Patents

Literature

31results about How to "Small construction machinery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wharf structure suitable for silt coast and construction method of wharf structure

ActiveCN105672199AIncrease land areaSave engineering investmentBreakwatersQuaysFront edgeCoupling beam

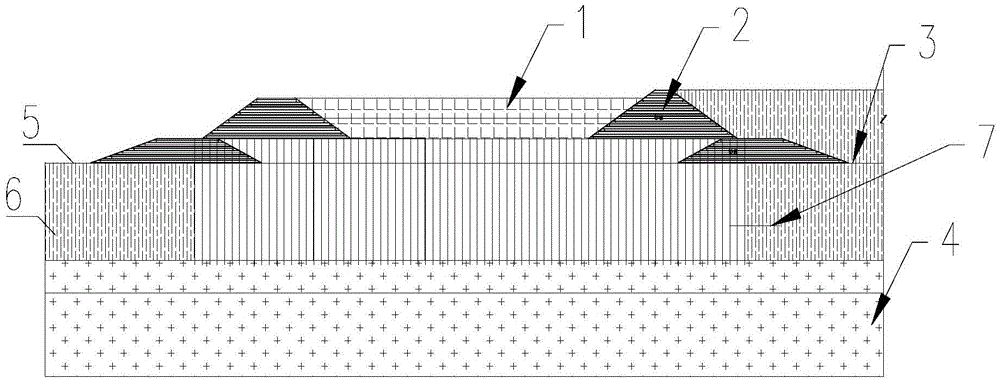

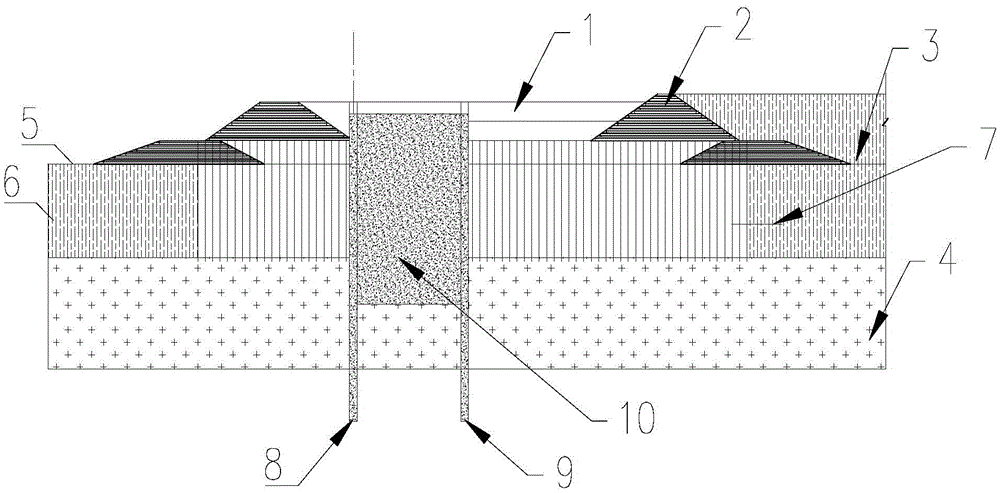

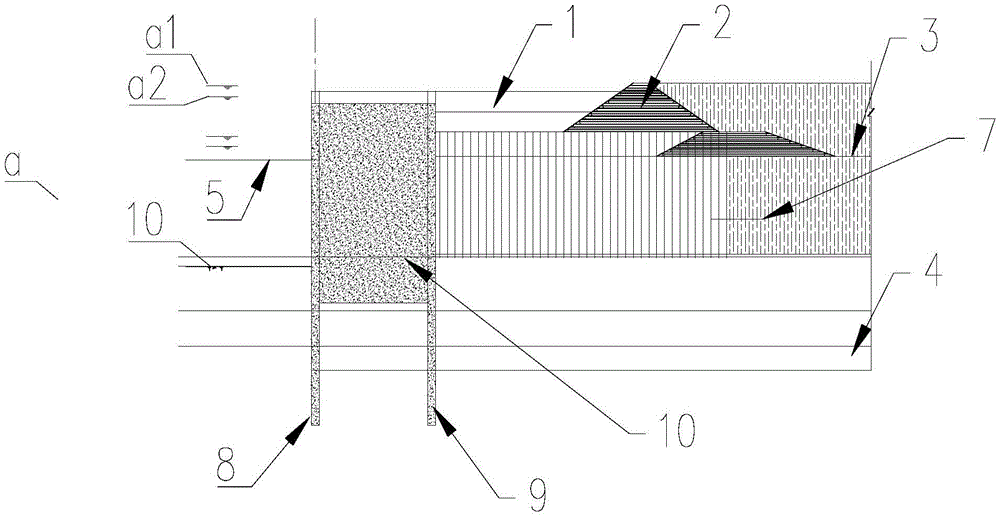

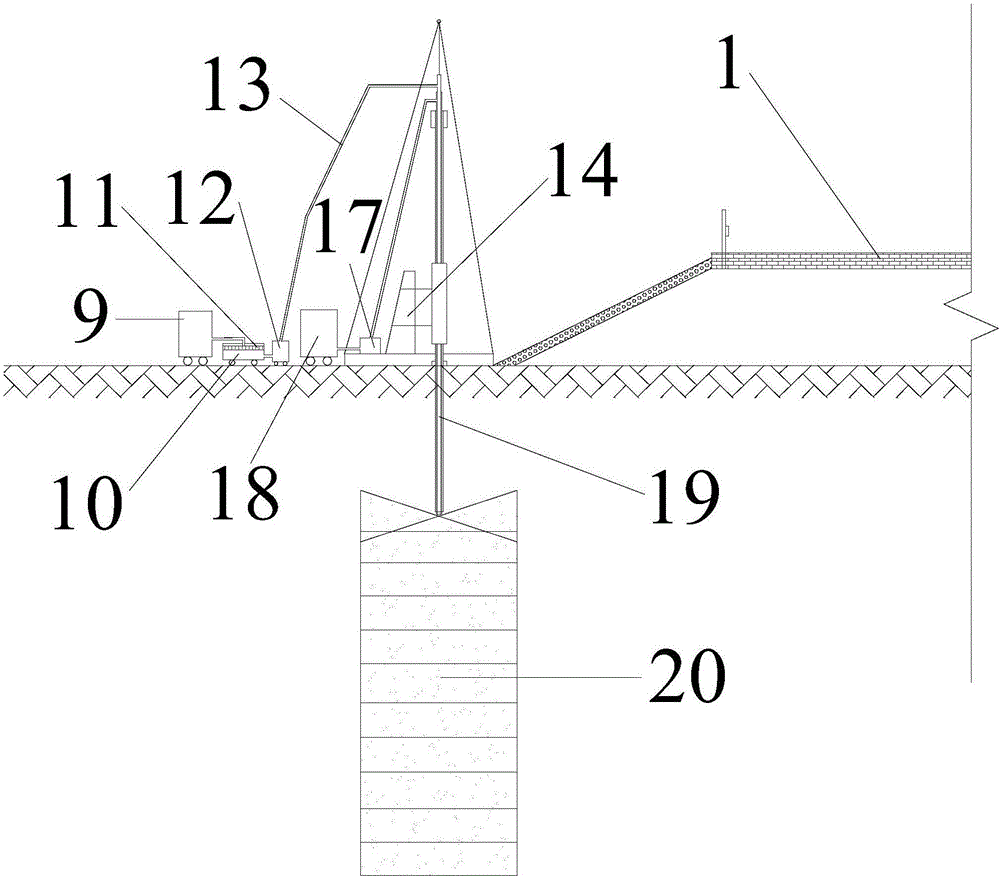

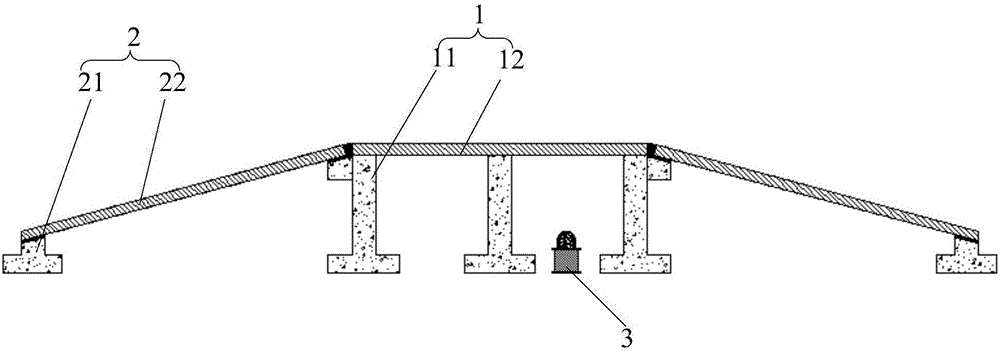

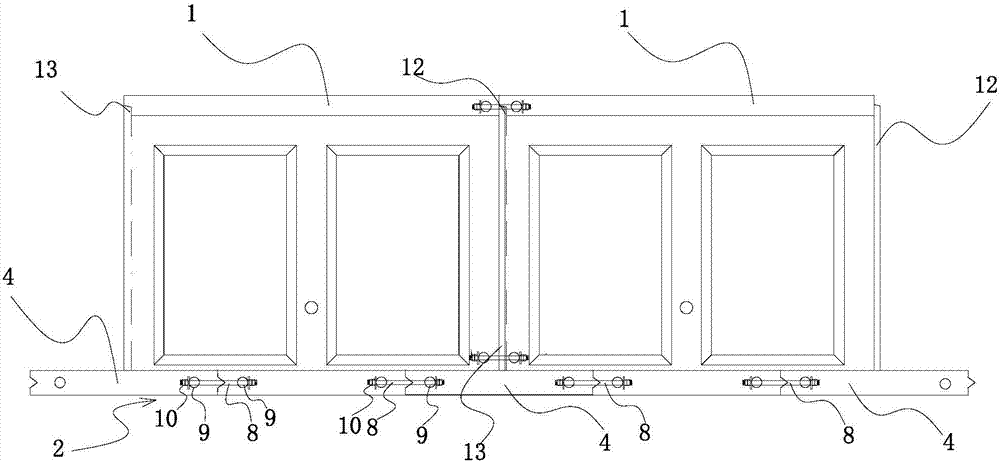

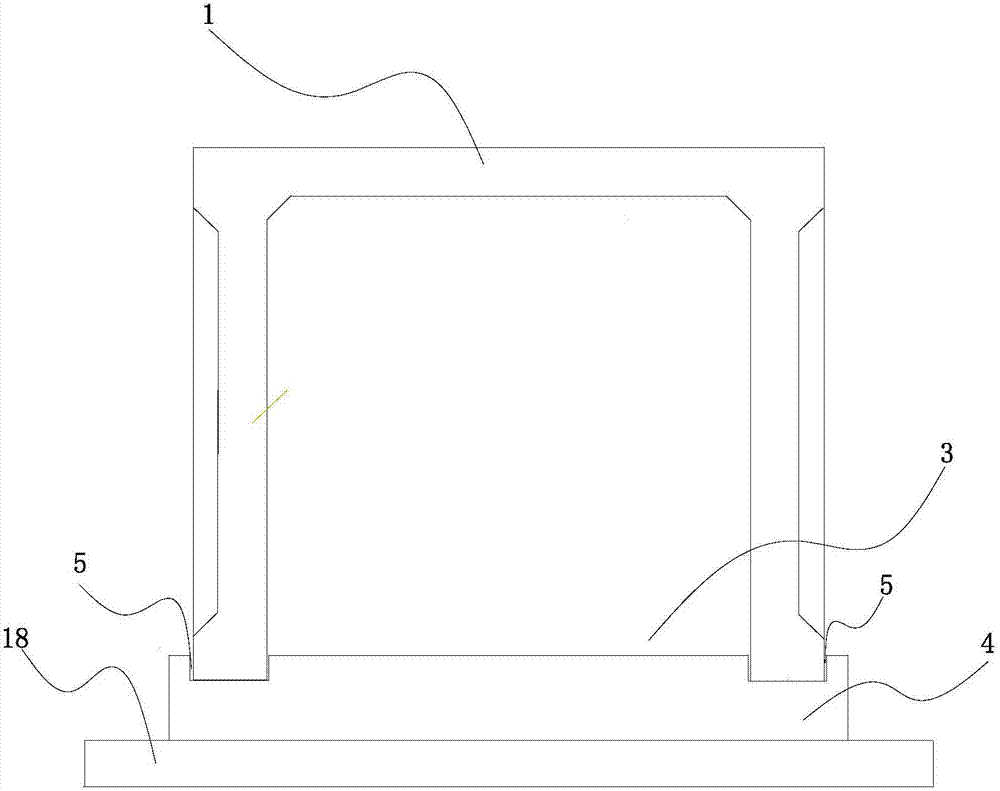

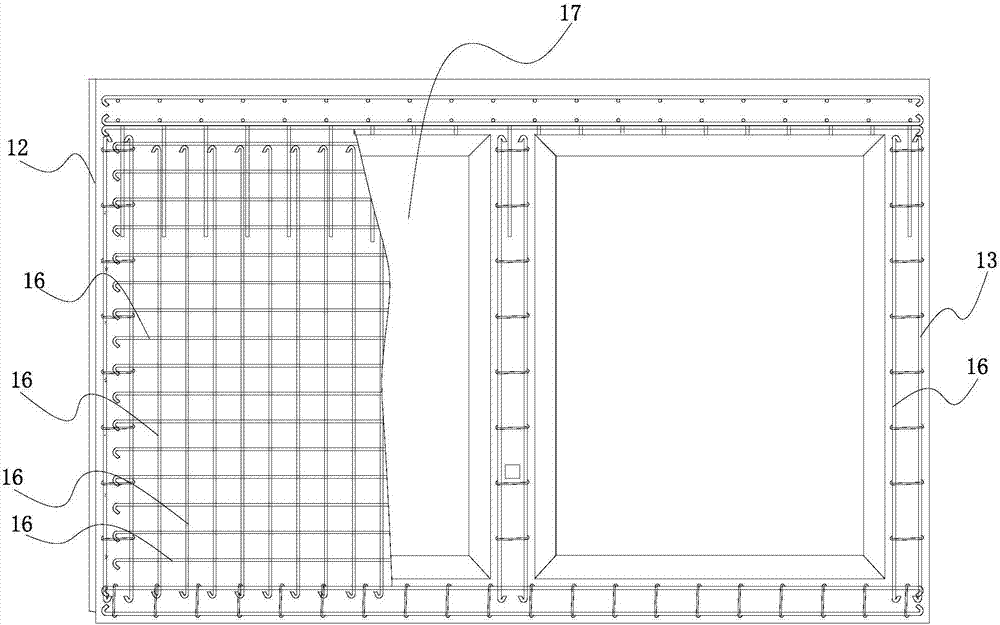

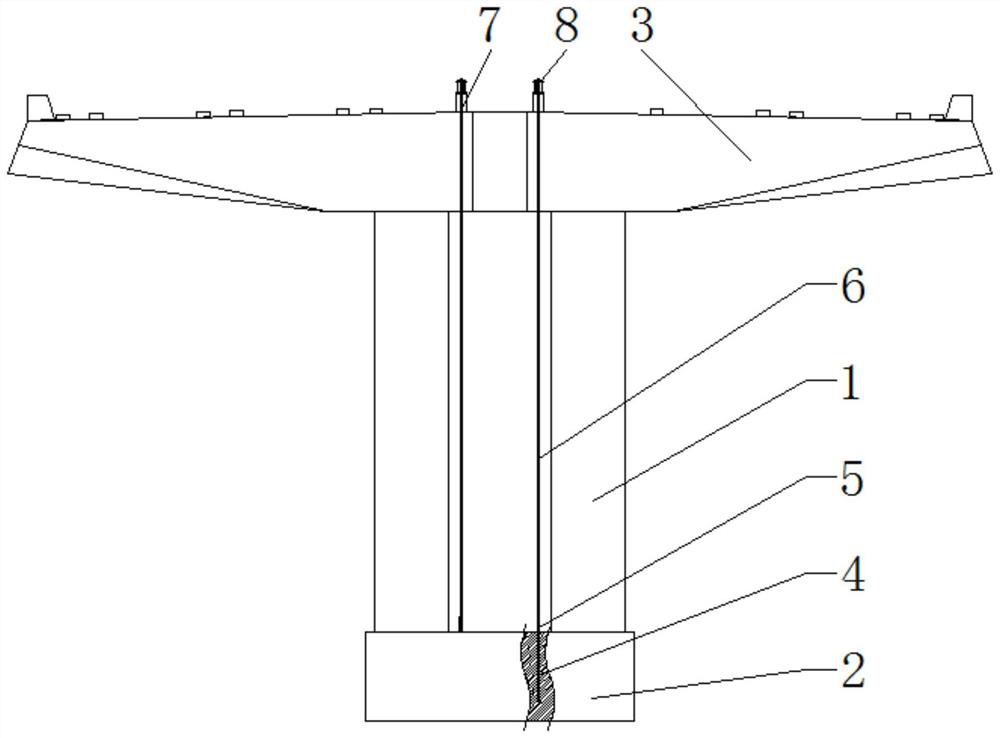

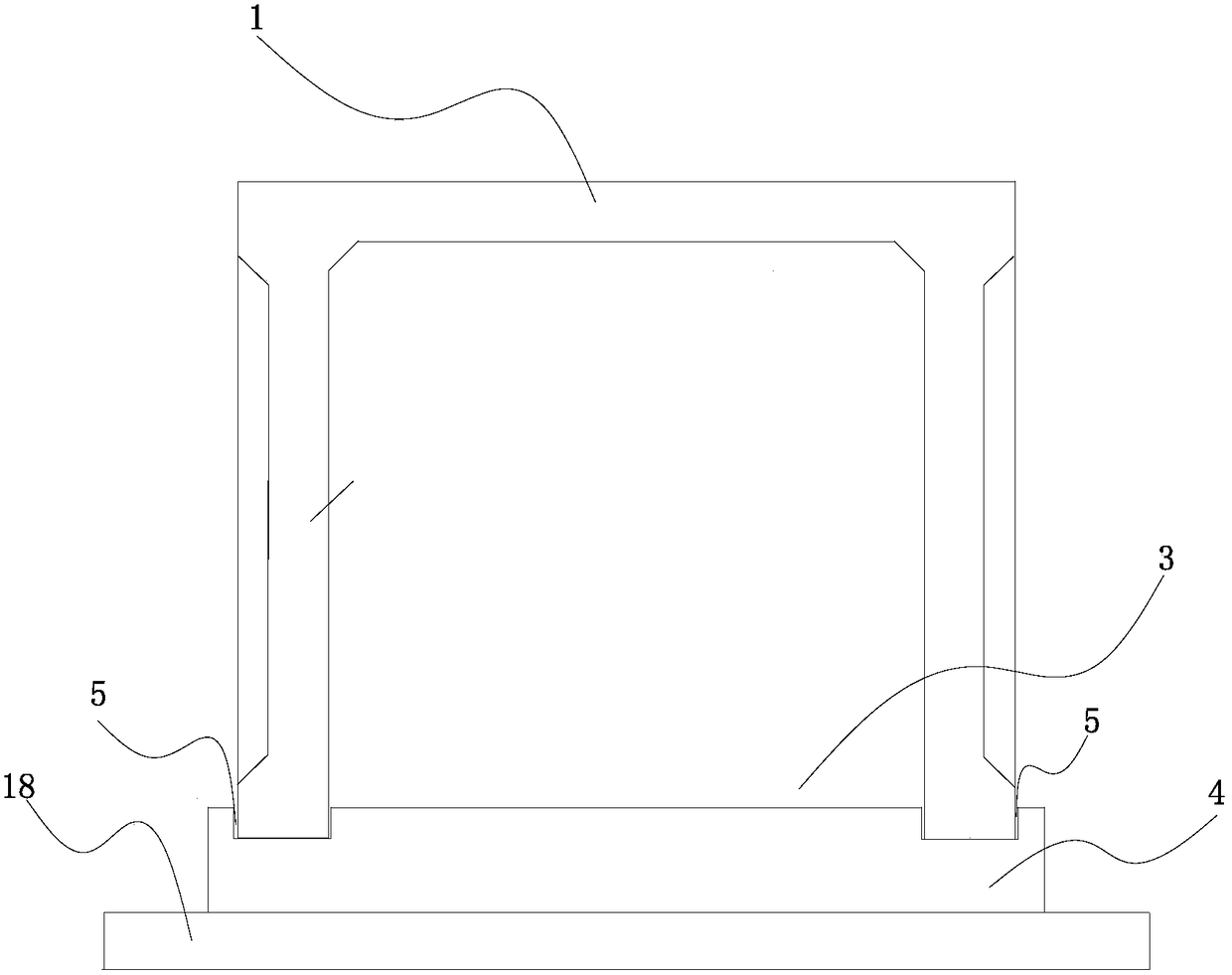

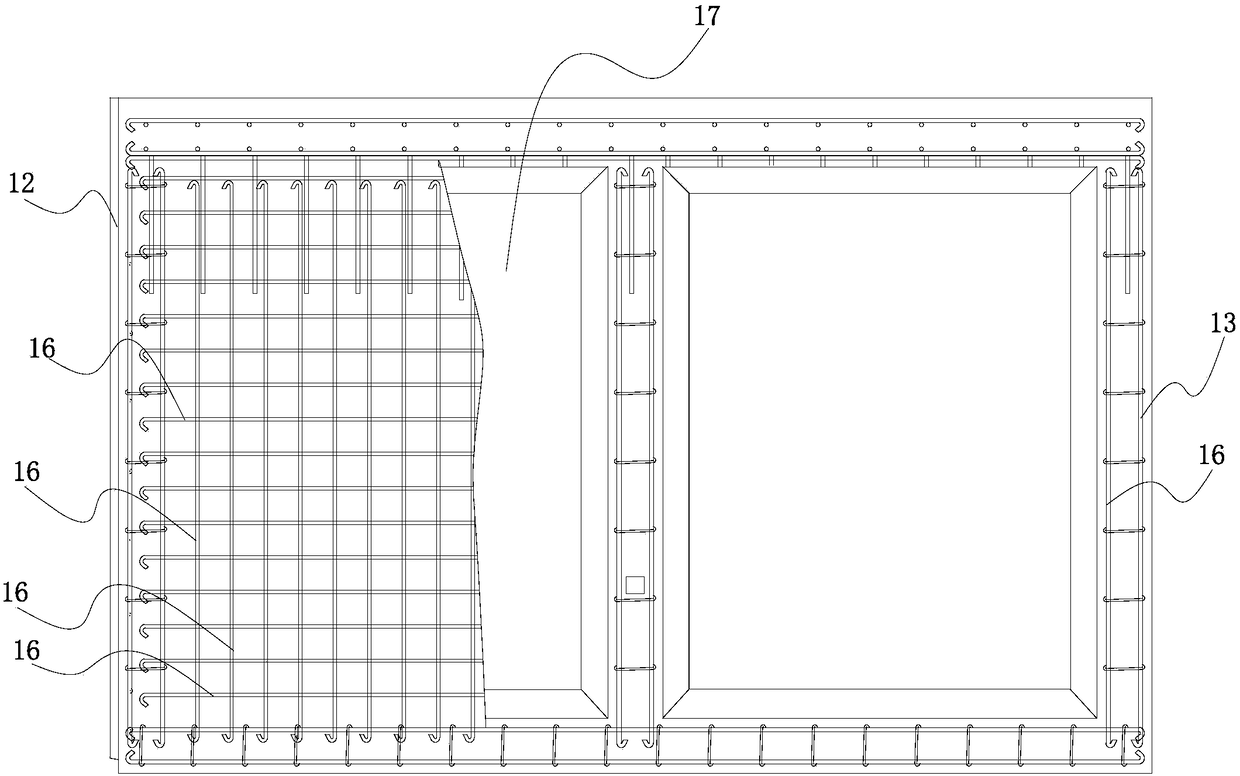

The invention discloses a wharf structure suitable for a silt coast. A direction which is close to the sea is used as a front direction, and a direction which is relatively away from the sea is used as a rear direction. The wharf structure comprises a causeway, a front diaphragm wall, a rear diaphragm wall, a partition, a plurality of coupling beams and a wharf upper part structure, wherein the front diaphragm wall, the rear diaphragm wall and the partition form a cylindrical caisson structure; the coupling beams are connected with the rear diaphragm wall and a pile foundation; and the wharf upper part structure covers the front diaphragm wall, the rear diaphragm wall, the partition and the pile foundation. By the structure, construction difficulty and engineering investment costs are reduced effectively. A construction method comprises the following steps: (1) constructing the causeway by bagged sand quilts; (2) reinforcing the causeway and silt filled at the rear of the causeway in a blowing manner, reinforcing new silt filled in the blowing manner, and constructing the front diaphragm wall, the rear diaphragm wall and the partition to form the cylindrical caisson structure when the bearing capacity of foundation soil reaches 5 tons at least; (3) excavating causeway remaining earthwork in front of the front diaphragm wall and earthwork under a natural silt surface, and enabling the front edge of a wharf to reach designed water depth; and (4) constructing the pile foundation and the coupling beams, and then constructing the wharf upper part structure. The construction method is simple.

