Super-resolution dry-method surface plasma photo-etching method

A surface plasmon and super-resolution technology, which is used in microlithography exposure equipment, photosensitive material processing, photoengraving process exposure devices, etc., and can solve the problems of pattern collapse, irregular pattern edges, and irregular shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. But the following examples only limit to explain the present invention, and the protection scope of the present invention should include the whole content of claim, and promptly can realize the whole content of claim of the present invention to those skilled in the art through following embodiment.

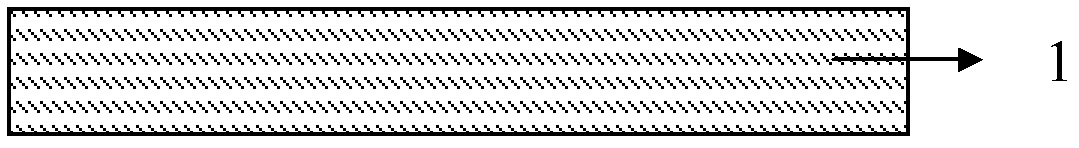

[0036] Such as figure 1 As shown, the schematic diagram of the first step of the present invention; first select a silicon substrate or K9 slide 1, and polish its surface, and then carry out further cleaning and drying;

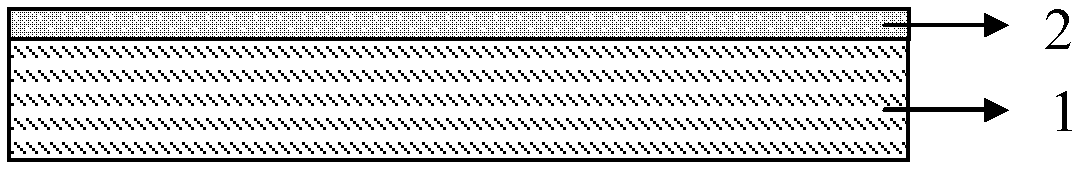

[0037] Such as figure 2 Shown, the production schematic diagram of the second step of the present invention; On the surface of the substrate 1, radio frequency reactive magnetron sputtering sputtering deposits a layer of TeO with a thickness of about 20nm. x film;

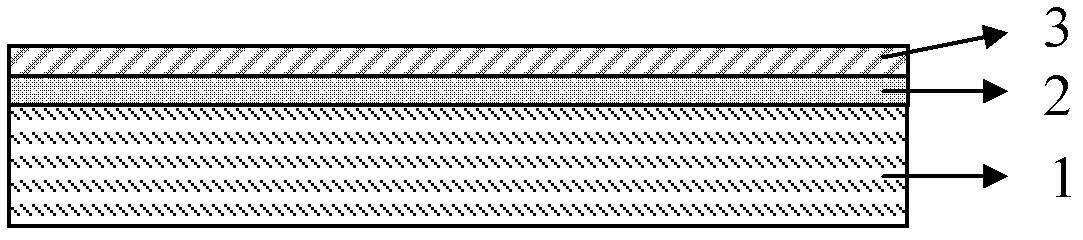

[0038] Such as image 3 Shown, the making schematic diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com