Method for preparing material with highly gradient surface micronano structure

A technology of micro-nano structure and target material, applied in the field of nano-material processing, to achieve the effects of high time consumption, high controllability and repeatability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

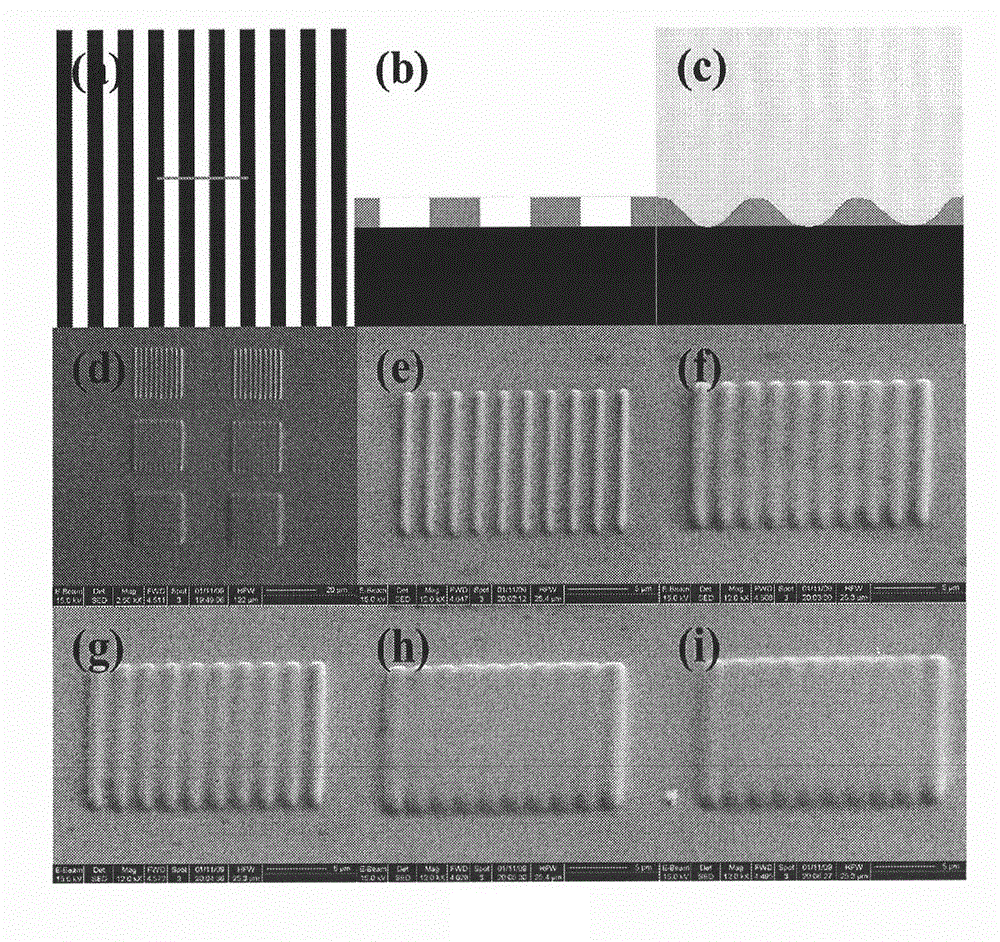

[0037] Example 1. Preparation of materials with wavy structure on the surface

[0038] 1) Coat PMMA on the Si substrate to obtain an electronic resist layer, and bake the glue at 170°C (heating rate of 20°C / min) for 30 minutes;

[0039] 2) Expose the PMMA layer that has been baked in the step 1) with electron beams, develop with a developer solution of methyl isobutyl ketone (MIBK): isobutanol = 1:3, and rinse with alcohol for fixing; the resulting pattern Such as figure 1 As shown in (a), the exposure pattern is a black area; figure 1 The exposure pattern of (b) is figure 1 (a) A cross-sectional view of the PMMA structure after exposure of the black short line indicates the area, wherein the lower part of the cross-sectional view is the silicon substrate, and the upper part is PMMA.

