Patents

Literature

31 results about "Electron resists" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

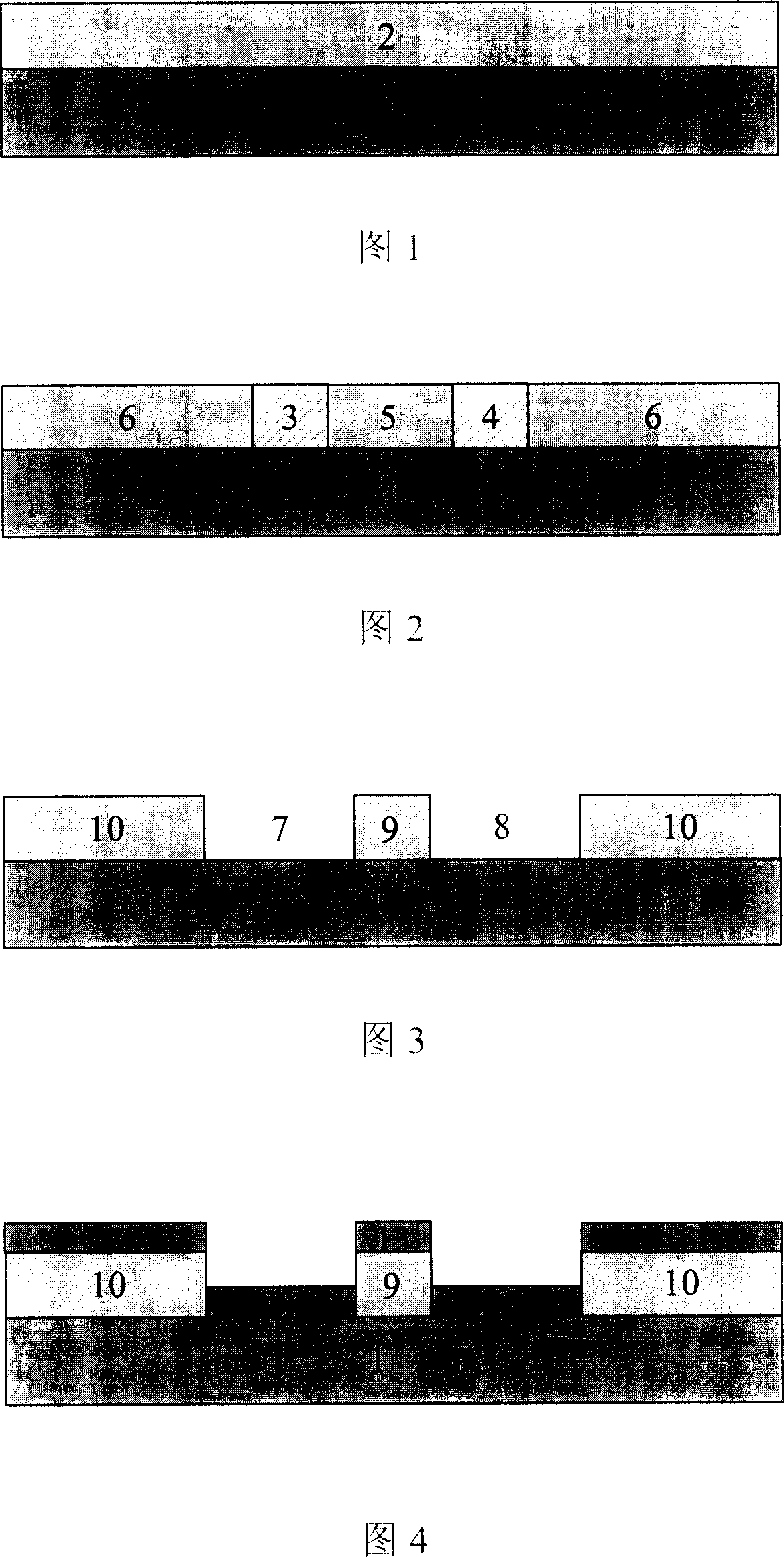

Method for producing nano-structure on insulated underlay

InactiveCN101295131AExcellent solubility propertiesSolve the accumulationPhotomechanical apparatusSemiconductor/solid-state device manufacturingElectron resistsNano structuring

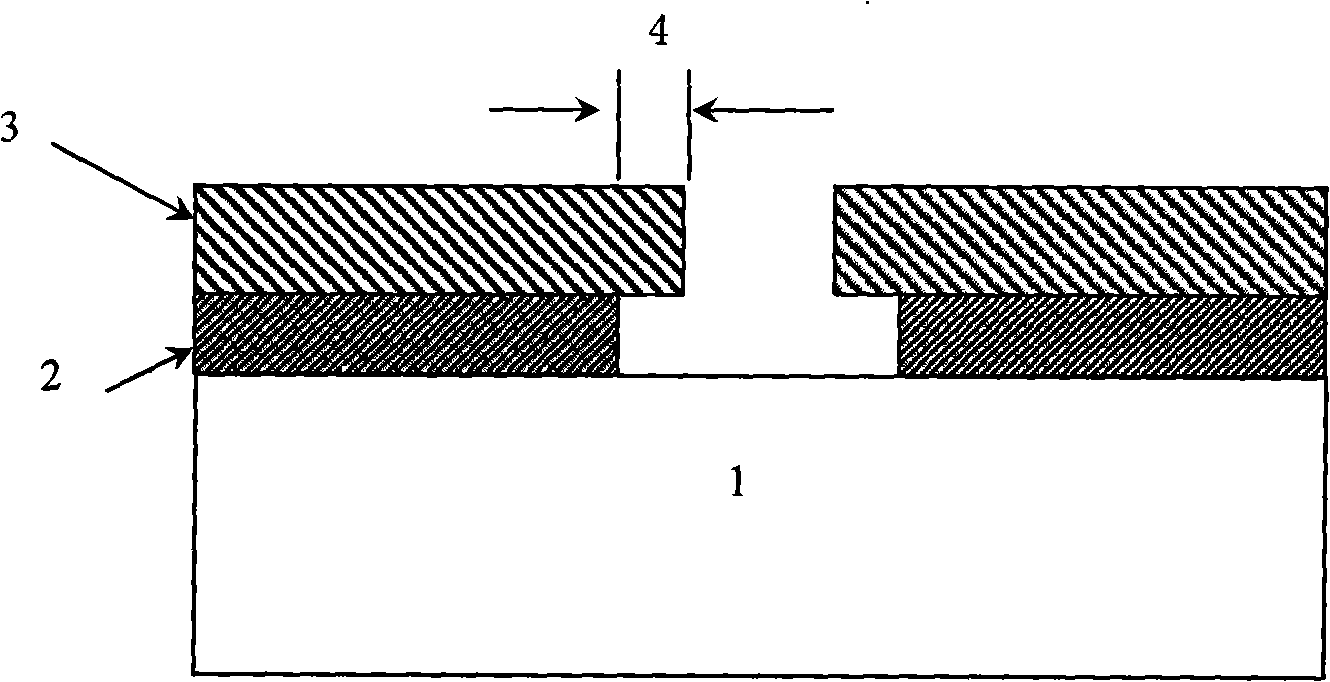

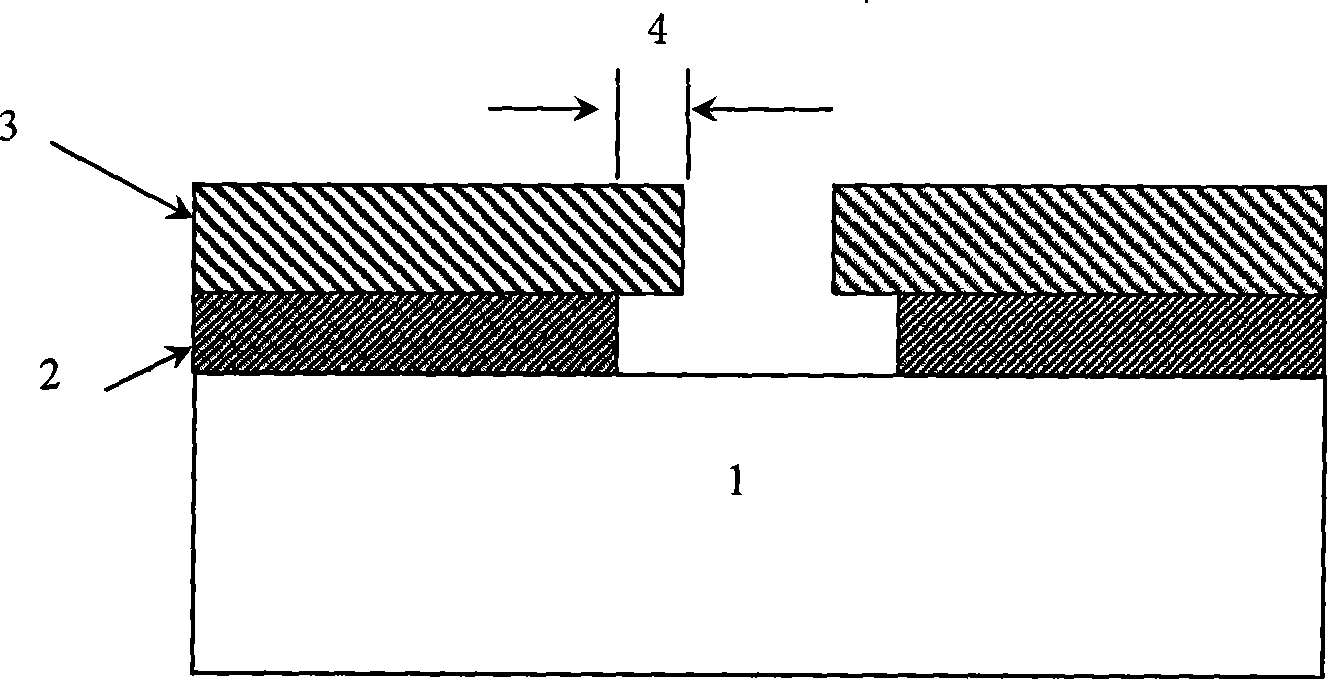

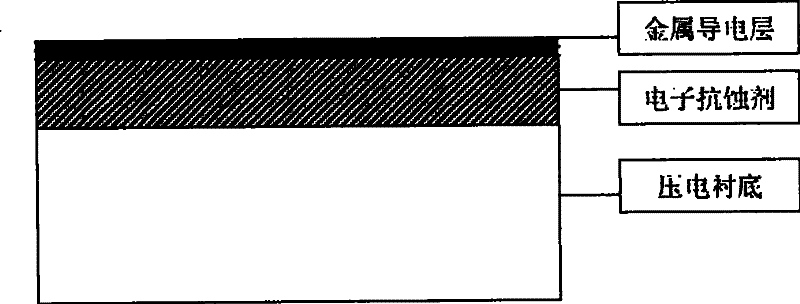

The invention relates to a method for preparing nanometer structures on an insulating substrate. The method comprises the following steps of: selecting and disposing the insulating substrate; spin-coating electronic anti-corrosion adhesive after an aluminium film with suitable thickness is aggraded on the substrate by coating equipment; designing the shape and the dimension of the required surface nanometer structure according to the requirement; realizing the precise exposal of the design graphics on the surface of the substrate in an electron beam exposal system; realizing suitable undercut structure at the exposal line position in a dual-layer structure of electronic anti-corrosion adhesive and aluminium by controlling the process parameters such as temperature of alkali liquor, consistency of alkali liquor and corrosion disposal time; finally realizing the sediment of nanometer structure material by the coating equipment and completing the preparation of the nanometer structure by solubilisation process and alkali liquor disposal. The method overcomes the charge accumulation effect of the insulating substrate in the electron beam exposal system and realizes the exposal of the nanometer graphics; meanwhile, the prepared undercut structure can extremely effectively assist the subsequent solubilisation process, thus ensuring that the surface nanometer structure is effectively, integrally and precisely realized on the insulating substrate material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

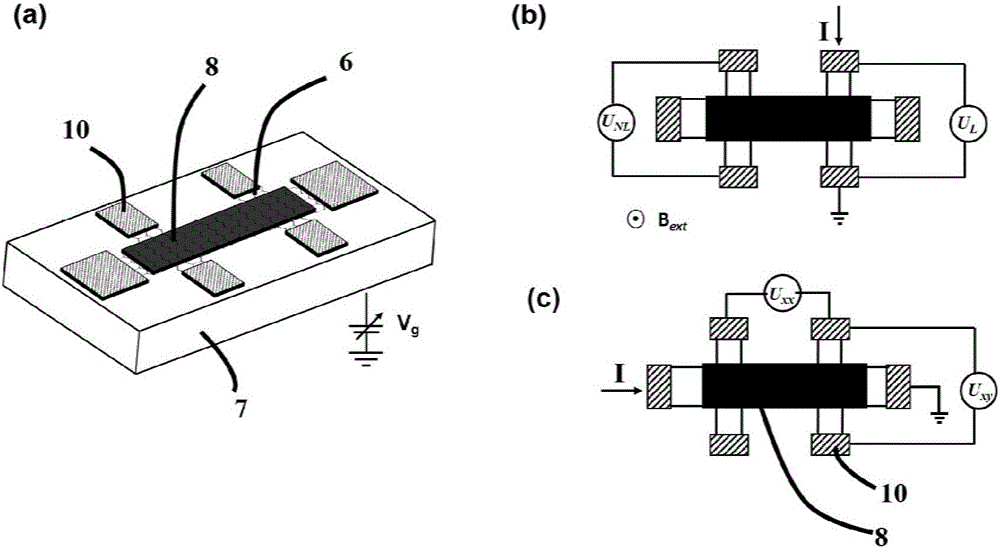

Graphene device capable of realizing spin polarization and preparation method thereof

ActiveCN106449968AFavors spin polarizationAvoid breakingGalvano-magnetic hall-effect devicesGalvano-magnetic device manufacture/treatmentElectron resistsSingle layer graphene

The invention discloses a graphene device capable of realizing spin polarization and a preparation method thereof. According to the graphene device and the preparation method thereof, single-layer graphene is prepared by adopting a micromechanical cleavage method, and a magnetic insulator nanosheet is selected according to the horizontal dimension of the single-layer graphene, and is transferred onto the single-layer graphene to form a magnetic insulator nanosheet / graphene heterogeneous structure through a glass needle of a nanometer micromechanical micromanipulation platform; an electron resist sheet is pressed above the magnetic insulator nanosheet, so that the magnetic insulator nanosheet can be combined with the single-layer graphene more closely, spin polarization of the graphene is facilitated, graphene breakage caused by spin coating can also be prevented, and the yield is improved; the advantages of a nanometer material are combined, so that the coupling effect of the single-layer graphene and the magnetic insulator nanosheet can be conveniently regulated and controlled, and the spin polarization efficiency of the graphene is improved; in addition, the device has the advantages of low cost, high yield and easiness for popularization, and the aim of convenient, efficient and flexible operation is fulfilled.

Owner:PEKING UNIV

A method for preparing the nano-electrode with the negative electronic erosion-resisting agent

InactiveCN101017778APhotomechanical apparatusSemiconductor/solid-state device manufacturingCooking & bakingElectron resists

The preparation method for nano electrode comprises: growing well-conductive metal or semiconductor layer; using EBL to obtain a couple or group negative electronic anti-corrosive agent, and coating the agent; first baking; with electron beam to direct expose; developing, fixing, etching, and stripping the photoresist. The product has 20-100nm space and fit to wide application. This invention is simple and reliable, and compatible with traditional CMOS technology.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