Owner:CCCC THIRD HARBOR CONSULTANTS

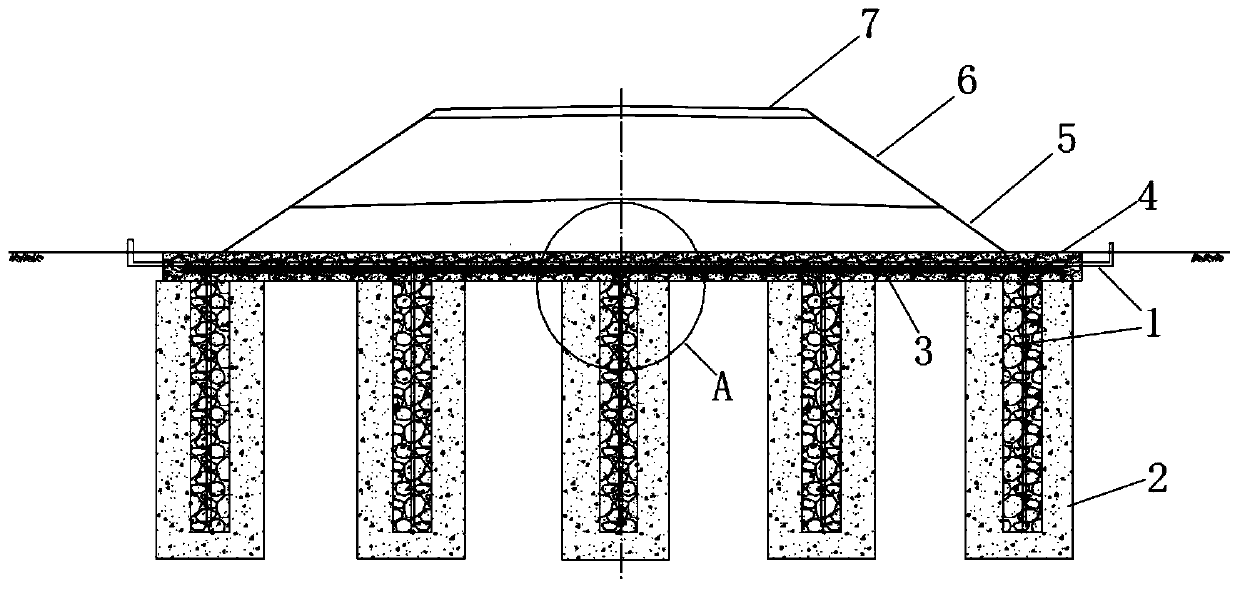

High-speed railway expanding cement slurry post-grouting bulk material pile composite foundation construction method

InactiveCN111379253ARapid Consolidation SettlementTake full advantage of drainageBulkheads/pilesStructural engineeringCement slurry

The invention provides a high-speed railway expanding cement slurry post-grouting bulk material pile composite foundation construction method. The high-speed railway expanding cement slurry post-grouting bulk material pile composite foundation construction method comprises the steps that segmented drilling for hole forming is conducted; grouting pipes are placed in a drill hole in a segmented connection mode, and the grouting pipes are bent by 90 degrees and extend out of the two sides of a roadbed in the horizontal direction; a bulk material is put in the drill hole; a reinforced gravel cushion layer is laid on the surface of a foundation; layered filling of embankment soil is carried out on the cushion layer; foundation soil is subjected to consolidated drainage; and expanding cement slurry is injected into the grouting pipes to form rigid pile bodies. The drainage performance of the bulk material is fully utilized to enable inter-pile soil to be subjected to drainage consolidation during embankment filling, the carrying capacity of pile foundations is improved through the expanding cement slurry, properties of the inter-pile soil are improved, and the advantages such as small post-construction settlement are achieved.

Owner:CHONGQING UNIV +1

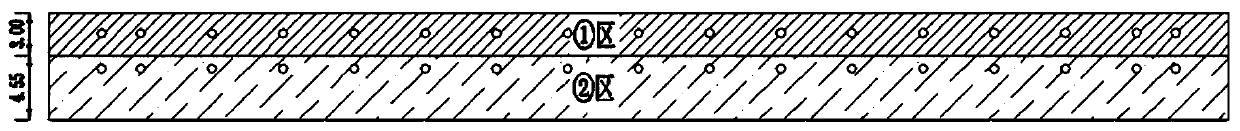

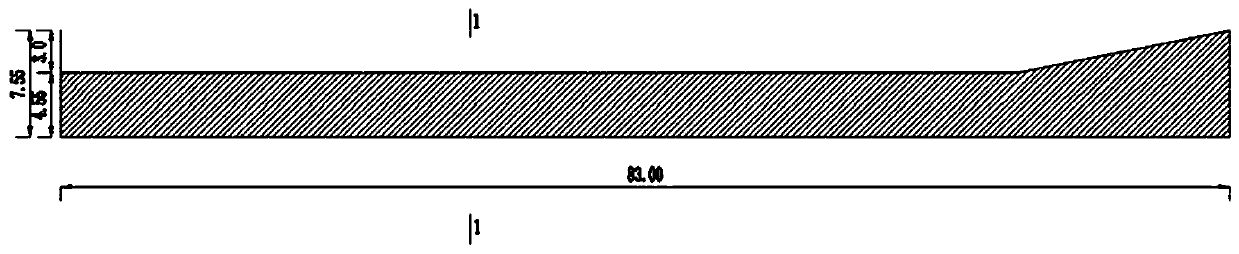

Construction method of mudstone-filled embankment

InactiveCN102031743ASimple methodSmall construction machineryRoadwaysGeotechnical engineeringStructural engineering

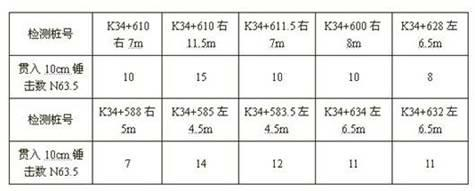

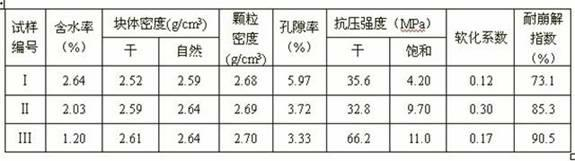

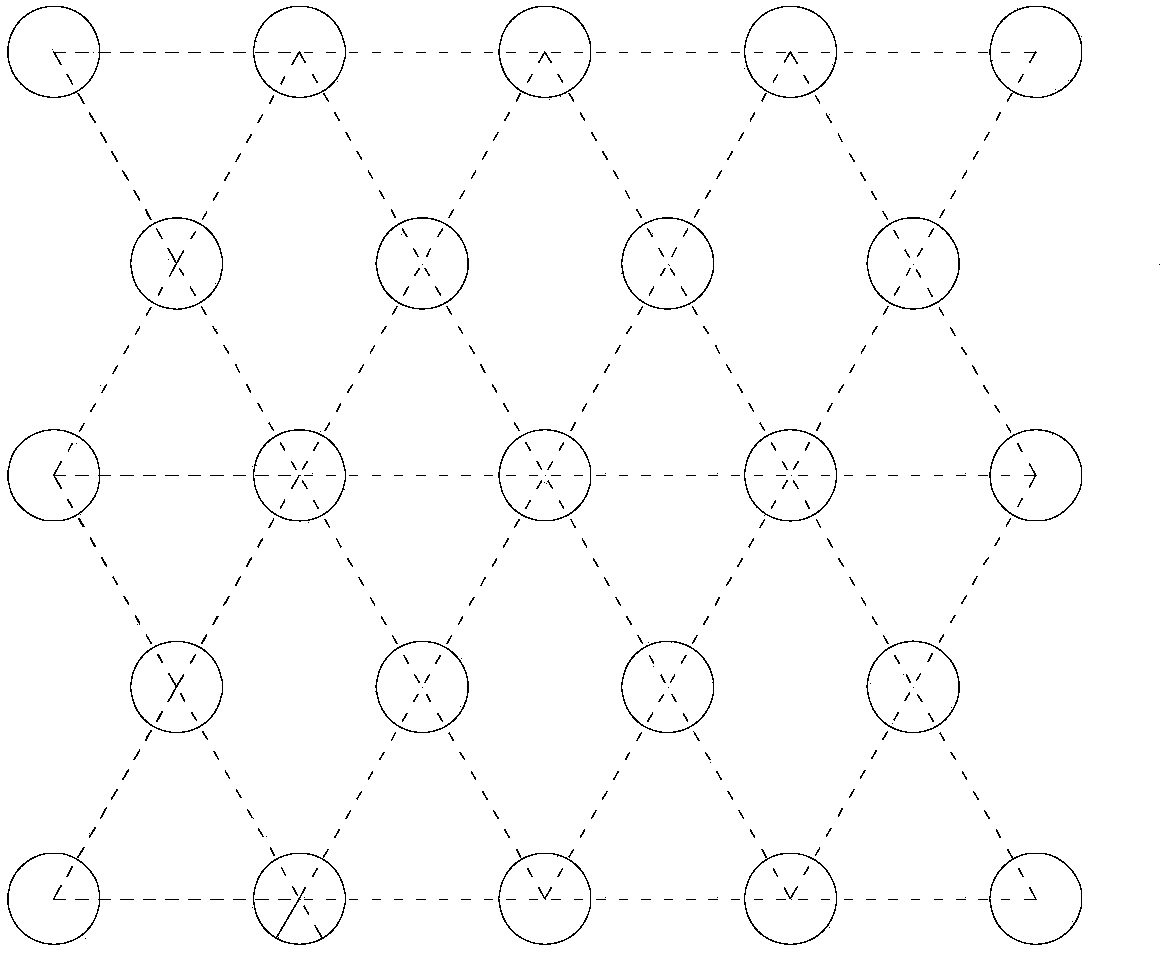

The invention relates to a construction method of a mudstone-filled embankment, comprising the following steps: levelling the embankment; arranging ramming points, wherein the positions of the ramming points on an upper layer and a lower layer are staggered, and the ramming points on the second layer are in the middle of the ramming points on the first layer; filling with the ramming points at positions which is 0.5-2.0 m far away from the top of a road bed, wherein the ramming point overlapping area is not less than 1 / 3; during strong forced ramming construction, carrying out forced ramming construction on the ramming points accurately by a forced rammer; detecting that settlement, heavy dynamic penetration value and surface wave velocity are qualified, filling next layer of embankment; carrying out forced ramming on half-dug and half-filled embankment, and ramming towards the middle of the embankment row by row from the edge of the embankment; carrying out the forced ramming on the embankment of the boundary of filling and digging; ramming the boundary of filling and digging row by row from the edge of the embankment on the position far away from the boundary of filling and digging; levelling after ramming is finished; and then, compacting by strong vibration. The invention has the advantages that fewer force ramming processing and constructing machines are utilized, the method is relatively simple, the construction period is obviously shorter than that of sand-mixed construction, the excavation utilization ratio is improved, the cost for carrying out the secondary crushing on rock is reduced, and the project quality is good.

