Surface acoustic wave filter and preparation method thereof

A surface acoustic wave and filter technology, which is applied in the field of surface acoustic wave filters and their preparation, can solve the problems of expensive lithography machines and electron beam direct writing equipment, and achieves reduction of preparation cost, reduction of preparation time, and consideration of line The effect of miniaturization of wide size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a method for preparing a surface acoustic wave filter, in particular a method for preparing a filter for high-frequency surface acoustic waves, which can realize batch and low-cost preparation of high-frequency surface acoustic wave filters.

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

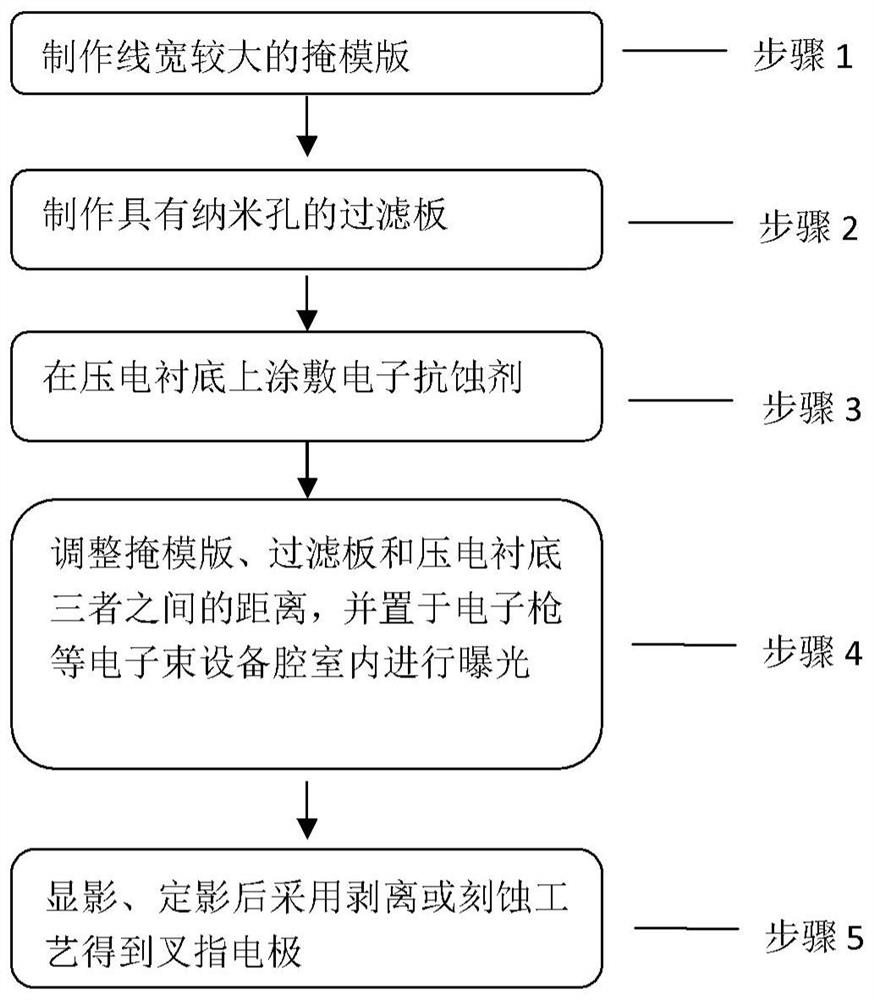

[0020] As an aspect of the present invention, a method for preparing a surface acoustic wave filter is provided, comprising the steps of:

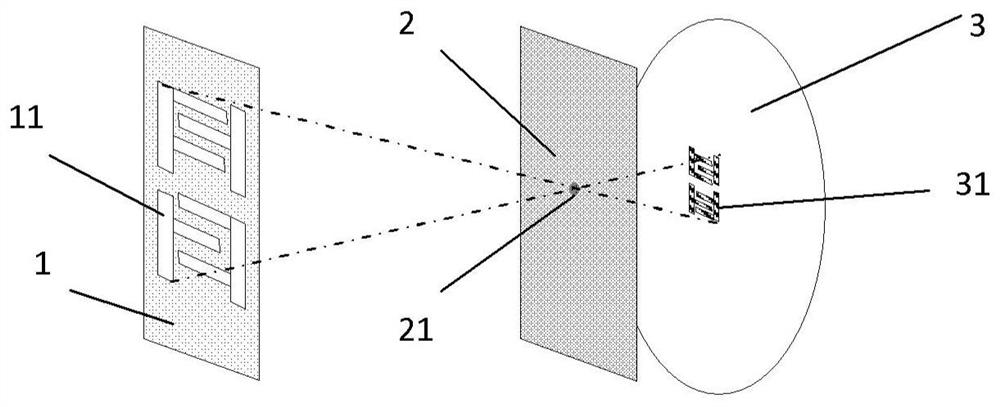

[0021] Step 1: Place the filter plate with nanopores between the mask plate and the piezoelectric substrate coated with electronic resist;

[0022] Step 2: Using the electron beam exposure method, image-transfer the pinholes of the interdigitated electrode mask pattern on the reticle to the electronic resist of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com