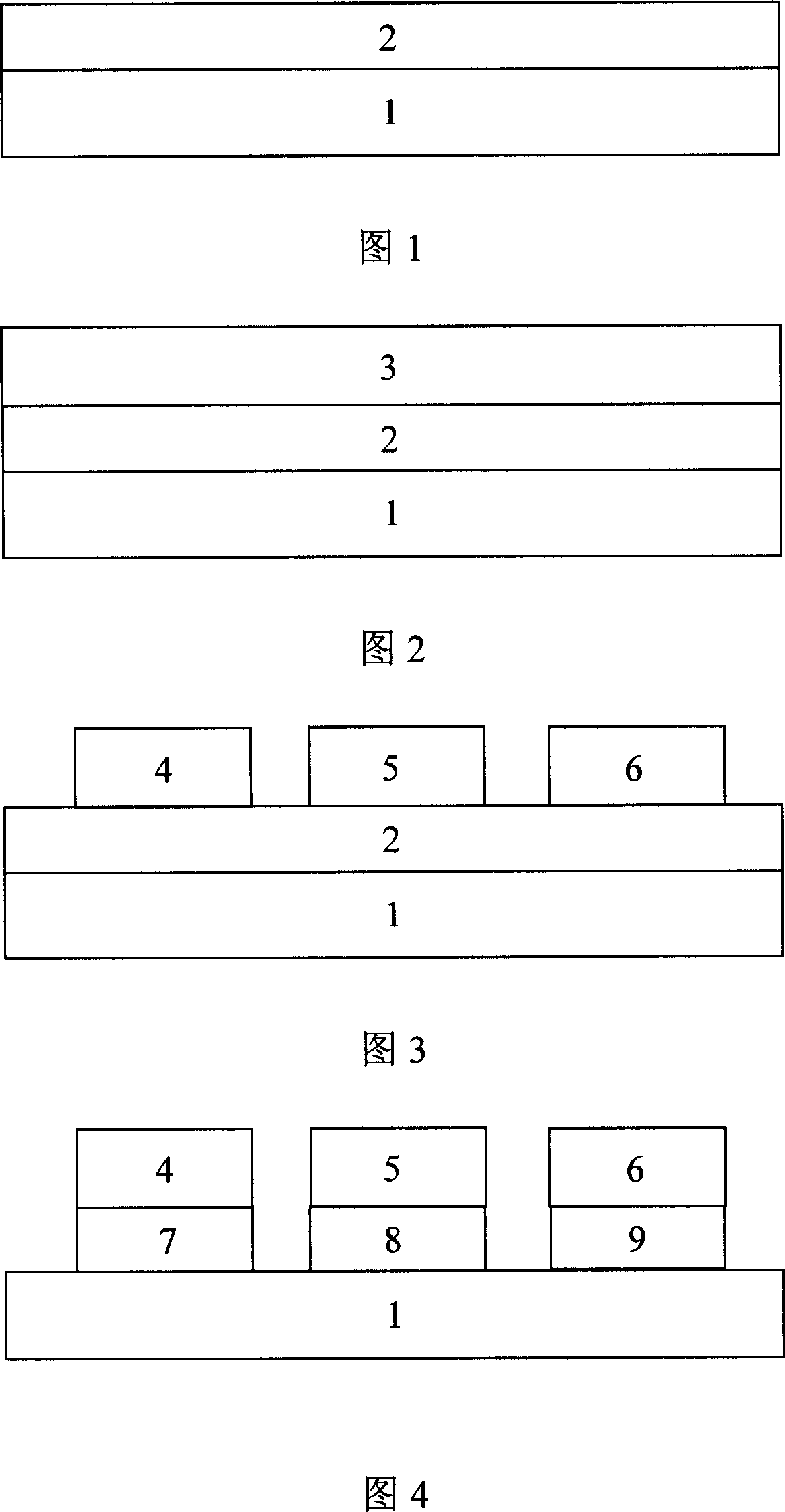

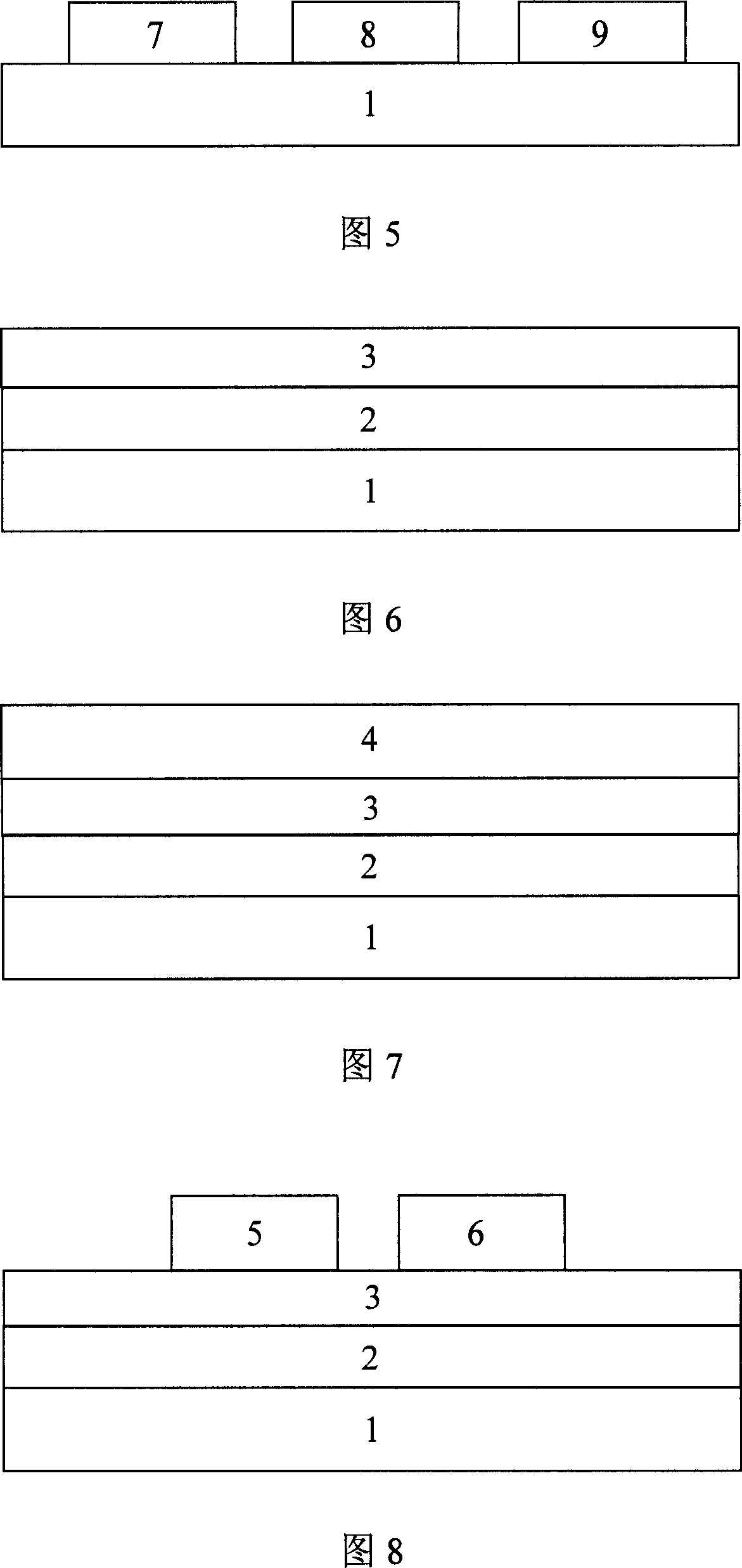

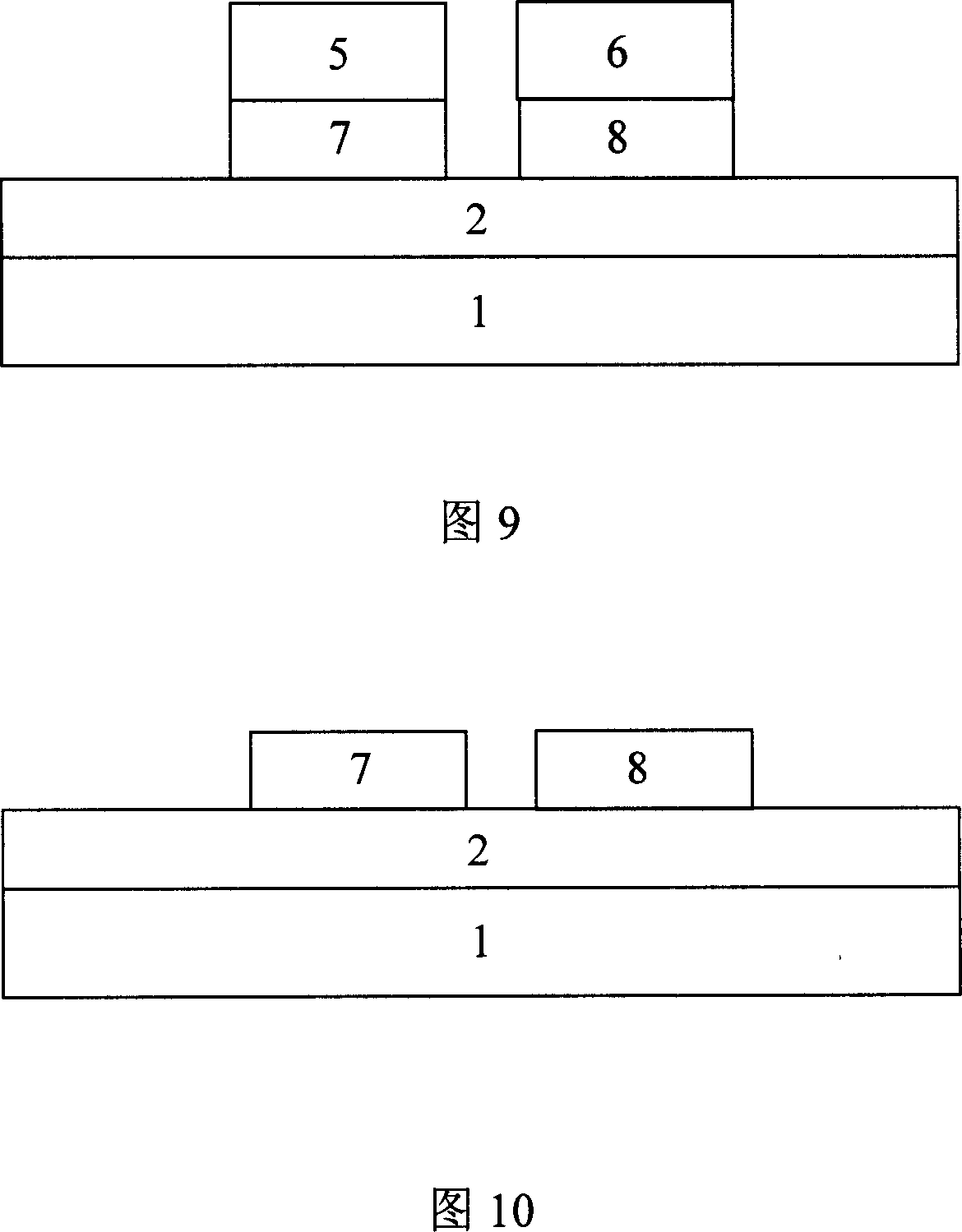

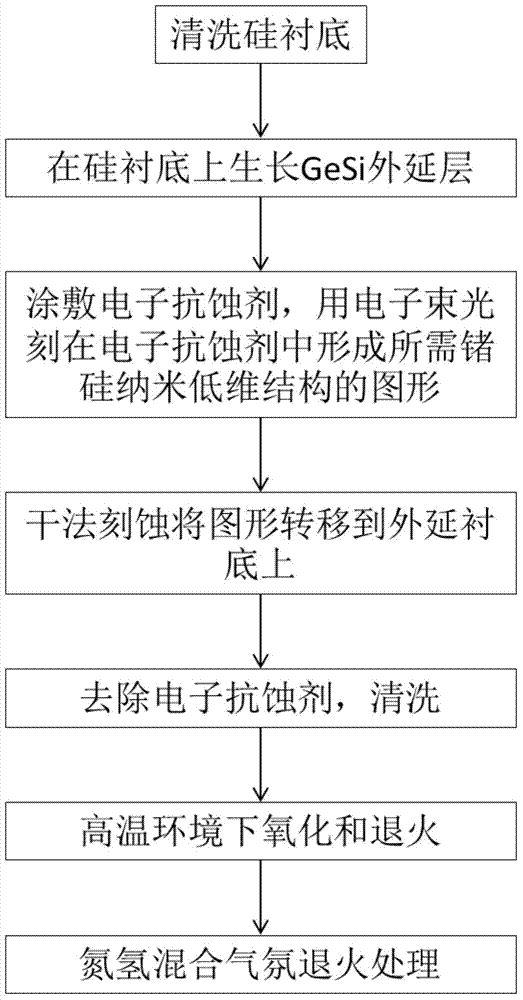

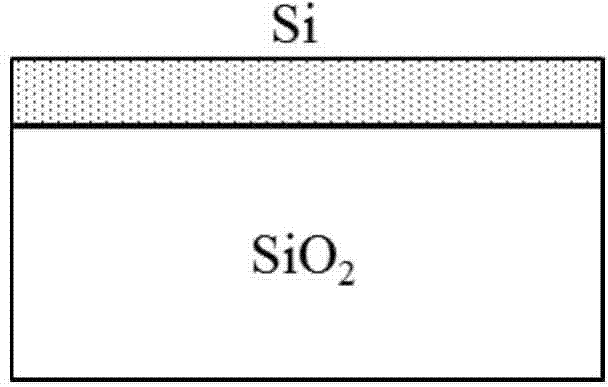

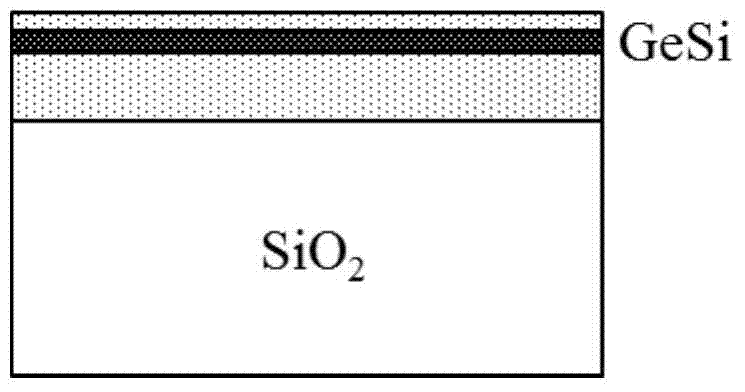

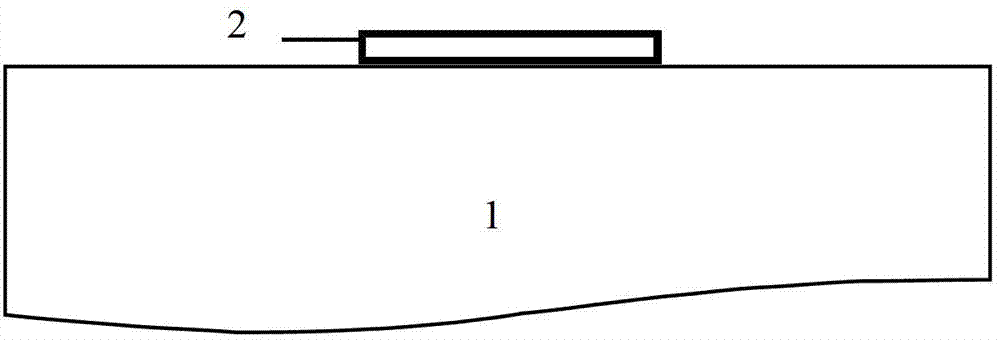

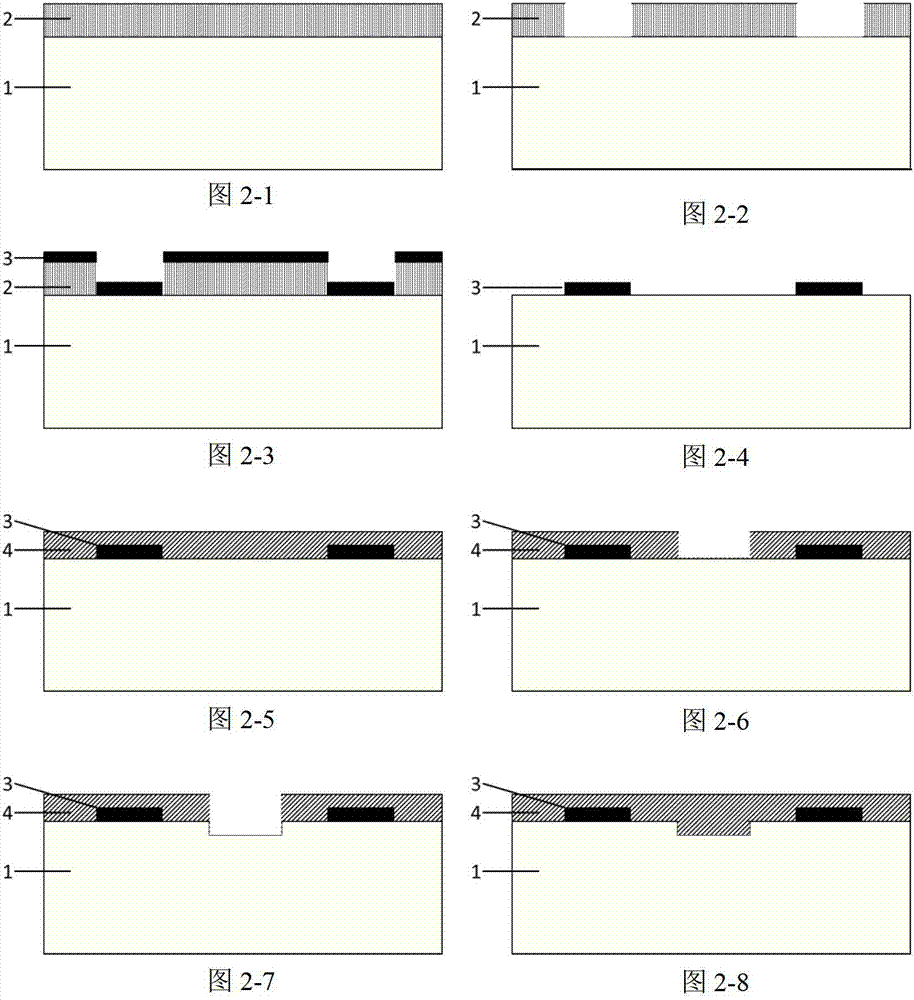

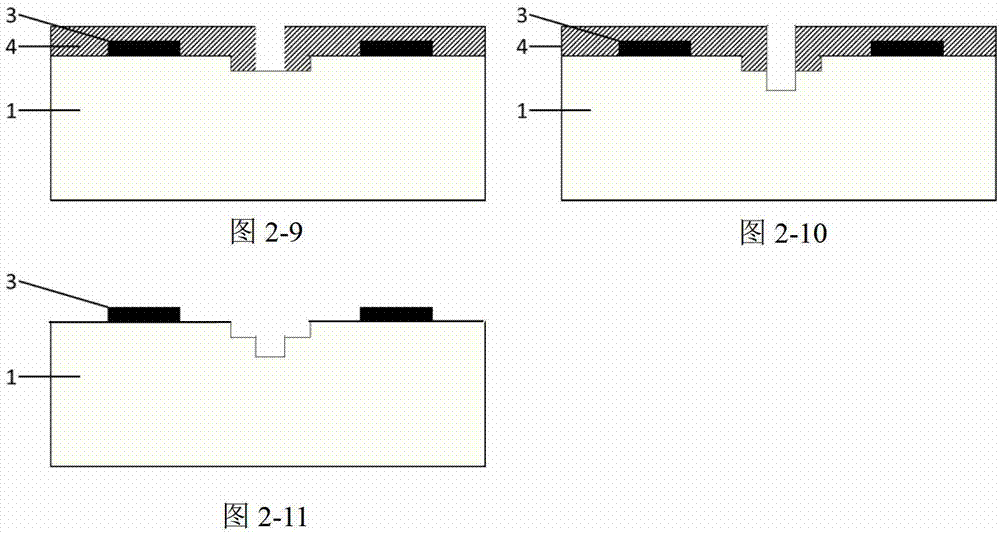

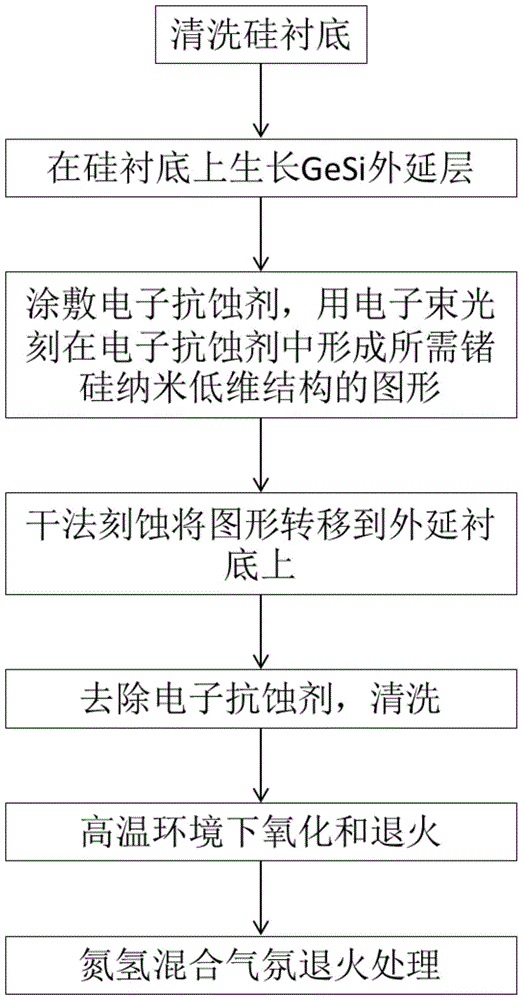

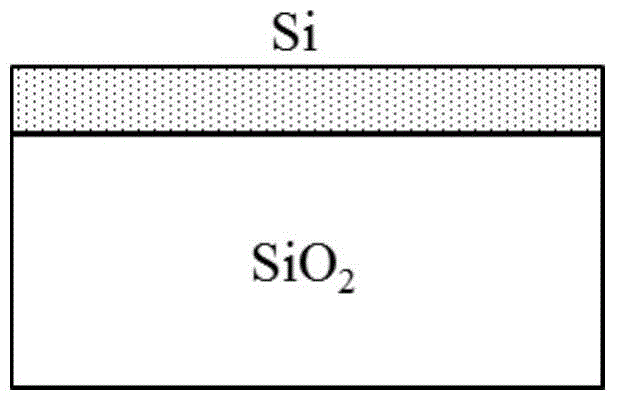

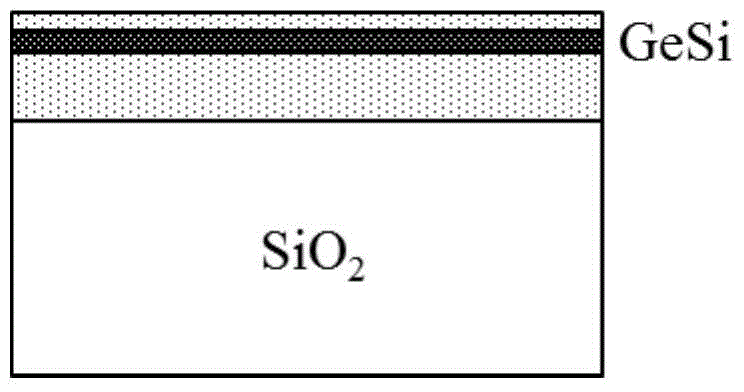

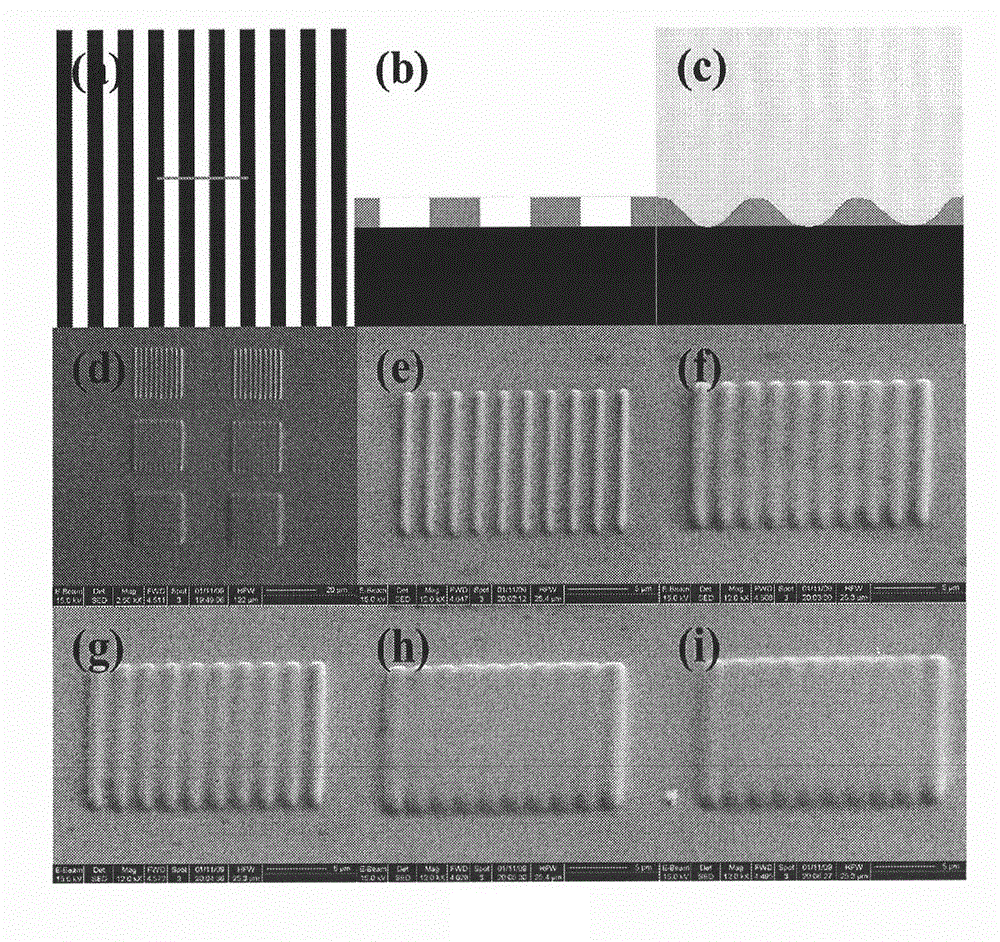

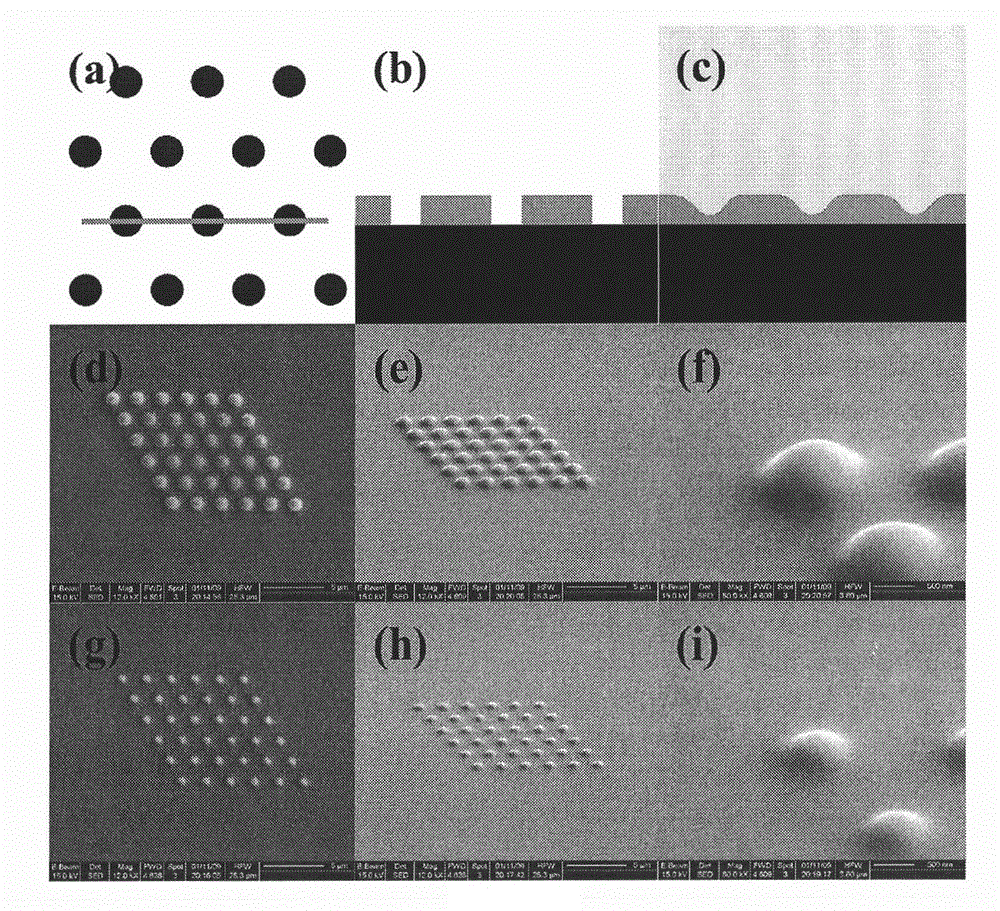

Controllable preparation method of germanium-silicon nano lower-dimension structure and germanium-silicon nano lower-dimension structure

InactiveCN103928297AReduce horizontal sizeLarge horizontal sizeSemiconductor/solid-state device manufacturingNanotechnologyResistElectron resists

The invention discloses a controllable preparation method of a germanium-silicon nano lower-dimension structure and the germanium-silicon nano lower-dimension structure. The controllable preparation method comprises the following steps of (a) cleaning a silicon substrate; (b) forming germanium-silicon alloy on the silicon substrate in an epitaxial growth mode to form an epitaxial substrate; (c) spreading electron resist and exposing the required germanium-silicon nano lower-dimension structure graph on the electron resist through the electron beam photolithography; (d) transferring the germanium-silicon nano lower-dimension structure graph to the epitaxial substrate through dry etching to obtain a sample; (e) removing the electron resist on the sample; (f) performing oxidation and anneal under a high-temperature environment to enable oxygen to react with silicon preferentially to form silicon oxide and germanium to be separated out; (g) performing anneal in a nitrogen and hydrogen mixing atmosphere to form the germanium-silicon nano lower-dimension structure. By means of the controllable preparation method, controllable preparation of the germanium-silicon nano lower-dimension structure in dimension, shape, position and component is achieved. Furthermore, the controllable preparation method has the advantages of being low in process difficulty, high in repeatability and capable of performing large-scale integration easily.

Owner:HUAZHONG UNIV OF SCI & TECH

Electron beam aligning mark based on hafnium oxide and manufacturing method of mark

InactiveCN102969302AReduce manufacturing costHigh melting pointSemiconductor/solid-state device detailsSolid-state devicesElectron resistsResist

The invention discloses an electron beam aligning mark based on hafnium oxide, which belongs to the field of micro and nano fabrication of a semi-conductor device. The electron beam aligning mark based on hafnium oxide comprises a substrate and a hafnium oxide thin film mark plated on the substrate. The invention further provides a manufacturing method which specifically comprises the steps of: (1) cleaning the substrate; (2) carrying out spin coating of an electronic resist on the substrate and forming a pattern array with an aligned mark in the electronic resist through an electron beam photolithography technique; (3) evaporating hafnium oxide thin films on the electronic resist and the substrate; and (4) peeling the hafnium oxide thin films attached to the positive electronic resist to obtain the hafnium oxide mark. The aligned mark obtained by the electron beam lithography is prepared by using hafnium oxide which is high temperature resistive, good in adhesion and low in cost. Compared with the conventional 'titanium+gold' marks, the process cost is reduced, the problem that the gold mark and the Si substrate are not adhered well is solved, the adhesion and high temperature bearing capacity of the aligned mark to the substrate are improved, and the higher aligning precision is maintained.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for adopting positive electronic corrosion-resistant to prepare metal nano electrode

ActiveCN1979768APhotomechanical apparatusSemiconductor/solid-state device manufacturingResistElectron resists

A method uses the positive electron anticorrosion agent to prepare metal nano electrode. The main features of the invention is to use the neighboring effect of electron band, use the EBL to gain a pair or a group of the positive electron anticorrosion agent groove figures that have line, hole and other various shapes at the space that is measured by nano on various underlay, and then use secondly the metal deposition and peel off technology to prepare various metal material nano electrode. The main procedures of which include coating the positive electron anticorrosion agent on the interlay; baking frontally; expose by direct electron band; develop; to fix; vaporize or sputtering metal; to peel off in the acetone. The distance between the metal nano electrode that is prepared by such method can be 30~100mm, is suitable to make various quanta component, nano line, nano tube component, single electronic component and various components or circuit. The method has many advantages, such as: less technology procedure, simple, stable and reliable, multiple uses and can be compatible with the traditional CMOS technology.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

