Process for producing nano-scale cross lines array structure organic molecule device

A technology of molecular devices and array structures, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of polluting organic materials, difficult processing, and improvement, and achieve the effect of avoiding damage and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

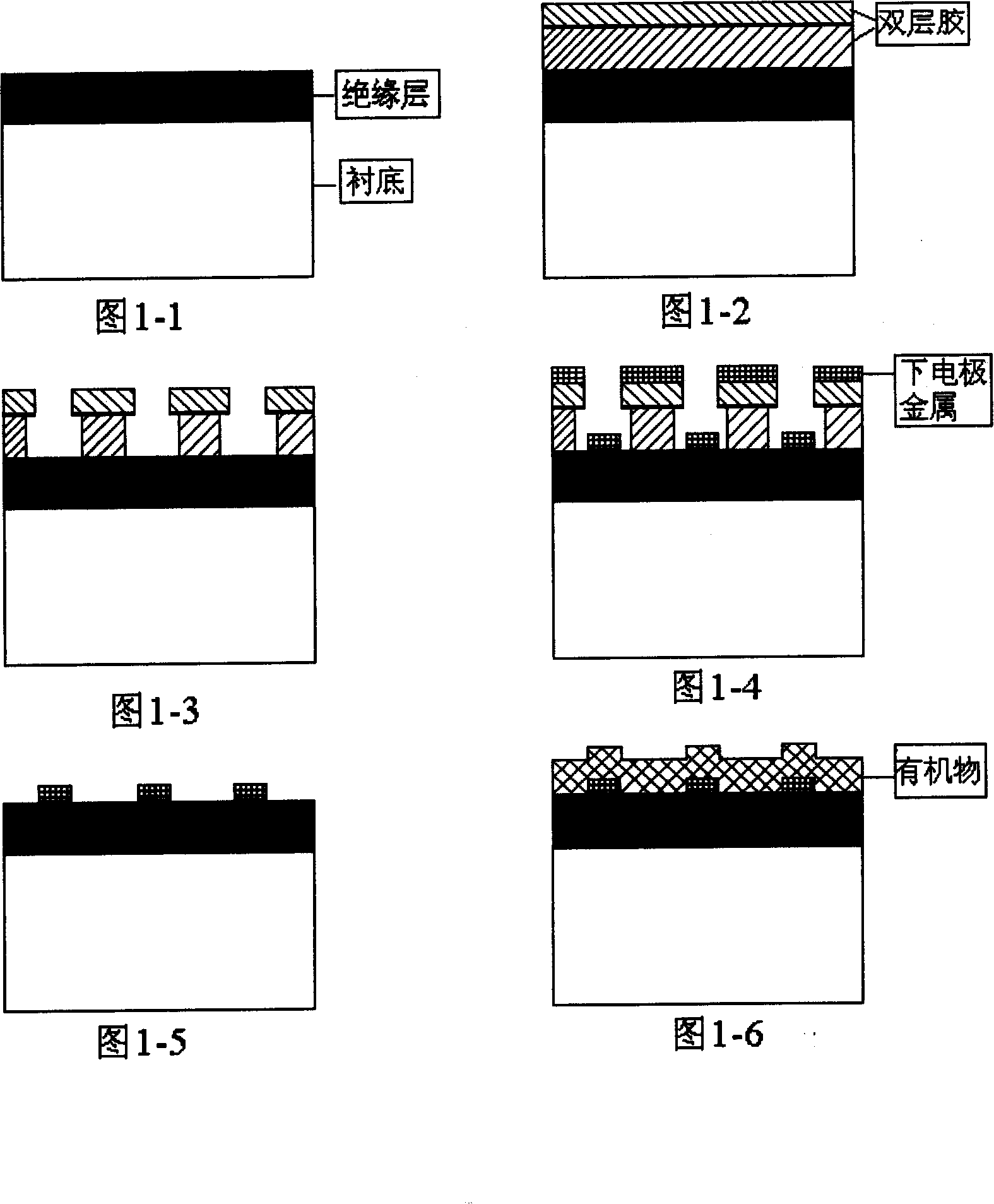

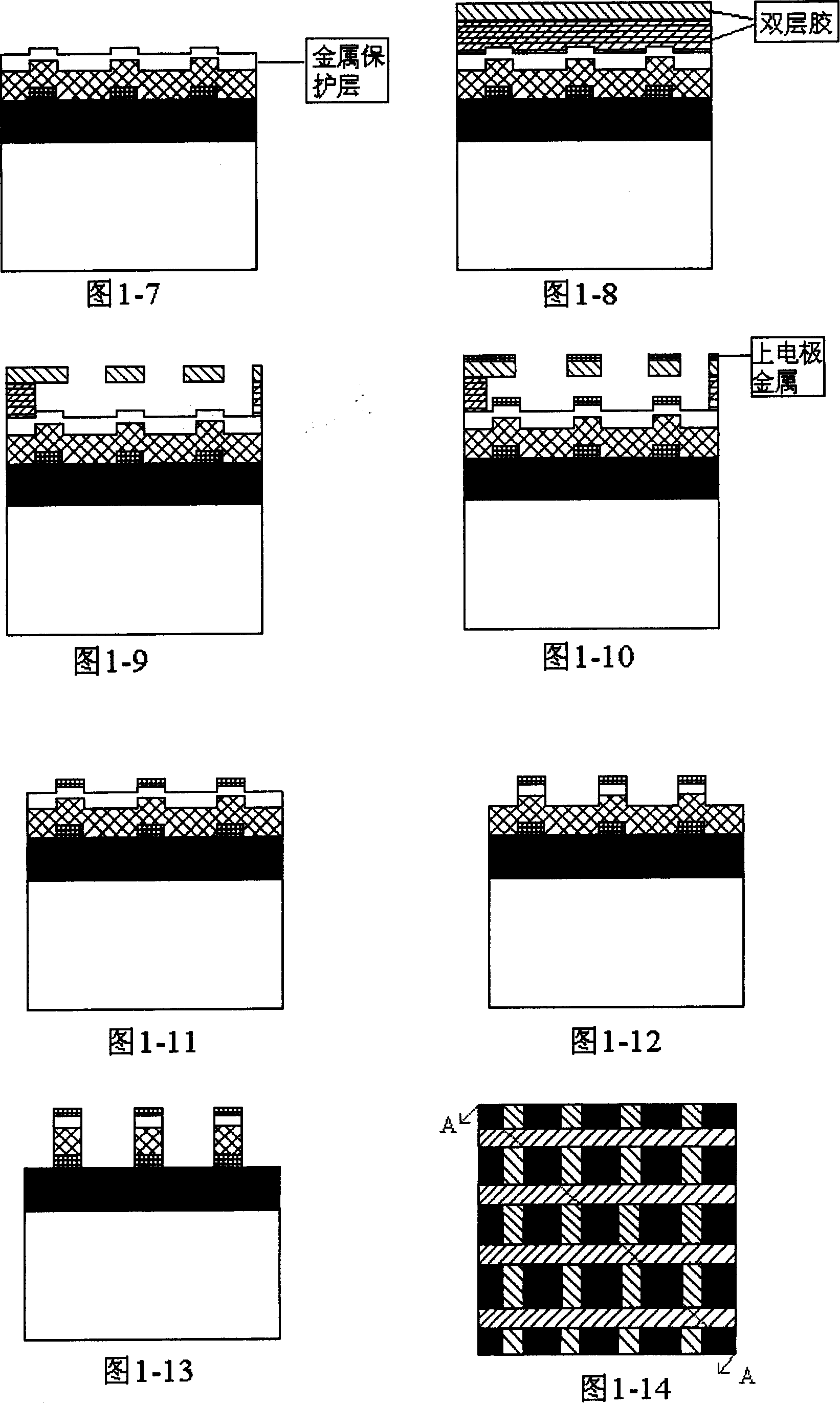

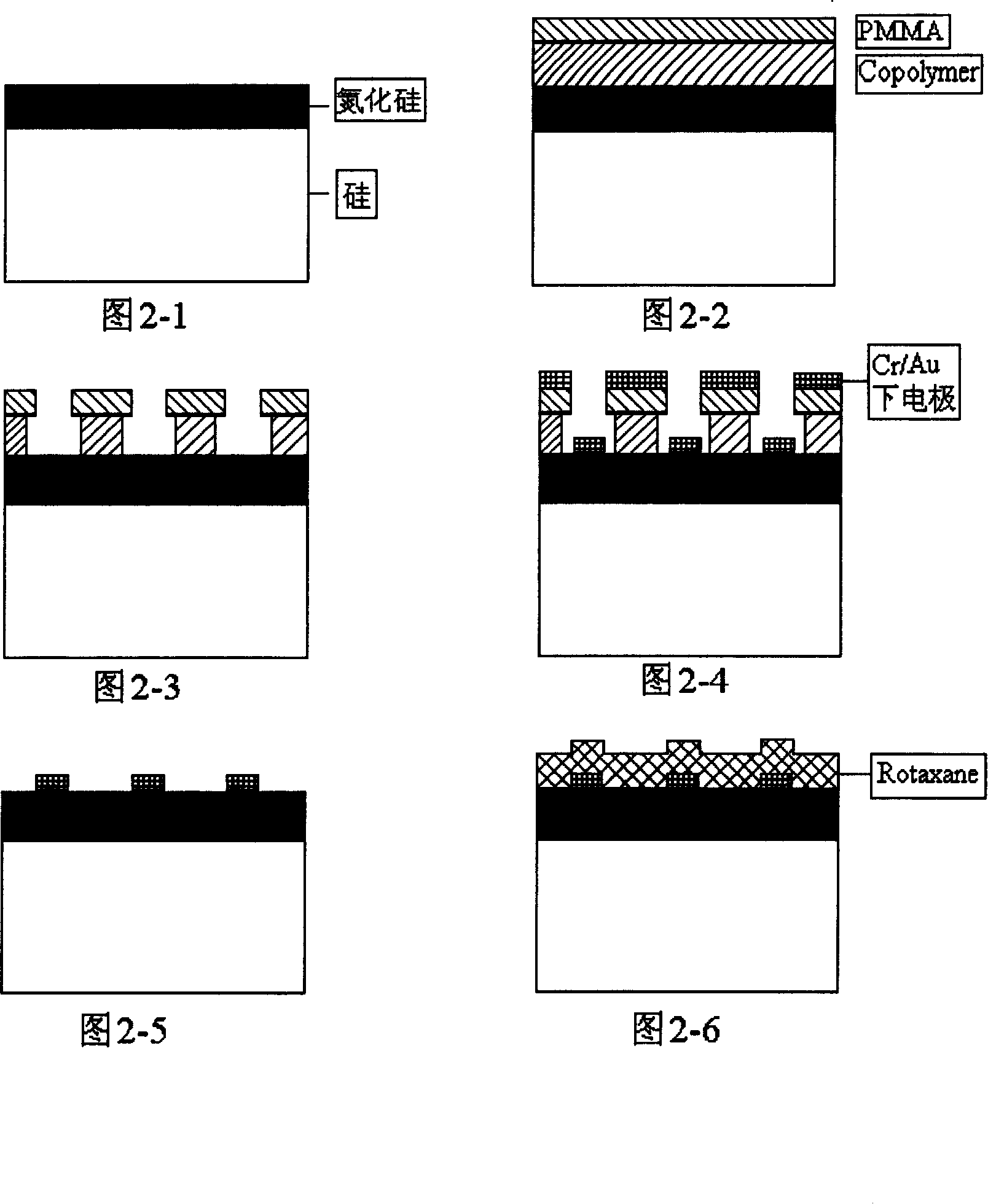

[0015] Invention flow chart (the section selected in the flow chart is the A-A section in Figure 1-14):

[0016] 1. As shown in Figure 1-1, an insulating layer film is prepared on the substrate surface by thermal oxidation growth or chemical vapor deposition.

[0017] 2. As shown in Figure 1-2, spin-coat electron beam photoresist on the surface of the insulating layer film, and bake it on a hot plate or an oven.

[0018] 3. As shown in Figure 1-3, the lower electrode pattern is obtained on the photoresist after electron beam exposure and development.

[0019] 4. As shown in Figure 1-4, the metal thin film of the lower electrode is obtained by metal evaporation.

[0020] 5. As shown in Figure 1-5, the metal lower electrode is prepared on the insulating layer after ultrasonic stripping with acetone, ethanol and deionized water.

[0021] 6. As shown in Figure 1-6, the organic molecular film is prepared by vacuum evaporation or liquid phase LB film. Organic molecular materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com