Manufacturing method for electro-chemical electrical conducting functional membrane

A manufacturing method and technology of functional film, applied in the field of electrode sheets, can solve the problems of inability to perform multi-level blank processing of special shape forming, single type, complicated manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

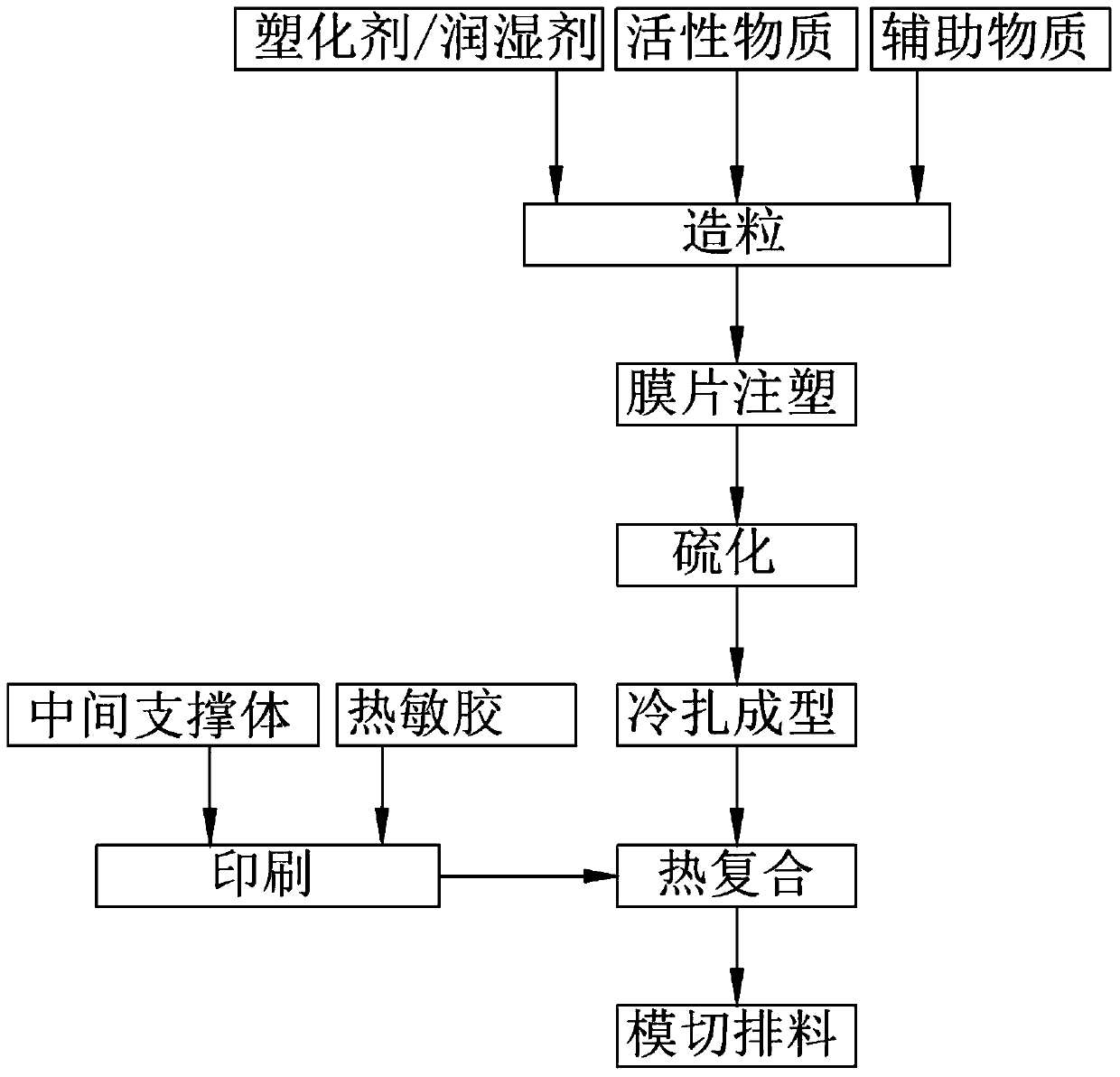

[0041] A kind of manufacture method of electrochemically conductive functional diaphragm, see Figure 1 to Figure 6 shown, including the following steps.