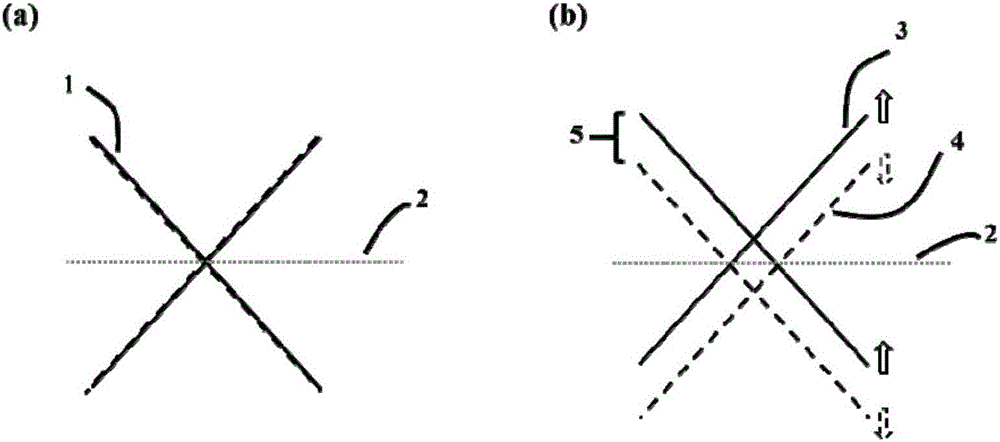

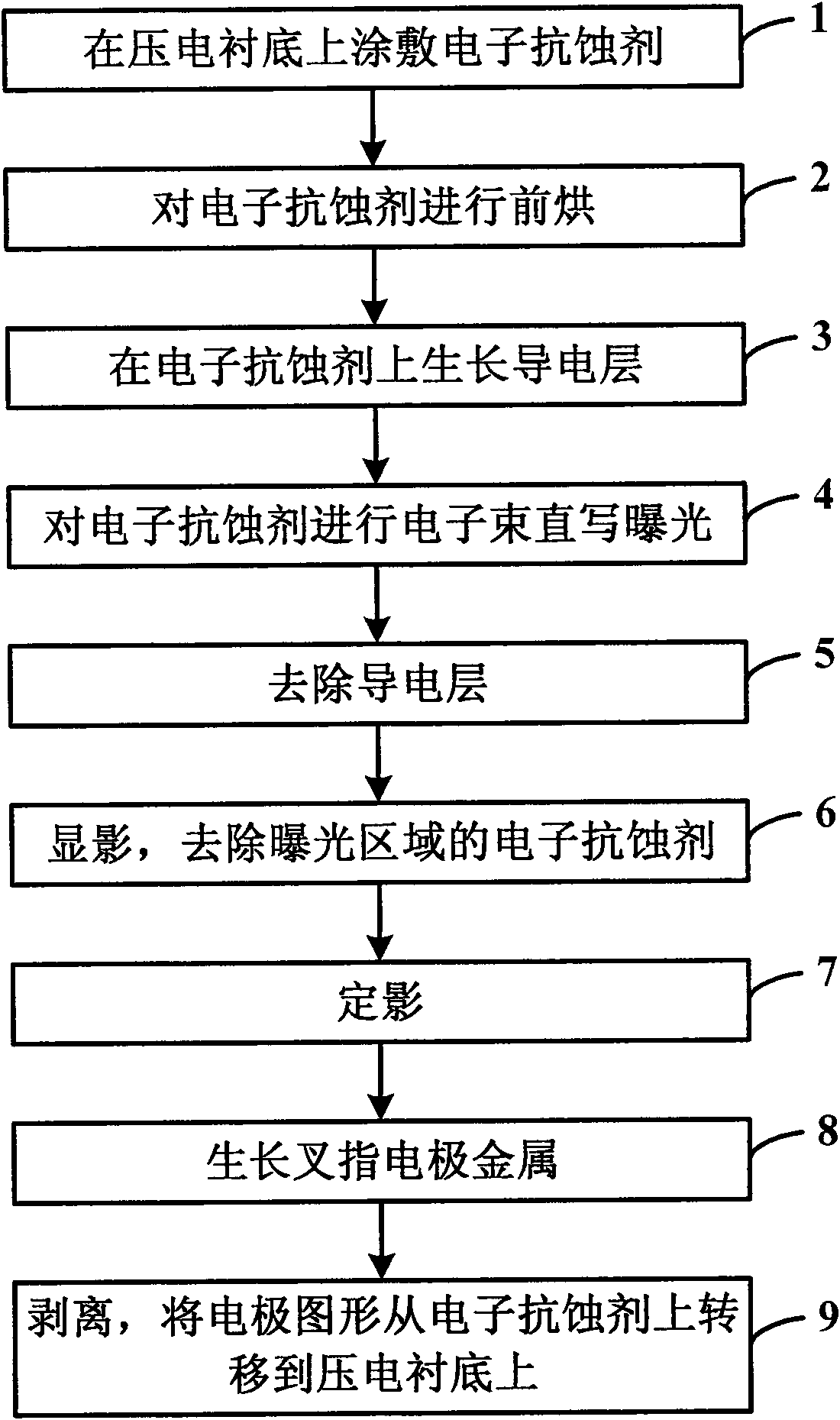

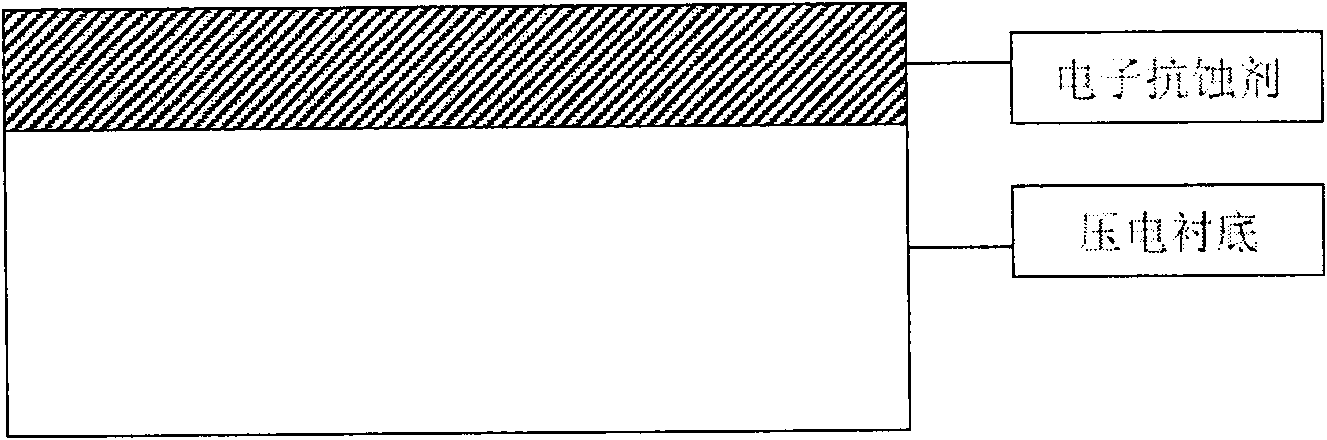

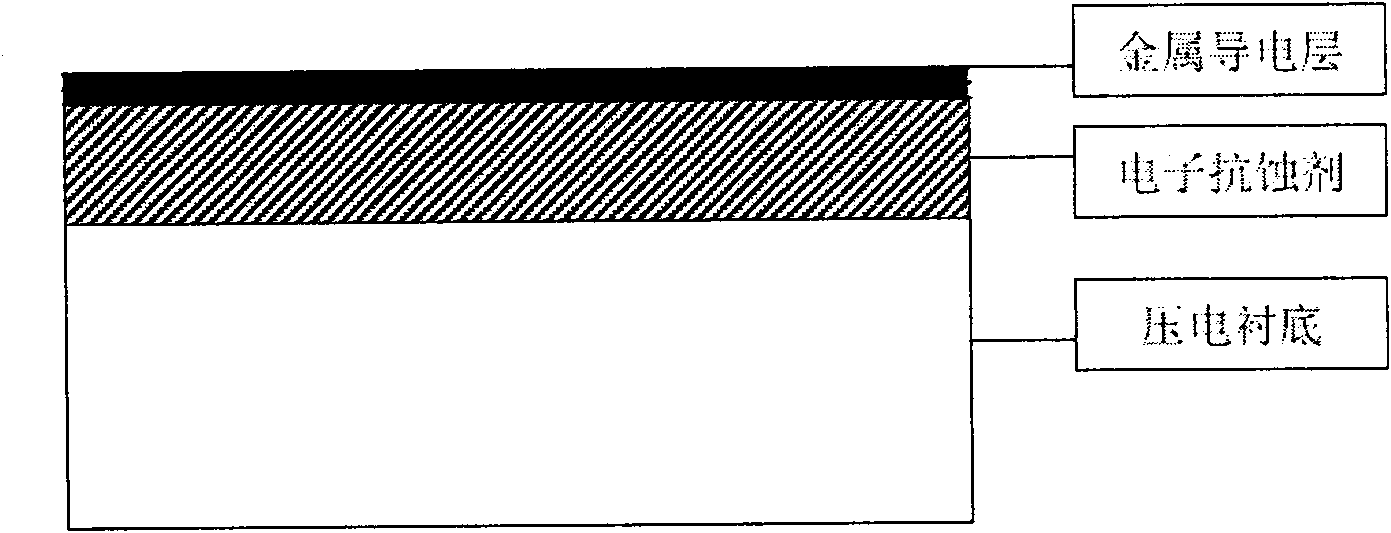

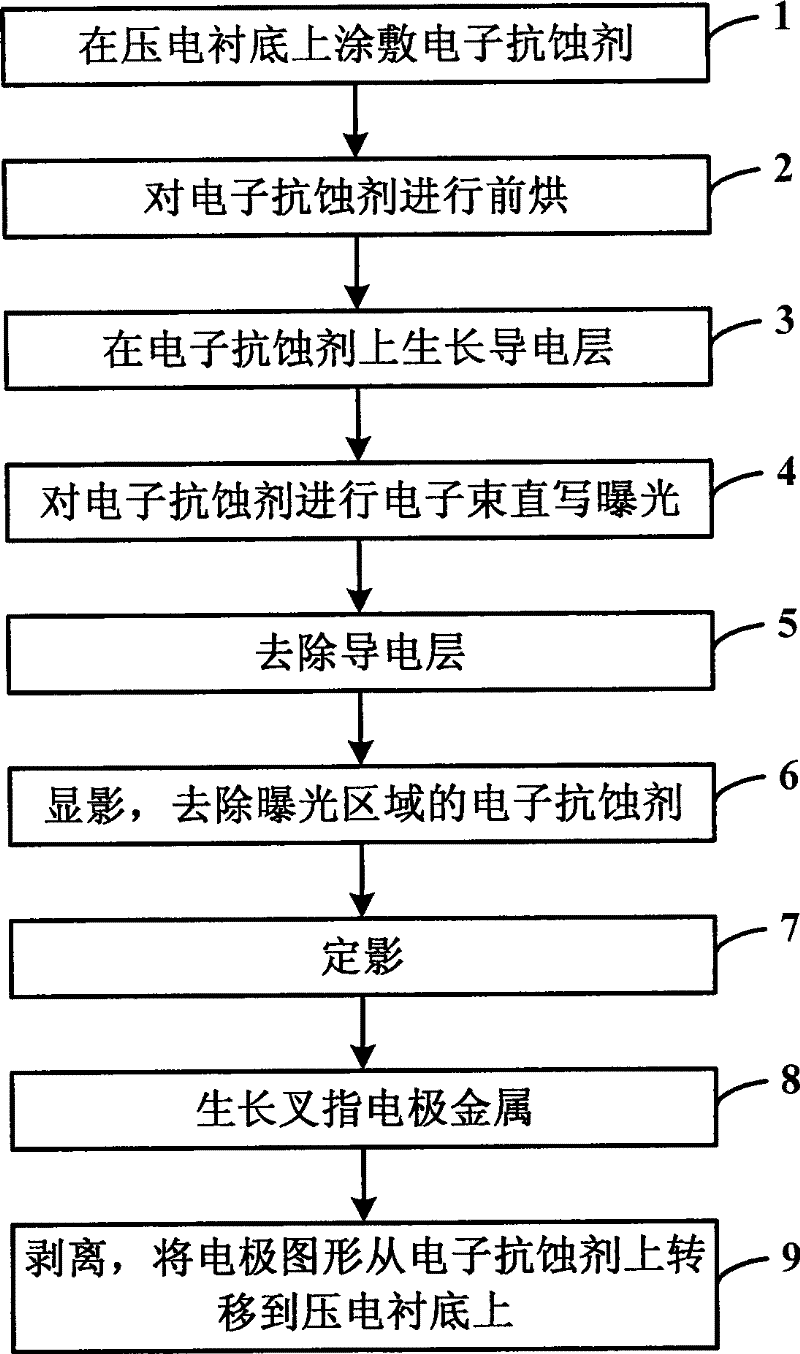

Method of producing surface acoustic wave devices by exposing X-rays in a direct writing way

ActiveCN101676797ASteep edgeGood width controlPhotomechanical exposure apparatusPhotosensitive material processingResistElectron resists

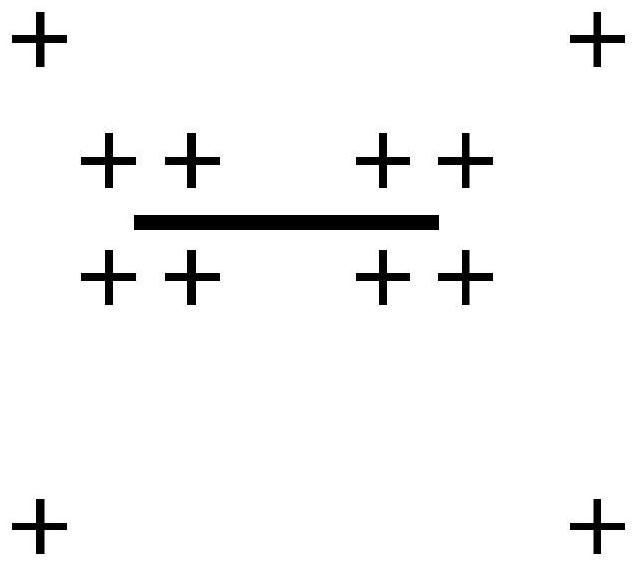

The invention discloses a method of producing surface acoustic wave devices by exposing X-rays in a direct writing way. Electron beam resist concave solid figures of an interdigital transducer are obtained by photoetching electron beams on a piezoelectric substrate, and various surface acoustic wave devices are produced with the stripping technology. The method of producing surface acoustic wave devices by exposing X-rays in a direct writing way comprises the following concrete steps: spreading the electron beam resist on the piezoelectric substrate; prebaking the electron beam resist; growingmetal material which has weak back scattering effect on the electron beam exposure; exposing the electron beams in a direct writing way; removing the metal layer; developing the electron beam resist;fixing the electron beam resist; growing interdigital electrode metal and stripping a beam resist masking film. An interdigital electrode produced with the method has steep and straight edges and good width control, and the method can be used for producing the surface acoustic wave devices which have the characteristic linewidth of less than 500nm. The method needs less process steps and is simple, stable and reliable.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

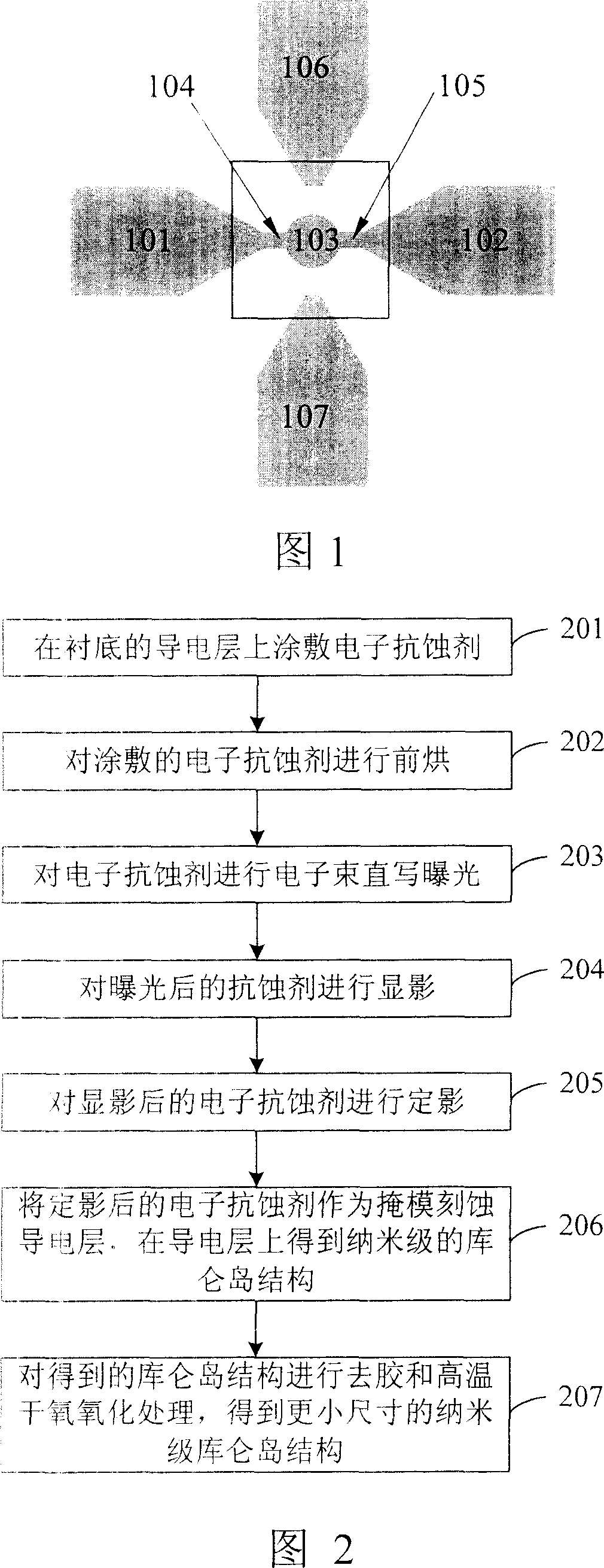

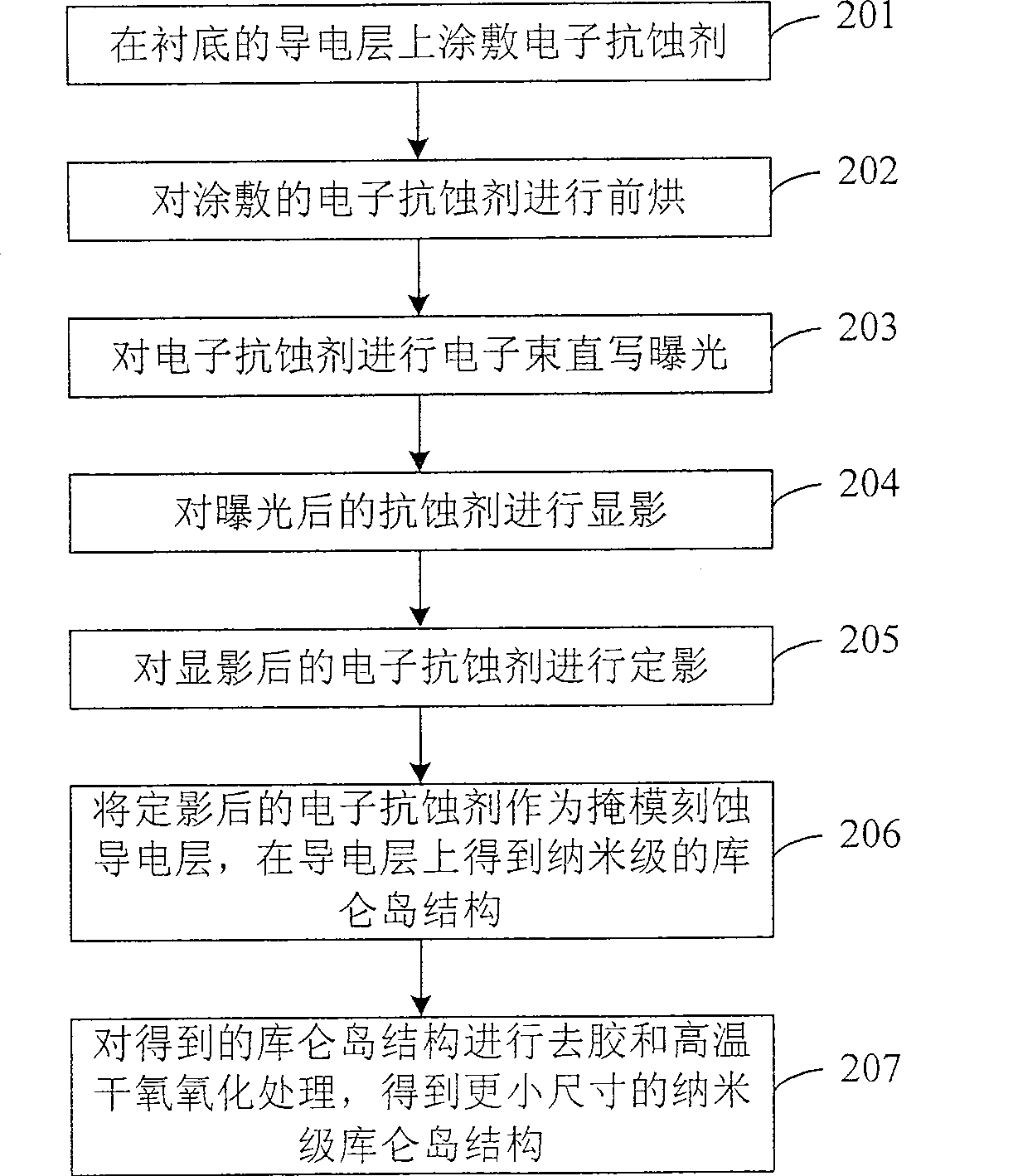

A making method for nano coulomb structure

InactiveCN101086966AImprove reliabilitySimple manufacturing processPhotomechanical apparatusSemiconductor/solid-state device manufacturingCMOSResist

The invention discloses a preparing method of nanometer-class coulomb island structure, it includes: A. smearing electron slushing compound on conducting layer of underlay; B. baking the electron slushing compound; C. electron beam exposing the electron slushing compound; D. imaging the electron slushing compound exposed; E. fixing the electron slushing compound imaged; F. process of glue-eliminating and high temperature oxidation is proceeded to coulomb island structure obtained to obtain nanometer-class coulomb island structure whose size is more smaller. With the invention, preparing craftwork is simplified, cost is decreased, efficiency is increased, and reliability of coulomb island structure is increased. The preparing method provided in the invention possesses advantages that it is compatible with traditional CMOS, fits for the extending and application.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

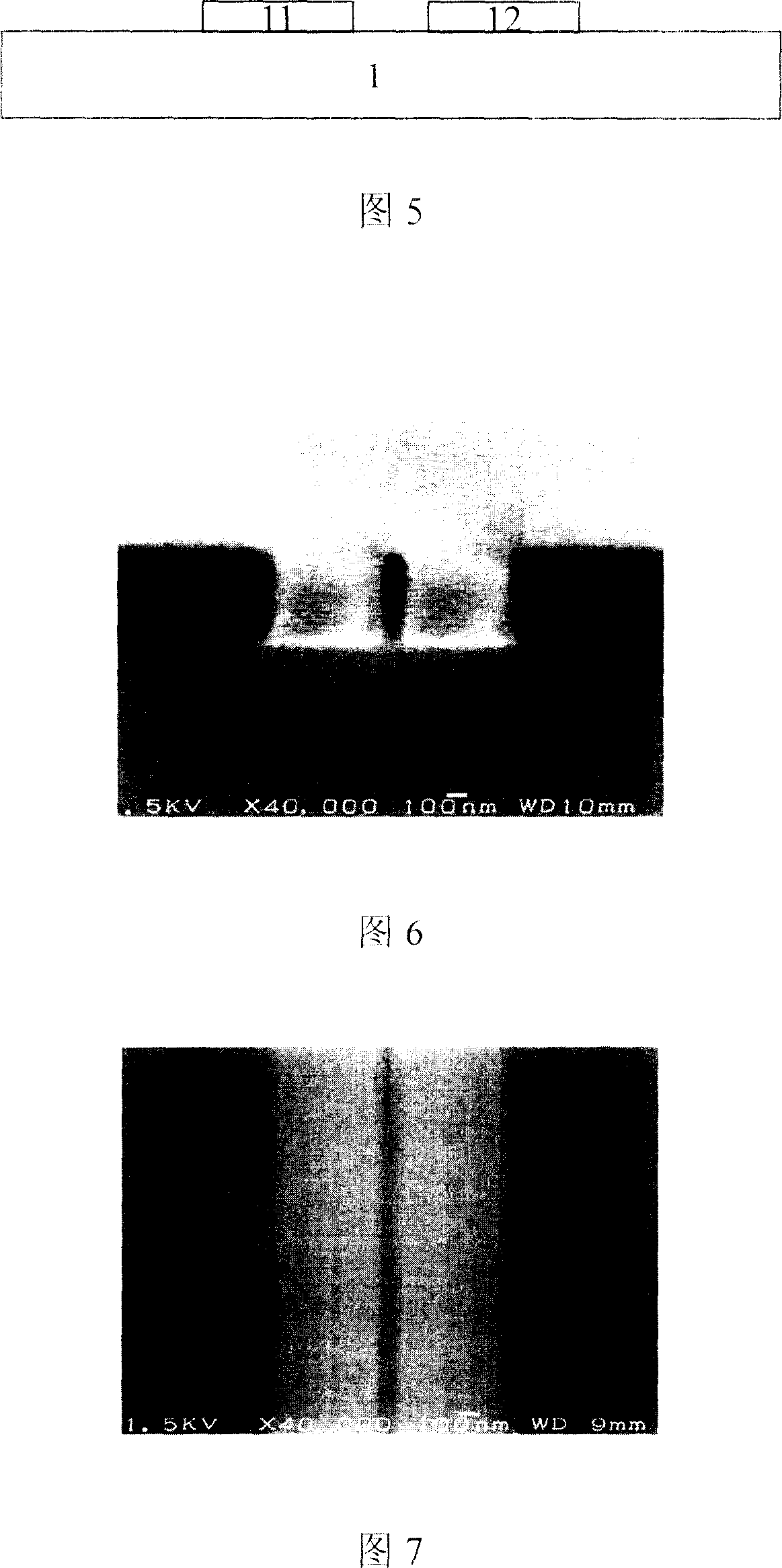

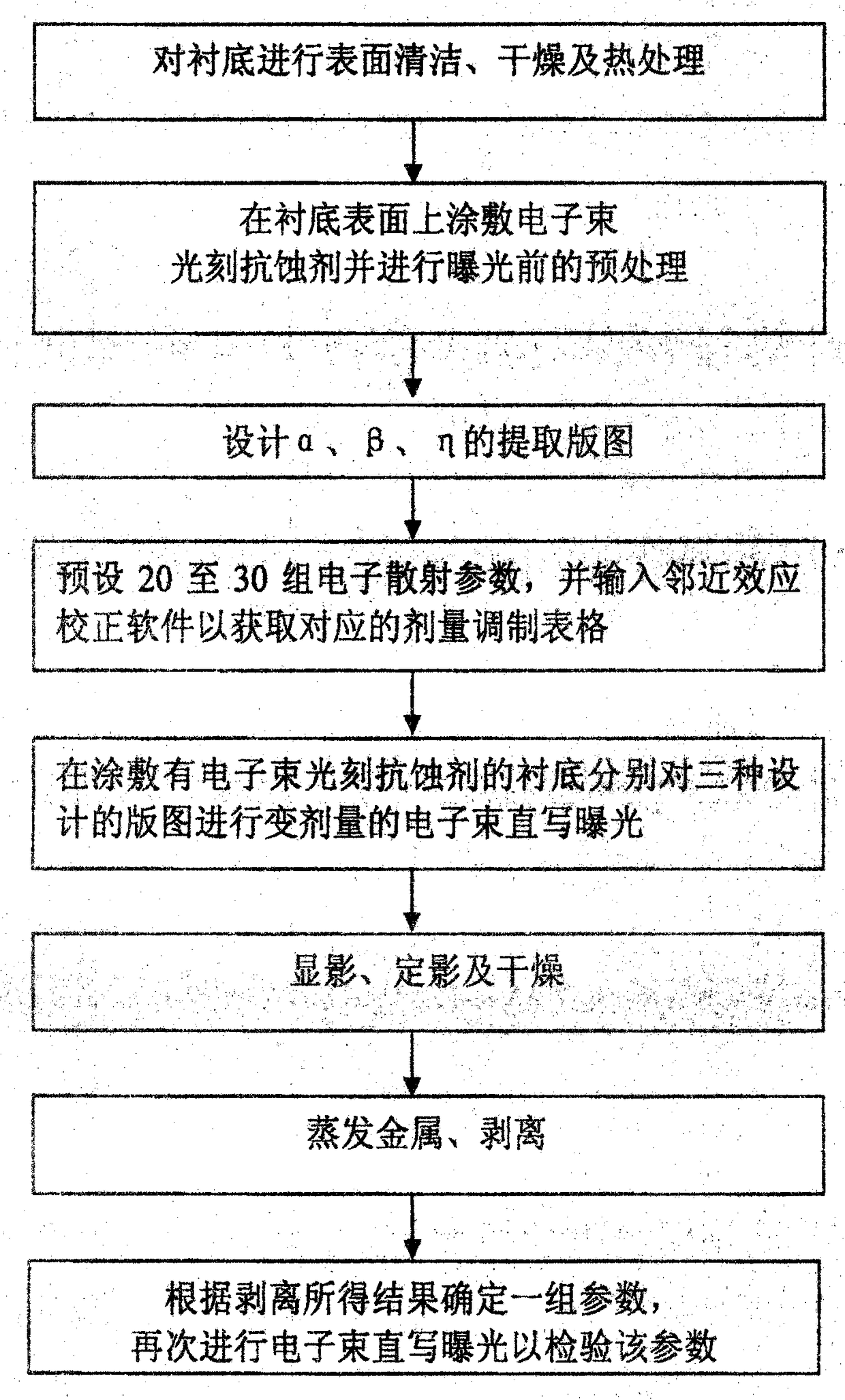

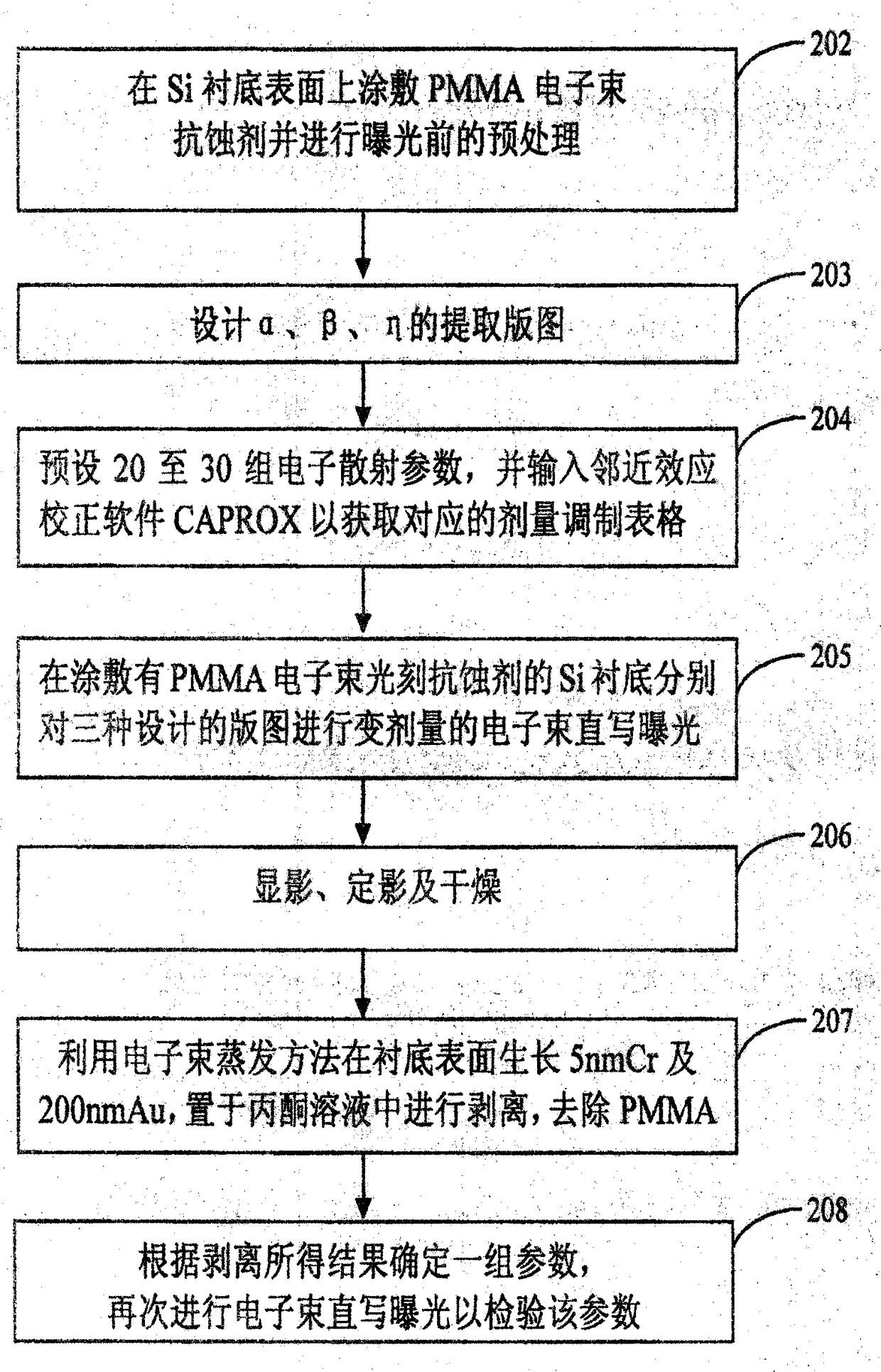

Method for extracting electron-beam exposure scattering parameter

ActiveCN101510050AExtraction is accurate and easyReduce mistakesSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusObservational errorElectron resists

