Method for adopting positive electronic corrosion-resistant to prepare metal nano electrode

A metal nano-resist technology, applied in circuits, electrical components, opto-mechanical equipment, etc., can solve the problems of single electrode material, low efficiency, and difficult optical lithography resolution to reach nanoscale resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

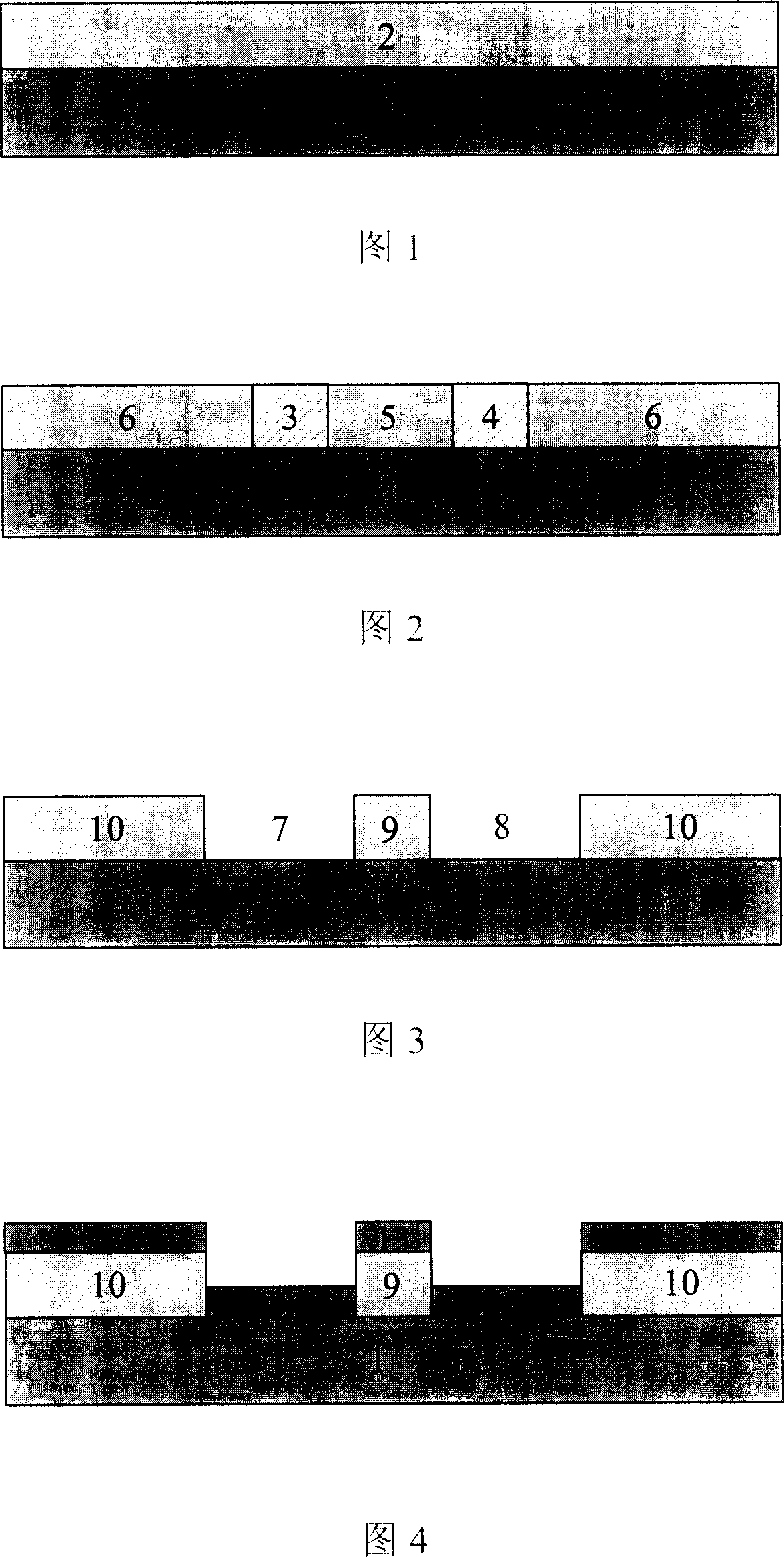

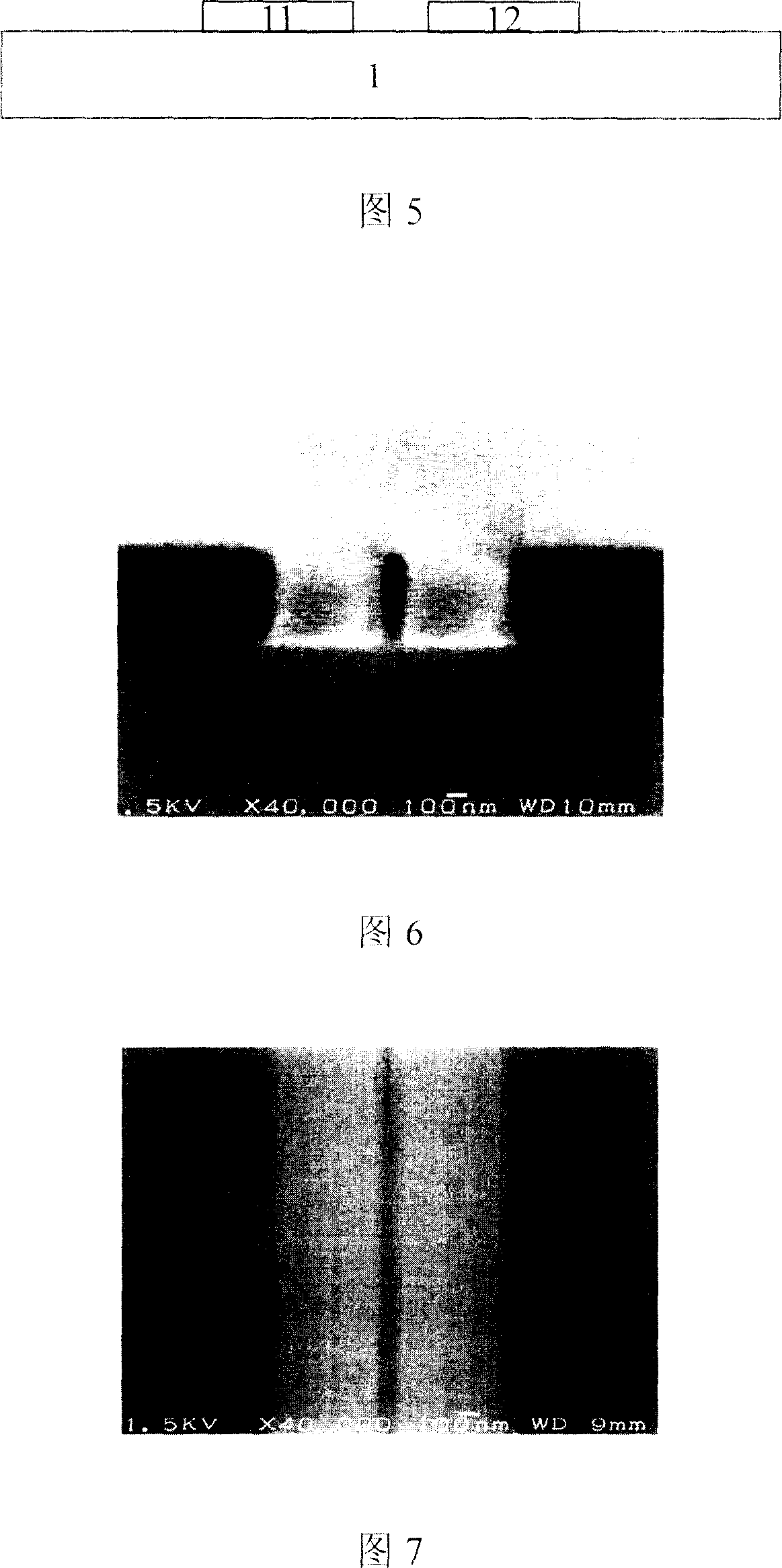

[0027] Taking the use of ZEP520 positive electronic resist and evaporating Cr / Au double-layer metal electrode film as an example, the detailed process and steps of the present invention are further described in conjunction with the accompanying drawings, wherein:

[0028] As shown in Figure 1, the surface is flat and clean with SiO 2 On the Si substrate 1 of the insulating film, a single-layer ZEP520 positive electronic resist 2 was coated with a coater, the coating speed was 2000 rpm, the coating time was 60 seconds, and the thickness of the resist was 485 nm. Then use an oven to pre-bake at 180°C for 20 minutes.

[0029] As shown in Figure 2, the electron beam direct writing exposure was performed on the regions 3 and 4 of the ZEP520 resist 2, and the regions 5 and 6 were not exposed. The width of the region 3 and the region 4 is 350 nm, and the interval between the region 3 and the region 4, that is, the width of the unexposed region 5 is 250 nm. Electron beam exposure ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com