Method for producing nano-structure on insulated underlay

An on-insulating, nano-structured technology, applied in opto-mechanical equipment, patterned surface photoengraving process, semiconductor/solid-state device manufacturing, etc. , the effect of assisting the dissolution process and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

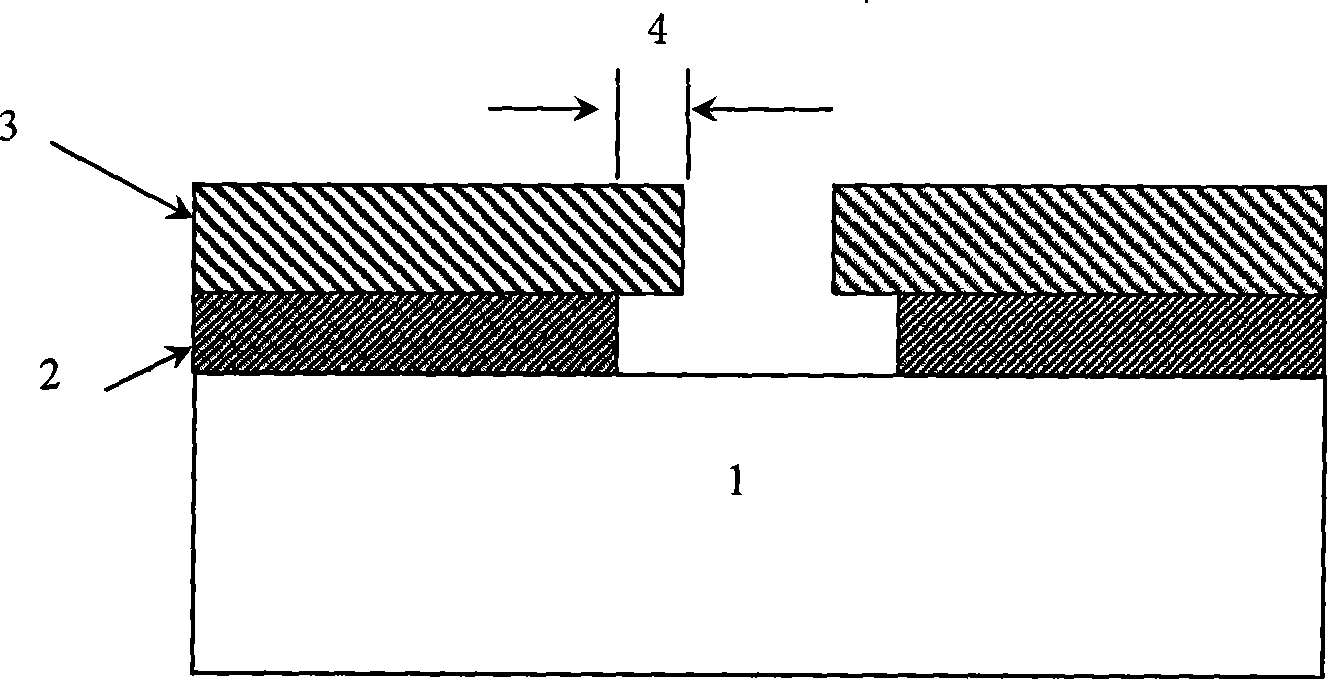

[0031] Embodiment 1, the method for making nanostructure on insulating quartz glass, comprises the following steps:

[0032] 1. Select insulating quartz glass as the substrate, choose 0.8mm double-sided polished quartz glass as the substrate 1, and clean it with acetone, alcohol and deionized water in sequence, after ultrasonic cleaning, then dry it with dry nitrogen, and put it at 95°C Bake on a hot plate for two hours and set aside;

[0033] 2. Use thermal evaporation coating equipment to deposit a layer of 80nm aluminum film 2 on the above-mentioned baked quartz glass substrate 1, and then spin-coat a layer of about 140nm thick electron beam resist on the aluminum film 2. Agent 3, the electron beam resist is selected from the PMMA495 glue purchased on the market, and the spin coating speed is 4000rpm; after spin coating, the sample is pre-baked with a hot plate at 180°C, and the pre-baking time is 65 seconds;

