Soft rock roadway anchored concrete filled steel tube anti-floor heave device and construction method thereof

A technology for anchoring steel pipes and concrete, which is applied in the fields of earthwork drilling, installation of anchor rods, and foundation structure engineering, etc. It can solve problems such as inability to really control bottom sag, mismatch between extension and bottom sag, and loss of control of bottom sag, etc. problems, to achieve the effect of controlling the bottom of the roadway, superior cost performance, and improving stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

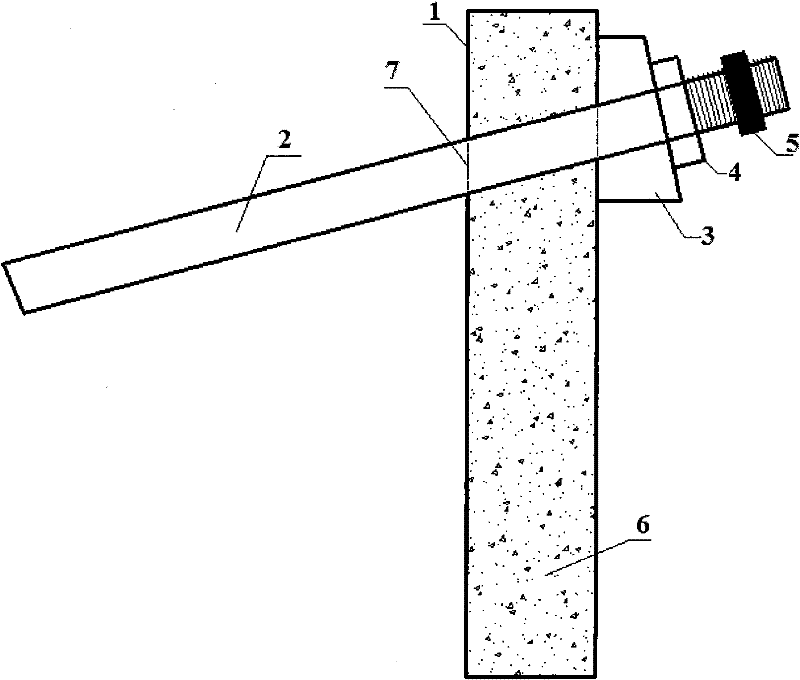

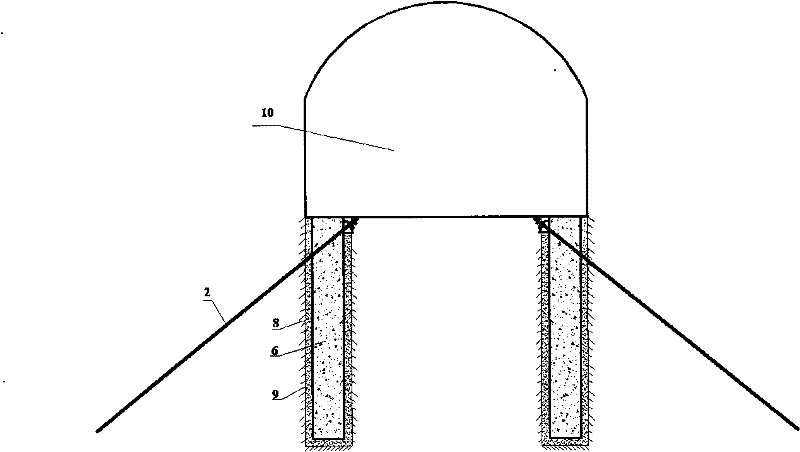

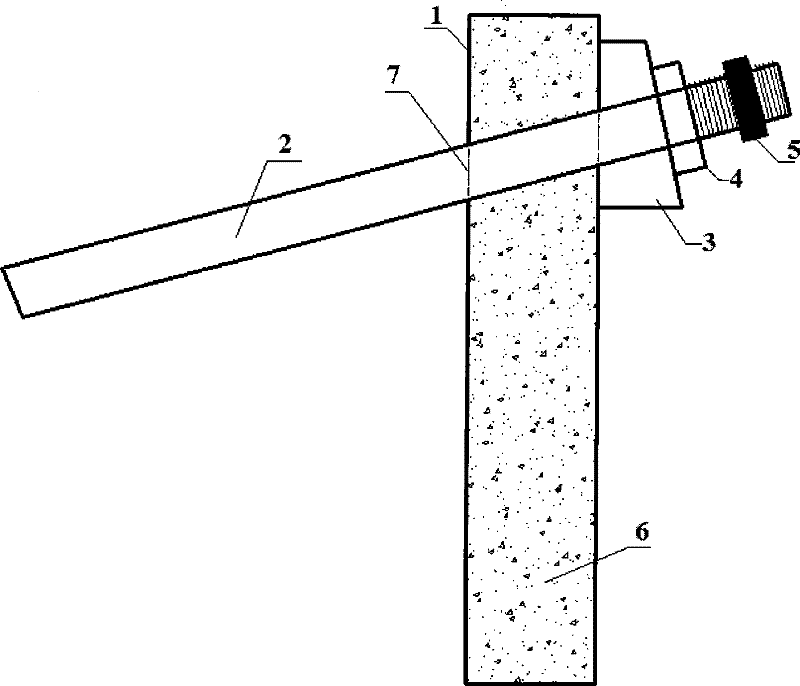

[0026] like figure 1 As shown, the anti-bottoming device of steel pipe concrete for soft rock roadway of the present invention is mainly composed of steel pipe piles, anchor rods or anchor cables 2, pads 3 and washers 4 to form an anchor system. The steel pipe pile is composed of a steel pipe body 1 with a diameter of 80-200mm and a thickness of 5-20mm and an internal cast-in-place concrete 6; the steel pipe pile is 100-200mm from the upper end and has a through hole 7 obliquely downward, The angle between the axis of the through hole 7 and the axis of the steel pipe pile is 10° to 15°; the pad 3 is a cylinder with a through hole in the middle, and the front end section of the cylinder is a curved surface that matches the steel pipe pile. The end section is an inclined plane perpendicular to the axial direction of the anchor rod or anchor cable 2; after the anchor rod or anchor cable 2 passes through the through hole 7 of the steel pipe pile, it is put on a spacer 3 and a wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com