Method for manufacturing hundred nano-scale electric solenoid or net-shaped structure

A network structure and solenoid technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the complex production process, no 100-nanometer solenoid or network structure, and many process steps, etc. problem, to achieve the effect of fewer process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

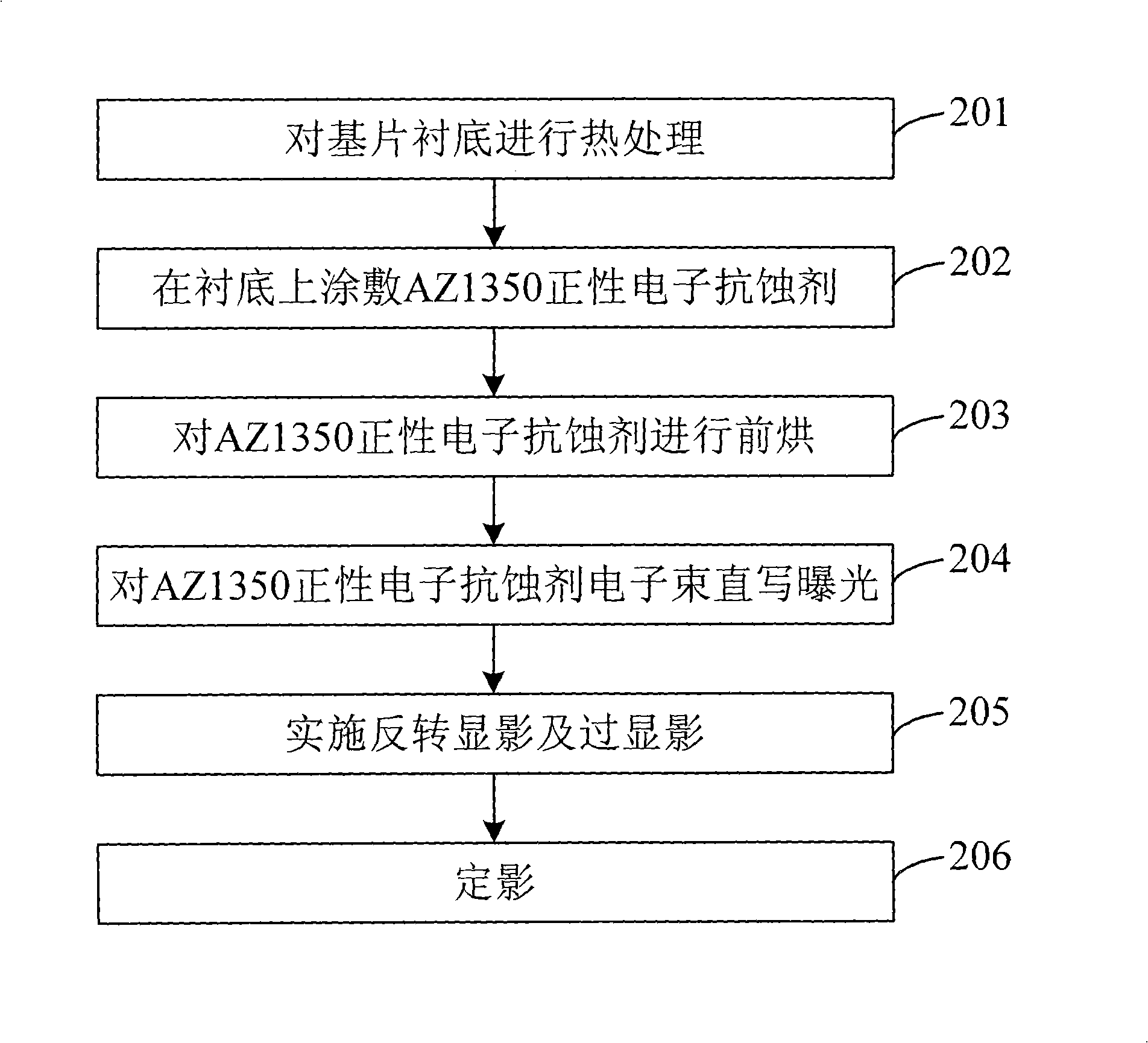

[0048] In this embodiment, taking AZ1350 positive electronic resist as an example, the detailed method and steps for fabricating a 100nm-scale solenoid or network structure by electron beam direct writing exposure technology are further described with reference to the accompanying drawings.