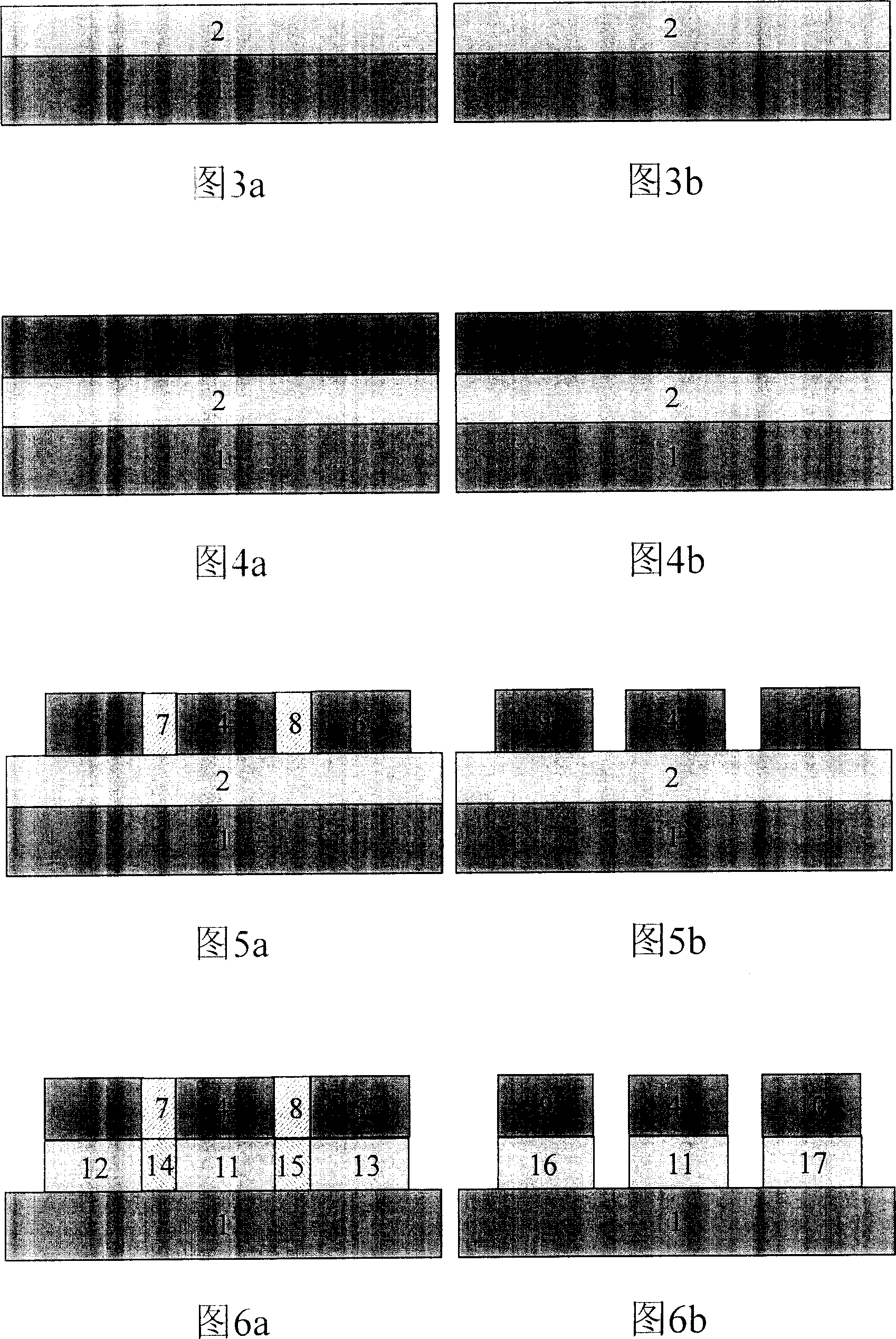

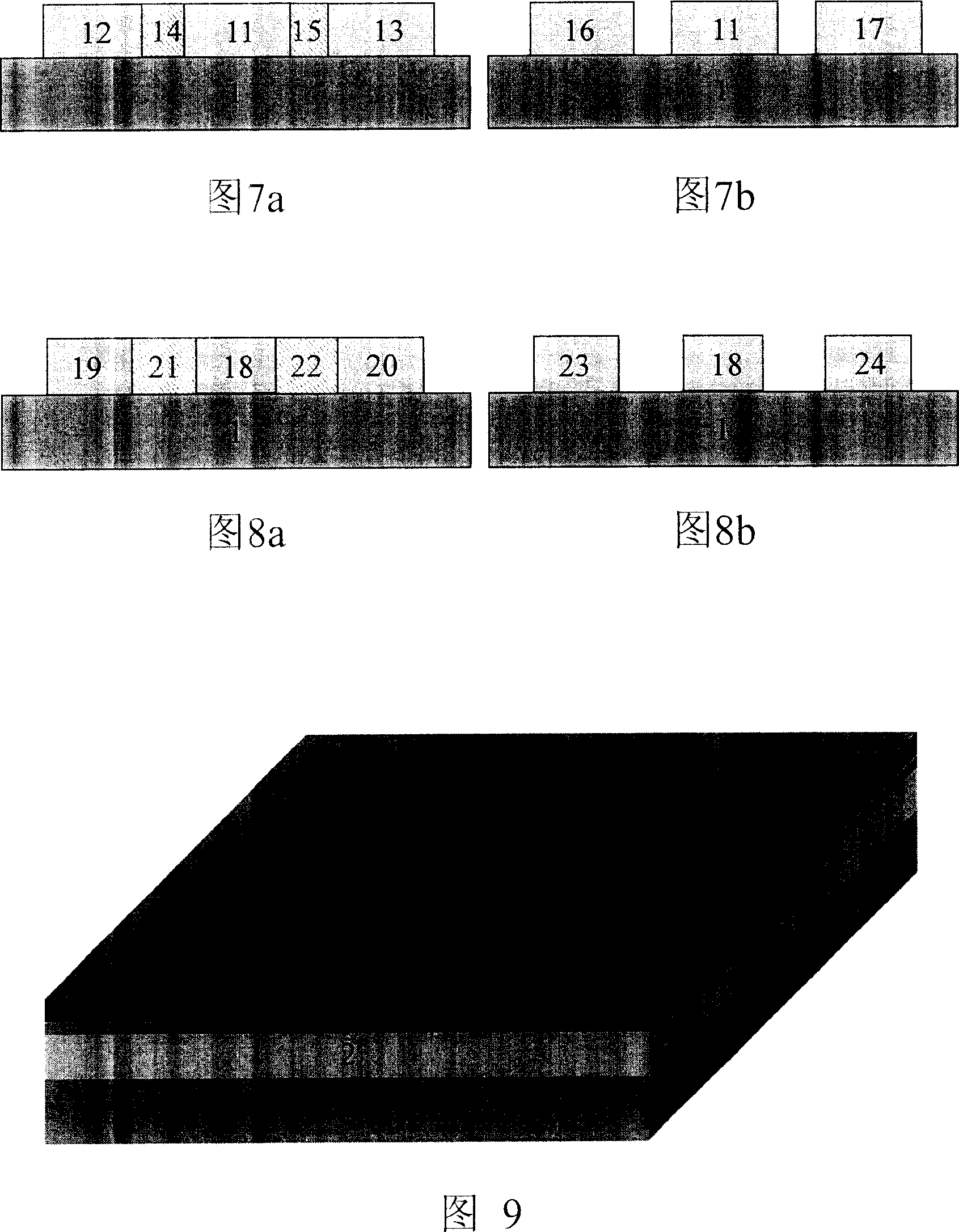

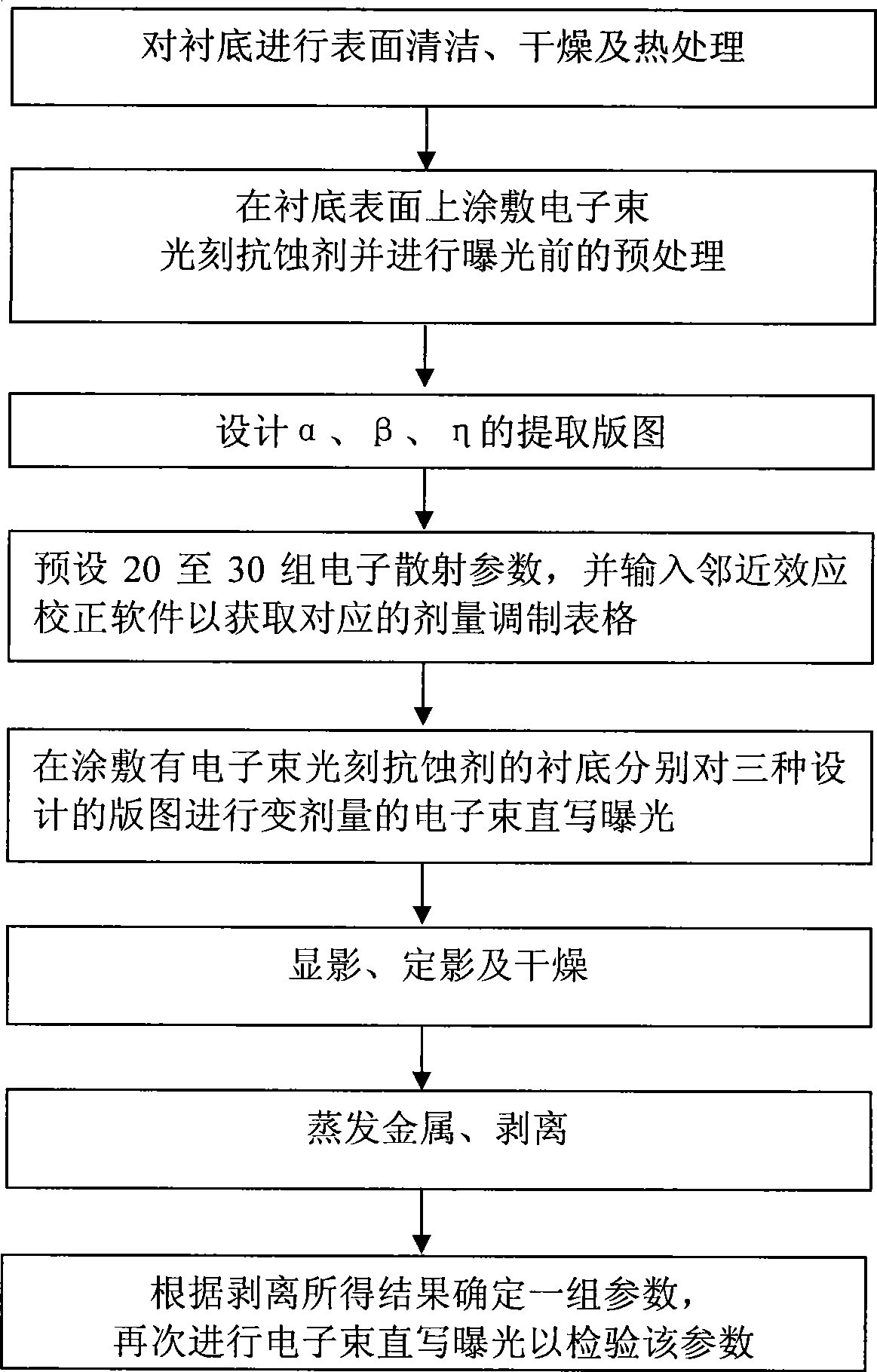

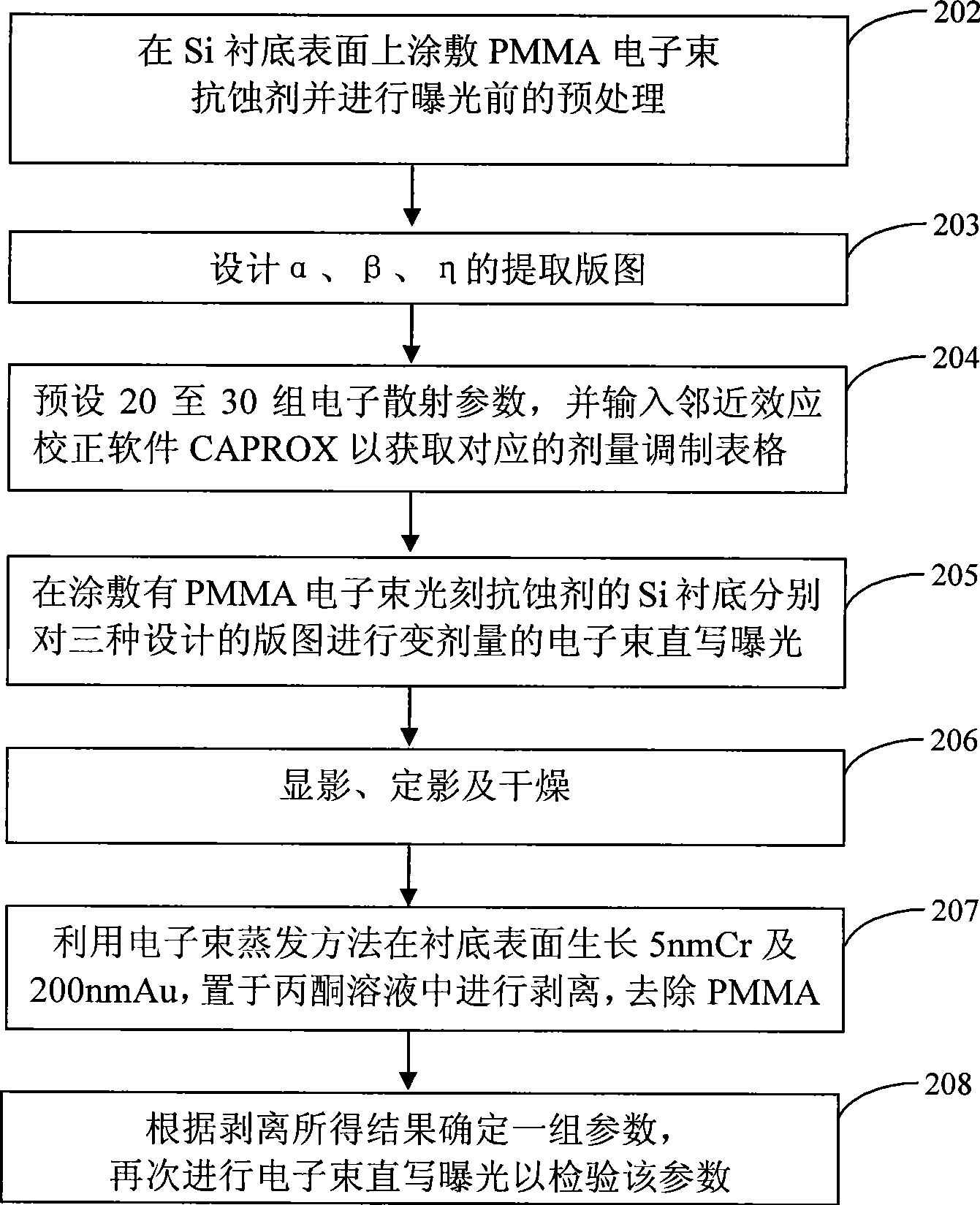

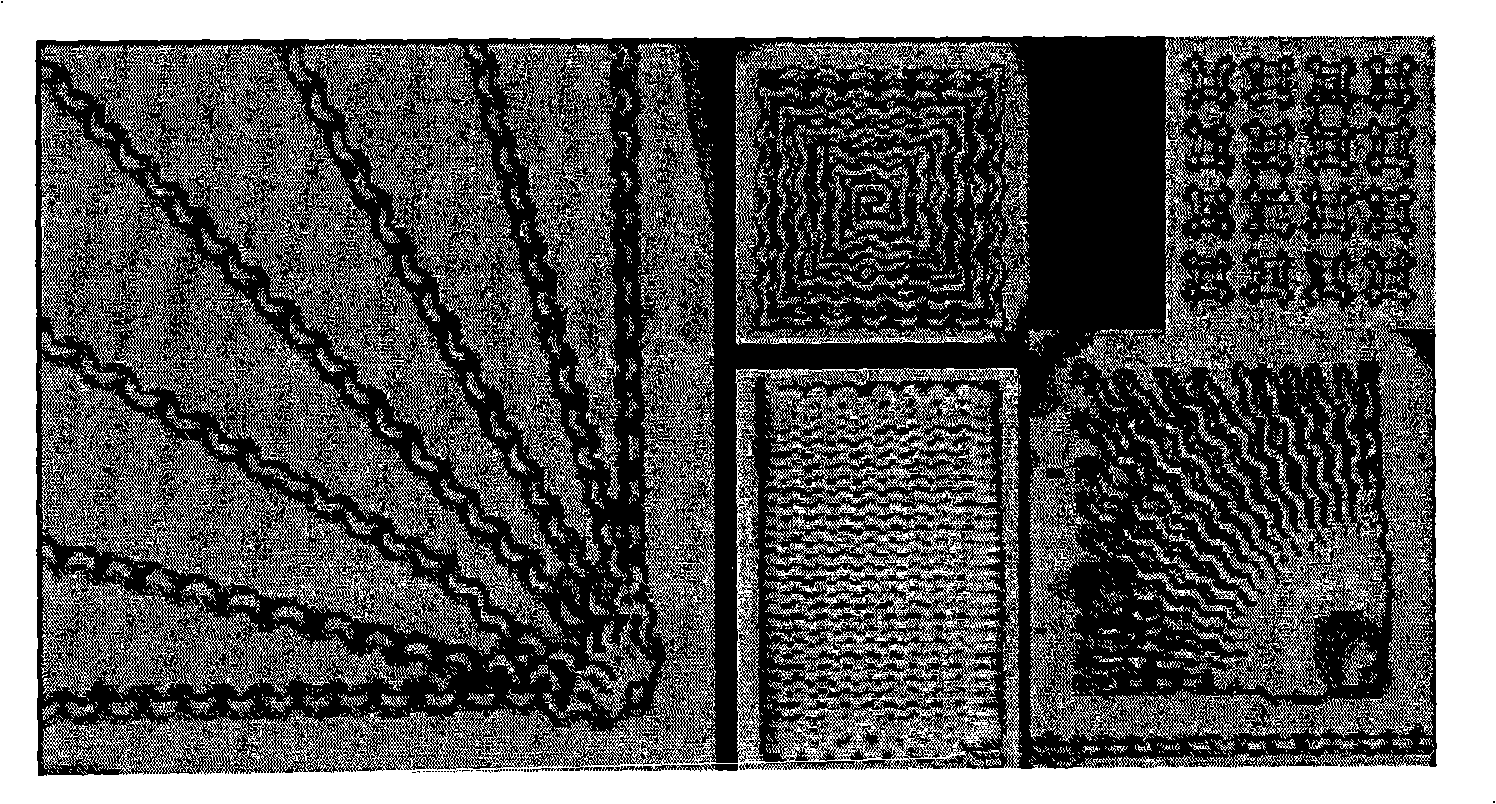

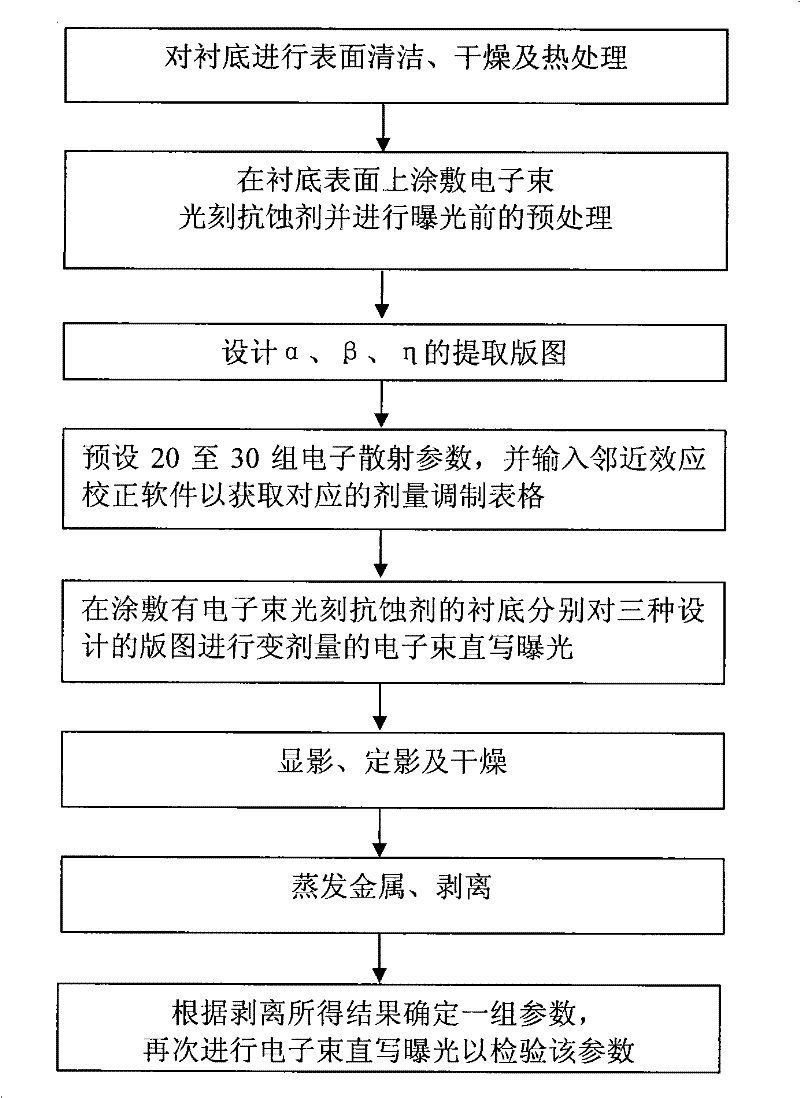

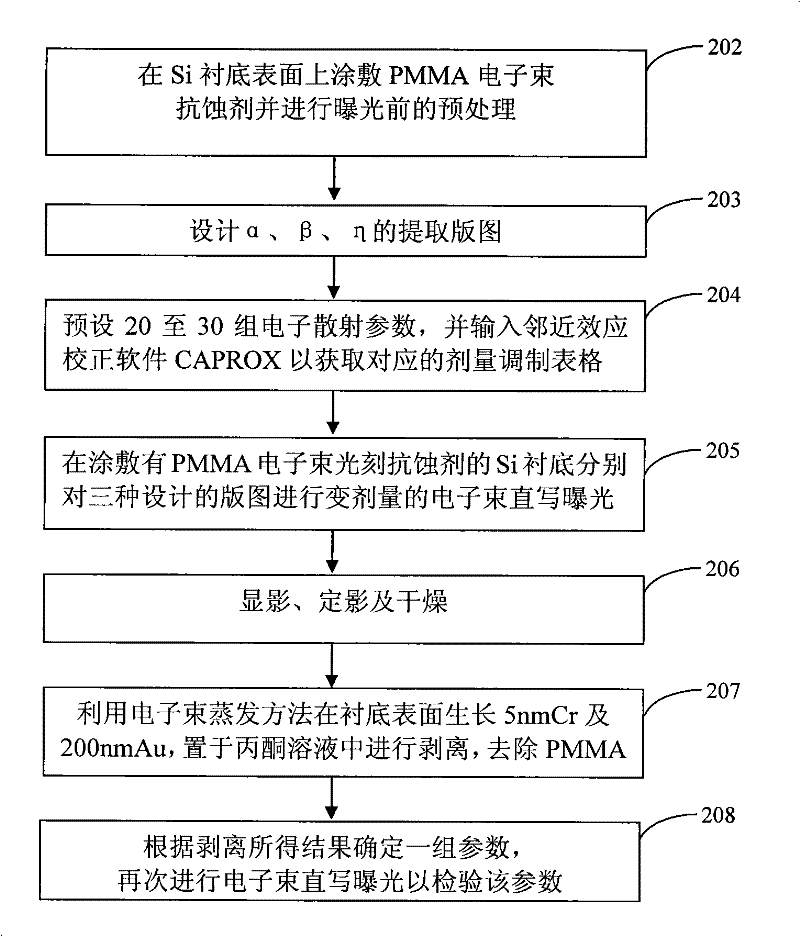

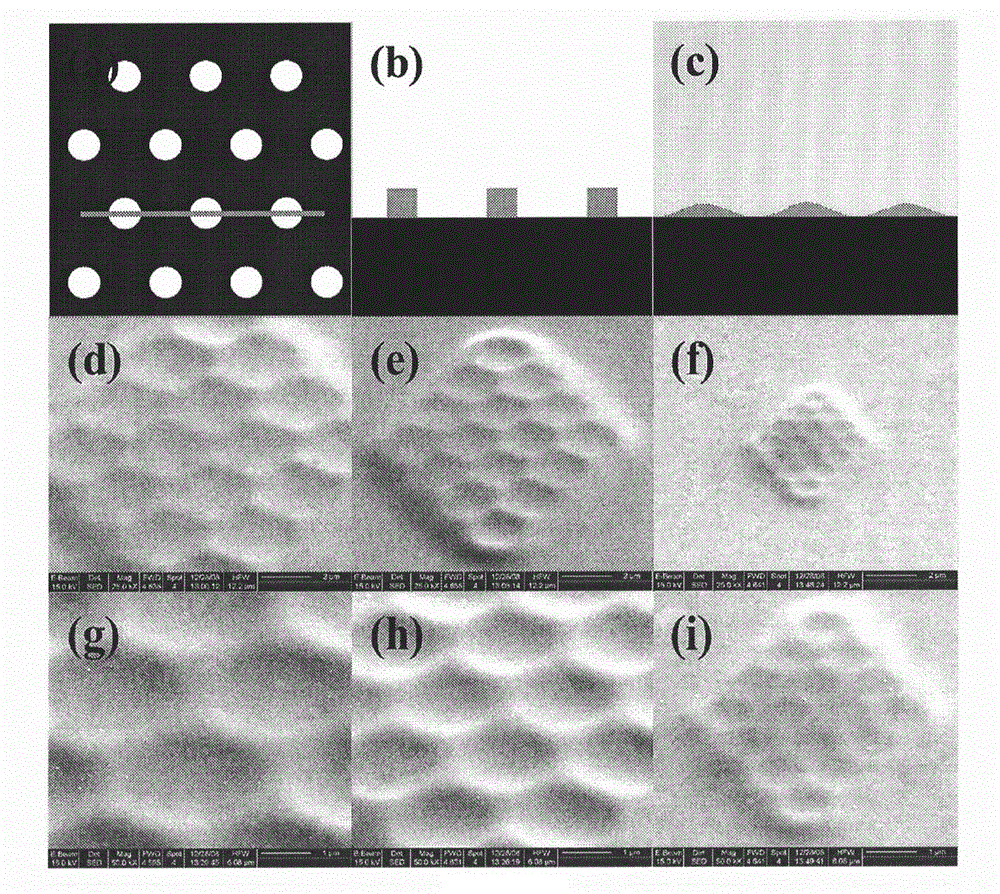

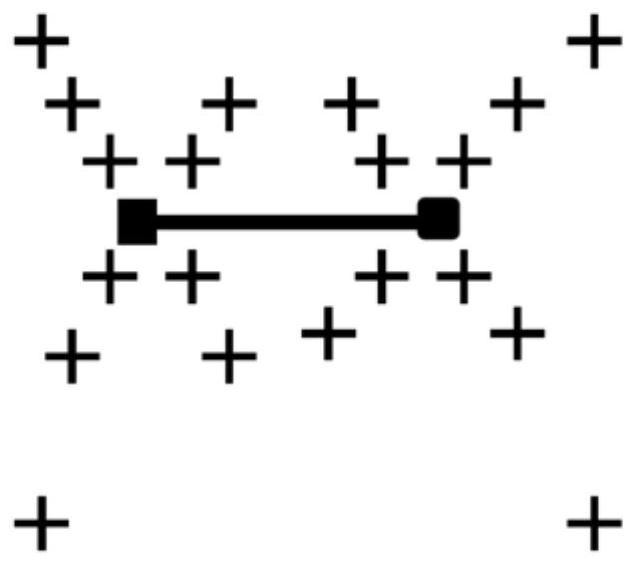

The invention relates to a method for extracting an electron beam lithography scattering parameter. In order to solve the problems of complex operation and difficult guarantee for the accuracy in the existing method for extracting the electron beam lithography scattering parameter, the invention provides the method for extracting the electron beam lithography scattering parameter. According to the electron beam resist agent for parameter extraction and the substrate structure characteristics, the method designs a suitable front-scattering parameter Alpha, a back-scattering parameter Beta, and an extracting version map of Gama which is the ratio of the back-scattering deposition energy and the front-scattering deposition energy; and then electron beam direct writing lithography of variable doses for three types of design version maps is carried out on the electron beam resist agent and the substrate structure; and finally, according to a plurality of groups of different parameter lithography, development and the stripped graph structure features, a group of suitable scattering parameters are determined. The invention does not need large amount of complex measurement, therefore, no measurement error exists, the error caused by mathematical treatment is reduced, and the parameter extraction is led to be accurate, simple and feasible.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