Owner:河南省新开元路桥工程咨询有限公司

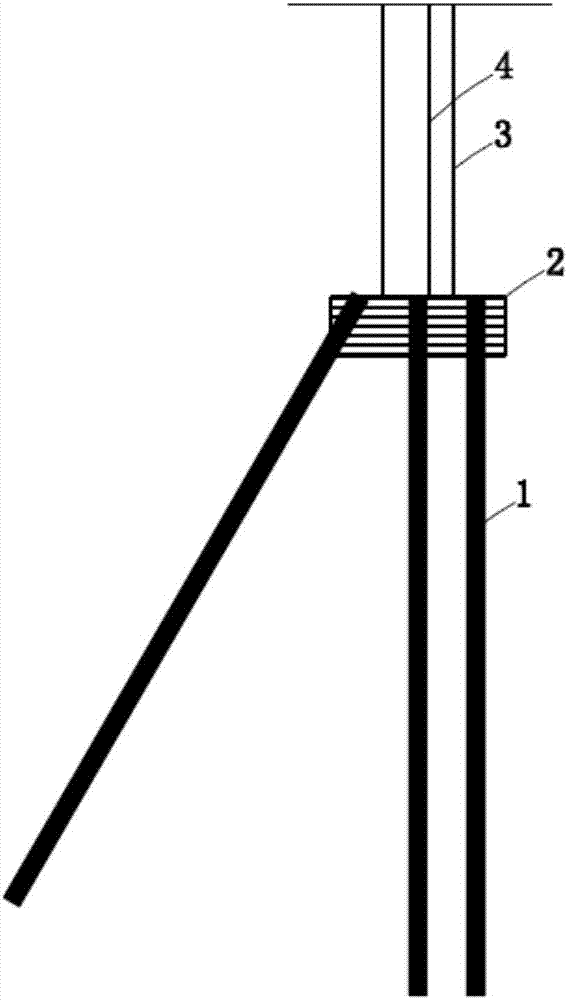

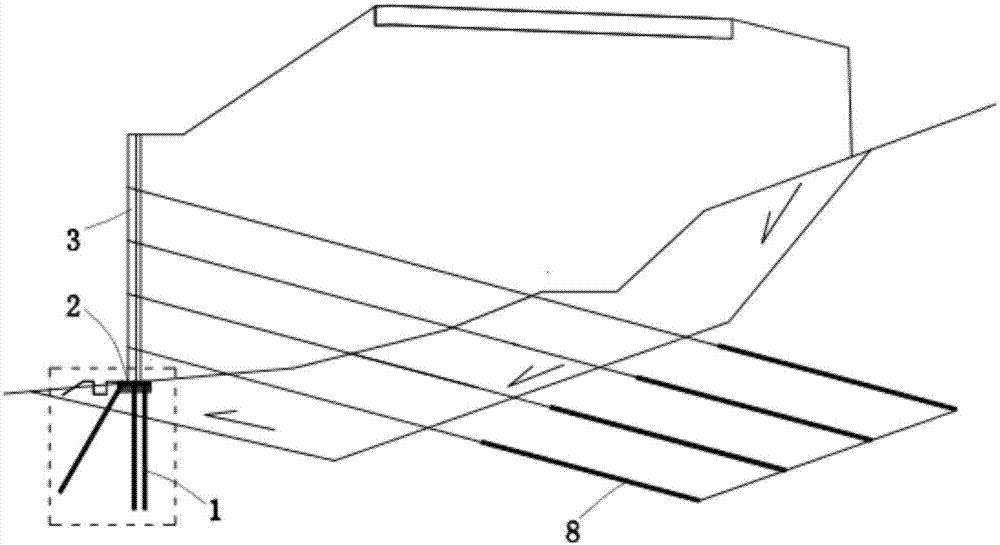

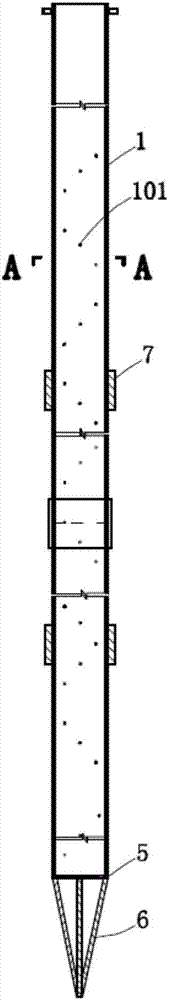

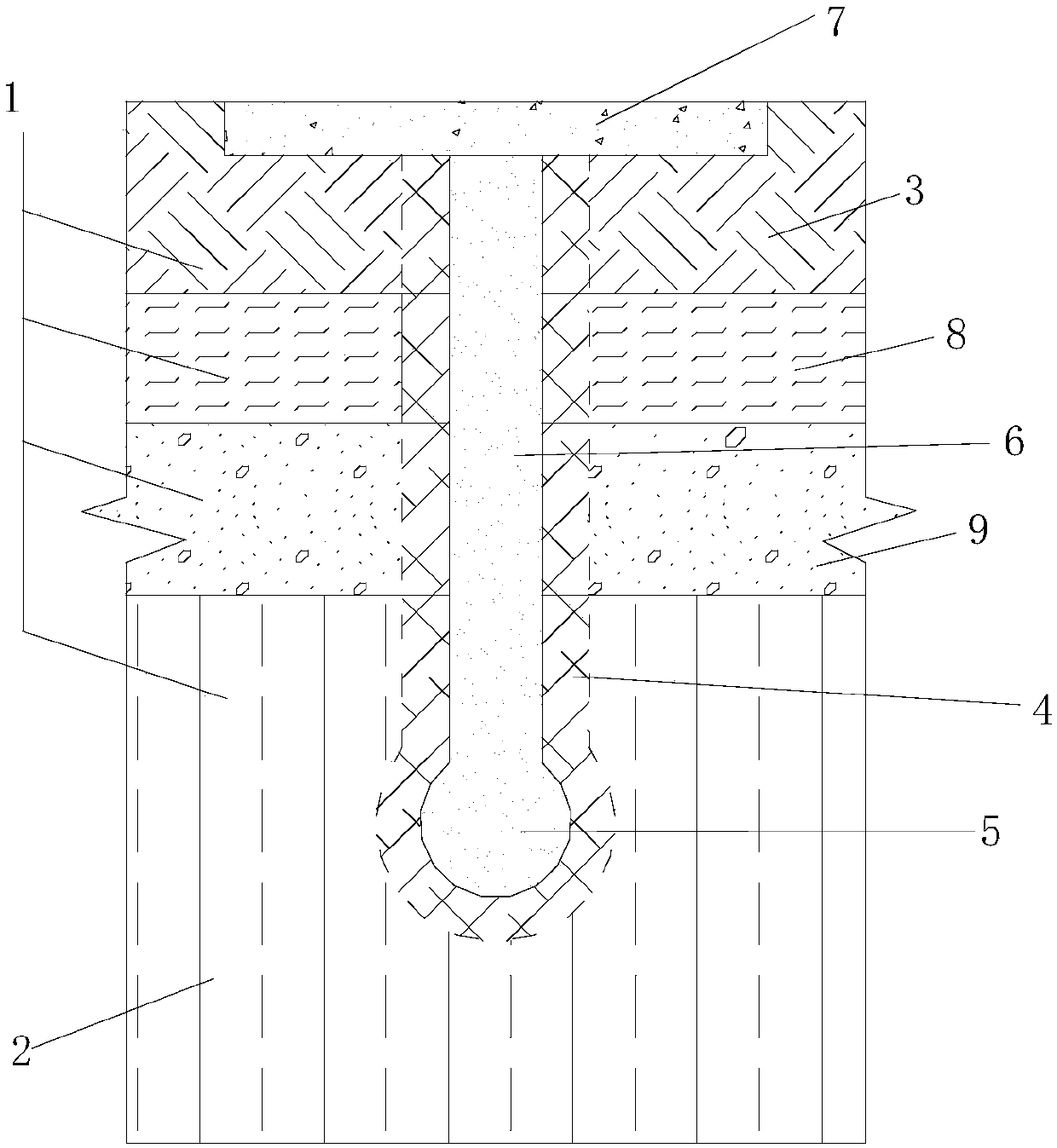

Vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure and construction method thereof

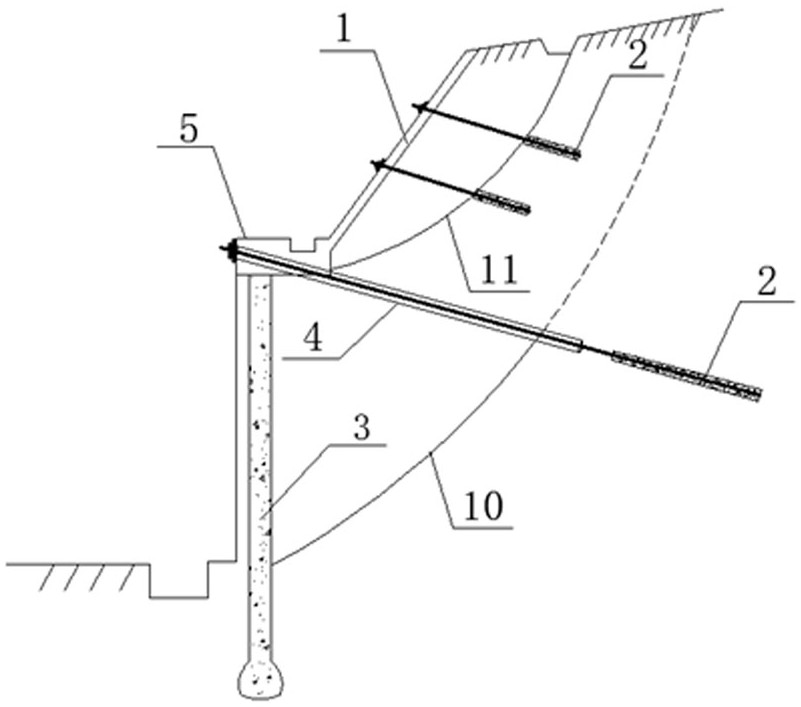

The invention relates to a vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure and a construction method thereof and belongs to the technical field of capital construction. The vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure comprises a steel perforated pipe drill hole formed in a slope, the steel perforated pipe drill hole is internally provided with a steel perforated pipe, and the steel perforated pipe is spirally provided with a plurality of secondary grouting holes; the bottom of the steel perforated pipe is provided with a blocking plate, and the side, away from the steel perforated pipe, of the blocking plate is fixedly connected with a triangular supporting frame; the steel perforated pipe drill hole is internally provided with a grouting body, a pipe opening of the steel perforated pipe is provided with a sealing cover, the position of the pipe opening of the steel perforated pipe is provided with a concrete supporting beam, the concrete supporting beam is internally provided with a steel bar structure, the steel bar structure is welded to the steel perforated pipe, and the concrete supporting beam is provided with a retaining wall. By means of the vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure, the technical problems that a traditional pile foundation technology is high in construction condition requirement, low in manual hole digging speed and high in comprehensive cost are solved, and the vertically-controlled grouting steel perforated pipe pile foundation supporting beam retaining wall structure is widely applied to slope reinforcement engineering, such as roads, railways, mines and municipal administration.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

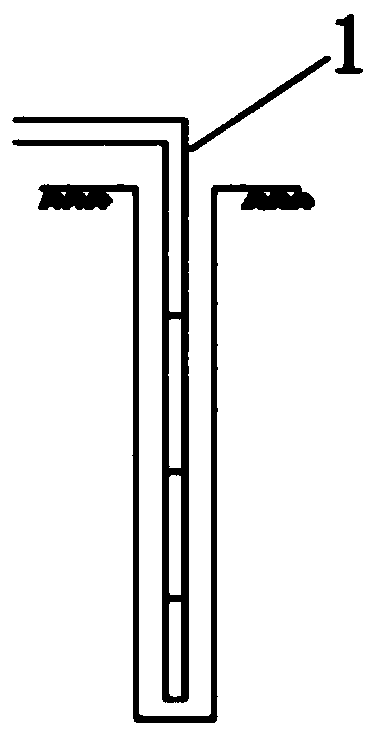

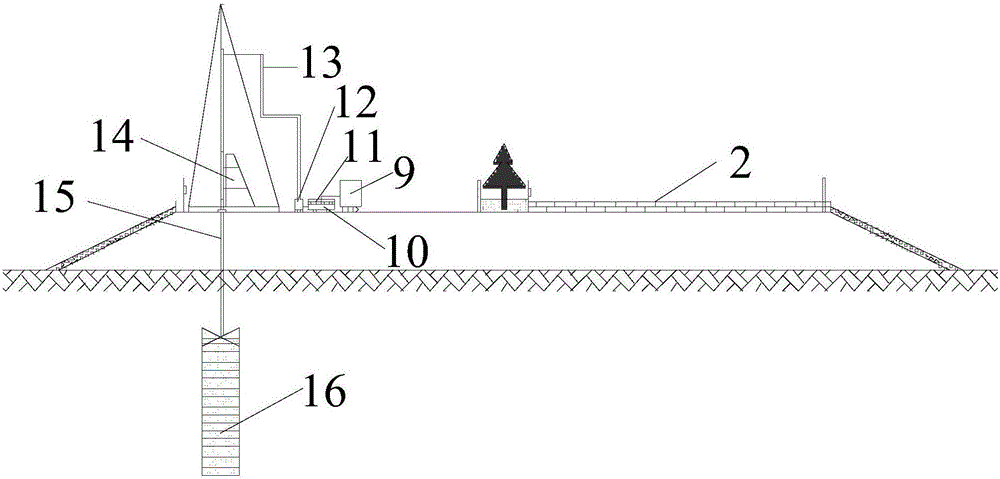

Construction method for in-situ water-injection pure soil compaction pile composite foundation

ActiveCN107905212ASmall construction machineryReduce construction costsSoil preservationPunchingEngineering

The invention relates to a construction method for an in-situ water-injection pure soil compaction pile composite foundation. The construction method mainly comprises the steps of site clearing and flattening; surveying and setting out; construction equipment assembling in-position; hole guiding; water injection for humidifying; pipe pulling for secondary punching; falling-back soil bottom tamping; padding humidifying; hole interior layering padding, compaction tamping and hole forming; top loosened layer removing; and spreading and compaction. Through the construction method, the composite foundation can be formed, and the construction method has the advantages that construction machines are saved, the construction cost is reduced, the working efficiency is improved, noise and muddy waterpollution are reduced, residue soil is removed, and the environment is protected.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

