Freezer oil for r32 refrigerant and composition comprising same

A technology of refrigerating machine oil, R32, applied in lubricating compositions, additives, petroleum industry, etc., can solve problems such as use restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

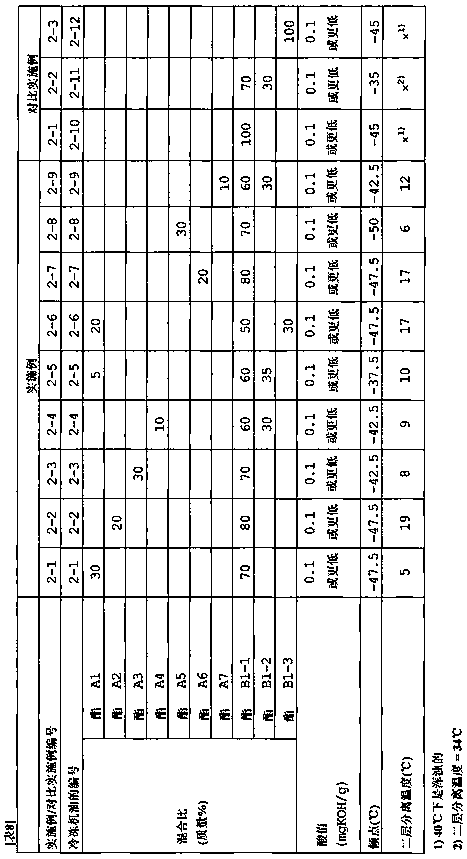

[0133] Hereinafter, the present invention is explained in more detail by showing Examples and Comparative Examples; however, the scope of the present invention is not limited by the following Examples.

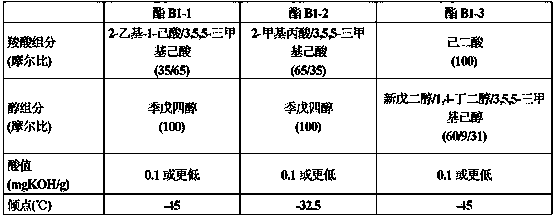

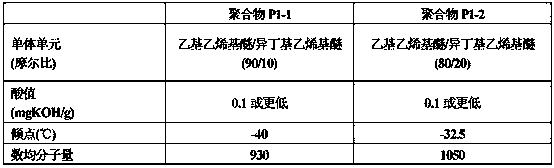

[0134] [Synthesis of citrate triester (component (A)) and other esters]

manufacture Embodiment 1

[0136] Citric anhydride (282g, 1.47mol), 1-butanol (294g, 3.97mol), and 2-ethyl-1-hexanol (114g, 0.87mol) were injected into a four-necked flask, under a nitrogen atmosphere, at 200 The reaction was carried out at normal pressure for 5 hours at °C while distilling off the reaction water. Thereafter, the reaction was continued at 200° C. until the acid value reached not more than 2 mgKOH / g. Next, the excess alcohol was distilled off at 200°C under reduced pressure of 1-5 kPa to give the crude ester. Cool the crude ester, add acid clay and an adsorbent based on silica-alumina respectively at 1.0% by mass of the theoretically obtained ester, and perform adsorption treatment (adsorption treatment temperature: 100°C, pressure: 1-5kPa, adsorption Processing time: 2 hours). Finally, the mixture was filtered through a 1-micron filter to give the target citrate triester (acid value not more than 0.1 mgKOH / g) (hereinafter referred to as "ester A1").

manufacture Embodiment 2

[0138] Citric anhydride (295g, 1.53mol), 1-butanol (326g, 4.40mol), and 1-octanol (86g, 0.66mol) were injected into a four-necked flask, and evaporated at 200°C under a nitrogen atmosphere. The reaction was carried out under normal pressure for 5 hours while reacting water. Subsequent steps were carried out in the same manner as in Production Example 1 to give the target citrate triester (hereinafter referred to as "ester A2").

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com