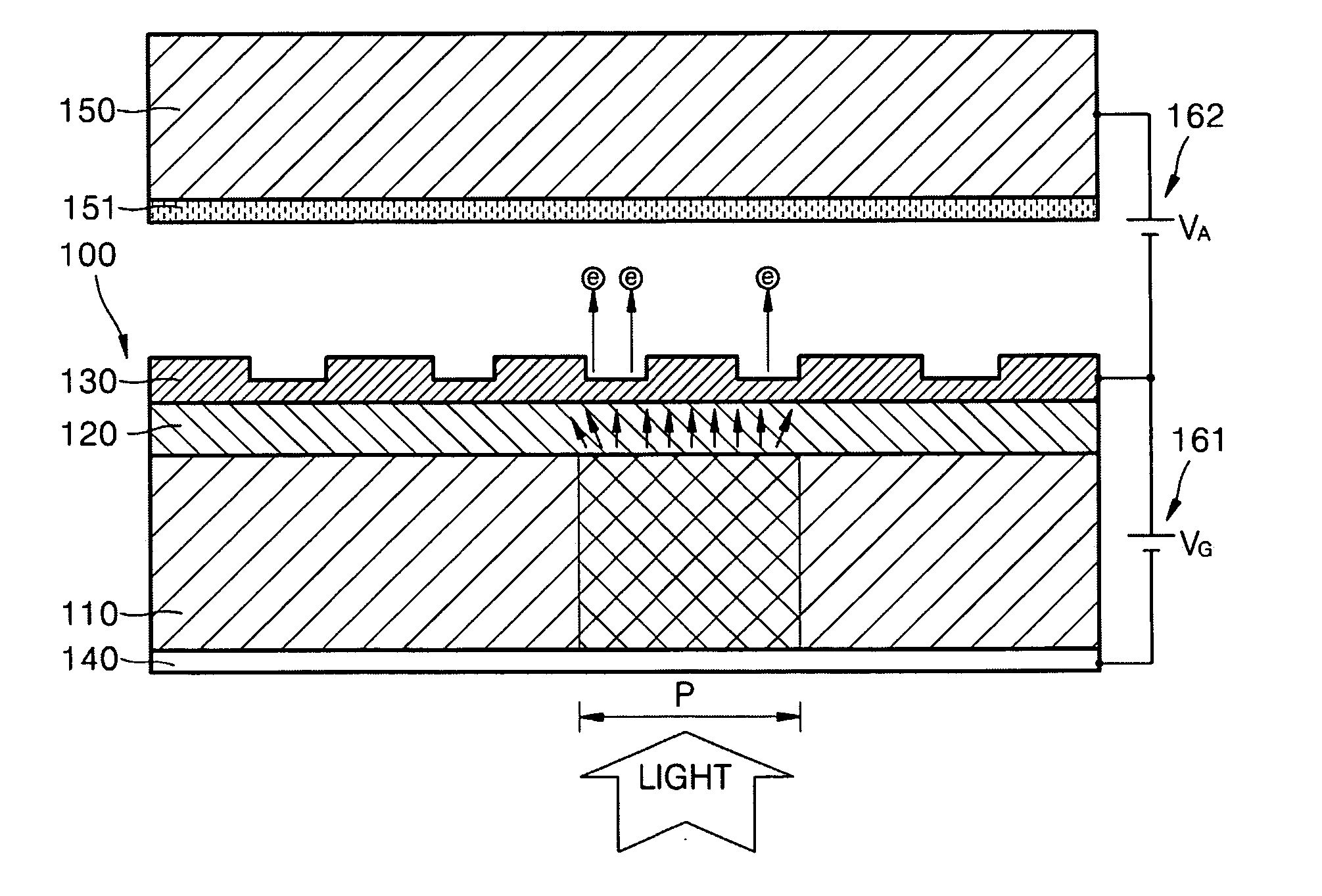

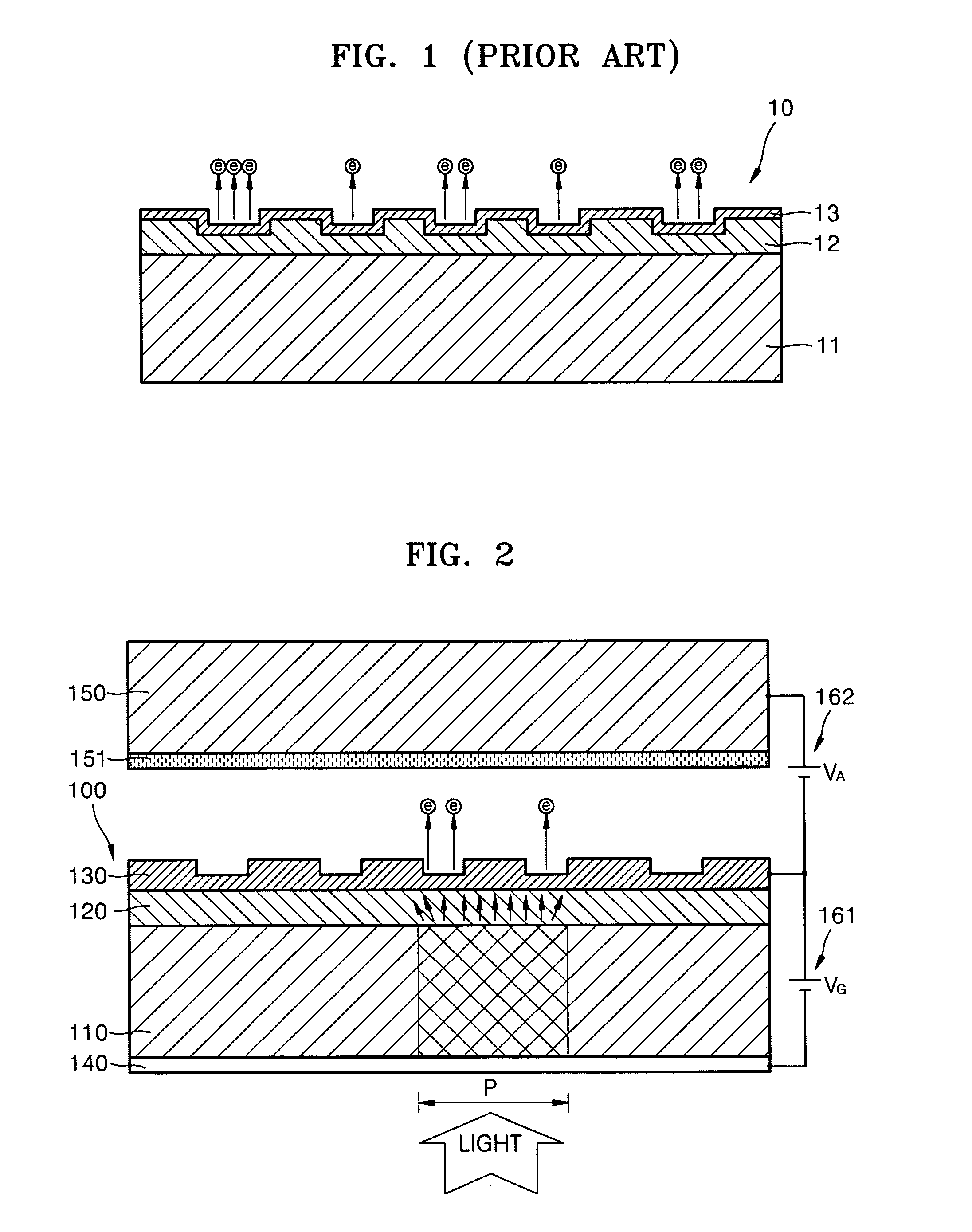

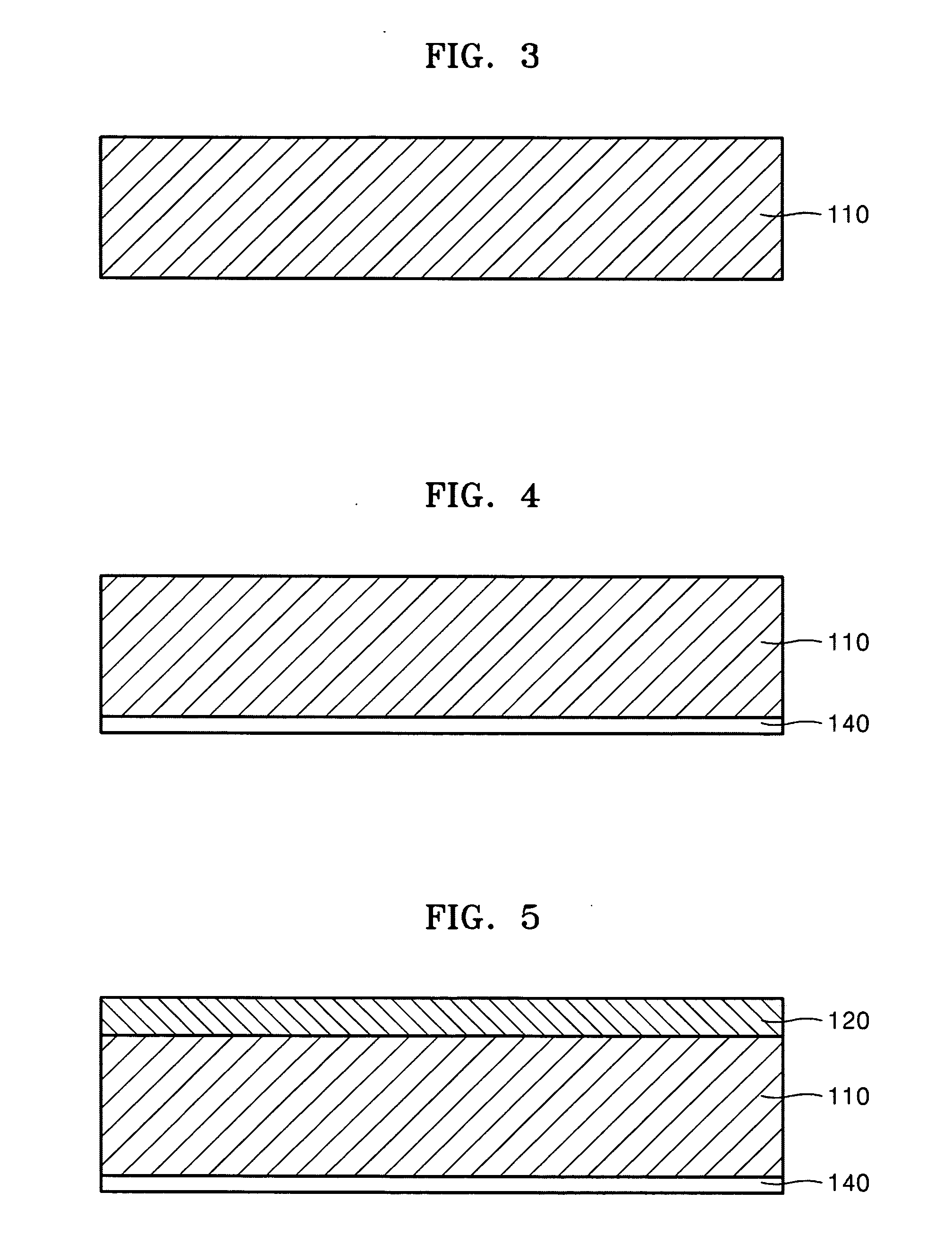

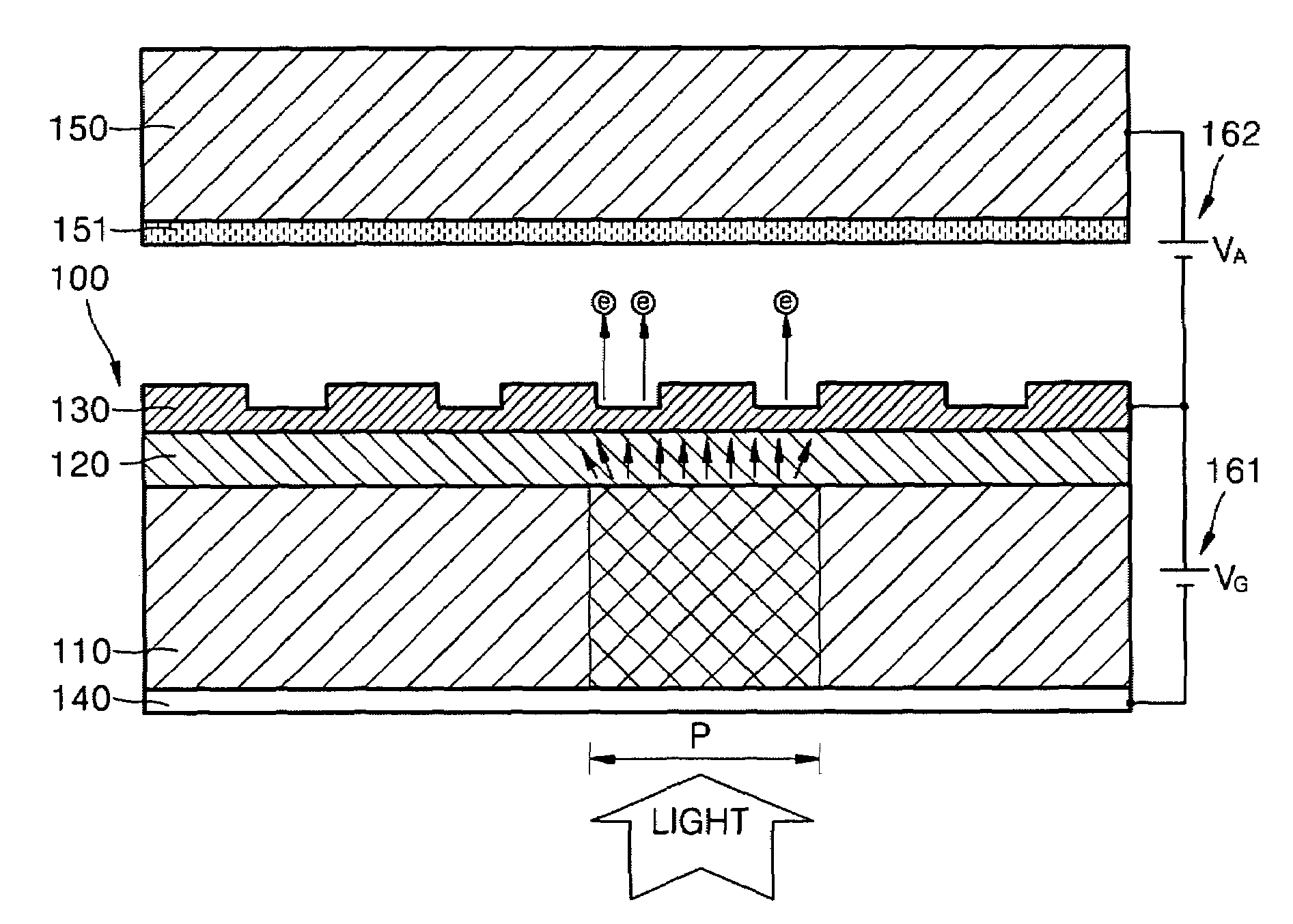

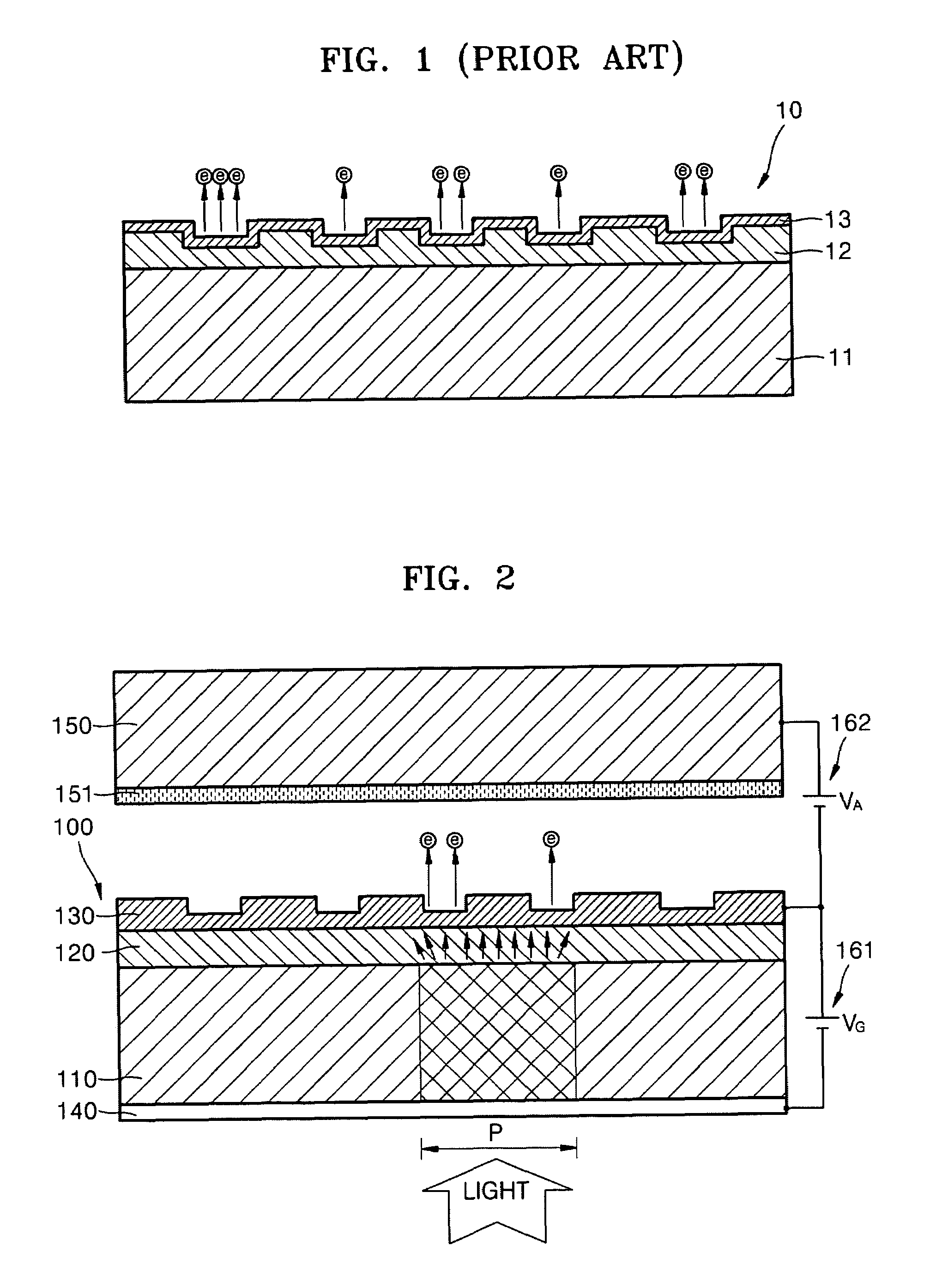

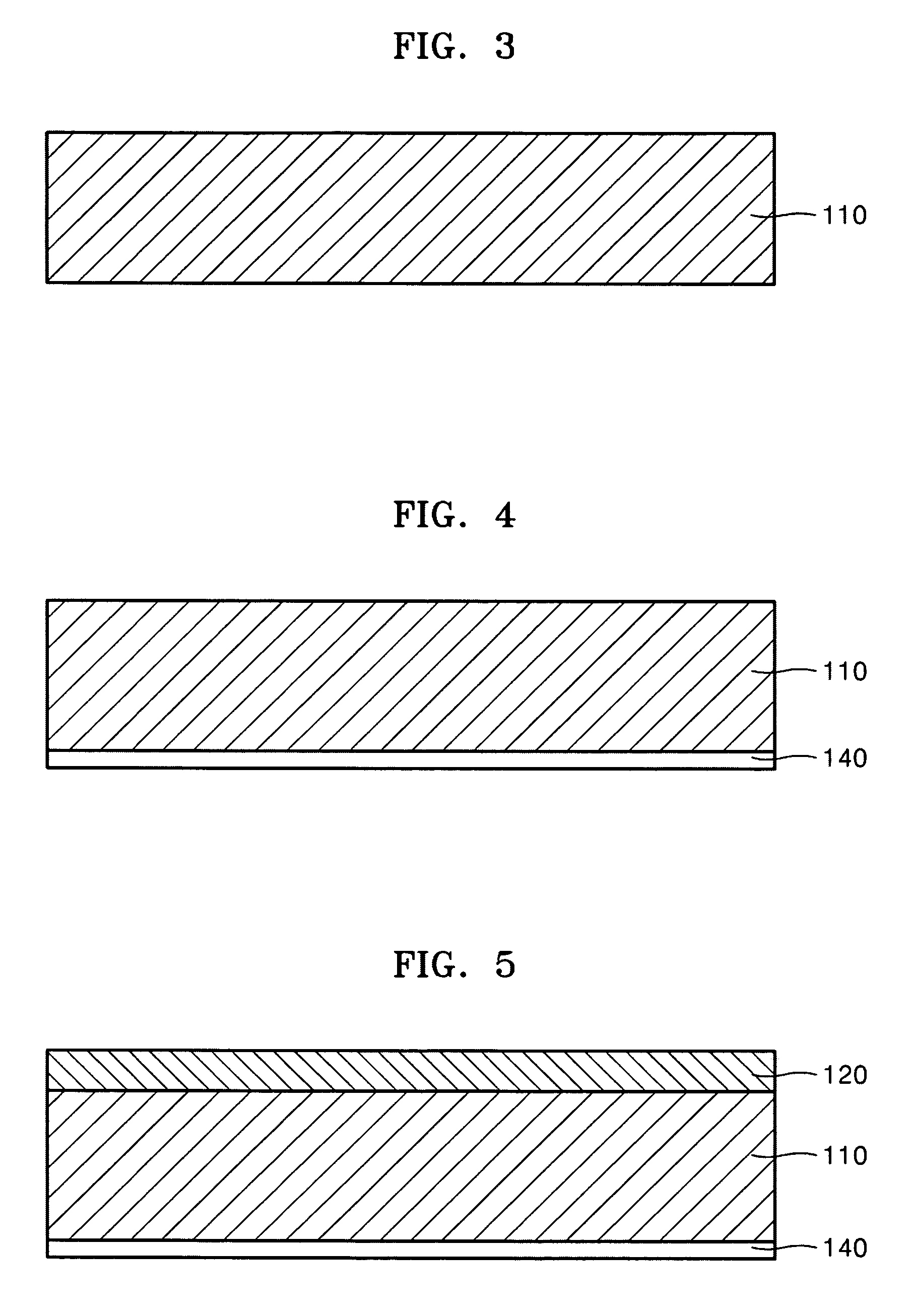

Emitter for electron-beam projection lithography system, and method of manufacturing and operating the emitter

InactiveUS20050077833A1Overcome problemsElectric discharge tubesElectric arc lampsElectron resistsLithographic artist

An emitter for an electron-beam projection lithography system includes a photoconductor substrate, an insulating layer formed on a front surface of the photoconductor substrate, a gate electrode layer formed on the insulating layer, and a base electrode layer formed on a rear surface of the photoconductor substrate and formed of a transparent conductive material. In operation of the emitter, a voltage is applied between the base electrode and the gate electrode layer, light is projected onto a portion of the photoconductor substrate to convert the portion of the photoconductor substrate into a conductor such that electrons are emitted only from the partial portion where the light is projected. Since the emitter can partially emit electrons, partial correcting, patterning or repairing of a subject electron-resist can be realized.