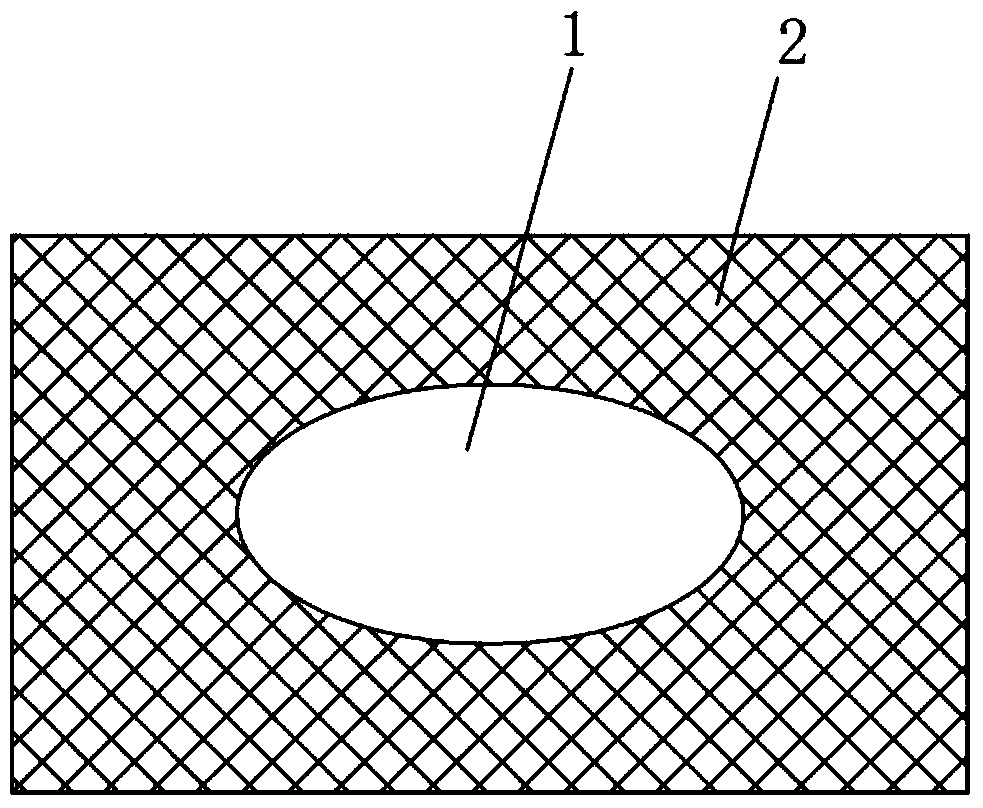

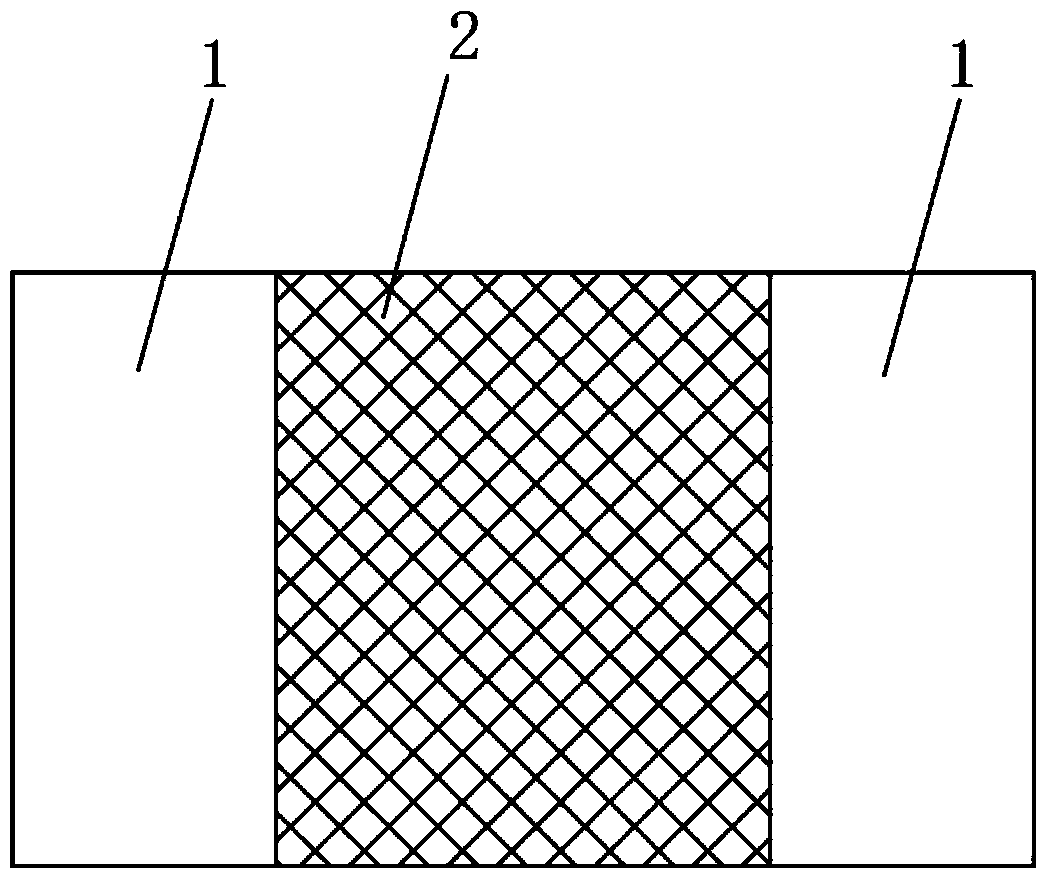

[0042] In the printing step, the intermediate support 1 is made of 25um corroded aluminum foil produced by East Sunshine, and the intermediate support 1 is used as the mold skeleton. The heat-sensitive adhesive is formed on the intermediate support 1 by printing, and the heat-sensitive adhesive formed on the intermediate support is formed. For the set pattern or shape, other parts of the intermediate support are blank parts. The printing method of the intermediate support body 1 is an anilox roller printing method, a rubber roller printing method, a screen printing method, a transfer printing method or a spray printing method.

[0043] In the batching step, the following weight ratios of active substances, auxiliary substances, plasticizers and wetting agents are mixed to form a primary masterbatch,

[0044]

[0045] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com