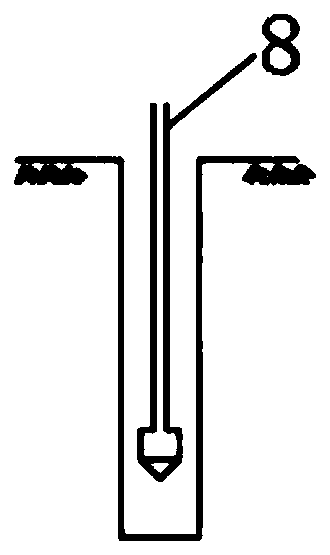

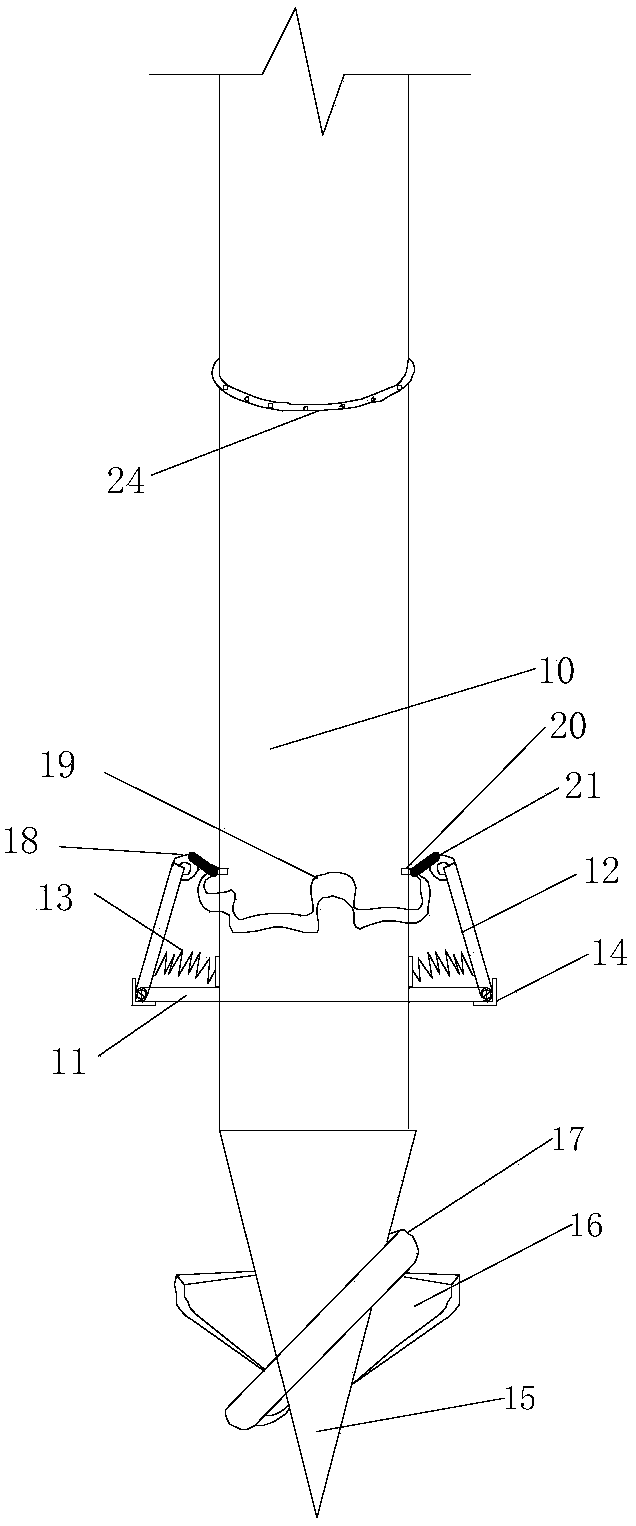

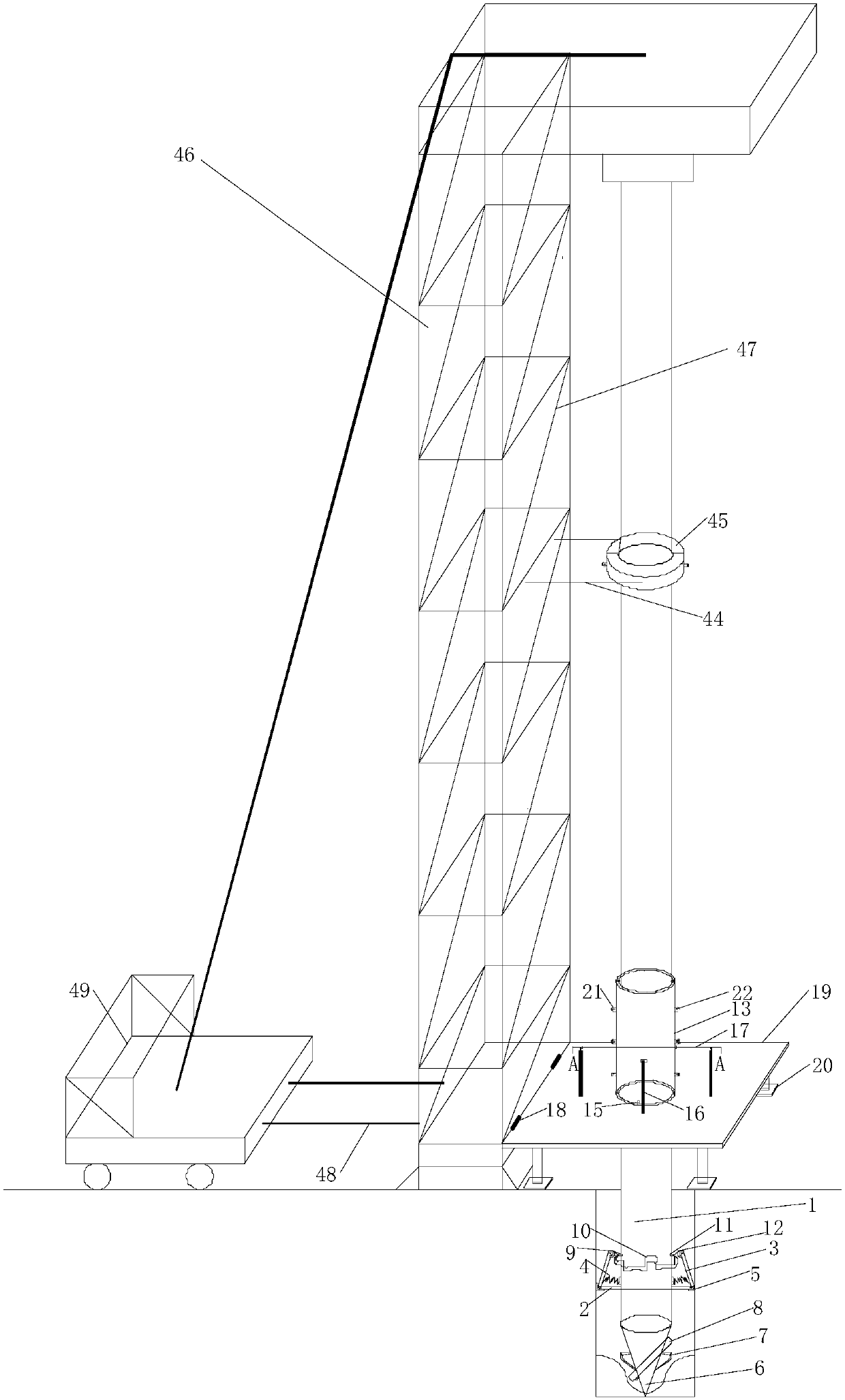

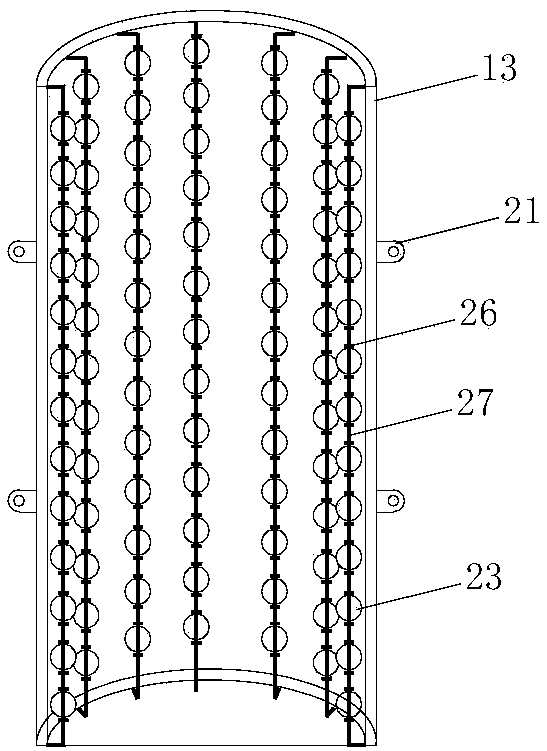

Plain soil compaction pile device and construction method

InactiveCN107630447ASmall construction machineryReduce construction costsSoil preservationMobile vehiclePunching

The invention relates to a plain soil compaction pile device. The device mainly comprises a hole forming device, a ramming and expanding device and a supporting device, wherein the hole forming deviceis composed of an immersed tube, a movable type pile tip, a bag and a fixed cylinder; the ramming-expanding device is composed of a rammer, a ramming machine, a rammer corner plate and a regulating rod; and the supporting device is composed of a supporting frame, a supporting rod and a moving vehicle. The construction method of the plain soil compaction pile device comprises the following steps that the hole forming device, the ramming-expanding device and the supporting device are installed on site, a rammer immersed tube compaction pile machine is adopted for hole immersing according to a designed pile length, water injection and humidifying are carried out in the hole forming process, the immersed tube is drawn out after the hole forming process is completed, secondary punching is carried out after the immersed tube is drawn out, falling-back soil is rammed by using the ramming-expanding device, and then filing materials are rammed layer by layer so as to complete the construction.The construction method is used so that soil between piles can be extruded and compacted to form a composite foundation. The plain soil compaction pile device and the construction method have the advantages that the construction machinery is saved, the construction cost is reduced, the working efficiency is improved, the noise and the muddy water pollution are reduced, muck is consumed and the environment is maintained.

Owner:HANGZHOU JIANGRUN TECH LIMITED

Construction method for machine-made glass magnesium composite plate air pipes

ActiveCN108591634AWith sound insulationWith heat insulation functionPipe laying and repairRigid pipesArchitectural engineeringSmall footprint

The invention discloses a construction method for machine-made glass magnesium composite plate air pipes. The construction method comprises the following steps that (1) plates of the air pipes are cut; (2) the air pipes are spliced; (3) the air pipes are hoisted and connected; and (4) parts of the air pipes are mounted. Compared with a tradition construction method for a galvanized steel plate airpipe, the construction method for the machine-made glass magnesium composite plate air pipes has the characteristics of less construction machines, simple construction procedures, less auxiliary material using amount, small floor space, short construction period and the like. Due to the fact that the air pipes are connected without flanges, a large amount of engineering materials such as angle steel, gaskets, bolts, welding rods, rivets, oxygen and acetylene can be saved; and the average construction efficiency of the galvanized air pipe is 3 m<2> / d per person, the average construction efficiency of the machine-made glass magnesium composite plate air pipes can reach to 12.1 m<2> / d per person, and as for manufacturing and mounting of the air pipes with the same area, the construction period can be shortened obviously for the machine-made glass magnesium composite plate air pipes.

Owner:QINGDAO XINHUAYOU CONSTR GROUP

Earthwork excavation method for long and narrow deep foundation pit

The invention provides an earth excavation method for a long and narrow deep foundation pit. The earth excavation method fully utilizes the strength and rigidity of a ground connecting wall supportingstructure and is suitable for earth excavation in the form of the long and narrow deep foundation pit, which is constructed by a large excavator. Earth of the long and narrow deep foundation pit is divided vertically according to the vertical spacing of steel pipe supports, and layered horizontally according to the horizontal spacing of the steel pipe supports; an upper soil body is excavated ina mechanical large excavation mode; a lower soil body is subjected to step-shaped layered regression excavation, and a mounting platform is retained; and after the steel pipe supports of the same vertical layer are mounted, a platform soil body is excavated, and the excavation of the next layer of soil continues until all construction is completed. The construction period can be obviously shortened; fewer construction machines are used, and exhaust emissions and air pollution can be reduced; and the supporting structure and a soil body of a middle trough are used fully, the use functions of the supporting structure and the soil body of the middle trough are developed, and convenience is created for the construction.