Owner:SAMSUNG ELECTRONICS CO LTD

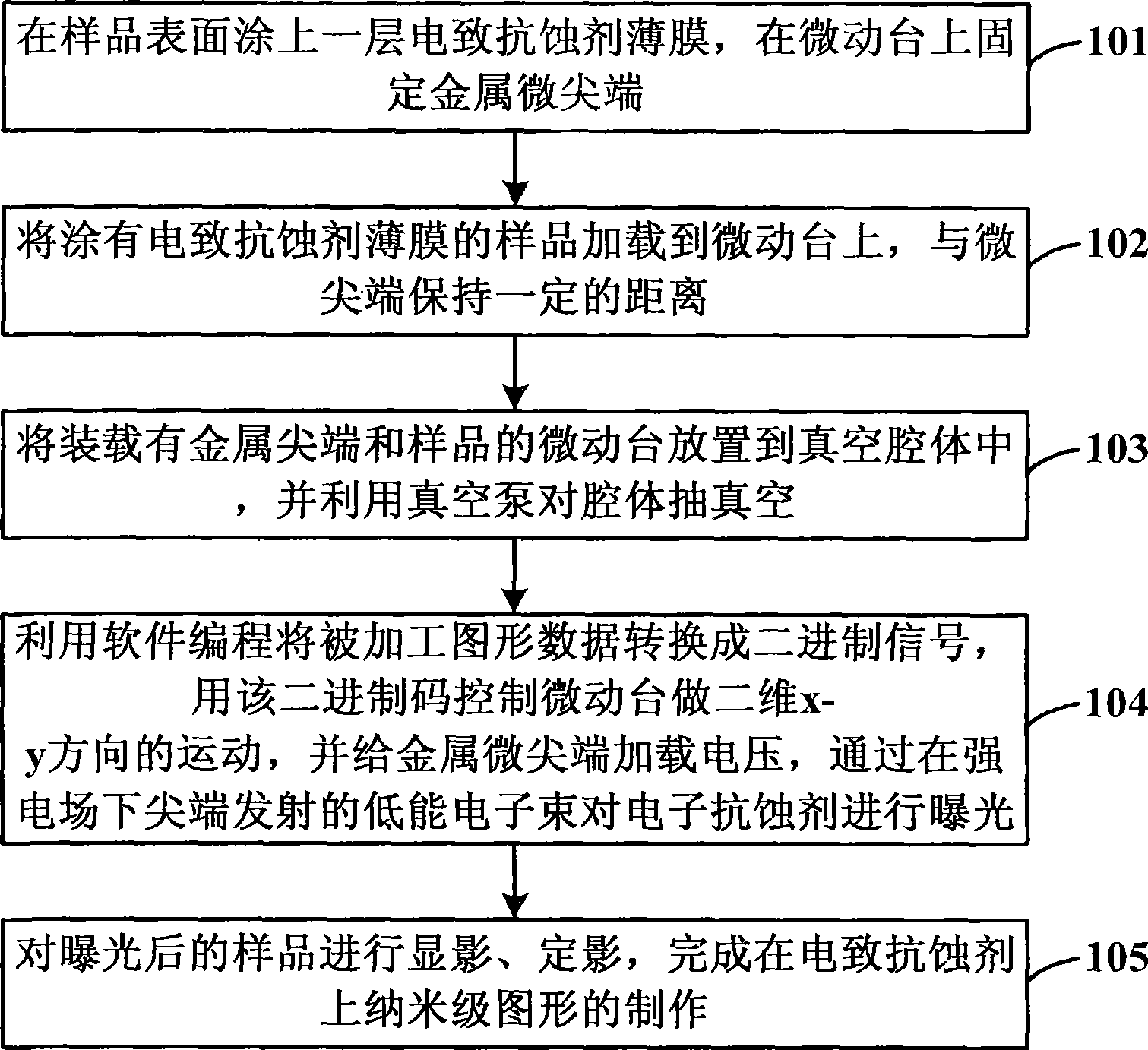

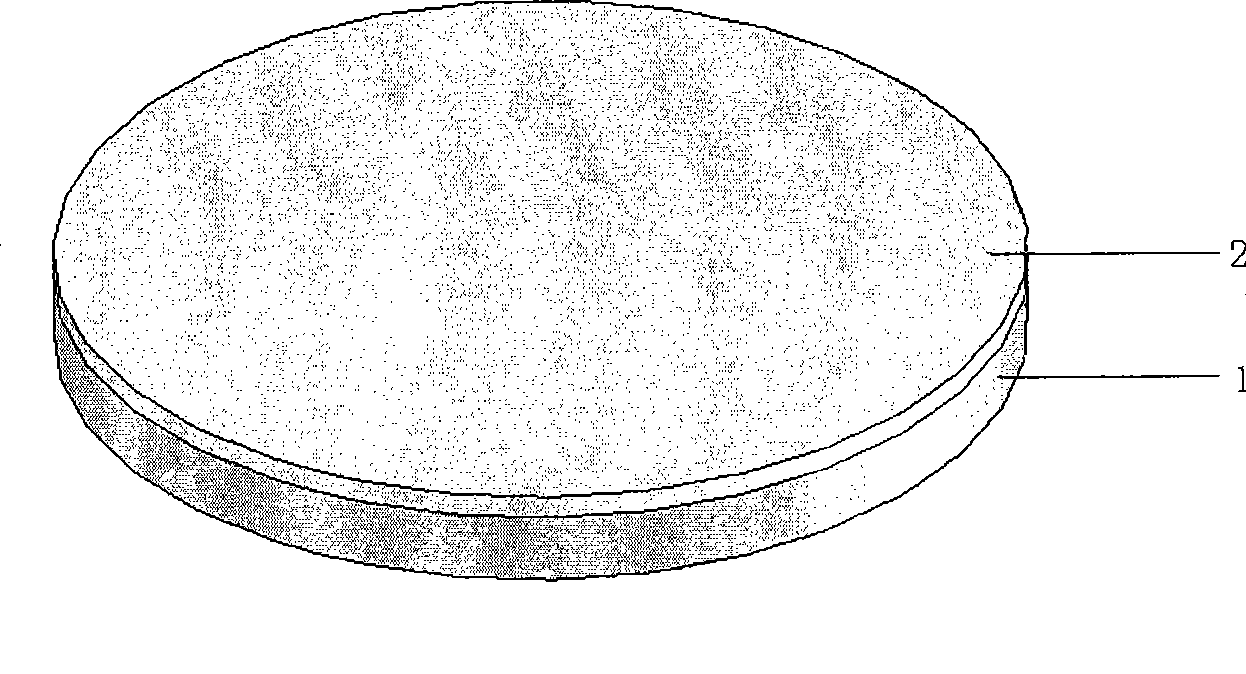

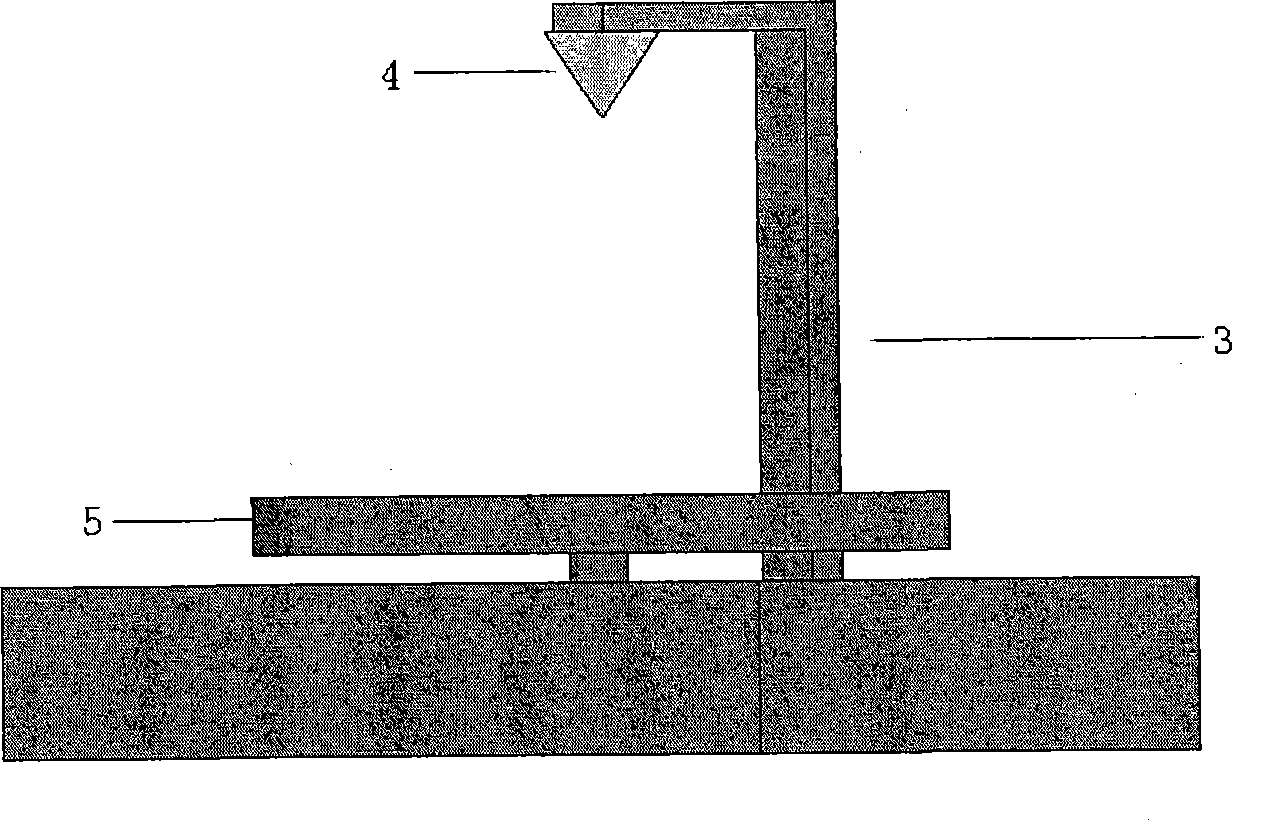

Method for manufacturing nano-scale pattern

ActiveCN101441410AHigh resolutionSolve the problem that the proximity effect affects the resolutionDecorative surface effectsPhotomechanical apparatusElectron resistsElectricity

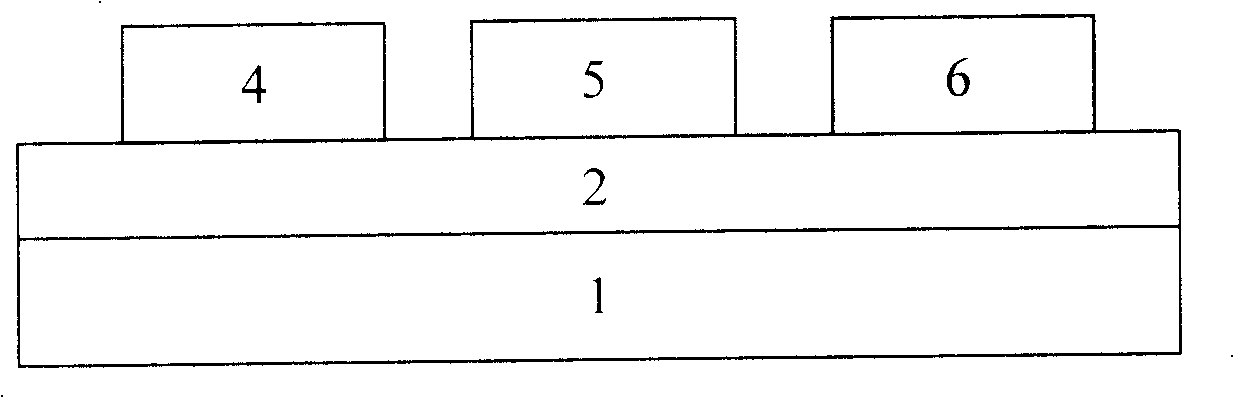

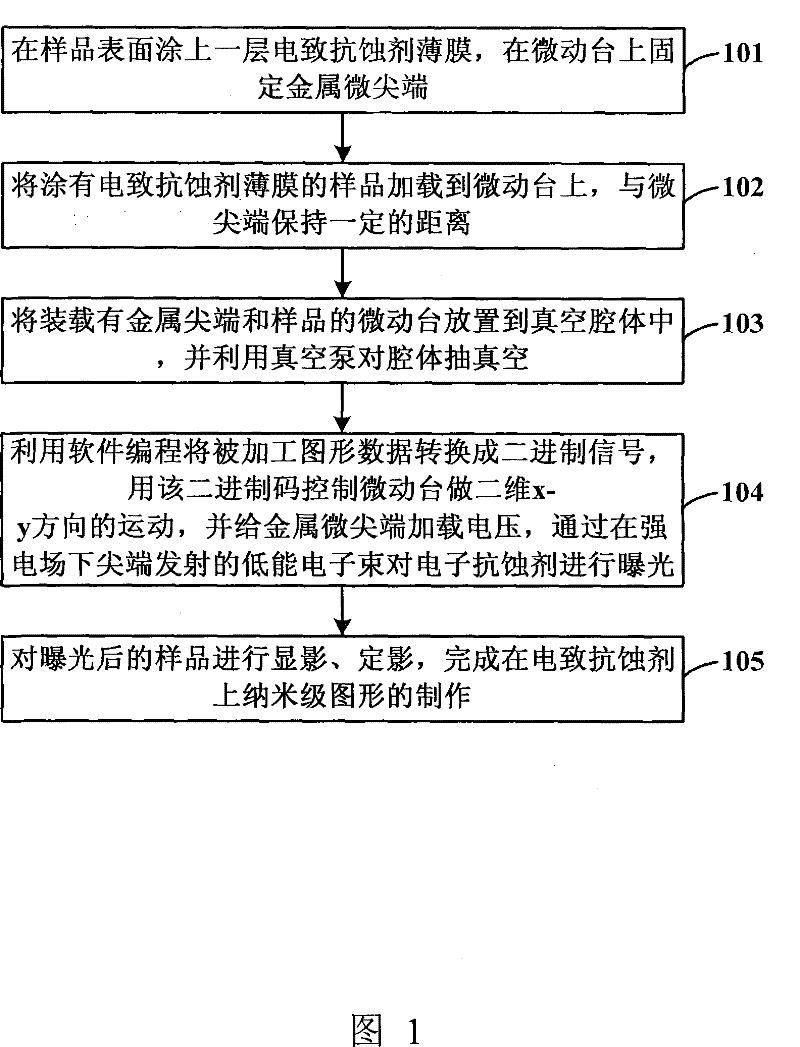

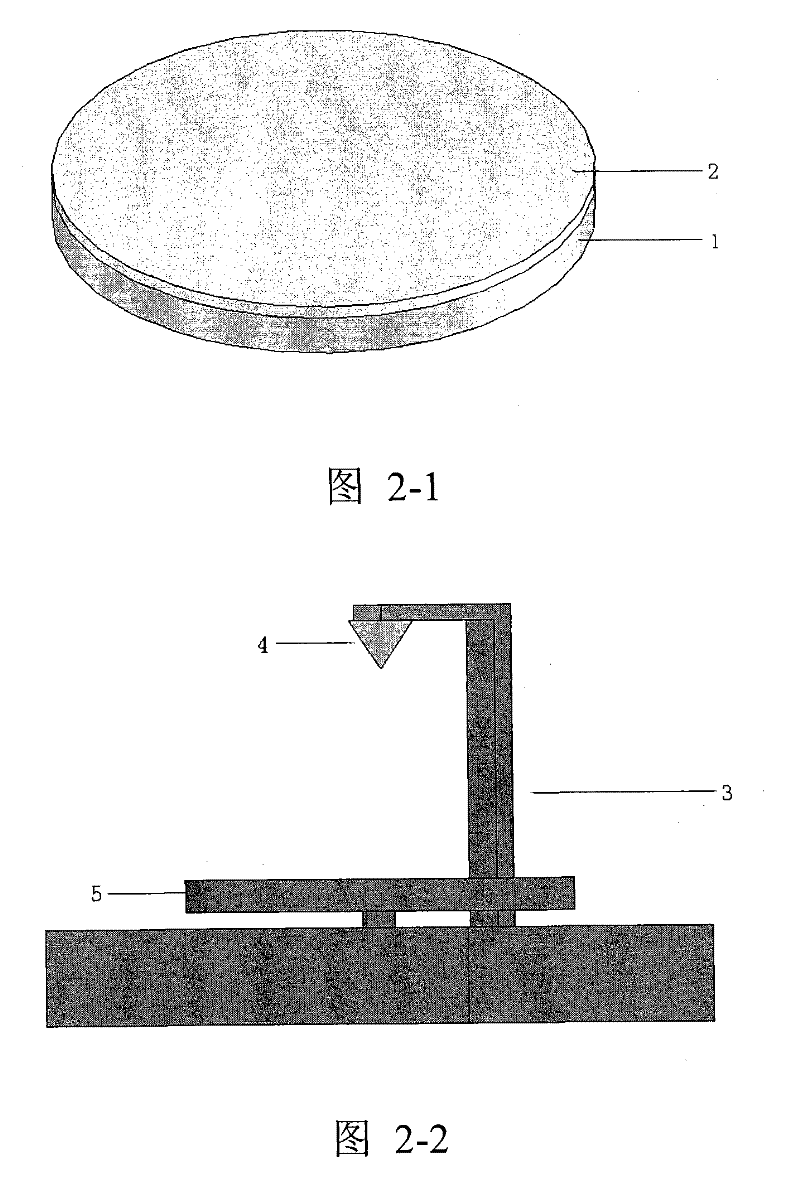

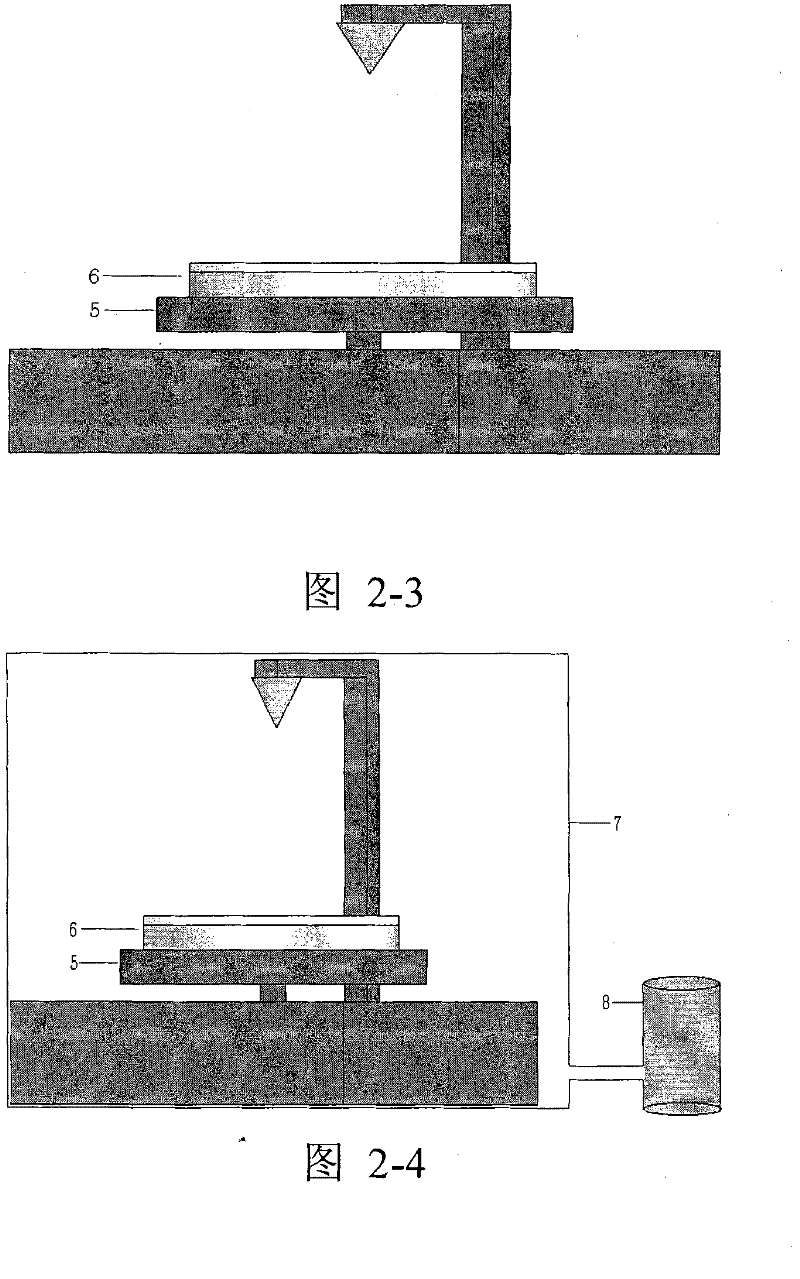

The invention discloses a method for preparing a nanometer pattern. Pattern data is converted into a binary signal to control the movement of a microchecker in the two-dimensional x-y direction and the loading of the metal tip voltage; and the nanometer pattern is obtained through the exposure of an electronic resist by the electron beam produced by the loaded tip voltage. The method comprises the following steps: coating an electric resist film onto the surface of a sample, and fixing a metal micro-tip on the microchecker; loading the sample coated with the electric resist film onto the microchecker, and keeping a certain distance from the micro-tip; placing the microchecker loaded with the metal tip and the sample into a vacuum cavity, and vacuumizing the cavity through a vacuum pump; converting the pattern data to be processed into the binary signal through software programming, using the binary code to control the microchecker to move in the two-dimensional x-y direction, loading the voltage to the metal micro-tip, and exposing the electronic resist through the low-energy electron beam emitted by the tip in a strong electric field; and carrying out the development and fixation of the exposed sample. The method effectively solves the problems that the immersed type photolithography has high cost; and a focused electron beam has a proximity effect on the resolution.

Owner:新疆中科丝路物联科技有限公司

Method for avoiding ZEP520 electronic resist to generate cracks

InactiveCN1815369AEasy to operateReduce usageSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistElectron resists

Fine graphics in Nano level can be prepared by using ZEP520 positivity electronic resist and electron beam write through photo etching. But, cracks are generated easily in resist in traditional technique, especially on substrate of gallium arsenide. There is no relevant solution for the problem. The disclosed method carries out heat treatment for substrate of wafer first; and then the method coats ZEP520 glue instantly so as to prevent ZEP520 from generation of cracks, as well as prevent poisonous tackifier HMDS from use. Advantages are: simple operation, convenience and reliable.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

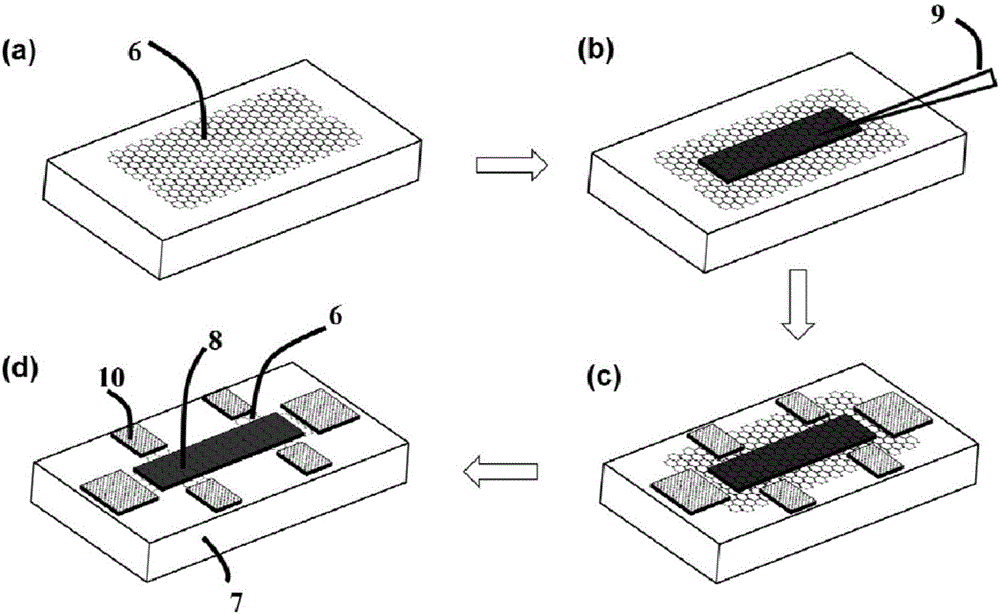

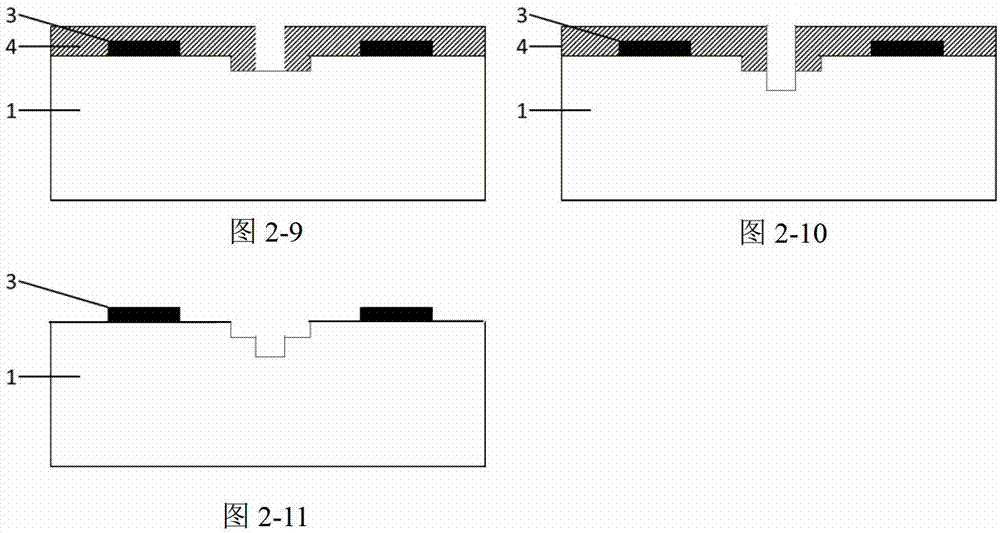

Method for preparing material with highly gradient surface micronano structure

InactiveCN101734619ATime consumingLow selectivityNanostructure manufactureElectron resistsOperation mode

The invention discloses a method for preparing a material with a highly gradient surface micronano structure. The method comprises the following steps of: 1) coating an electron beam resist on a substrate to obtain an electron beam resist layer, and baking the electron beam resist layer ; 2) exposing, developing and fixing electron beams; 3) coating anisole to obtain an anisole layer, and baking the anisole layer; 4) depositing a target material on the anisole layer to obtain a target material layer; 5) attaching the target material layer to another substrate; and 6) separating the target material layer from the electron beam resist layer. The method has the advantages of simple and convenient operation mode, wide material application range, customized shape and position of a pattern, smooth structural surface and high controllability and repeatability, and can play an important role in fields of surface plasmon research, self assembly of nano particles, utilization of solar energy, micro-flow research and the like.

