A method for optimizing the resolving power of electron beam lithography machine

An electron beam exposure machine and a technology with analytical capabilities, which are used in opto-mechanical equipment, microlithography exposure equipment, photolithography process exposure devices, etc. high contrast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

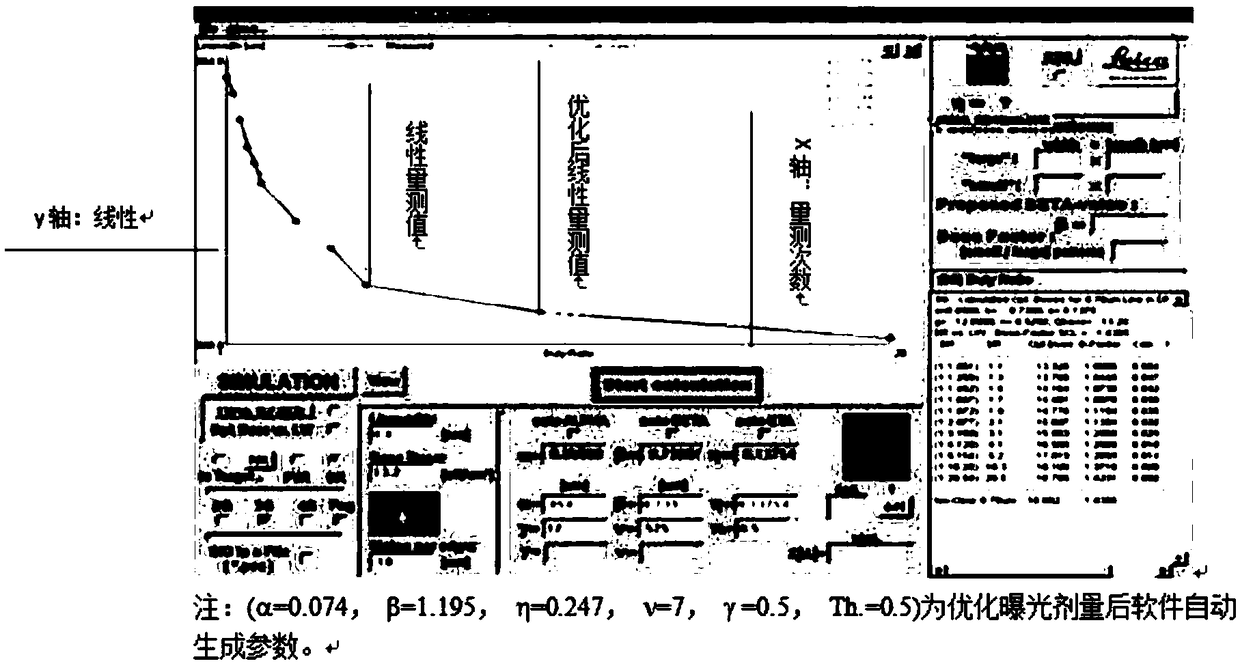

[0023] Exposure equipment: Leica SB350, the support technology node of the exposure equipment is 0.13μm mask production, in the current process,

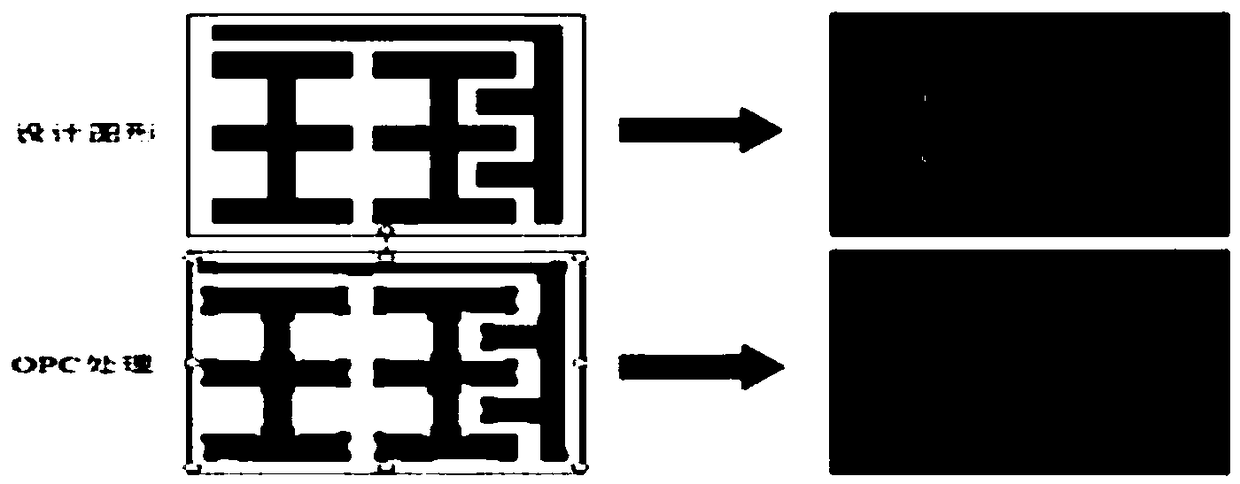

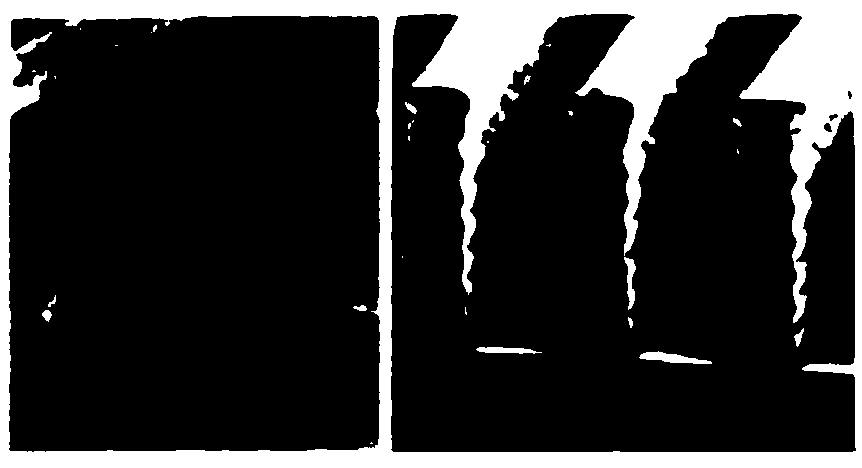

[0024] There are several aspects to improve the analytical capabilities of the exposure machine:

[0025] (1) The characteristics of electronic resists: resists are also called photosensitive glues. After electron beam exposure of commonly used linear chain high-molecular polymers, the polymer will undergo both chain scission and cross-chain reactions. Any resist with a dominant chain scission reaction is called a positive resist, and any resist with a dominant cross-chain reaction is called a negative resist. At present, the resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com