Owner:北京清河水利建设集团有限公司

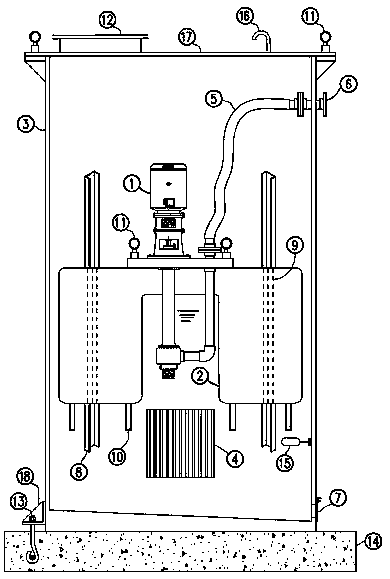

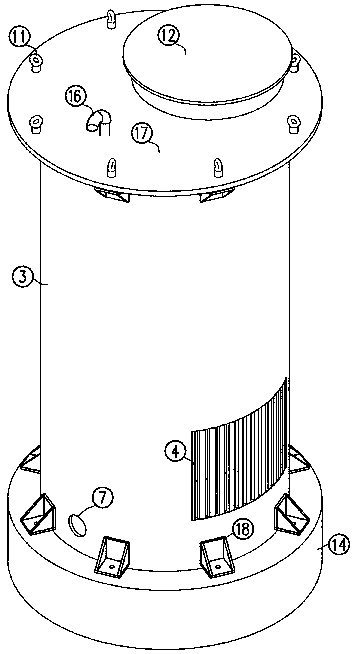

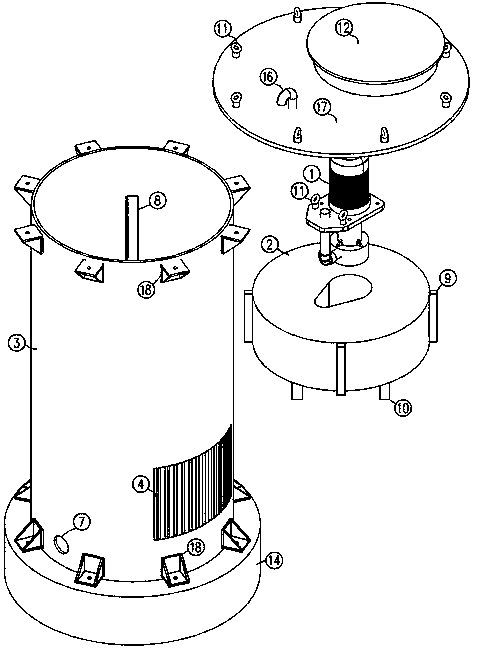

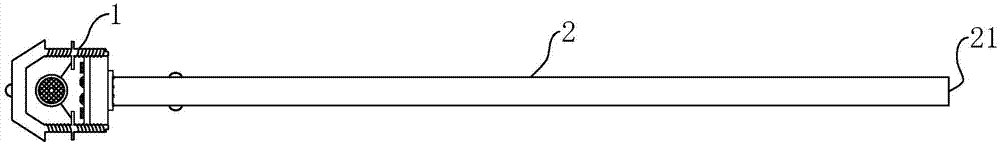

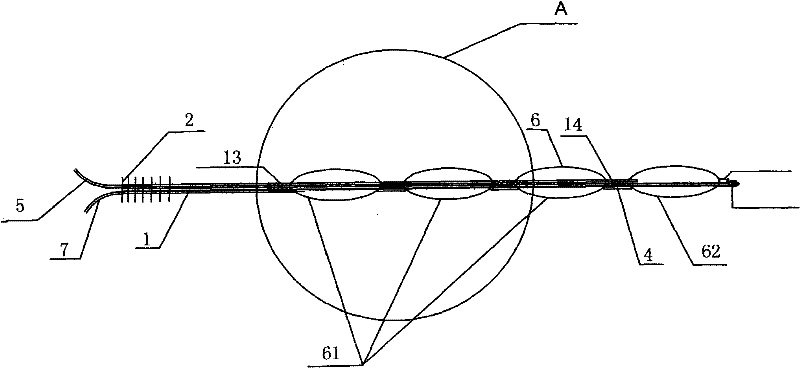

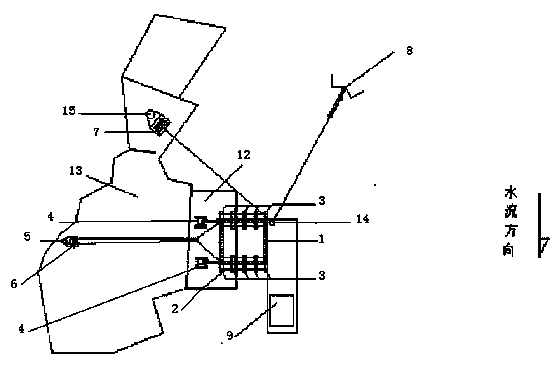

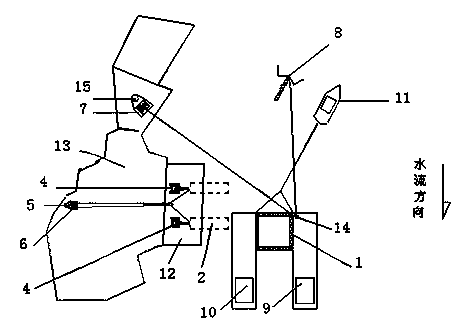

Moveable water intaking device for small and medium-sized seawater desalination system

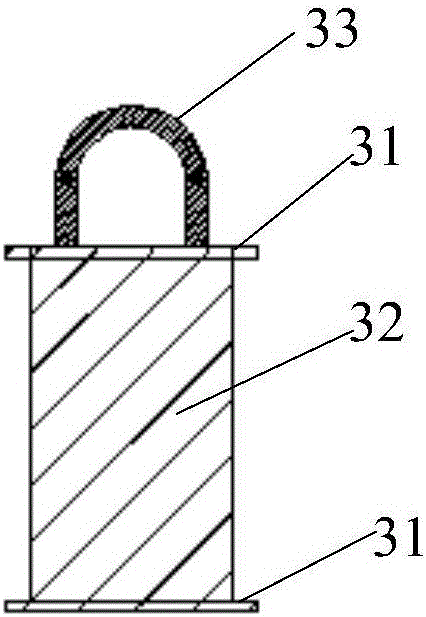

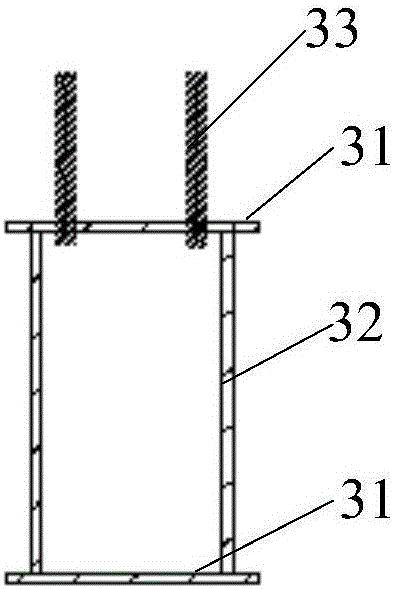

PendingCN109555186AStrong flexibilityReduce the difficulty and cost of construction and daily maintenance managementDrinking water installationRebarSeawater

The invention discloses a moveable water intaking device for a small and medium-sized seawater desalination system. The moveable water intaking device for the small and medium-sized seawater desalination system comprises a reinforced concrete fixed base installed on the seabed, a glass fiber reinforced plastic prefabricated cylinder body mounted on the fixed base through a fixed foundation bolt, aplastic float cylinder arranged in the prefabricated cylinder body, an underwater water intaking pump fixed to the top of the plastic float cylinder and a water outlet hose connected with an outlet of the underwater water intaking pump. The lower part of the prefabricated cylinder body is provided with a water inlet grating, and a contamination draining hole is formed in the bottom of the prefabricated cylinder body; the plastic float cylinder and the underwater water intaking pump float up and down with a water intaking surface going up and down by arranging a fixed rail on the inner wall ofthe prefabricated cylinder body and a slide rail on the outer wall of the plastic float cylinder, and supporting legs are arranged at the bottom of the plastic float cylinder. The water intaking device is provided with few construction machines, and a non-submersible pump is used as the water intaking pump, internal equipment and facilities are arranged in a centralized mode, and the high flexibility and the reuse are realized.

Owner:江苏丰海新能源工程技术有限公司

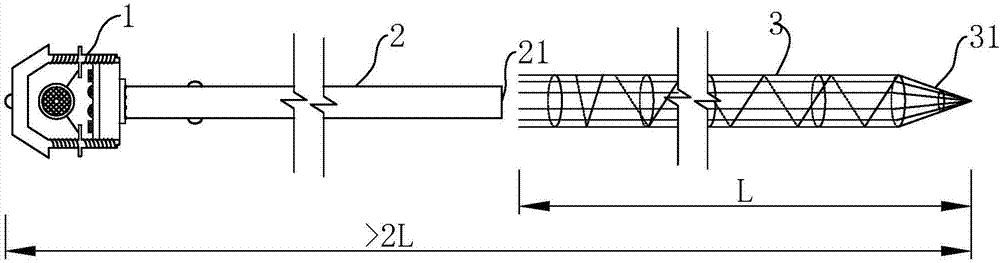

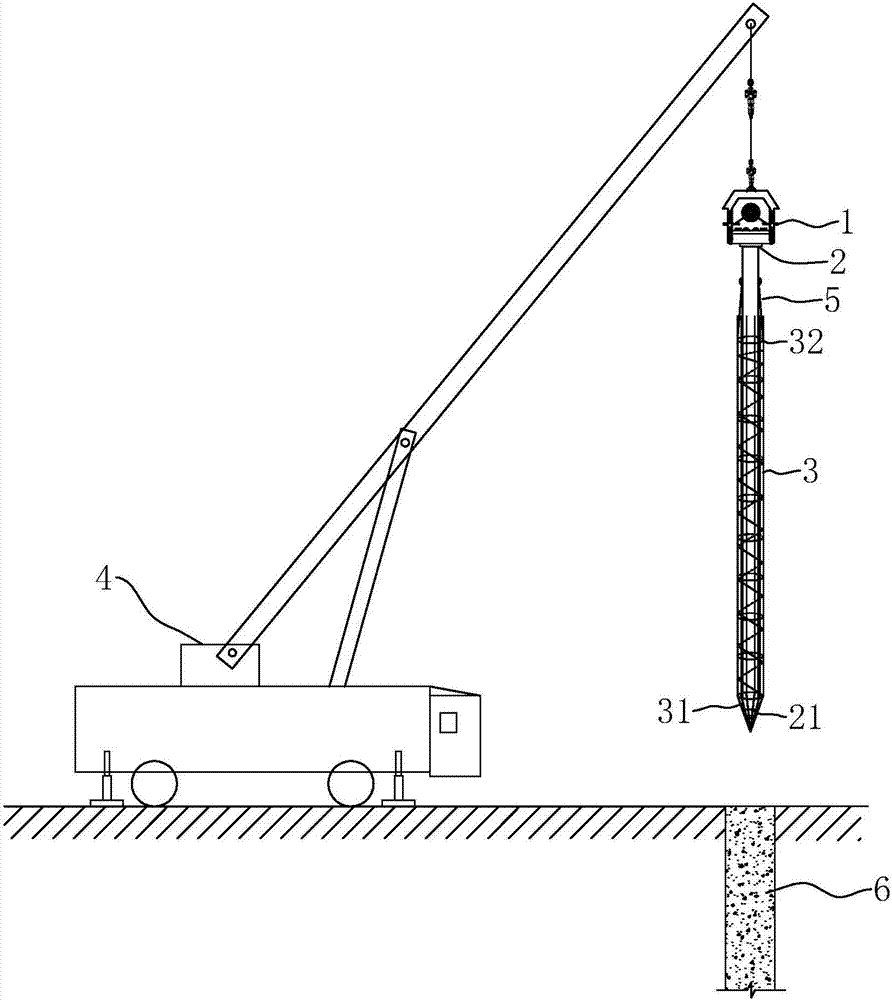

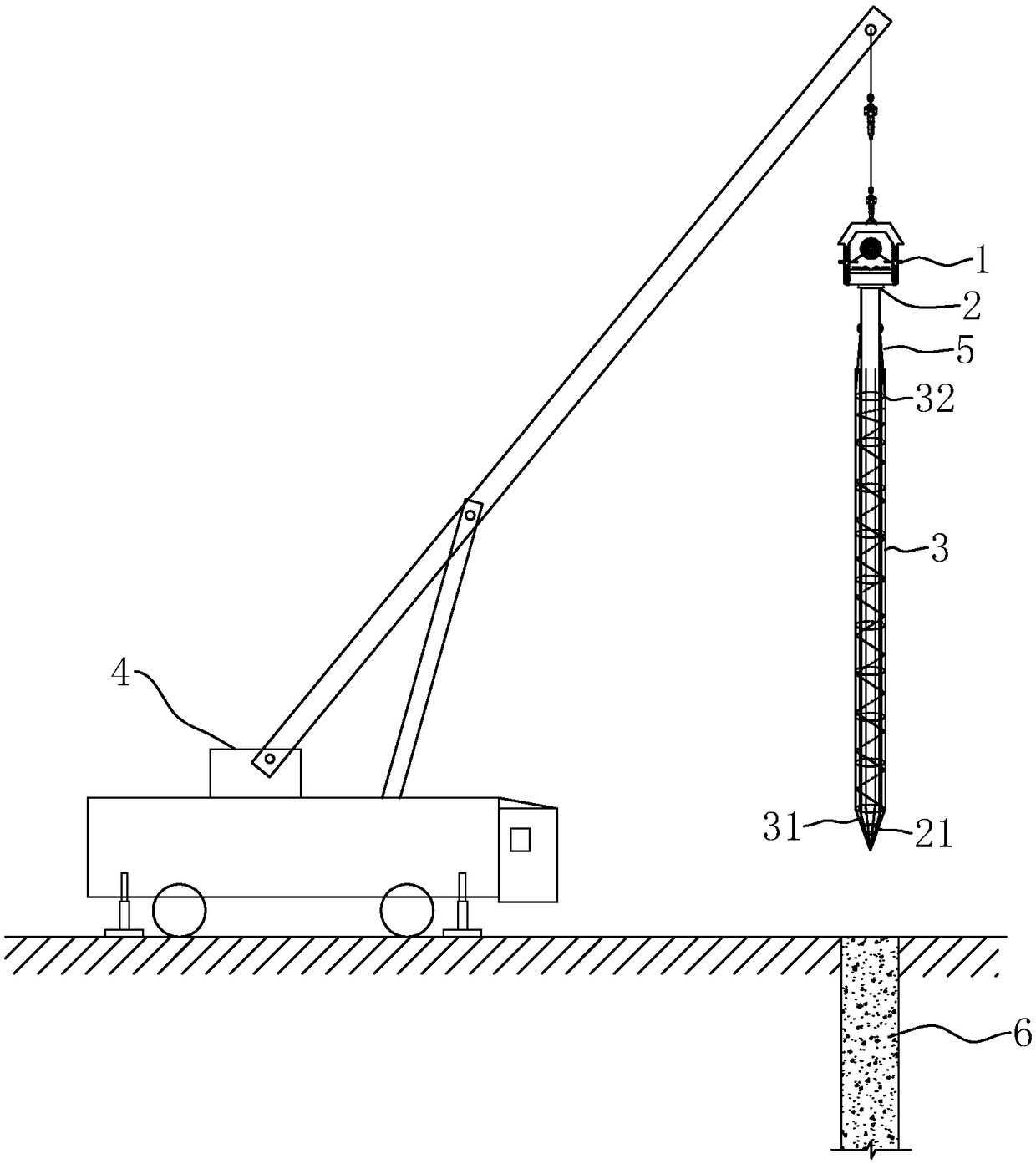

Method for effectively inserting long spiral bored pile with post-inserted cage into vibration pipe

