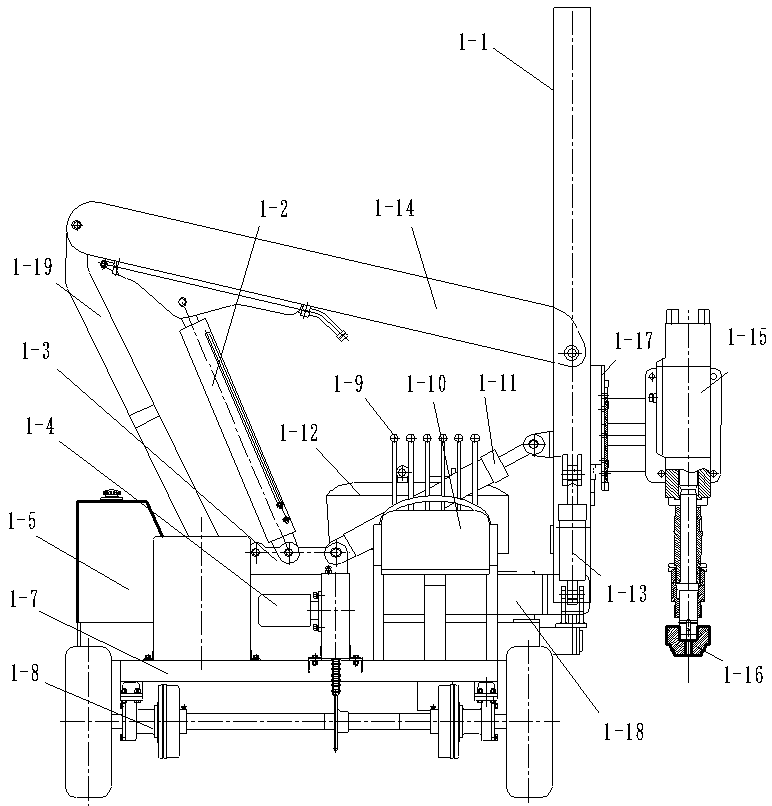

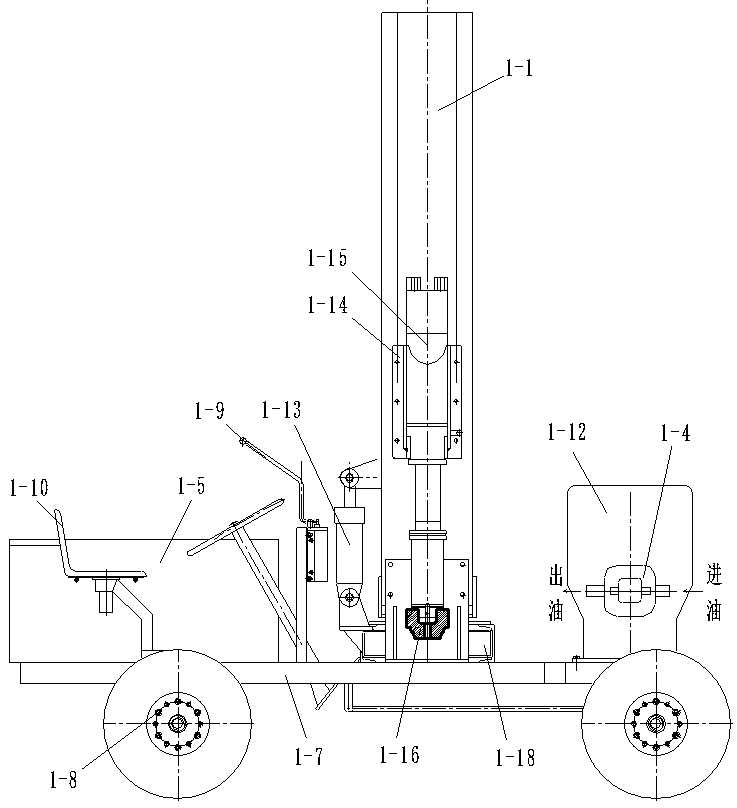

Operating mechanism of highway guardrail pile driving and pulling machine

A technology of working mechanism and highway guardrail, which is applied in the direction of roads, roads, sheet pile walls, etc., can solve the problems of large vibration, complicated operation, short stroke, etc., and achieve the effect of small vibration, high verticality and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

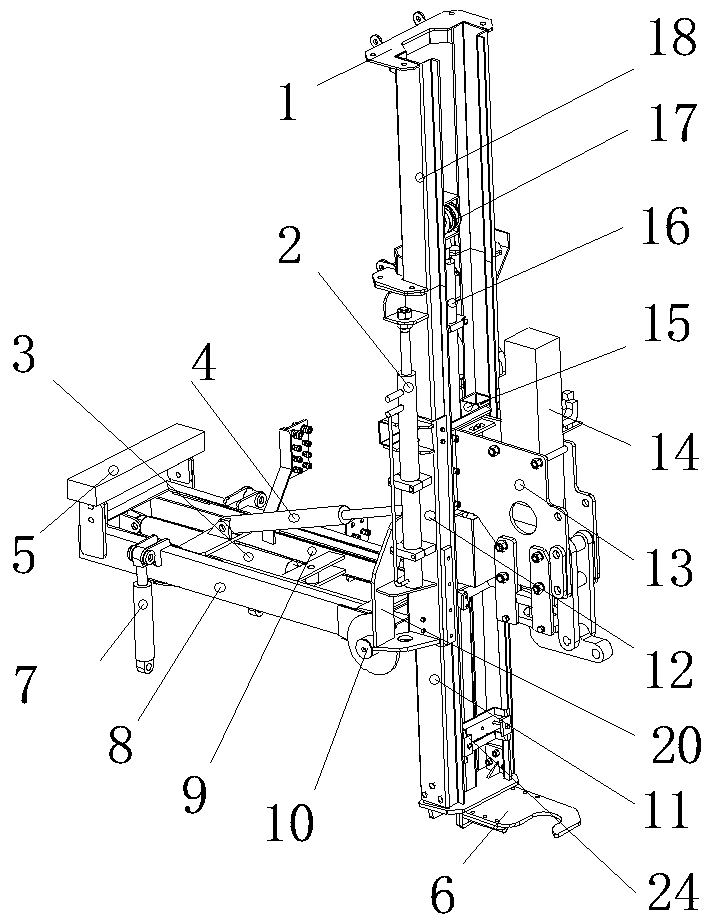

Embodiment 1

[0057] Example 1: In image 3 , Figure 4 Among them, the working mechanism includes: a column, a limit frame 24, a pile holder 6, a lifting device, a horizontal device, a left and right device, a pitching device and a working device; Device 6; a working device is connected to the column through a lifting device, and the lifting device slides up and down along the column, and drives the working device to move up and down; the column is hinged on one end of the horizontal device through a pitching device, and the column can move laterally with the horizontal device, and The horizontal device can be used as the fulcrum for pitching movement; the bottom of the horizontal device is hinged on the ground, the left and right devices are hinged between the horizontal device or the column and the site, and the horizontal device uses the bottom hinge as the fulcrum, driven by the left and right devices together with the column Make left and right movements.

[0058] exist Figure 8 A...

Embodiment 2

[0080] Example 2: In Figure 4 Among them, it is an embodiment in which a secondary lifting cylinder 4-2 is respectively installed on both sides of the fixed column.

Embodiment 3

[0081] Example 3: In Figure 5 Among them, it is the embodiment that an auxiliary lifting cylinder 4-2 is installed on the rear side of the fixed column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com