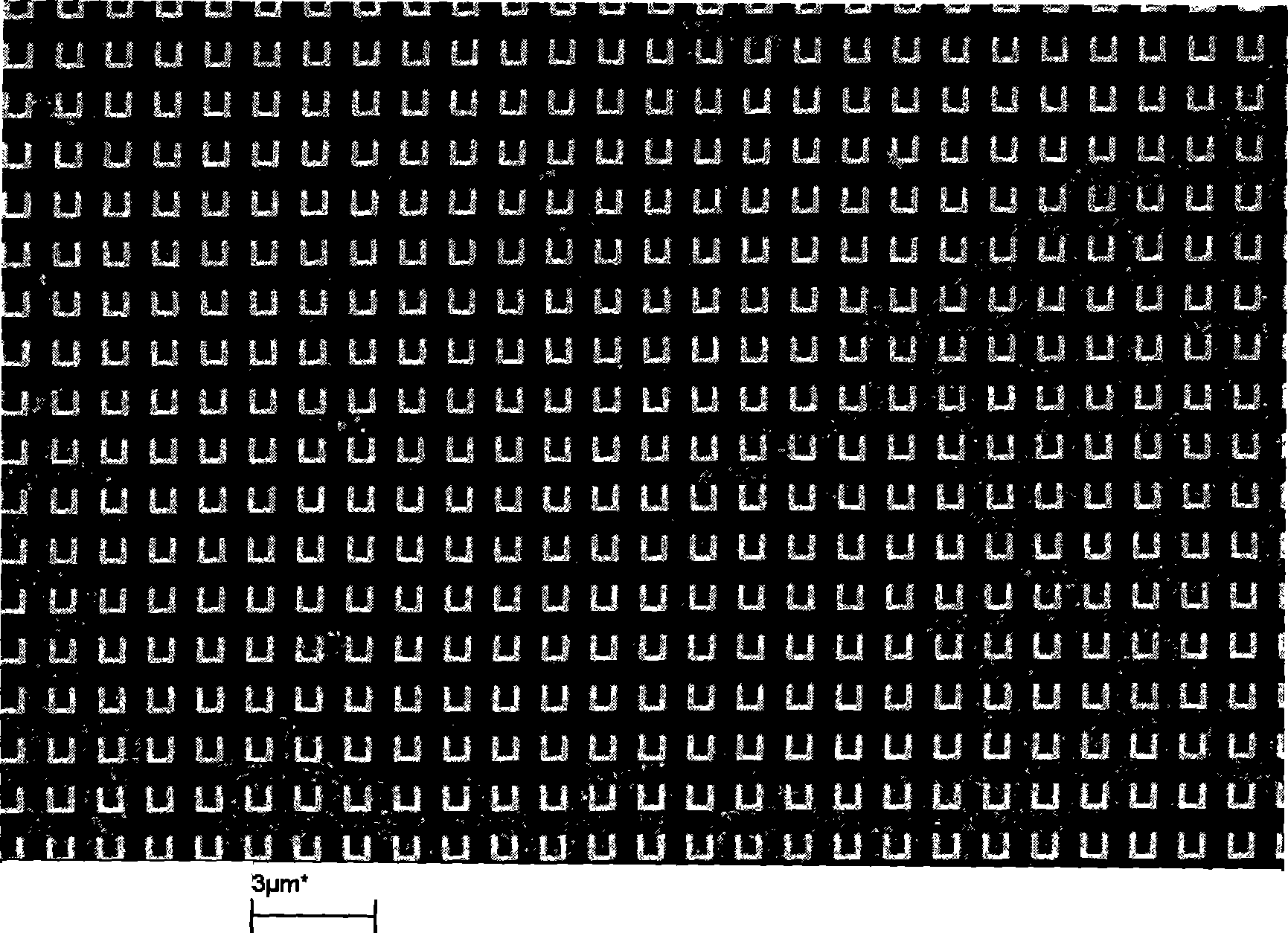

[0034] 3 Design of nanostructure pattern: According to the siz...

Embodiment 2

[0041] The preparation method of the present embodiment is identical with embodiment 6, but condition is as follows:

[0042] Fabrication of nano-copper electrodes on insulating sapphire substrate 1: 1 mm thick double-sided polished sapphire was cleaned ultrasonically with acetone, alcohol and deionized water, dried with dry nitrogen, and baked on a hot plate at 115°C for two hours . A layer of 120nm aluminum film 2 is deposited on the sapphire substrate using magnetron sputtering coating equipment, and then a layer of electron beam resist 3 with a thickness of about 120nm is spin-coated on the aluminum film 2. The electron beam resist Use the PMMA950 glue purchased in the market. After spin coating, the sample was pre-baked in an oven at 180°C for 30 minutes. The samples were then exposed using an electron beam exposure system. The exposure pattern is edited by GDSII software, including the line structure with a minimum line width of 60nm. Exposure parameters: write field...

Embodiment 3

[0044] The preparation method of the present embodiment is identical with embodiment 6, but condition is as follows:

[0045] Fabrication of nano-gold electrodes on insulating glass substrate 1: After cleaning the 0.5mm thick glass substrate with acetone, alcohol and deionized water with ultrasonic cleaning and drying with dry nitrogen, bake it on a hot plate at 180°C for 20 minute. A layer of 60nm aluminum film 2 is deposited on a sapphire substrate using magnetron sputtering coating equipment, and then a layer of electron beam resist 3 with a thickness of about 200nm is spin-coated on the aluminum film. The electron beam resist is selected from ZEP520 glue purchased in the market. After spin coating, the samples were pre-baked on a hot plate at 200°C for 2 minutes. The samples were then exposed using an electron beam exposure system. The exposure pattern is edited by L-edit software, including a line structure with a minimum line width of 80nm and a minimum line spacing o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com