Method for manufacturing nano-scale pattern

A nano-scale, graphic technology, used in the manufacture of microstructure devices, photoengraving processes for patterned surfaces, processes for producing decorative surface effects, etc. Solve high-cost, high-resolution, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

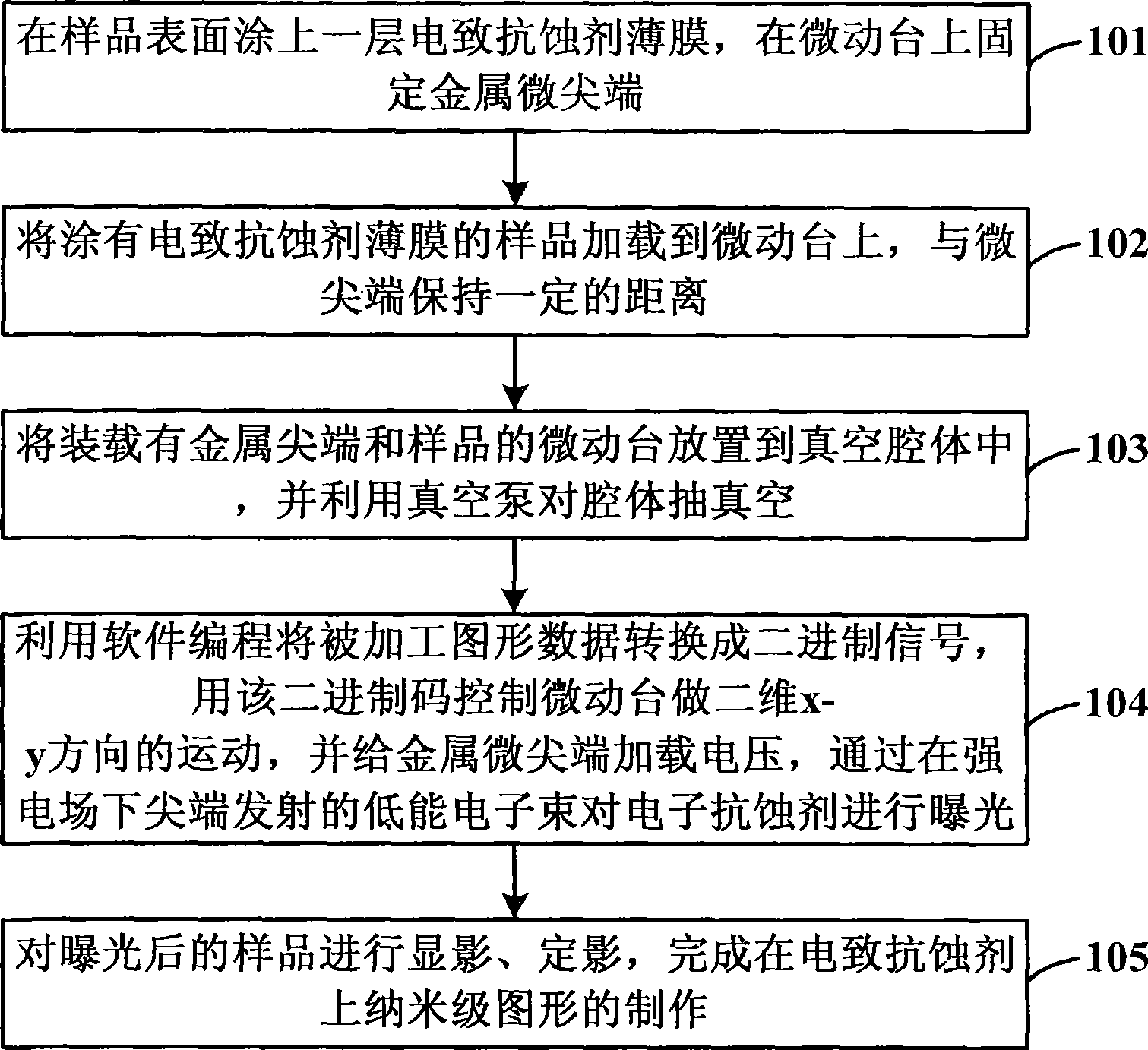

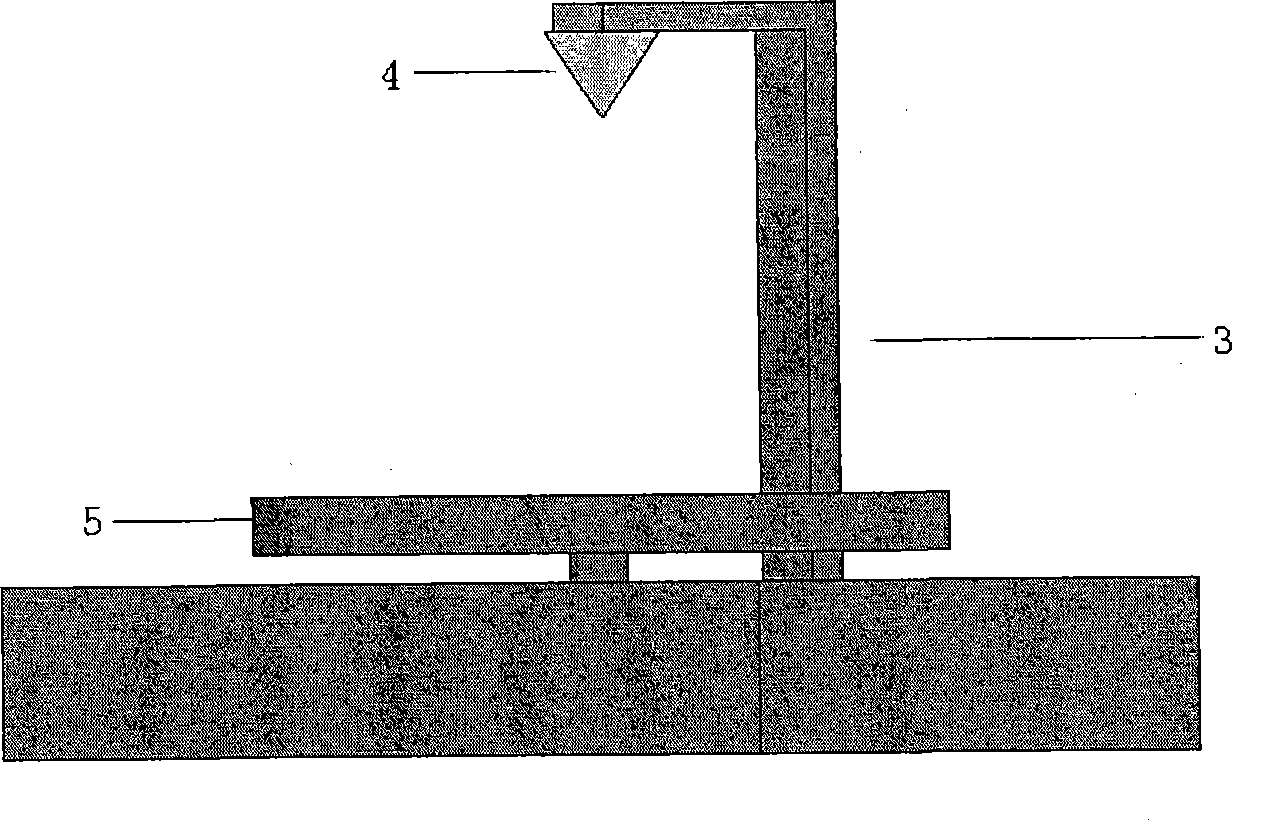

[0028] Such as figure 1 as shown, figure 1 It is a flow chart of the method for making nanoscale graphics using electron beams generated by field emission provided by the present invention. The nanoscale