The invention discloses a method for effectively inserting a long spiral bored pile with a post-inserted cage into a vibration pipe. According to the key points of the technical scheme, the method comprises the following construction steps that a, an assembly hole with the diameter larger than the diameter of a steel reinforcement cage is drilled in the ground; b, the steel reinforcement cage is vertically hoisted into the assembly hole; c, the vibration pipe is hoisted into the steel reinforcement cage in the assembly hole, wherein the bottom of the vibration pipe is made to abut against the conical portion of the steel reinforcement cage; and d, a vibration hammer, the vibration pipe and the steel reinforcement cage are hoisted to the upper portion of a concrete pile to be subjected to cage insertion, and insertion of the steel reinforcement cage into the concrete pile begins. By means of the method, pipe penetration operation which is originally carried out on the ground is changed to be carried out in the special assembly hole, the pipe penetration operation is changed to be in the vertical direction from the horizontal direction, original manual pipe penetration is changed to mechanical pipe penetration, the high requirements on construction sites and the arm length of a crane are lowered, and the construction efficiency is greatly improved.

Owner:北京中润宝成工程技术有限公司

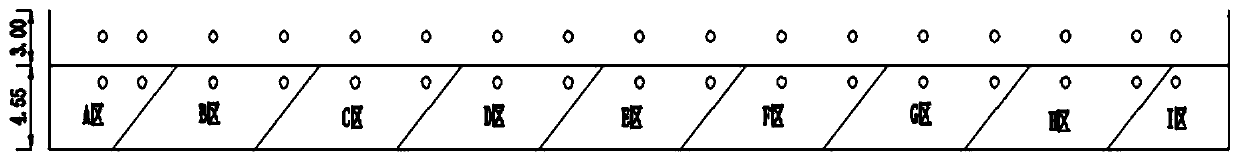

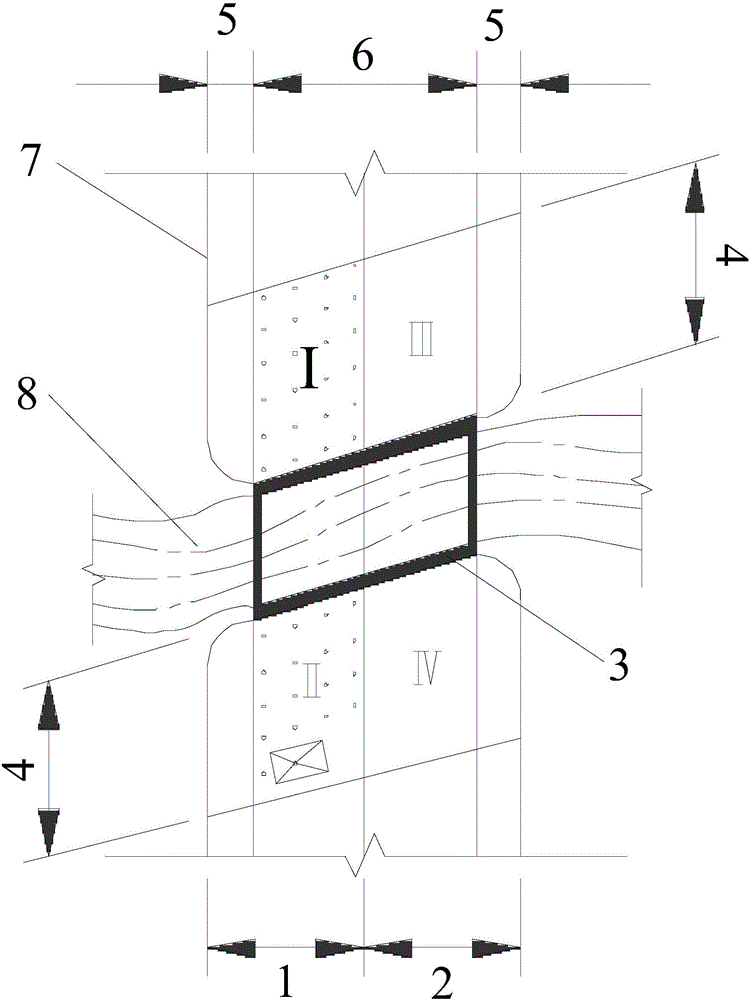

Method for treating open-to-traffic soft soil foundation bridgehead settlement through high-pressure jet grouting piles by means of embankment hole drilling

InactiveCN106522072ASmooth handlingDoes not affect trafficExcavationsRoads maintainenceAfter treatmentRoad surface

The invention relates to a method for treating open-to-traffic soft soil foundation bridgehead settlement through high-pressure jet grouting piles by means of embankment hole drilling. The method comprises the following steps that (1) the treatment lengths of settlement highway sections on the two sides of an open-to-traffic highway bridge are determined, the treatment sections are divided into four subsections of the subsection I, the subsection II, the subsection III and the subsection IV, the subsection I and the subsection III are located on the left highway section, and the subsection II and the subsection IV are located on the right highway section; (2) the left highway section is closed, asphalt running pavements or concrete running pavements of the subsection I and the subsection II of the left highway section are cleaned, pavement bed courses and embankment filling which are located under the pavements are exposed, the part, from the shoulder to the slope toe, of the left highway section is kept in the original state, and passage of the right highway section is ensured; (3) running pavement subgrades are treated through the single-tube high-pressure jet grouting pile; and (4) after treatment of the running pavement subgrades is completed, the triple-tube high-pressure jet grouting pile is adopted for treating embankment slopes. The method has the advantages that the method is suitable for treatment of excessive settlement of bridgehead highway sections and also suitable for treatment of excessive settlement of any other highway sections of open-to-traffic highways.

Owner:NINGBO UNIV

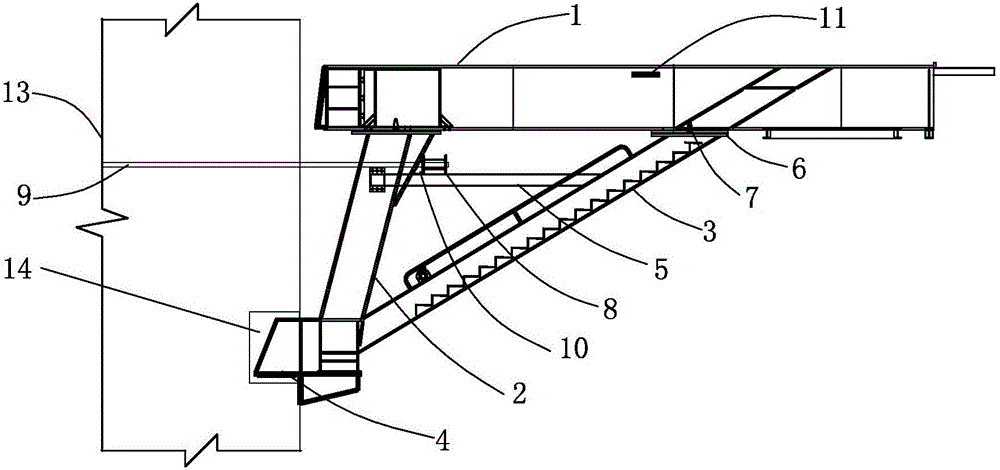

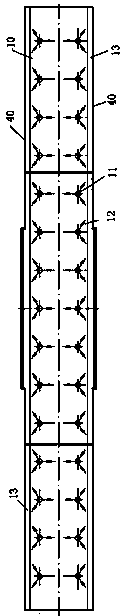

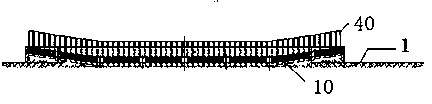

Assembly type overhead platform and construction method thereof

InactiveCN106437165AEasy constructionNo waiting time for maintenanceBuilding material handlingRoad surfaceMaterial resources

The invention discloses an assembly type overhead platform and a construction method thereof. The platform comprises a horizontal section and slope sections at two ends of the horizontal section, and one end, away from the horizontal section, of each slope section is set up on the ground. The horizontal section comprises first supporting columns and a horizontal pavement slab on the first supporting columns. Each slope section comprises a second supporting column and a slope pavement slab, two ends of each slope pavement slab are set up on the adjacent first supporting column and the corresponding second supporting column, and the first supporting columns are higher than the second supporting columns. Compared with the prior art, the assembly type overhead platform and the construction method thereof have advantages that (1) by adoption of the prefabricated first and second supporting columns, the horizontal pavement slab and the slope pavement slab, convenience and quickness in construction are realized, waiting time for curing is avoided, and accordingly construction period is shortened; (2) small quantity of onsite construction machines, convenience in transferring, saving of manpower and material resources, energy saving and environment friendliness are realized, smoke dust and noise in onsite manufacturing are avoided, waste caused by pavement chiseling removal after completion of construction is avoided, and recycling after demounting is realized, so that construction cost is reduced.

Owner:SHANGHAI CONSTR NO 1 GRP

Cable trench assembly

ActiveCN107276002AEasy maintenanceEasy to replaceElectrical apparatusEngineeringMechanical engineering

The invention discloses a cable trench assembly which includes at least two cable trenches and a base plate assembly. The adjacent cable trenches are horizontally and detachably fixed together by means of butt joint sealing. The base plate assembly is detachably fixed to the ground or a mounting surface. The lower part of each cable trench is detachably fixed to the upper part of the base plate assembly by means of sealing and inserting. Each cable trench has a trench opening at the bottom. The upper middle part of the base plate assembly is disposed in the trench openings. The cable trench assembly of the invention is simple in structure, convenient to install and disassemble and easy to transport, and is installed by means of splicing on an installation site. The cable trench assembly can be used in renovation of old cable channels or old cable lines. The cable trench assembly can be directly used in a channel with unmovable equipment, and can be installed without moving the original equipment. Thus, time is saved. The cable trench assembly is inclusive. There is no need to reinstall the original cable and other lines.

Owner:宁夏众力管廊科技有限公司

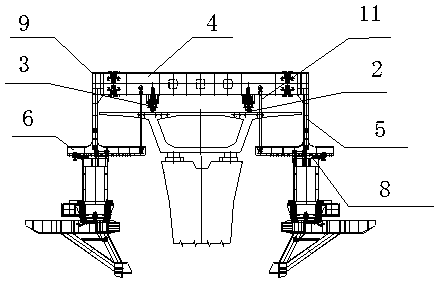

Assembly type bridge splicing bent cap mounting method and supporting structure

PendingCN111851312ARealize floor-free installationLow costBridge structural detailsBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses an assembly type bridge splicing bent cap mounting method and a supporting structure, and the method comprises the following steps: 1, forming at least one mounting hole in thetail of a to-be-mounting bent cap, and fixedly connecting at least one connecting base to a bearing platform below a bridge; 2, hoisting the to-be-mounted bent cap to the upper end of the bridge stand column through hoisting equipment; 3, enabling a supporting rod to penetrate through the bent cap tail mounting hole, wherein the lower end of the supporting rod is fixedly connected with the connecting base on the bearing platform, the top end of the supporting rod is fixedly connected with the bent cap tail, the hoisting tool is withdrawn, and mounting of the bent cap is completed; and 4, repeating the step 3; hoisting the other bent cap and connecting the two bent caps together through pouring so as to complete mounting of the spliced bent caps; according to the mounting method, the rearanchor type and front support rear anchor type assembly type bridge bent cap mounting technology is adopted, the site construction space is reduced, normal transportation is guaranteed, constructors and construction machines are reduced, and the safety risk in construction is also reduced.