[0040] 3) On the electronic resist layer that has been fixed in step 2), coat anisole when the rotation speed of the spinner reaches 3000 rpm, and heat it at 170°C (heating rate is 20°C / min) 30min und...

Embodiment 2

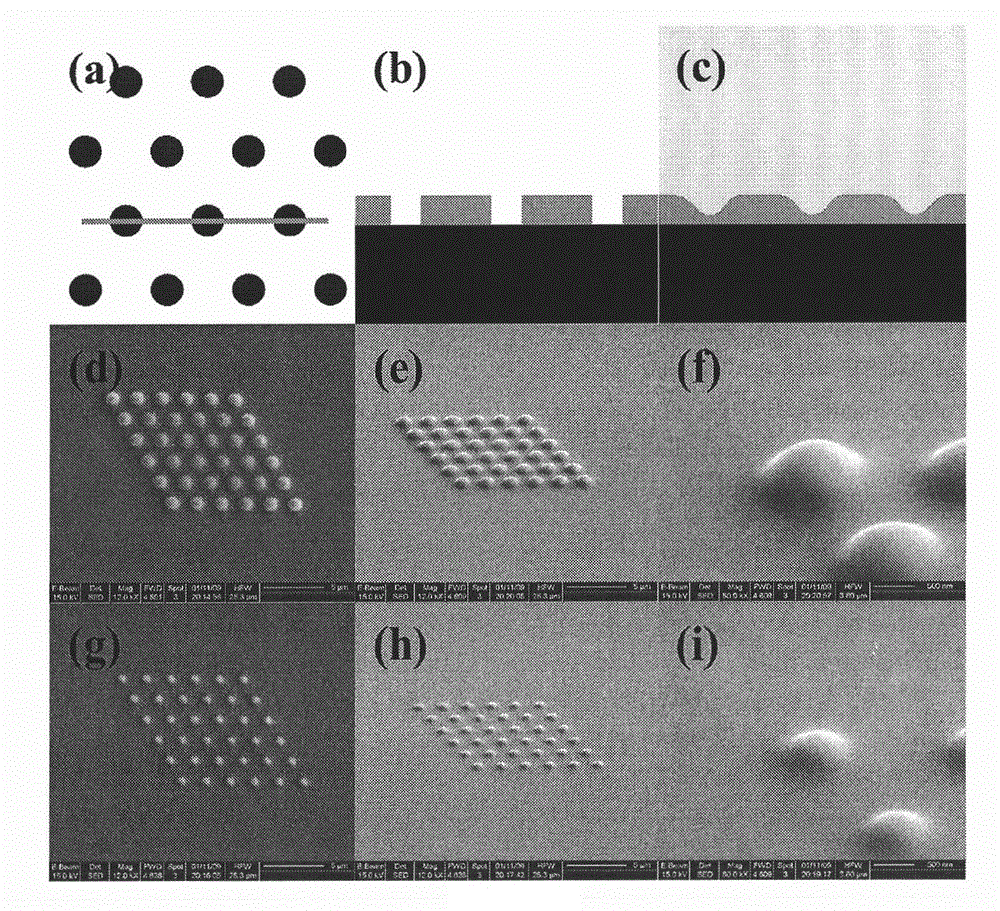

[0047] Example 2. Preparation of a material with a smooth protrusion structure on the surface

[0048] 1) Coat PMMA on the Si substrate to obtain an electronic resist layer, and bake the glue at 170°C (heating rate of 20°C / min) for 30 minutes;

[0049] 2) Expose the PMMA layer that has been baked in the step 1) with electron beams, develop with a developer solution of methyl isobutyl ketone (MIBK): isobutanol = 1:3, and rinse with alcohol for fixing; the resulting pattern Such as figure 2 As shown in (a), the exposure pattern is a blue area; figure 2 The exposure pattern of (b) is figure 2 (a) A cross-sectional view of the PMMA structure after exposure of the black short line indicates the area, wherein the lower part of the cross-sectional view is the silicon substrate, and the upper part is PMMA.