Owner:PEKING UNIV

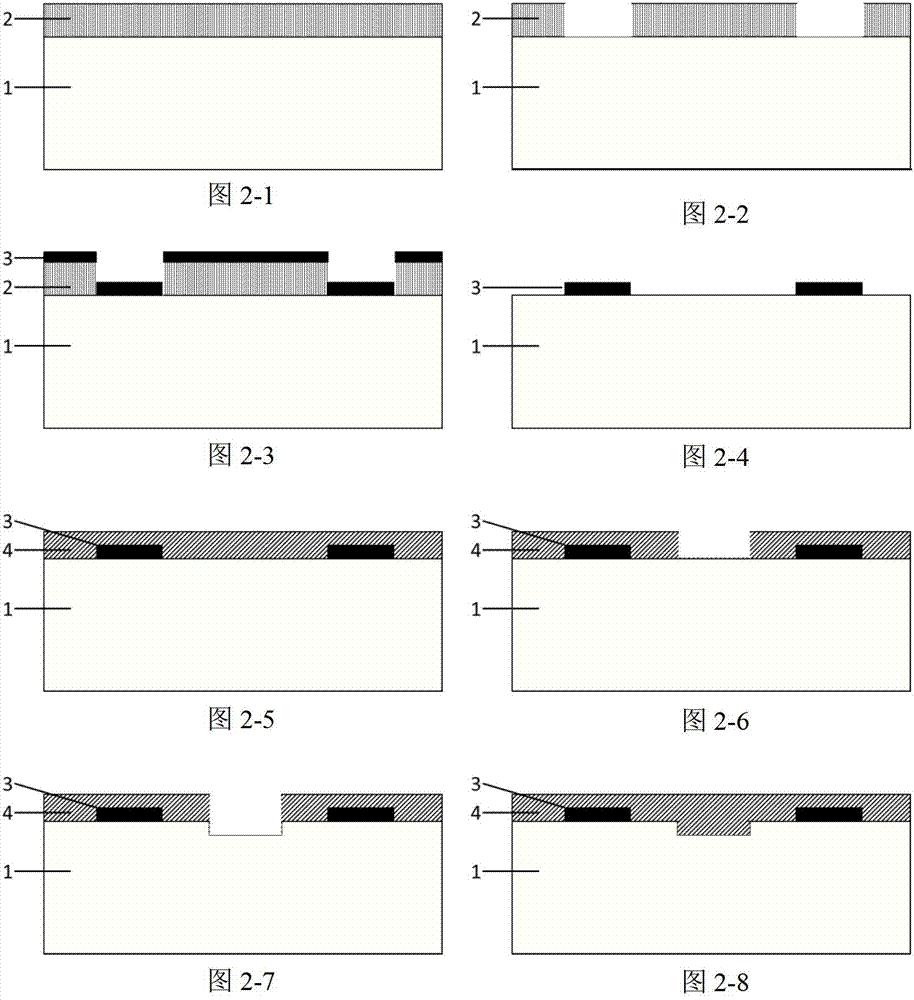

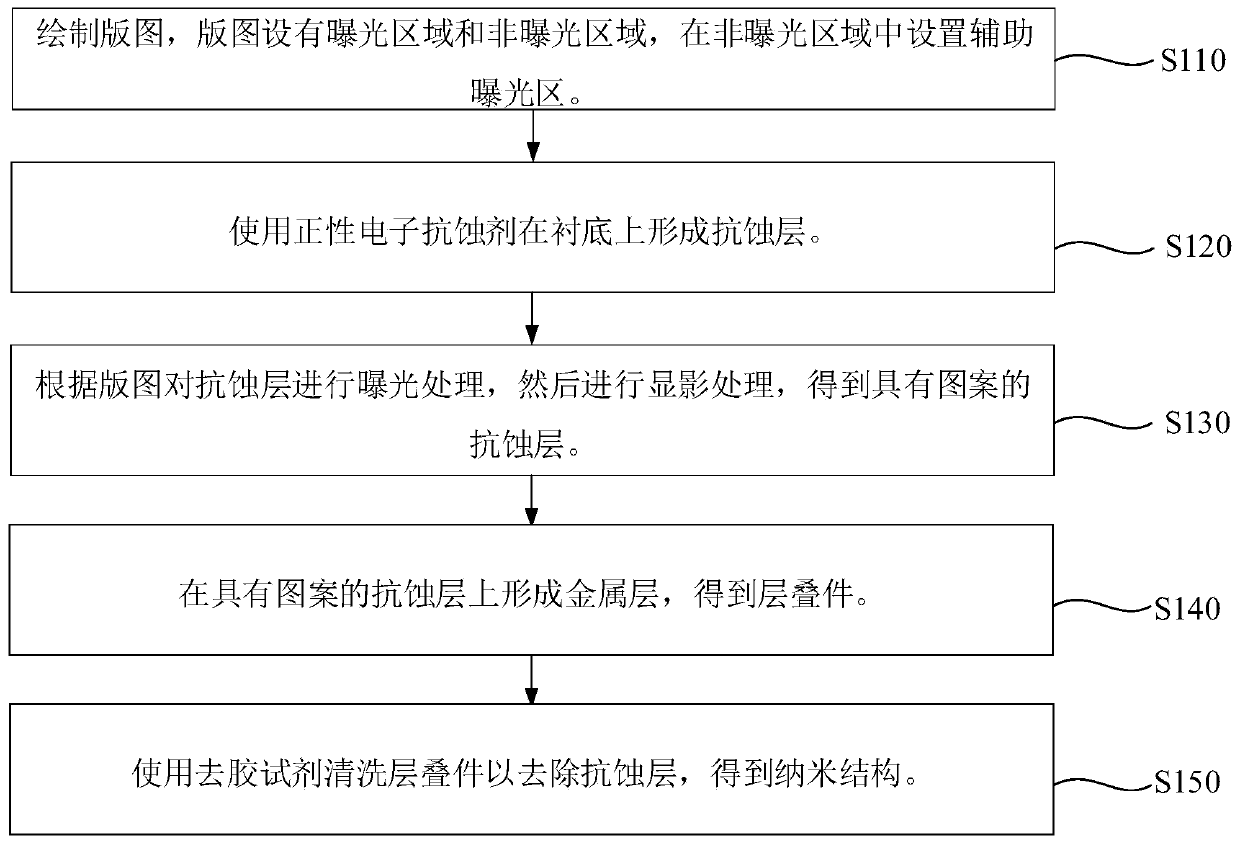

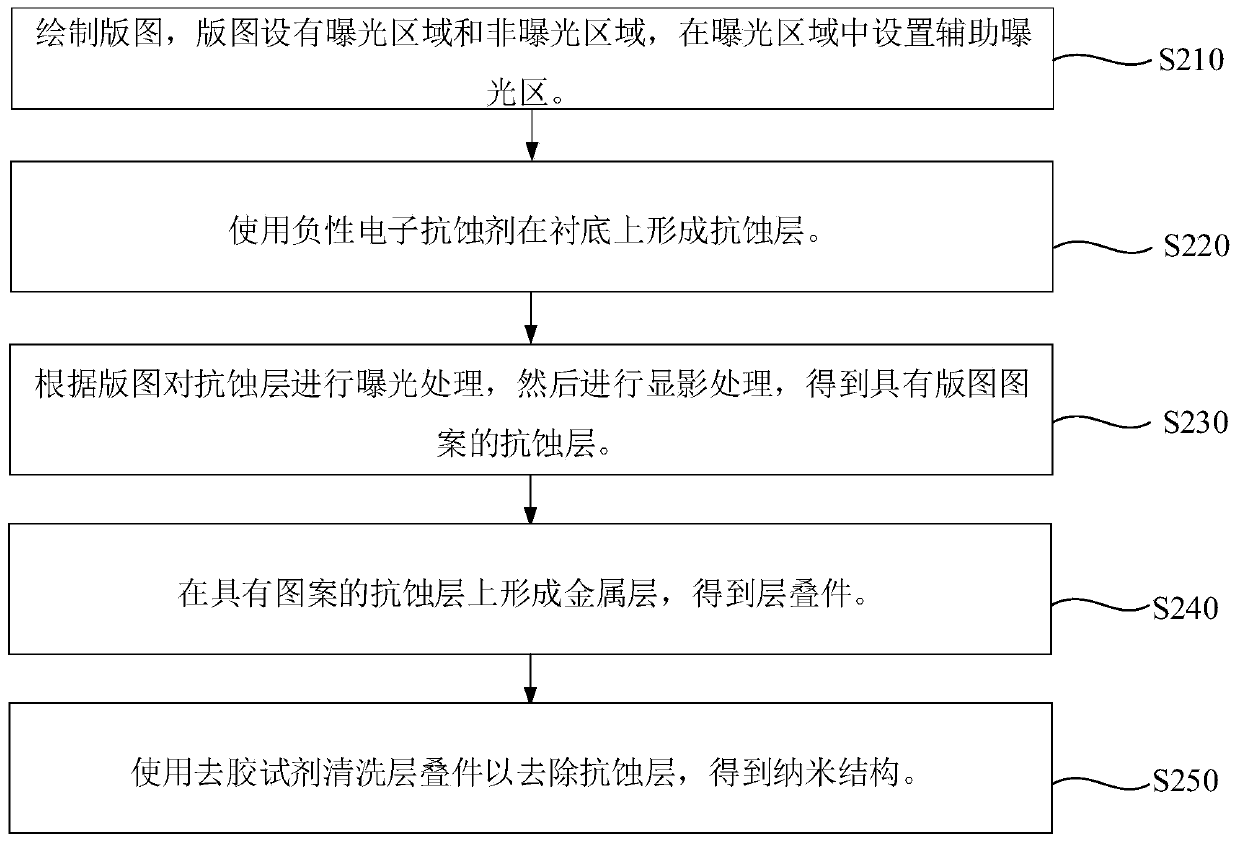

Manufacturing method of nano structure

The invention relates to a manufacturing method of a nano structure. The method comprises the steps that a layout which is provided with an exposed area and a non-exposed area is drawn, and an auxiliary exposure area is set in the non-exposed area; a positive electron resist is used to form a resist layer on a substrate; and the resist layer is exposed according to the layout, and then developed to acquire a patterned resist layer. In the step of the exposure process, the exposure dose of the auxiliary exposure area is smaller than the exposure dose of the exposed area, so that a groove is formed in the area of the resist layer corresponding to the auxiliary exposure area. A metal layer is formed on the patterned resist layer to acquire a laminate. The laminate is cleaned with a stripper reagent to remove the resist layer to acquire the nano structure. According to the manufacturing method of the nano structure, a pattern is easily peeled, and the acquired pattern is complete.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

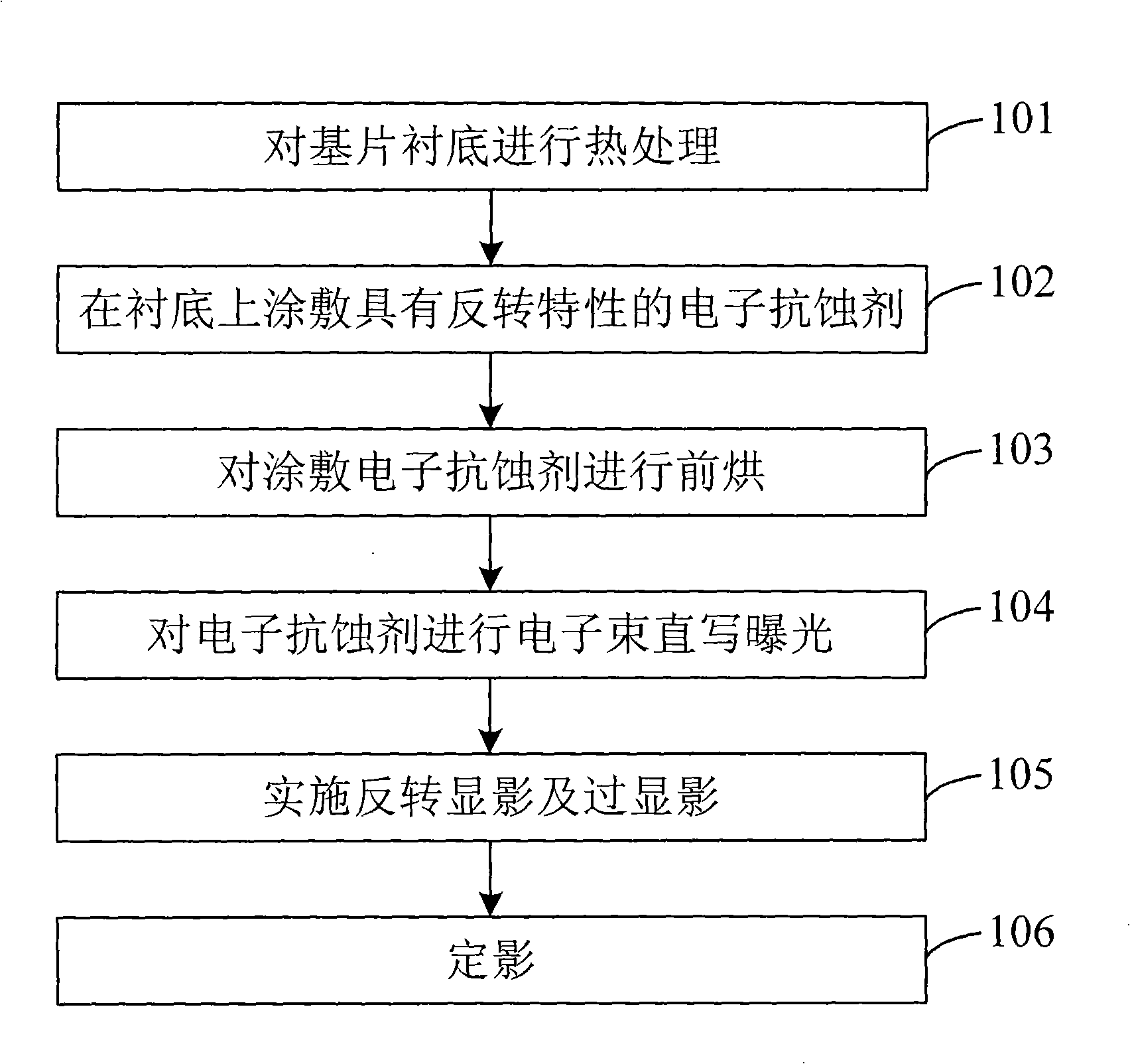

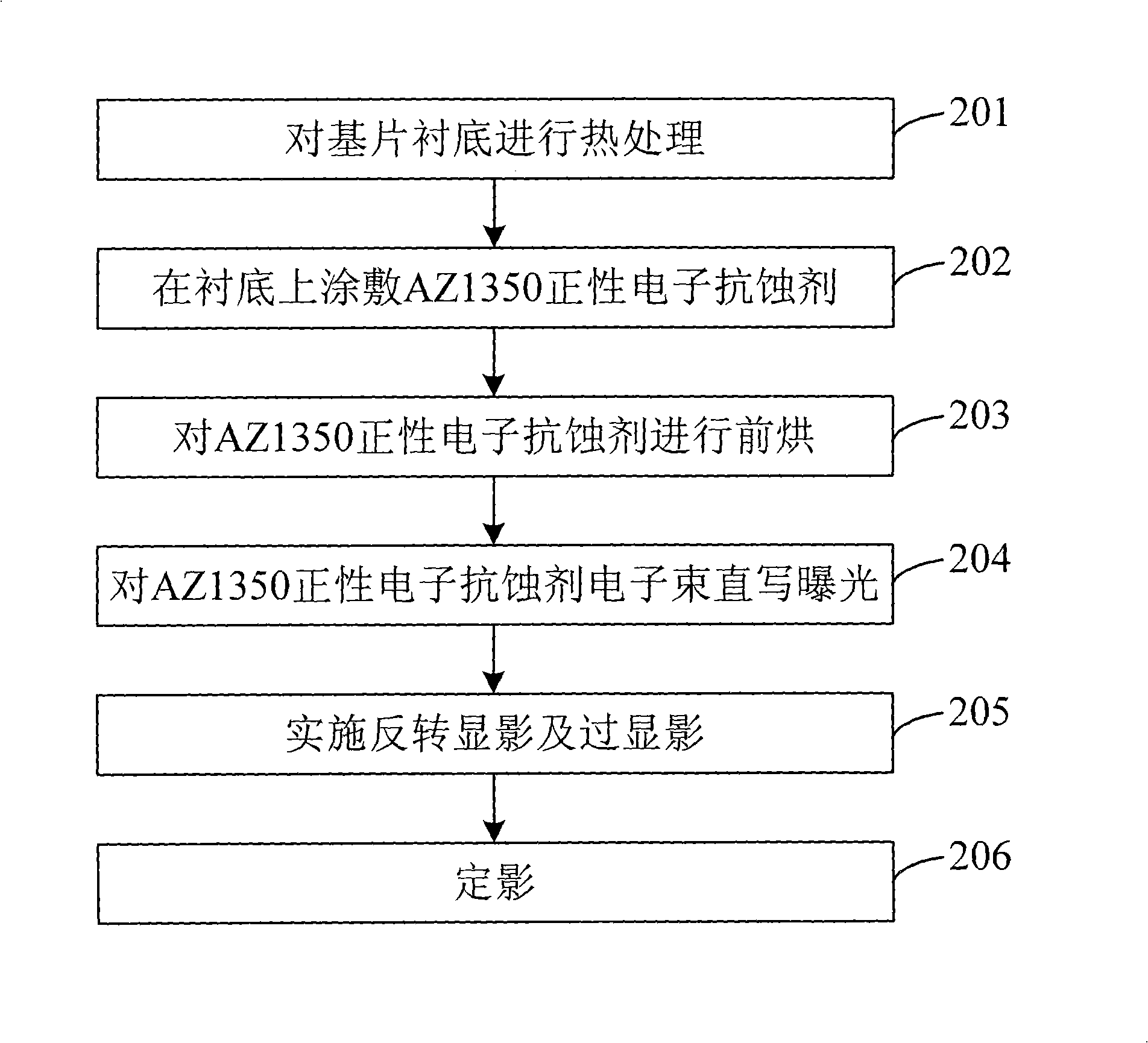

Method for manufacturing hundred nano-scale electric solenoid or net-shaped structure

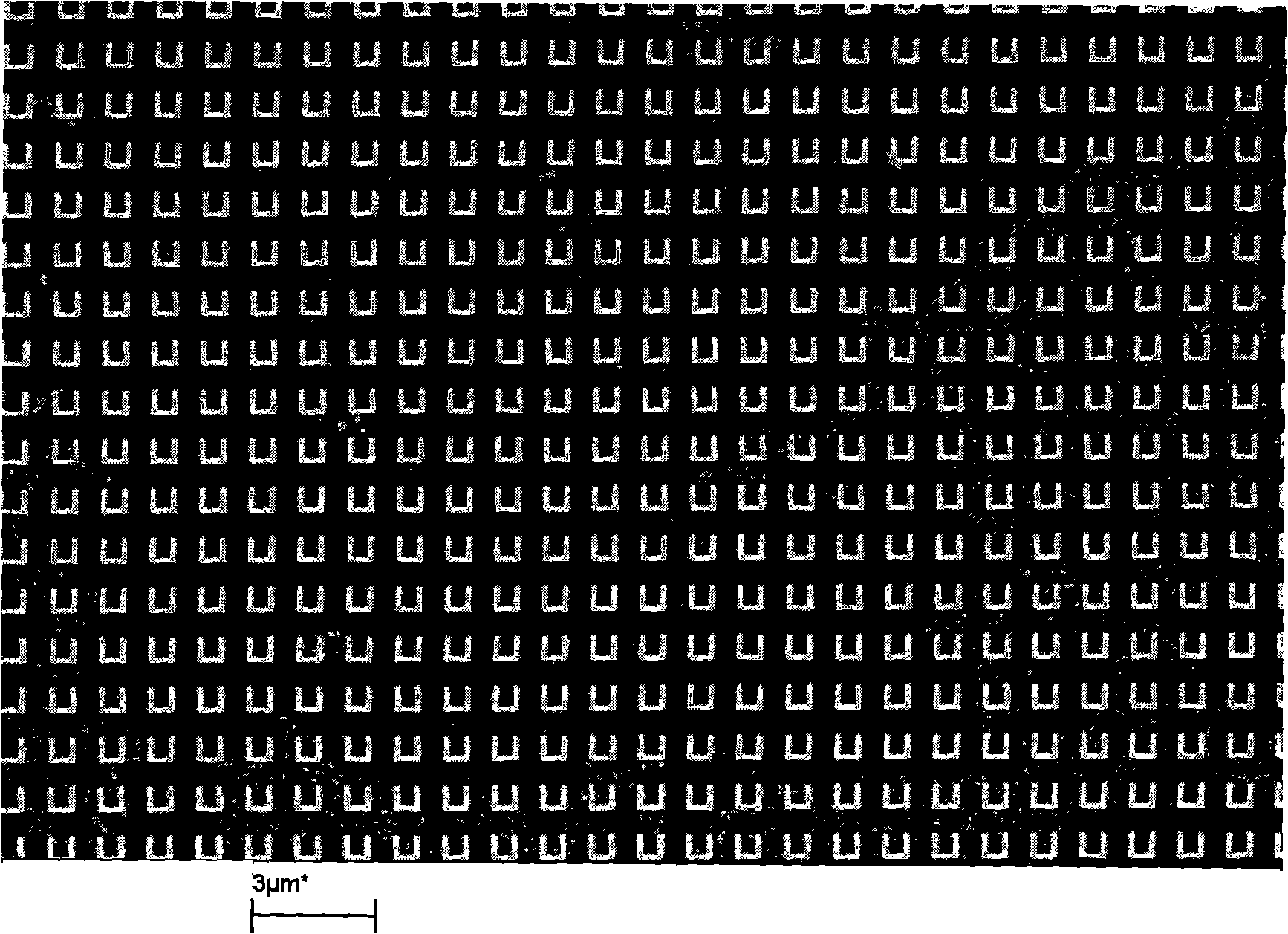

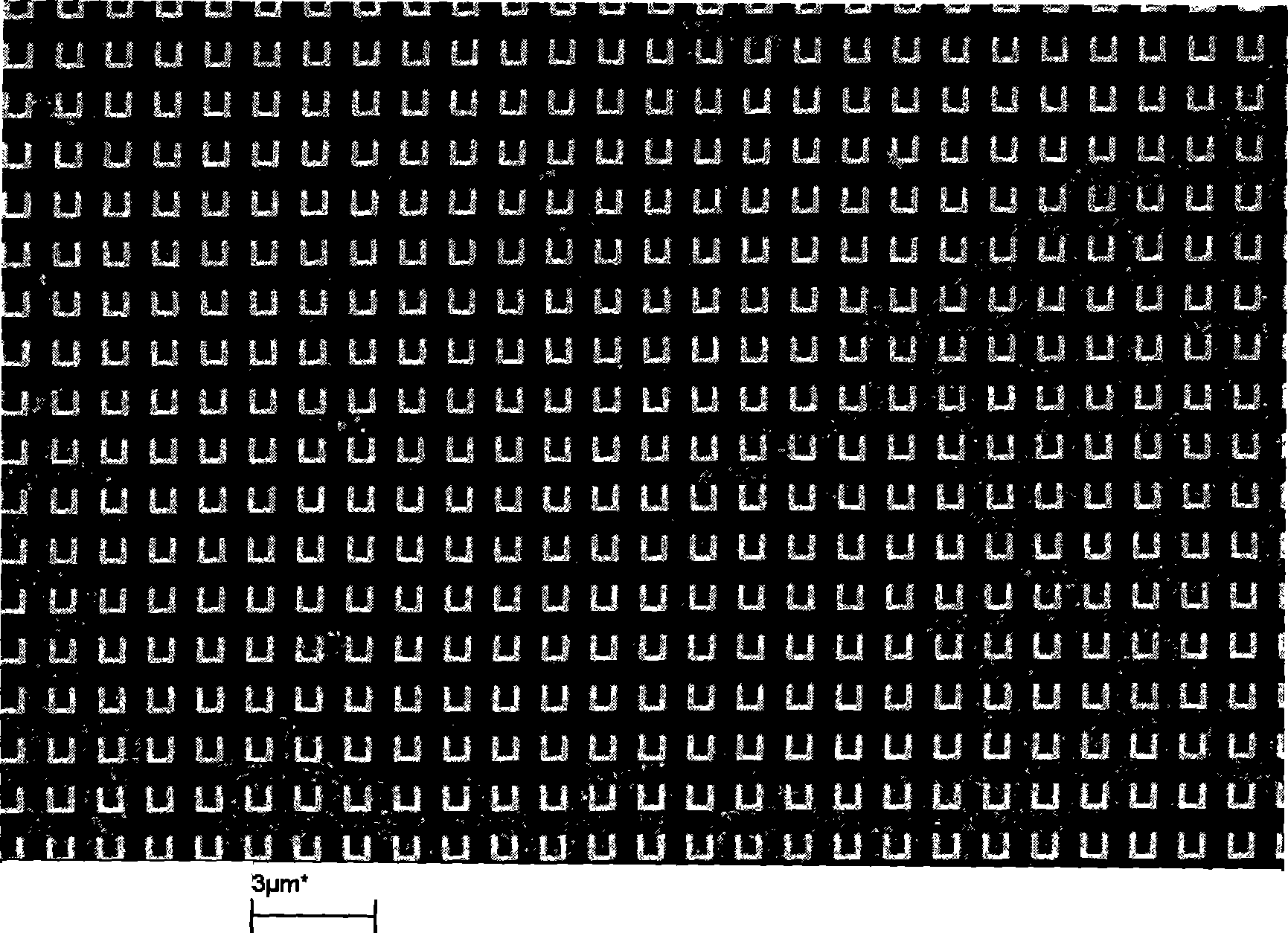

InactiveCN101276149AReduce process stepsThe process steps are simpleNanostructure manufacturePhotomechanical exposure apparatusElectron resistsResist

The present invention relates to a technical field of nano fabrication, providing a method of producing hundreds nanometer level solenoid or reticular formation, the method includes: A, processing heat treatment to a substrate; B, coating an electronic resist having inversion characteristic on the substrate; C, processing prebaking to the coating electronic resist; D, processing e-beam direct-writing exposure to the electronic resist; E, implementing inversion development and over development; F, fixing. The invention simplifies the producing process, achieving the aim of obtaining a stereostructure by planar exposure.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for extracting electron-beam exposure scattering parameter

ActiveCN101510050BExtraction is accurate and easyReduce mistakesSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusObservational errorElectron resists

The invention relates to a method for extracting an electron beam lithography scattering parameter. In order to solve the problems of complex operation and difficult guarantee for the accuracy in the existing method for extracting the electron beam lithography scattering parameter, the invention provides the method for extracting the electron beam lithography scattering parameter. According to the electron beam resist agent for parameter extraction and the substrate structure characteristics, the method designs a suitable front-scattering parameter Alpha, a back-scattering parameter Beta, andan extracting version map of Gama which is the ratio of the back-scattering deposition energy and the front-scattering deposition energy; and then electron beam direct writing lithography of variabledoses for three types of design version maps is carried out on the electron beam resist agent and the substrate structure; and finally, according to a plurality of groups of different parameter lithography, development and the stripped graph structure features, a group of suitable scattering parameters are determined. The invention does not need large amount of complex measurement, therefore, no measurement error exists, the error caused by mathematical treatment is reduced, and the parameter extraction is led to be accurate, simple and feasible.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

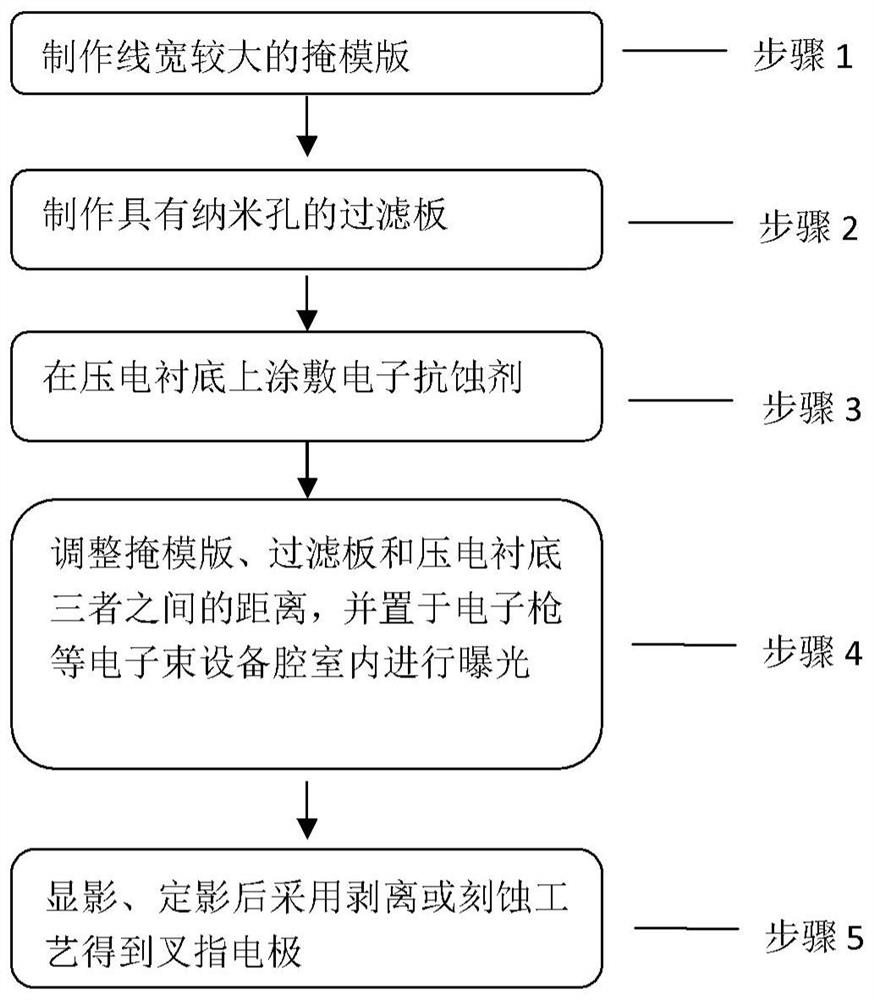

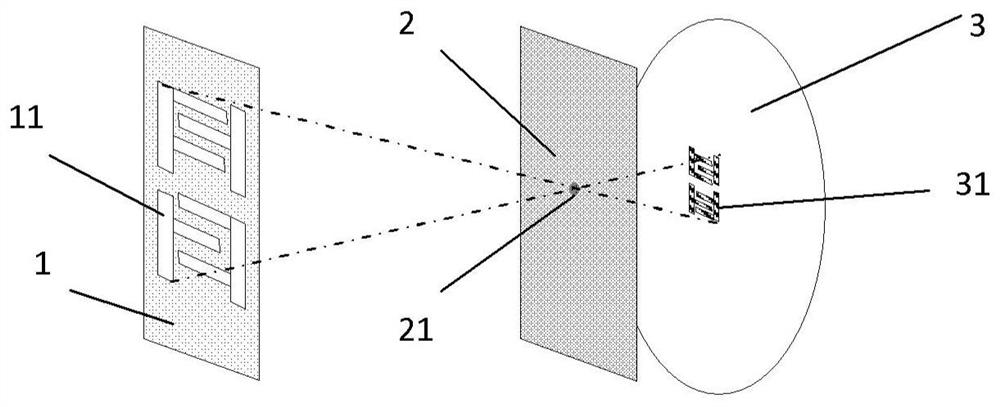

Surface acoustic wave filter and preparation method thereof

ActiveCN111769816ATaking into account batchMiniaturizationImpedence networksPhotomechanical exposure apparatusElectron resistsNanohole

The invention relates to a surface acoustic wave filter and a preparation method thereof. The preparation method comprises the following steps: step 1, placing a filter plate with nanopores between amask plate and a piezoelectric substrate coated with an electronic resist; step 2, transferring the interdigital electrode mask pattern pinhole image on the mask onto the electronic resist of the piezoelectric substrate by using an electron beam exposure method, and forming an interdigital electrode pattern of which the line width is reduced relative to the interdigital electrode mask pattern of the mask on the piezoelectric substrate; step 3, stripping or etching an exposed area outside the interdigital electrode pattern of the piezoelectric substrate; and step 4, removing the electronic resist, and forming an interdigital electrode on the piezoelectric substrate to obtain the surface acoustic wave filter. According to the method disclosed in the invention, the line width of the a devicecan be reduced, the center frequency of the device can be improved, meanwhile, the preparation method can realize rapid and large-batch preparation of the device, and the processing cost is reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Emitter for electron-beam projection lithography system, and method of manufacturing and operating the emitter

An emitter for an electron-beam projection lithography system includes a photoconductor substrate, an insulating layer formed on a front surface of the photoconductor substrate, a gate electrode layer formed on the insulating layer, and a base electrode layer formed on a rear surface of the photoconductor substrate and formed of a transparent conductive material. In operation of the emitter, a voltage is applied between the base electrode and the gate electrode layer, light is projected onto a portion of the photoconductor substrate to convert the portion of the photoconductor substrate into a conductor such that electrons are emitted only from the partial portion where the light is projected. Since the emitter can partially emit electrons, partial correcting, patterning or repairing of a subject electron-resist can be realized.

