Vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure and construction method thereof

A technology of foundation joist retaining and vertical control, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of high requirements on construction conditions, high comprehensive cost, slow artificial hole digging speed, etc. Body strength, small footprint, and small construction machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

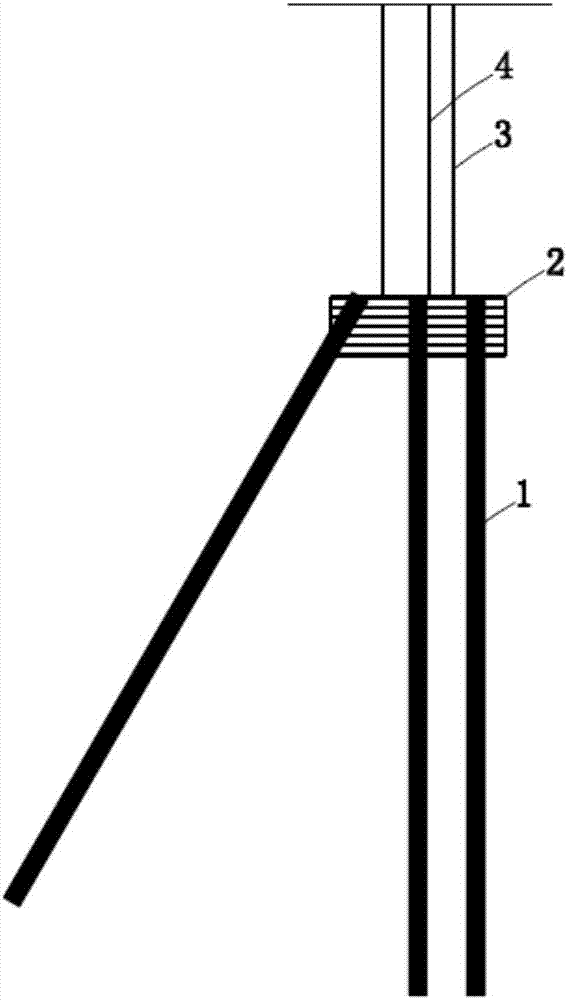

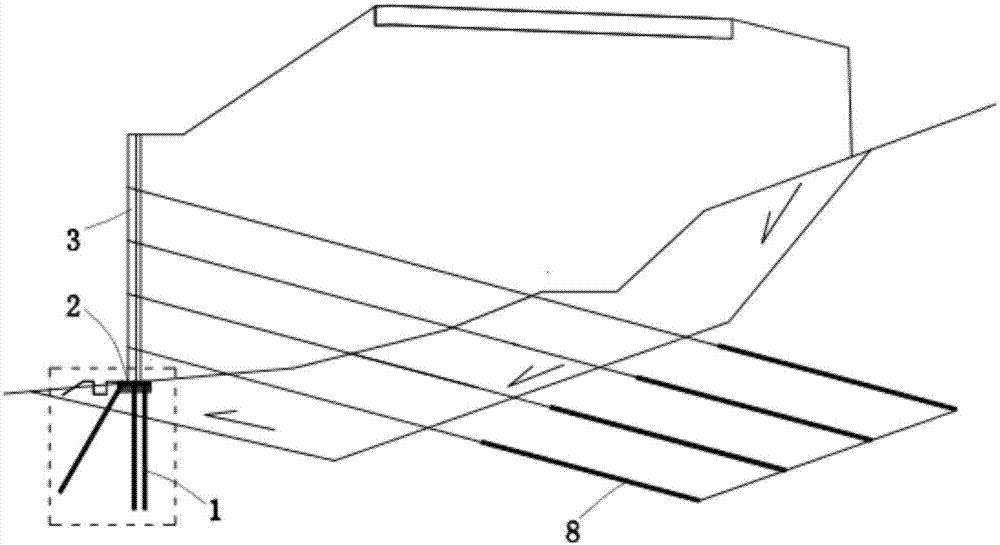

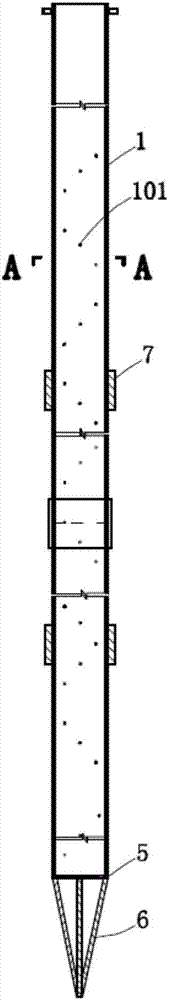

[0031] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a vertical control grouting steel flower tube pile foundation joist retaining wall structure, including steel flower tube boreholes arranged on the side slope, steel flower tubes 1 are arranged in the steel flower tube boreholes, steel flower tubes 1 Generally, a single 6m-long, Φ89×4.5mm seamless steel pipe is used, which can be lengthened or shortened according to the needs in the project. There are several secondary grouting holes 101 spirally arranged on the steel flower pipe 1, such as Figure 4 As shown, a secondary grouting hole 101 with a diameter of 8mm is drilled every 45° along the radial direction of the steel flower tube 1. The bottom of the steel flower tube 1 is provided with a blocking plate 5, and the side of the sealing plate 5 away from the steel flower tube 1 is fixedly connected. Triangular bracket 6, one end of the three edges of the triangular bracket 6 is set on ...

Embodiment 2

[0036] The present invention provides a vertical control grouting steel pipe pile foundation joist retaining wall structure, the structure is basically the same as the first embodiment, the difference is that on the basis of the first embodiment, the following features are added, making A further improvement has been made to improve the performance of the present invention.

[0037] Such as figure 1 and figure 2 As shown, the retaining wall 3 is provided with a vertical rib concrete beam 4, and the retaining wall 3 is connected with a number of prestressed anchor cables 8, and the prestressed anchor cables 8 are anchored in the stable bedrock of the slope with an inclination angle of 10°-25°. , played a good reinforcement effect.

[0038] Taking the second-level slope work site as an example, the vertical height of the first-level side slope is H (m), the width of the top platform of the first-level side slope is ≥ 2m, and the first-level side slope adopts light-weight anch...

Embodiment 3

[0040] The invention provides a construction method for vertically controlling a grouted steel flower tube pile foundation joist retaining wall structure, which includes the following steps:

[0041] (1) Processing of steel floral tubes. There are several secondary grouting holes spirally arranged on the steel floral tubes. The diameter of the secondary grouting holes is 8mm, and the outer surface of the steel floral tubes is fixedly installed with primary grouting tubes;

[0042](2) Drilling, drilling vertically downward or obliquely on the slope, requiring the drilled hole to enter the weathered rock formation at least 4m, and the diameter of the drilled hole is 130mm;

[0043] (3) For the centering and lowering pipe, at least three centering steel bars are fixedly installed on the outer surface of the steel flower pipe. The surrounding is wrapped by grouting body to improve the anti-corrosion performance and tensile bearing capacity of the steel flower tube;

[0044] (4) O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com