[0050] 3) On the electronic resist layer that has been fixed in step 2), coat anisole when the rotation speed of the spinner reaches 3000 rpm, and heat it at 170°C (heating rate is 20...

Embodiment 3

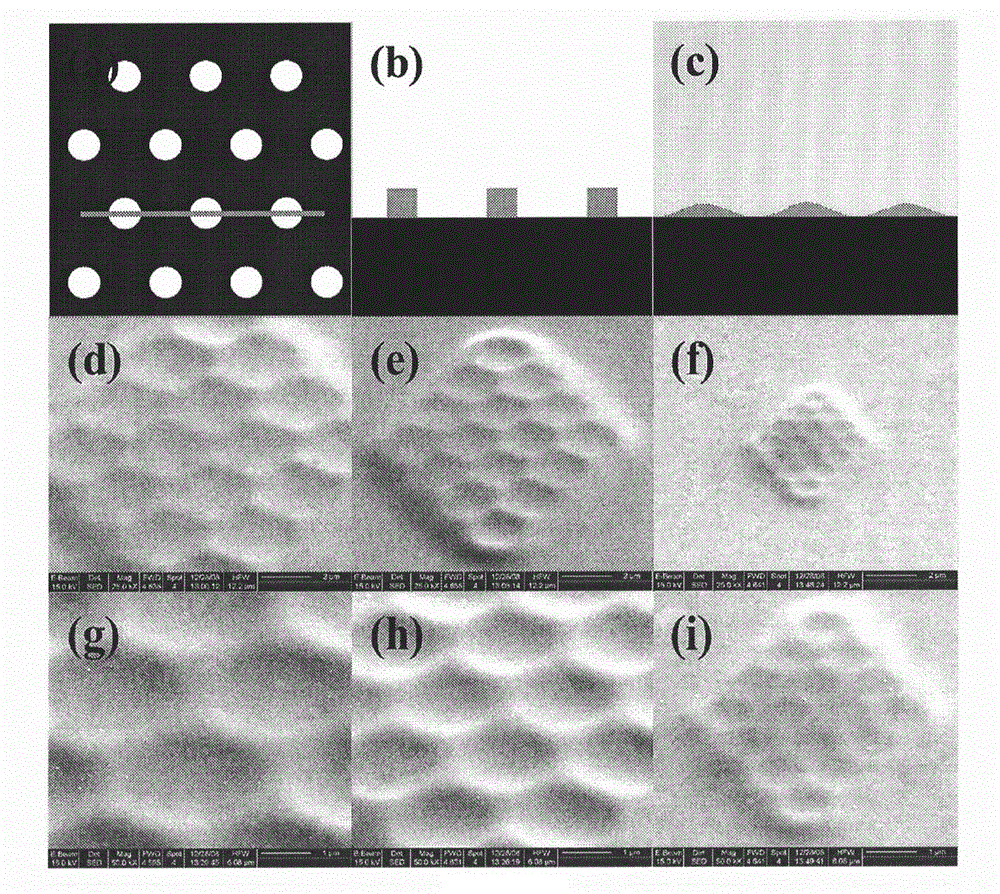

[0057] Embodiment 3. Preparation of a material with a smooth concave array structure on the surface

[0058] 1) Coat PMMA on the Si substrate to obtain an electronic resist layer, and bake the glue at 170°C (heating rate of 20°C / min) for 30 minutes;

[0059] 2) Expose the PMMA layer that has been baked in the step 1) with electron beams, develop with a developer solution of methyl isobutyl ketone (MIBK): isobutanol = 1:3, and rinse with alcohol for fixing; the resulting pattern Such as image 3 As shown in (a), the exposure pattern is a blue area; image 3 The exposure pattern of (b) is image 3 (a) A cross-sectional view of the PMMA structure after exposure of the black short line indicates the area, wherein the lower part of the cross-sectional view is the silicon substrate and the upper part is PMMA.

[0060] 3) On the electronic resist layer that has been fixed in step 2), coat anisole when the rotation speed of the spinner reaches 3000 rpm, and heat it at 170°C (heating rate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com