Owner:SAMSUNG ELECTRONICS CO LTD

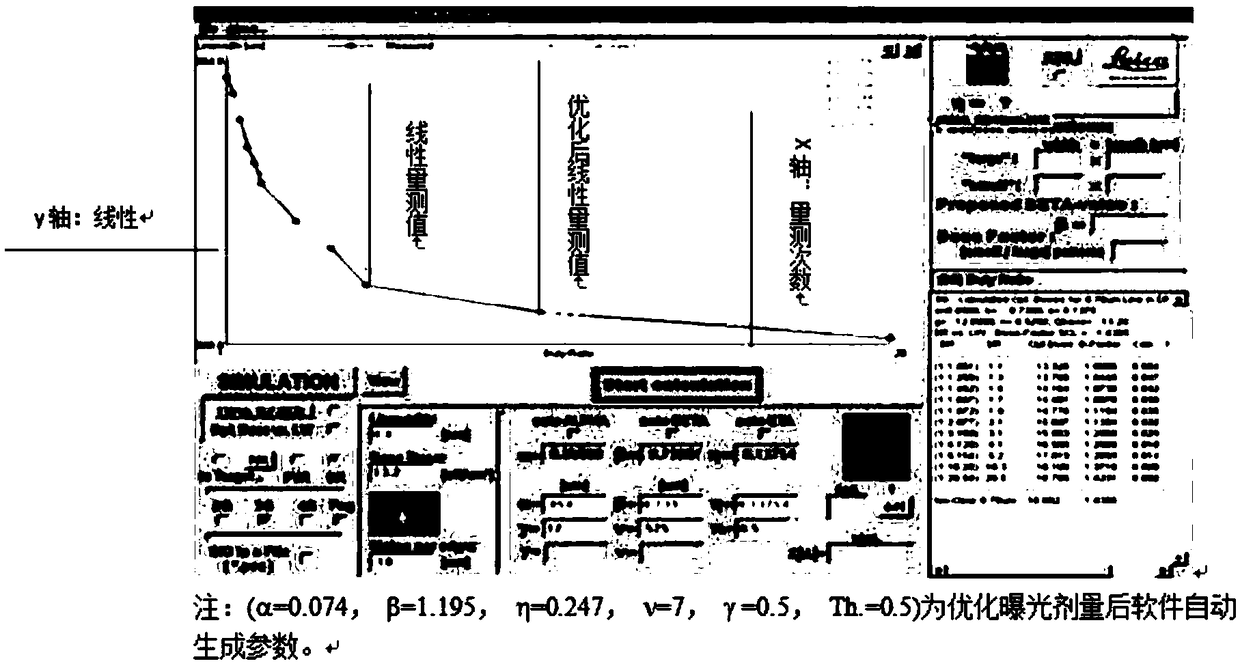

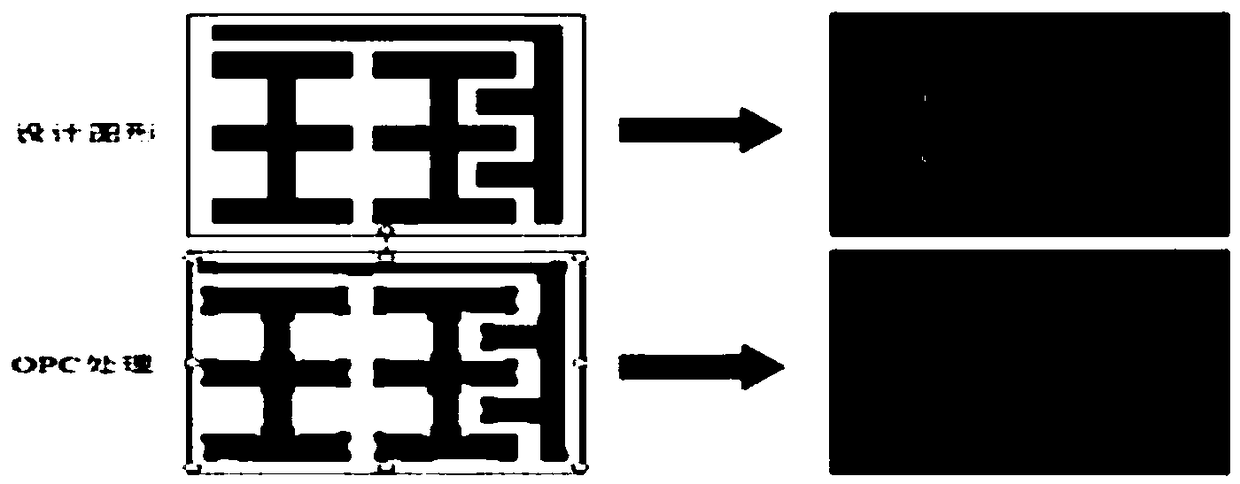

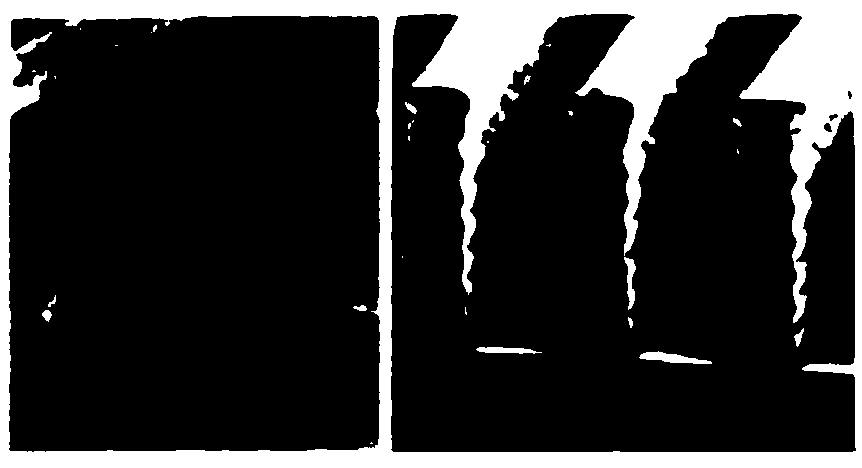

A method for optimizing the resolving power of electron beam lithography machine

InactiveCN109085739AHigh sensitivityHigh resolutionPhotomechanical exposure apparatusMicrolithography exposure apparatusCooking & bakingElectron resists

The invention discloses an optimization method for the resolution ability of an electron beam exposure machine, which comprises the following steps: (1) optimizing the characteristics of an electronicresist: selecting a FEP positive photoresist, wherein the photoresist has high sensitivity, high resolution and contrast; (2) optimization of proximity effect: adopting software correction measures to correct proximity effect by adjusting the geometry of wavefront engineering, or by exposure dose modulation, or by combining the two; (3) Optimization of developing program of developing machine: baking after exposure. The method of the invention finds a critical point of the maximum resolution capability of the current exposure equipment, and at the same time, searches for the possibility of improving the exposure resolution capability of the mask without changing the exposure equipment by optimizing the exposure process, so as to meet the exposure process requirements of the high-end mask.

Owner:WUXI ZHONGWEI MASK ELECTRONICS

Method for extracting scattering parameters of electron beam exposure

InactiveCN109324482AExtraction is accurate and easyReduce mistakesPhotomechanical exposure apparatusMicrolithography exposure apparatusObservational errorElectron resists

The invention relates to a method for extracting scattering parameters of electron beam exposure, aiming at solving the problems that the existing method for extracting the scattering parameters of the electron beam exposure is complicated in operation and difficult in guarantee of accuracy. The invention provides the method for extracting the scattering parameters of the electron beam exposure; the method comprises the steps of deigning proper extraction domains of a front scattering parameter alpha, a back scattering parameter beta and a deposition energy ratio eta of back scattering to front scattering according to the characteristics of an electron beam resist and a substrate structure which are about to be subjected to parameter extraction; then, separately performing variable dose electron beam direct writing exposure on the three designed extraction domains on the electron beam resist and the substrate structure which are to be tested; finally, determining the group of suitablescattering parameters according to the pattern structure characteristics of the multiple groups of different parameters after exposure, development and stripping. After the method is adopted, a greatdeal of tedious measurement does not need to be performed, so that measurement error is avoided, and the error caused by the mathematical processing is reduced; therefore, the method enables parameterextraction to be accurate, simple and east to implement.

Owner:吴辉

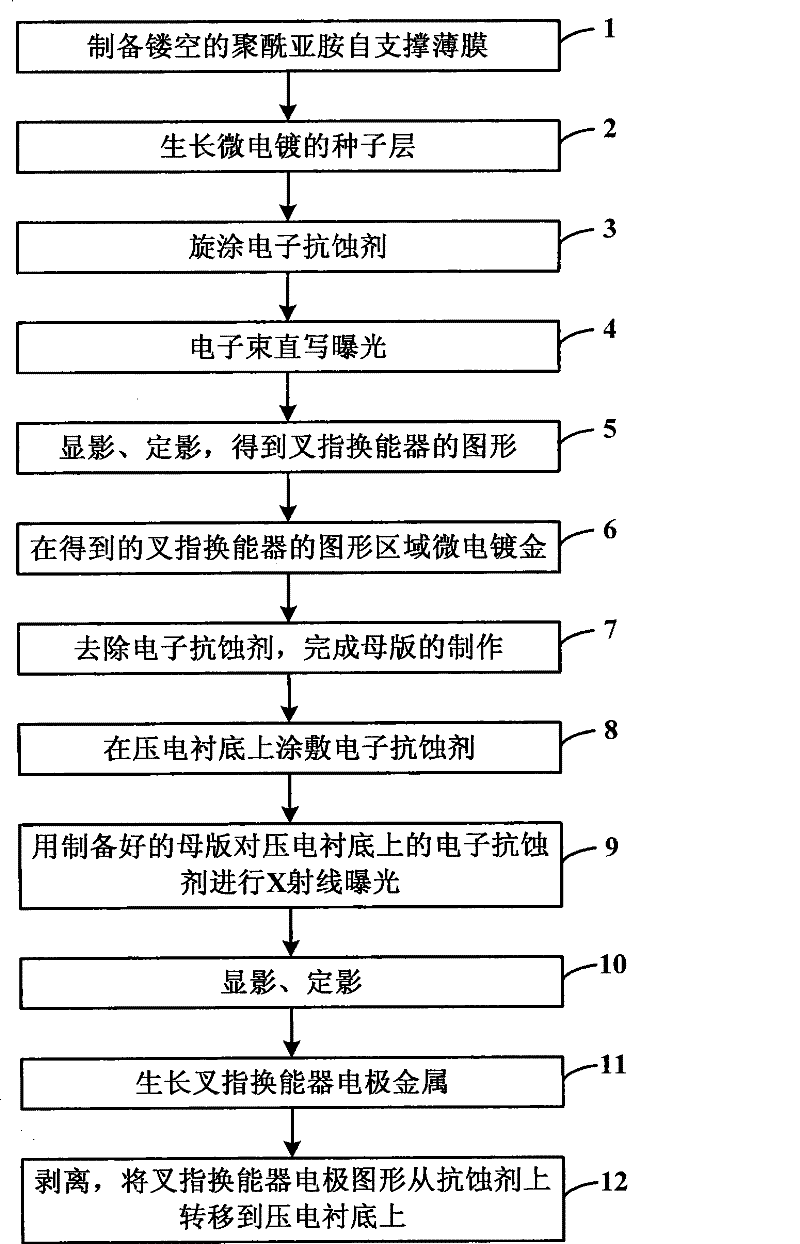

Method of producing surface acoustic wave devices by exposing X-rays

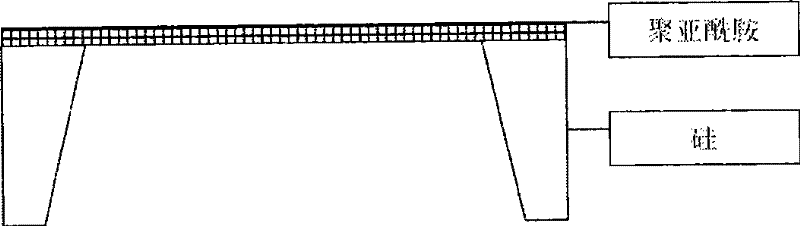

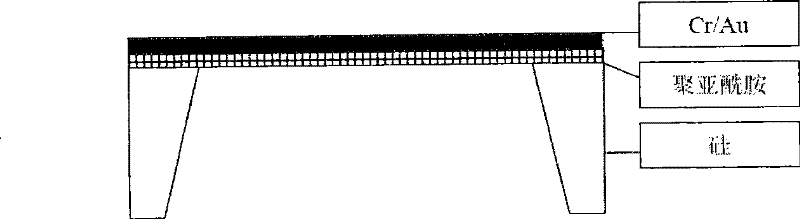

ActiveCN101677231BIncrease working frequencyImprove work performanceImpedence networksElectron resistsX-ray

The invention discloses a method of producing surface acoustic wave devices by exposing X-rays. A master set of an interdigital transducer is produced by photoetching electron beams on a hollow polyimide self-supporting film; electron beam resist concave solid figures of the interdigital transducer are obtained by exposing X-rays on a piezoelectric substrate; and various surface acoustic wave devices are produced with the stripping technology. By adopting the method of producing the surface acoustic wave devices by exposing X-rays, the back scattering effect of the material of the nano-scale interdigital transducer electrode can be greatly reduced, the nano-scale interdigital transducer electrode can be obtained, and the working performance and the performance of the surface acoustic wavedevices are improved; and in addition, the X-rays can be exposed repeatedly for many times, thus the producing efficiency of the surface acoustic wave devices is improved, and the producing cost is lowered.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

A method for preparing the nano-electrode with the negative electronic erosion-resisting agent

InactiveCN100435285CPhotomechanical apparatusSemiconductor/solid-state device manufacturingCooking & bakingElectron resists

The preparation method for nano electrode comprises: growing well-conductive metal or semiconductor layer; using EBL to obtain a couple or group negative electronic anti-corrosive agent, and coating the agent; first baking; with electron beam to direct expose; developing, fixing, etching, and stripping the photoresist. The product has 20-100nm space and fit to wide application. This invention is simple and reliable, and compatible with traditional CMOS technology.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

A method for making nanoscale graphics

ActiveCN101441410BHigh resolutionSolve the problem that the proximity effect affects the resolutionDecorative surface effectsPhotomechanical apparatusElectron resistsElectronic load

Owner:新疆中科丝路物联科技有限公司

Electron beam overlay marking based on hafnium dioxide and its manufacturing method

InactiveCN102969302BReduce manufacturing costHigh melting pointSemiconductor/solid-state device detailsSolid-state devicesResistElectron resists

The invention discloses an electron beam aligning mark based on hafnium oxide, which belongs to the field of micro and nano fabrication of a semi-conductor device. The electron beam aligning mark based on hafnium oxide comprises a substrate and a hafnium oxide thin film mark plated on the substrate. The invention further provides a manufacturing method which specifically comprises the steps of: (1) cleaning the substrate; (2) carrying out spin coating of an electronic resist on the substrate and forming a pattern array with an aligned mark in the electronic resist through an electron beam photolithography technique; (3) evaporating hafnium oxide thin films on the electronic resist and the substrate; and (4) peeling the hafnium oxide thin films attached to the positive electronic resist to obtain the hafnium oxide mark. The aligned mark obtained by the electron beam lithography is prepared by using hafnium oxide which is high temperature resistive, good in adhesion and low in cost. Compared with the conventional 'titanium+gold' marks, the process cost is reduced, the problem that the gold mark and the Si substrate are not adhered well is solved, the adhesion and high temperature bearing capacity of the aligned mark to the substrate are improved, and the higher aligning precision is maintained.

Owner:HUAZHONG UNIV OF SCI & TECH

Controllable preparation method and product of germanium silicon nanometer low-dimensional structure

InactiveCN103928297BReduce horizontal sizeAvoid the problem of random nucleation growthSemiconductor/solid-state device manufacturingNanotechnologyResistElectron resists

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing material with highly gradient surface micronano structure

InactiveCN101734619BHigh technical requirementsTime consumingNanostructure manufactureElectron resistsMicro nano

The invention discloses a method for preparing a material with a highly gradient surface micronano structure. The method comprises the following steps of: 1) coating an electron beam resist on a substrate to obtain an electron beam resist layer, and baking the electron beam resist layer ; 2) exposing, developing and fixing electron beams; 3) coating anisole to obtain an anisole layer, and baking the anisole layer; 4) depositing a target material on the anisole layer to obtain a target material layer; 5) attaching the target material layer to another substrate; and 6) separating the target material layer from the electron beam resist layer. The method has the advantages of simple and convenient operation mode, wide material application range, customized shape and position of a pattern, smooth structural surface and high controllability and repeatability, and can play an important role in fields of surface plasmon research, self assembly of nano particles, utilization of solar energy, micro-flow research and the like.

Owner:PEKING UNIV

Method for producing nano-structure on insulated underlay

InactiveCN101295131BExcellent solubility propertiesSolve the accumulationPhotomechanical apparatusSemiconductor/solid-state device manufacturingElectron resistsNano structuring

The invention relates to a method for preparing nanometer structures on an insulating substrate. The method comprises the following steps of: selecting and disposing the insulating substrate; spin-coating electronic anti-corrosion adhesive after an aluminium film with suitable thickness is aggraded on the substrate by coating equipment; designing the shape and the dimension of the required surface nanometer structure according to the requirement; realizing the precise exposal of the design graphics on the surface of the substrate in an electron beam exposal system; realizing suitable undercutstructure at the exposal line position in a dual-layer structure of electronic anti-corrosion adhesive and aluminium by controlling the process parameters such as temperature of alkali liquor, consistency of alkali liquor and corrosion disposal time; finally realizing the sediment of nanometer structure material by the coating equipment and completing the preparation of the nanometer structure bysolubilisation process and alkali liquor disposal. The method overcomes the charge accumulation effect of the insulating substrate in the electron beam exposal system and realizes the exposal of the nanometer graphics; meanwhile, the prepared undercut structure can extremely effectively assist the subsequent solubilisation process, thus ensuring that the surface nanometer structure is effectively, integrally and precisely realized on the insulating substrate material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

A prodcution method for nano coulomb structure

InactiveCN100466204CImprove reliabilitySimple manufacturing processPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistElectron resists

The invention discloses a preparing method of nanometer-class coulomb island structure, it includes: A. smearing electron slushing compound on conducting layer of underlay; B. baking the electron slushing compound; C. electron beam exposing the electron slushing compound; D. imaging the electron slushing compound exposed; E. fixing the electron slushing compound imaged; F. process of glue-eliminating and high temperature oxidation is proceeded to coulomb island structure obtained to obtain nanometer-class coulomb island structure whose size is more smaller. With the invention, preparing craftwork is simplified, cost is decreased, efficiency is increased, and reliability of coulomb island structure is increased. The preparing method provided in the invention possesses advantages that it is compatible with traditional CMOS, fits for the extending and application.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method of producing surface acoustic wave devices by exposing X-rays in a direct writing way

ActiveCN101676797BSteep edgeGood width controlPhotomechanical exposure apparatusPhotosensitive material processingResistElectron resists

The invention discloses a method of producing surface acoustic wave devices by exposing X-rays in a direct writing way. Electron beam resist concave solid figures of an interdigital transducer are obtained by photoetching electron beams on a piezoelectric substrate, and various surface acoustic wave devices are produced with the stripping technology. The method of producing surface acoustic wave devices by exposing X-rays in a direct writing way comprises the following concrete steps: spreading the electron beam resist on the piezoelectric substrate; prebaking the electron beam resist; growing metal material which has weak back scattering effect on the electron beam exposure; exposing the electron beams in a direct writing way; removing the metal layer; developing the electron beam resist; fixing the electron beam resist; growing interdigital electrode metal and stripping a beam resist masking film. An interdigital electrode produced with the method has steep and straight edges and good width control, and the method can be used for producing the surface acoustic wave devices which have the characteristic linewidth of less than 500nm. The method needs less process steps and is simple, stable and reliable.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Multi-time overlay method

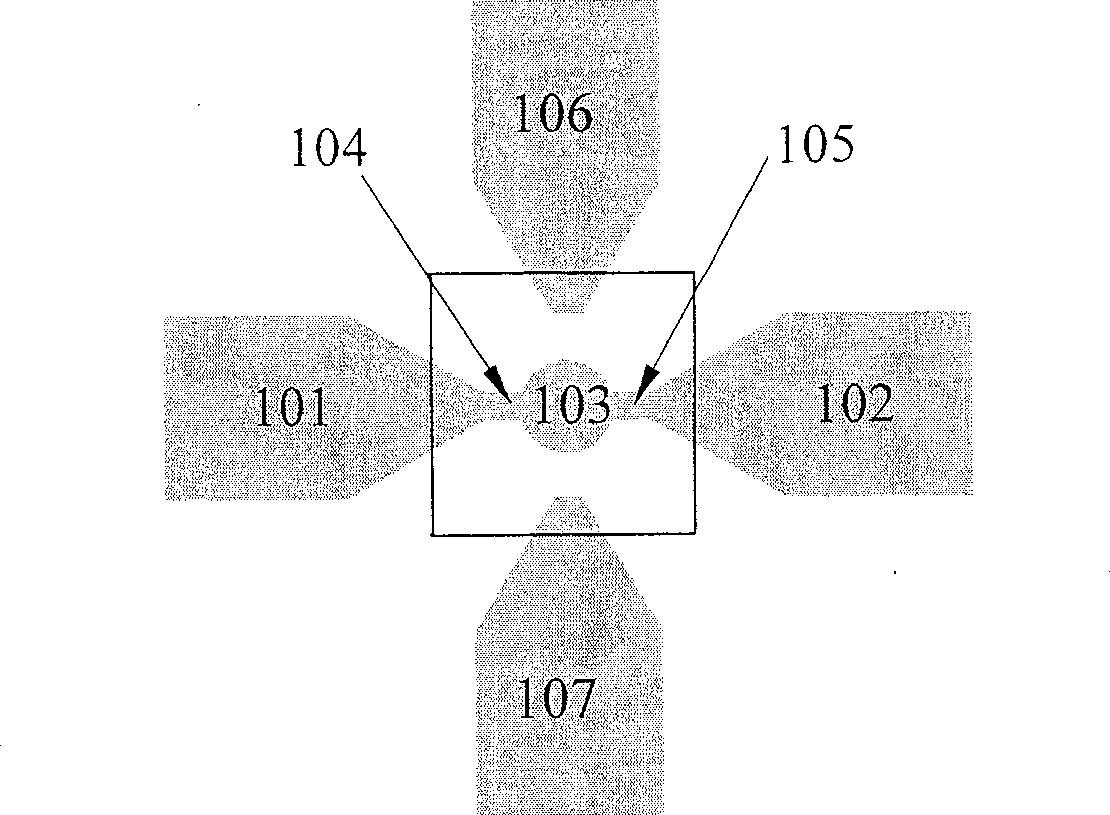

InactiveCN113394083APrevent deviationImprove overlay accuracySemiconductor/solid-state device detailsSolid-state devicesElectron resistsEtching

The invention discloses a multi-time overlay method, which belongs to the technical field of semiconductor micro-nano manufacturing, and comprises the following steps: cleaning a substrate; spin-coating an electronic resist on the substrate; performing electron beam exposure on the pattern, and meanwhile exposing the mark array near the pattern needing to be overlaid; developing the spin-coating electronic resist; etching the pattern and the mark which are overlayed for the first time at the same time; removing the electronic resist; spin-coating an electronic resist on the substrate; using the etching mark near the position needing to be overlayed in the last processing as an overlay mark, performing electron beam overlay on the pattern, and exposing the mark array at the same time; developing the spin-coating electronic resist; etching the pattern and the mark which are subjected to the last overlay at the same time; removing the electronic resist; and finishing the last time of overlay and etching. According to the method, the accumulation of two adjacent overlay deviations and the influence of the relative position deviation of the mark and the graph caused by field splicing are solved, the overlay precision is improved, and the problem that the overlay precision is influenced by the pollution of the mark can also be solved.

Owner:天津华慧芯科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com