graphics convert graphic data into binary signals to control the two-dimensional x-y direction movement of the micro-motion stage and the loading of the metal tip voltage , obtained by exposing the electronic resist with an electron beam generated after the tip is loaded with a voltage, the method includes:

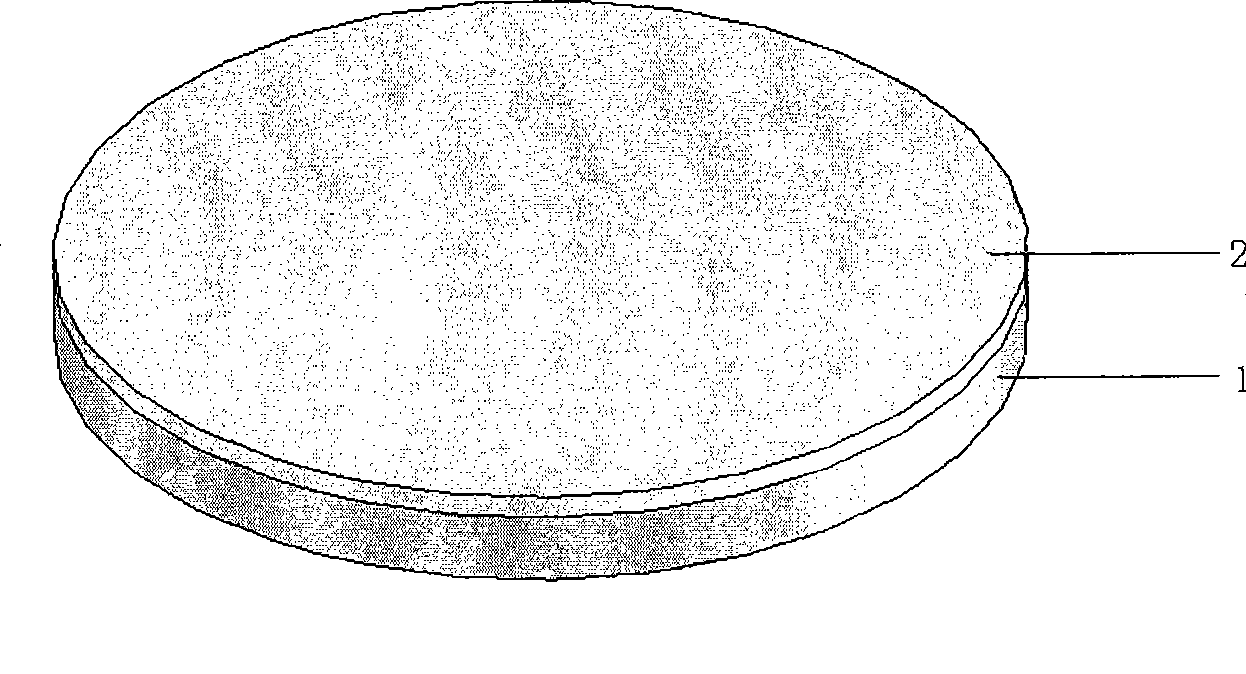

[0029] Step 101: Coating a layer of electroresist film on the surface of the sample, and fixing the metal microtip on the micro-motion stage; in this step, a layer of electroresist is coated on the surface of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com