Electron beam overlay marking based on hafnium dioxide and its manufacturing method

A technology of hafnium dioxide and its production method, which is applied to the photoplate making process of the patterned surface, circuits, electrical components, etc., and can solve the problems of poor adhesion between gold and silicon substrates, expensive gold targets, and metal melting deformation. , to achieve strong adhesion, lower production costs, and high alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

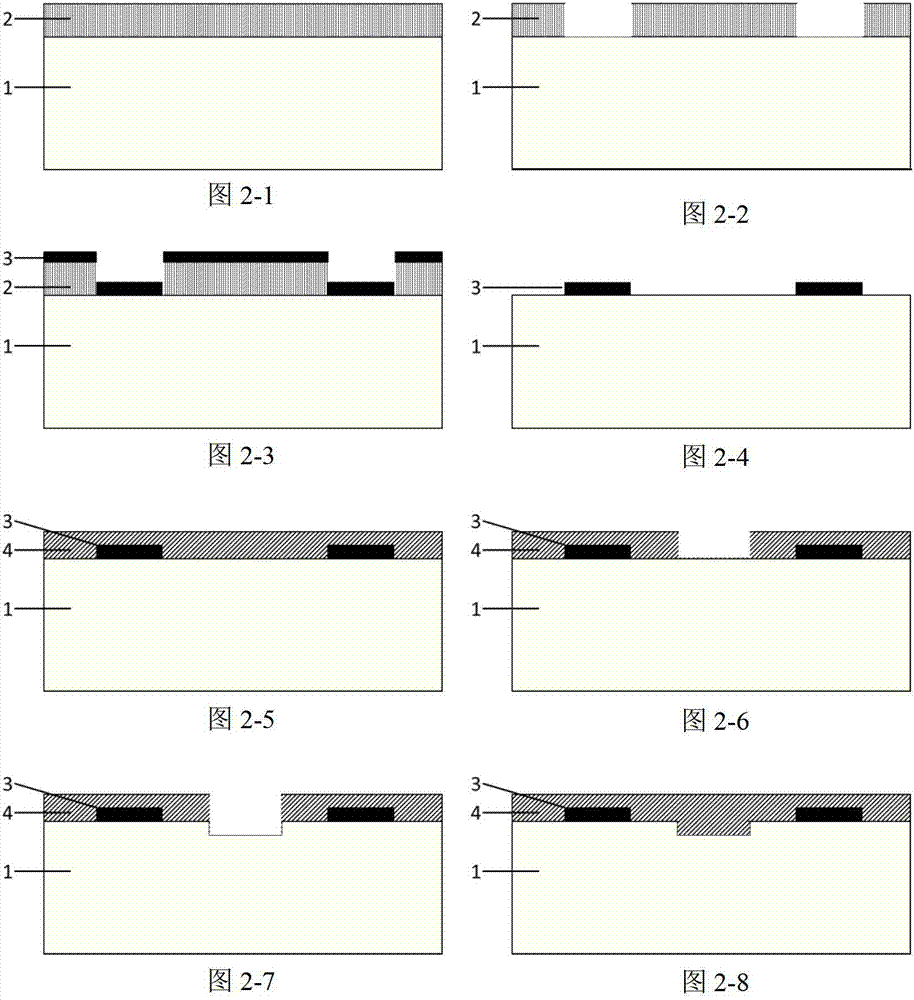

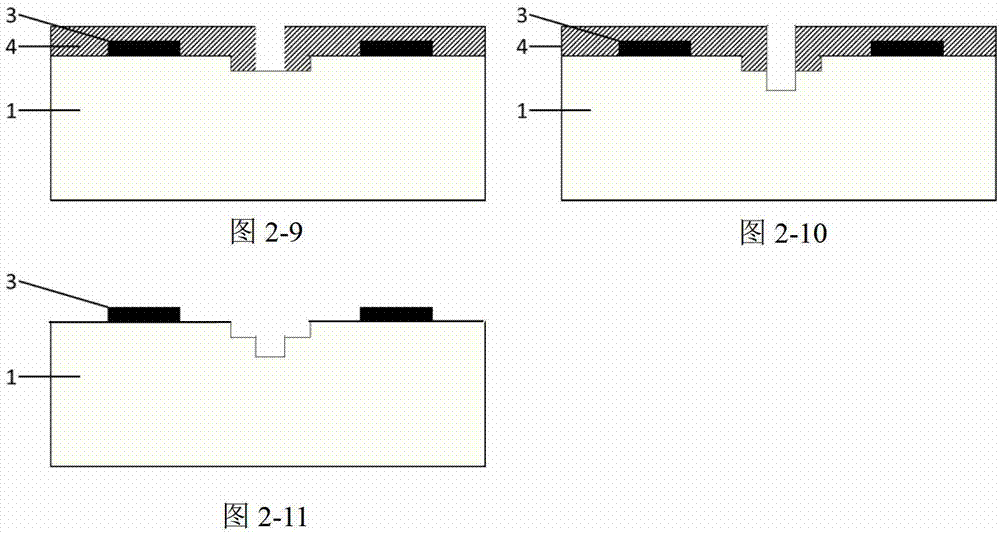

Method used

Image

Examples

Embodiment

[0054] Example: Experimental measurement of hafnium dioxide overlay accuracy.

[0055] Design layout such as image 3 , the left and right parts respectively represent the A and B two-layer waveguides that need to be engraved. The width of the waveguide (that is, the blank part between the white strips and the shadow strips) is 500nm, and the vertical arrangement interval of the waveguides in the B layer is 2.5μm; the position deviation of the waveguide in the center of the A and B layers in the y direction is 0 , along the y-axis positive and negative A-layer waveguide arrangement period is 25nm larger than B-layer waveguide arrangement period. Use positive electronic resist ZEP520 as a mask, and use ICP to etch about 200nm on the substrate after electron beam overlay exposure; after the two-layer waveguide etching is completed, send the sample to the scanning electron microscope to measure the alignment error (such as Pic 4-1 ,4-2). Pic 4-1 , 4-2 represent the overlay a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com