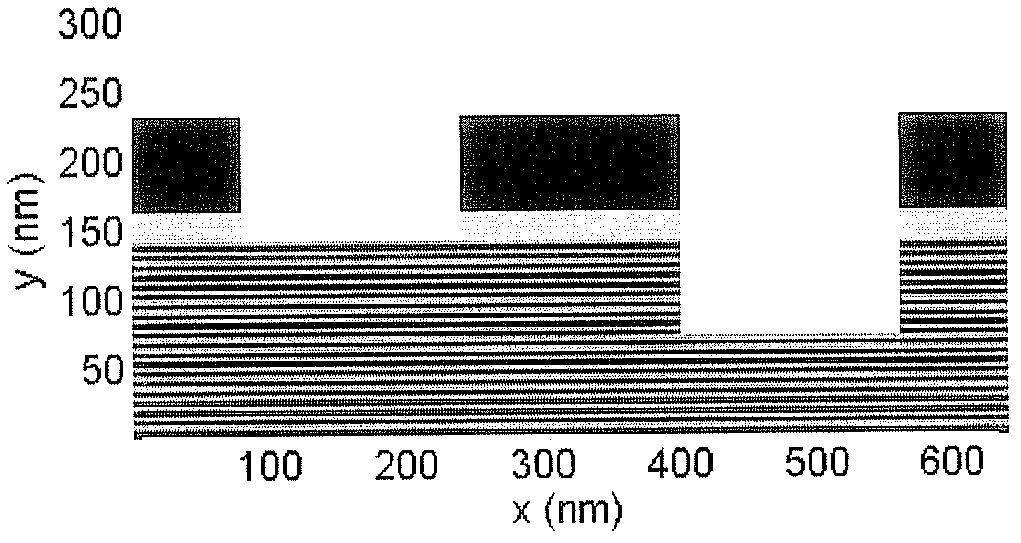

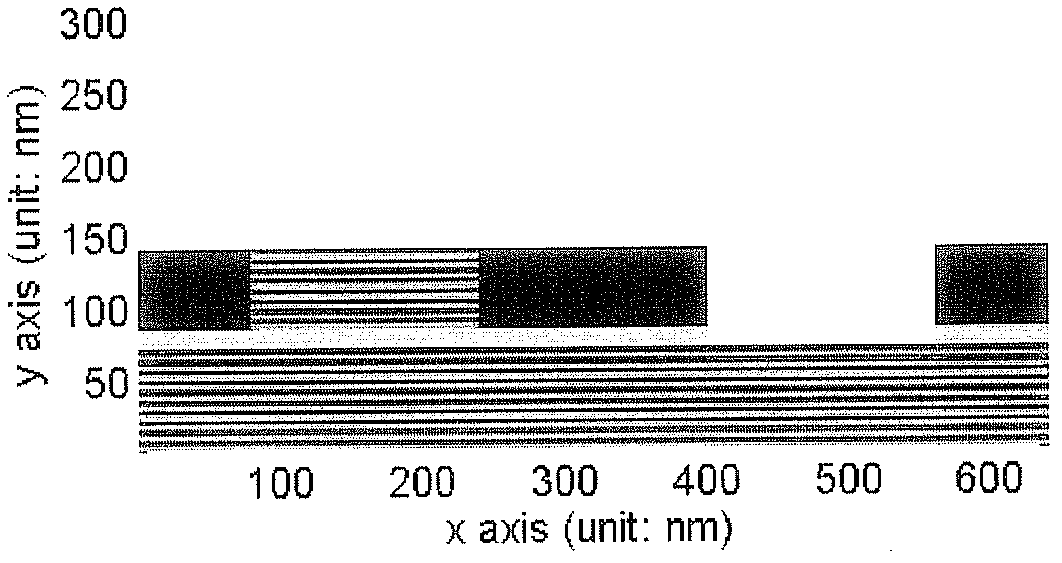

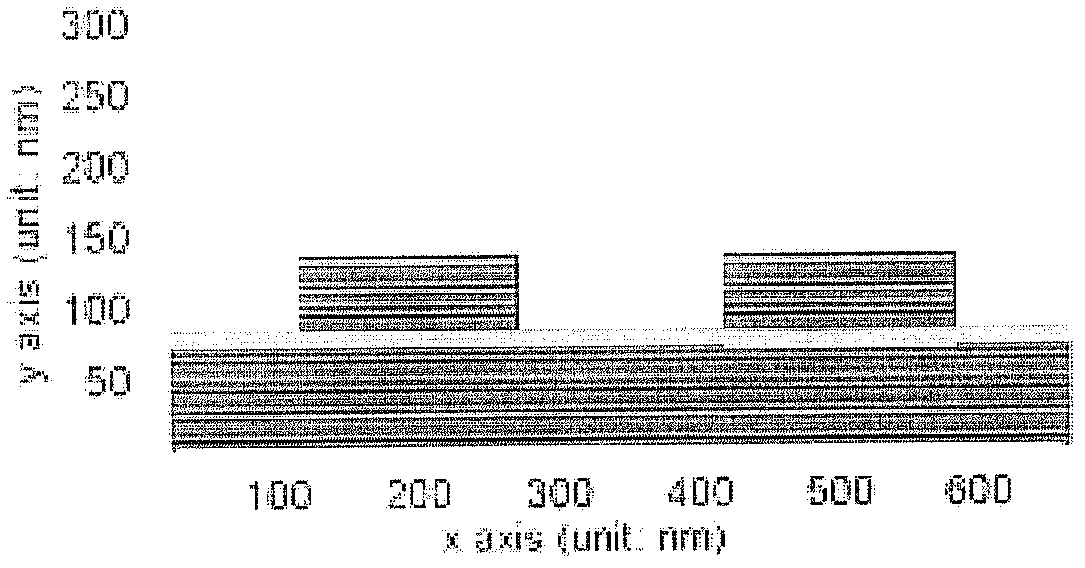

[0018] At present, the structural design of extreme ultraviolet lithography masks is mainly as follows figure 1 or figure 2 The reflective alternating phase shift mask shown, and as image 3 The two structures of the traditional reflective attenuated phase shift mask are shown. The extreme ultraviolet lithography chromium sidewall attenuation type phase shift mask provided by the present invention, such as Figure 4 Shown, with figure 1 Shows the traditional alternating phase shift mask and image 3 Compared with the shown attenuated phase-shifting mask structure, chromium sidewalls are added on both sides of the phase-shifting area of the traditional attenuated mask structure, and the simulation result of the far-fie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com