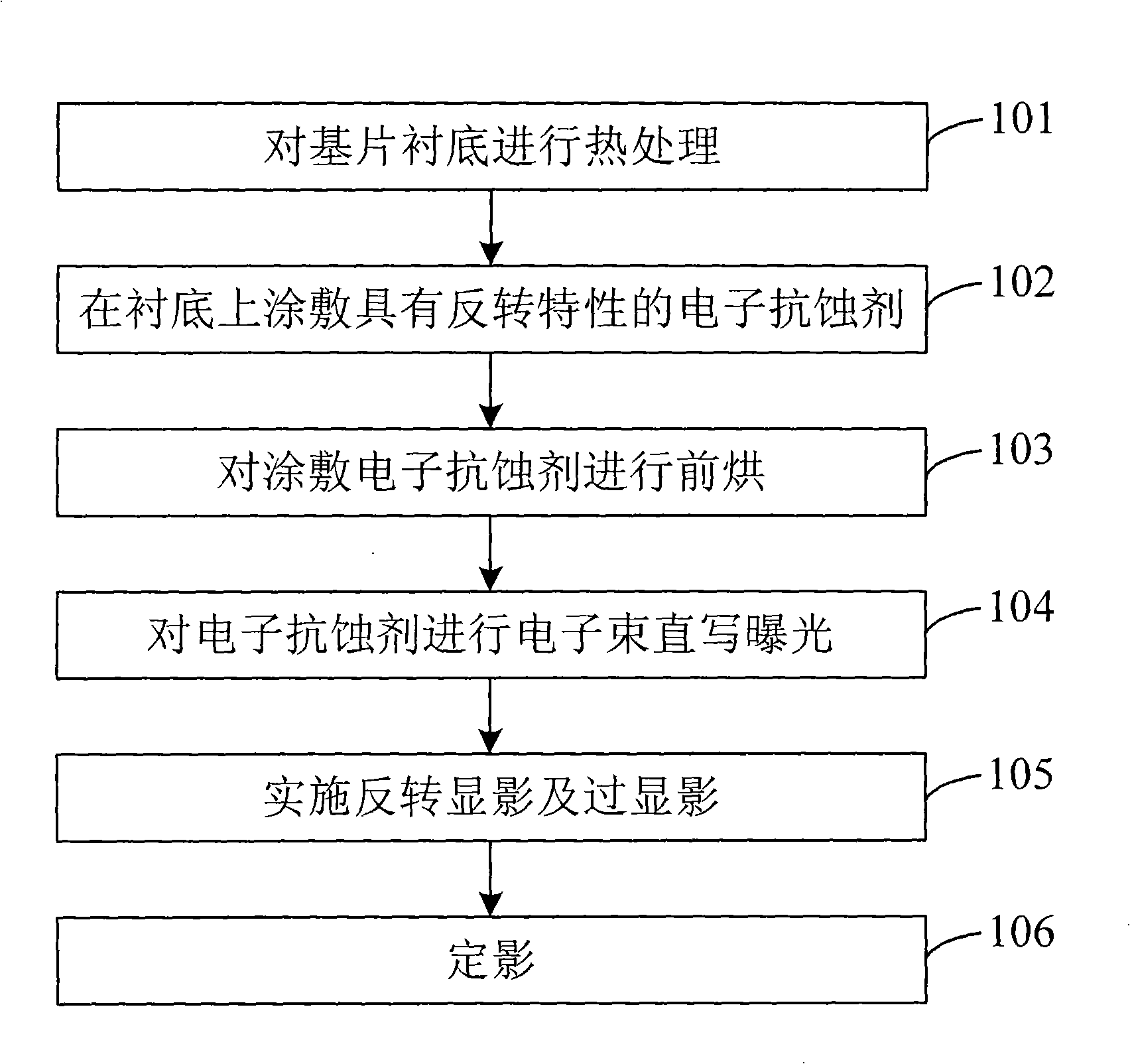

[0049] Such as figure 2 as shown, figure 2 It is a flow chart of a method for fabricating a hundred-nanometer-scale solenoid or a mesh structure using electron beam direct writing exposure technology according to an embodiment of the present invention. The method includes the following steps:

[0050] Step 201: performing heat treatment on the substrate;

[0051] In this step, the heat treatment includes performing strict surface cleaning treatment on the base substrate and high temperature treatment on a hot plate at 120 degrees for 2 minutes.

[0052] Step 202: coating AZ1350 positive electronic resist on the substrate;

[0053] In this step, the substrate is a flat and clean Si su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com