Owner:THE FIRST ENG CO LTD OF CTCE GRP +1

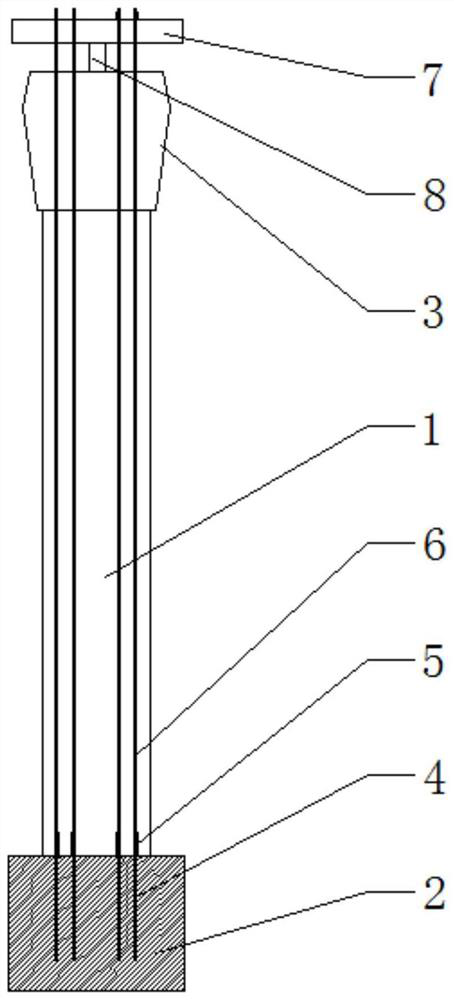

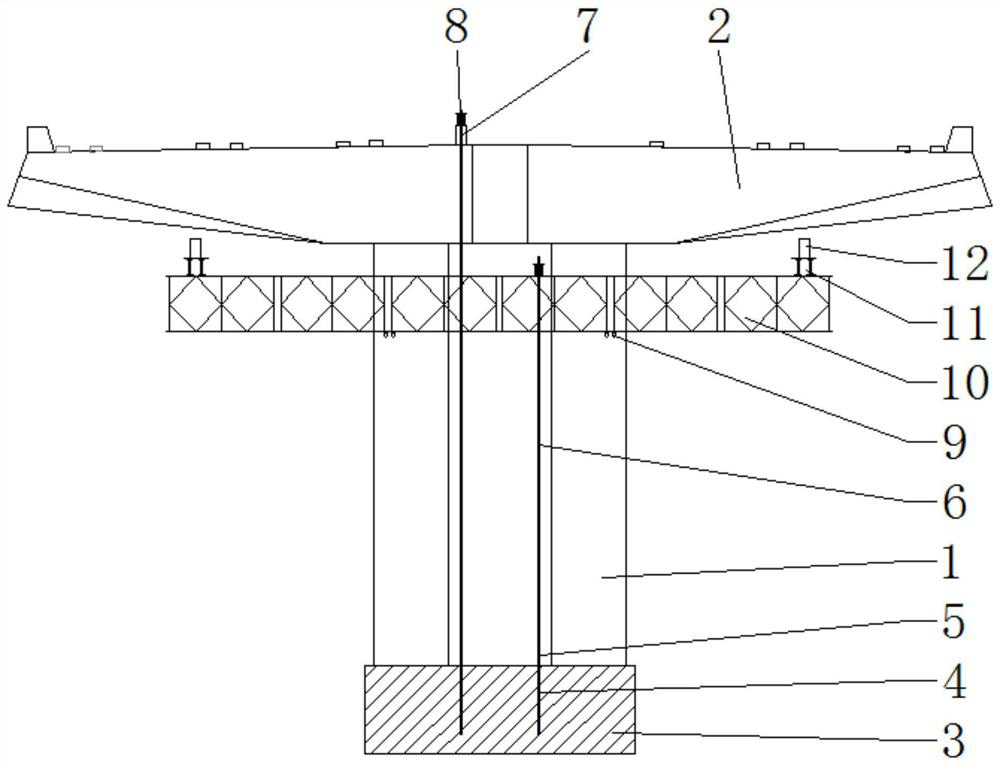

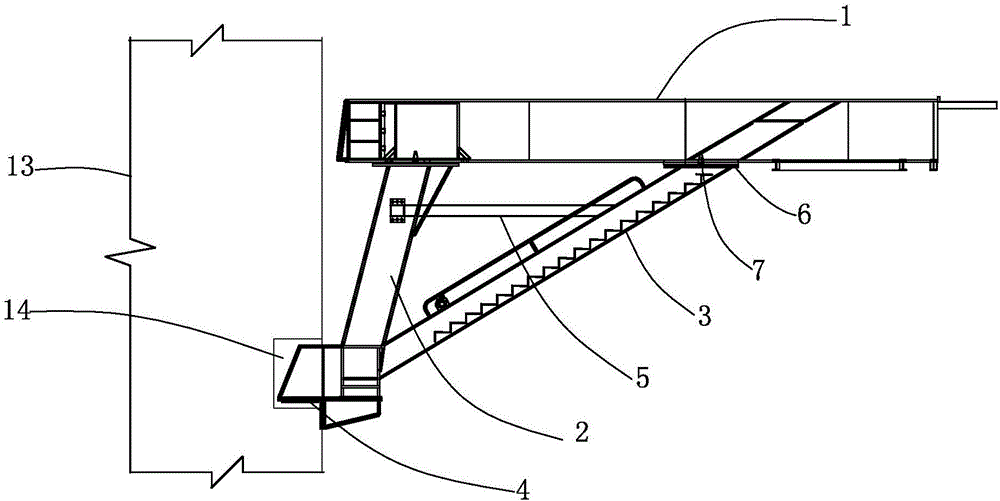

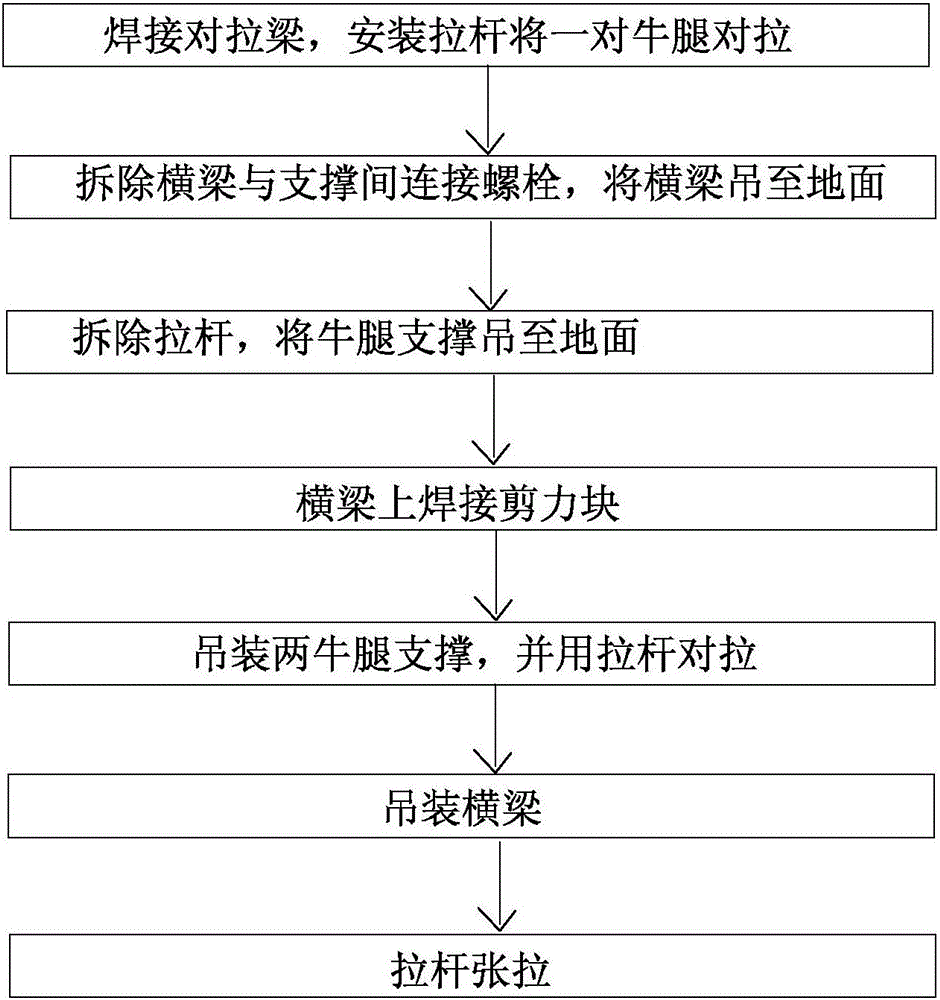

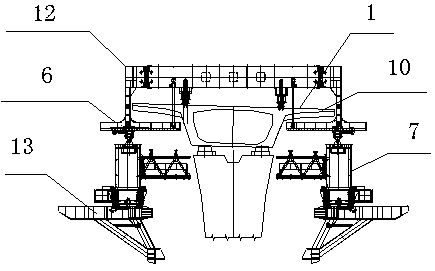

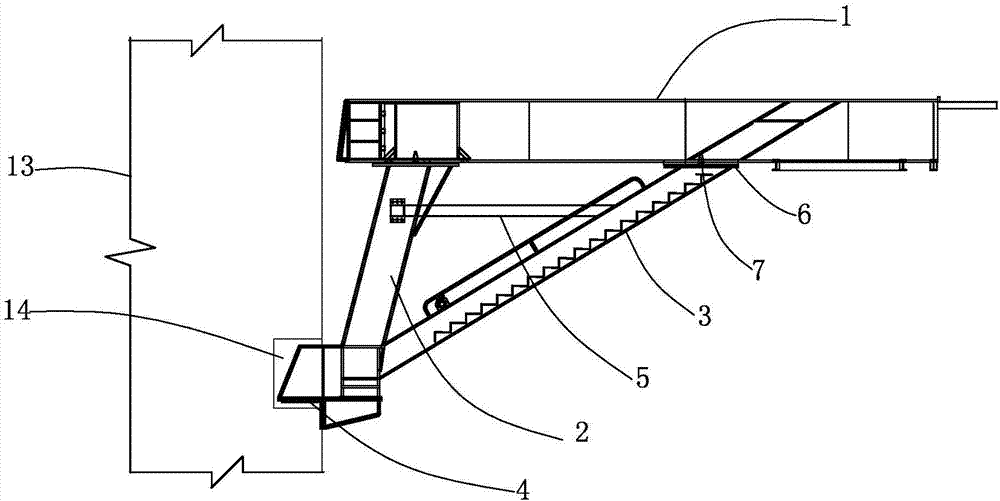

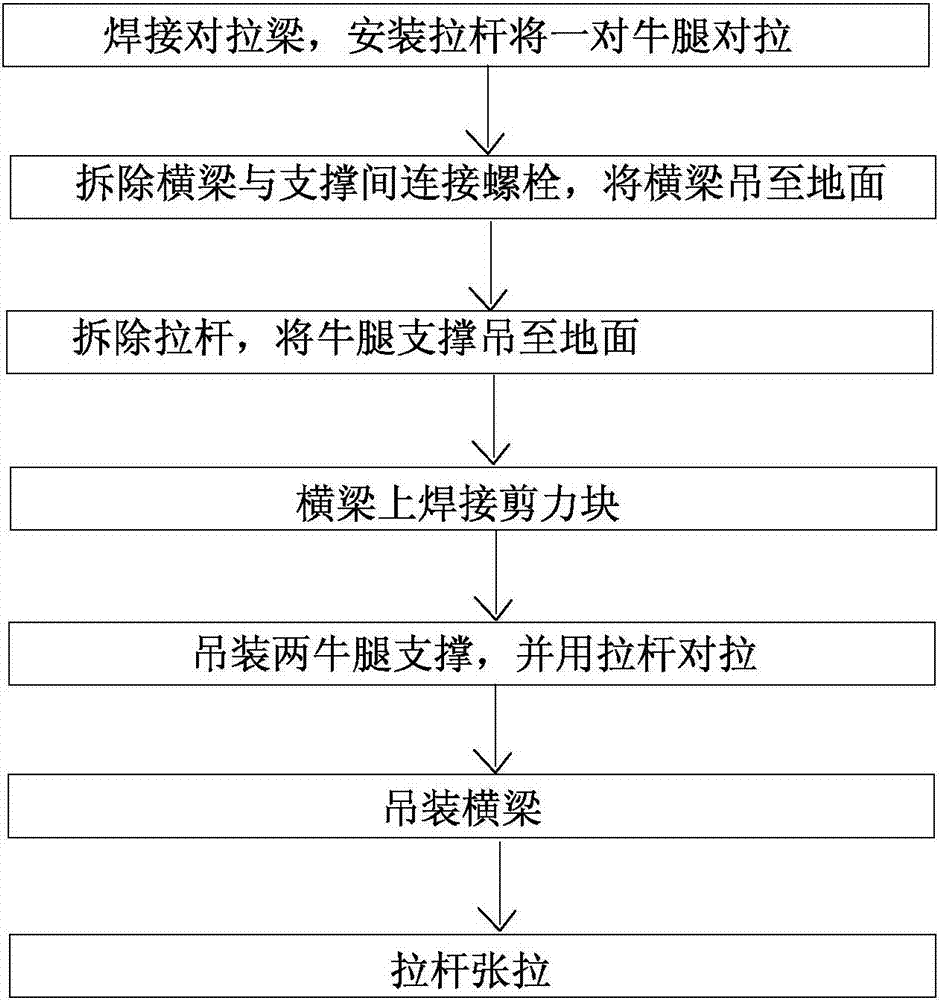

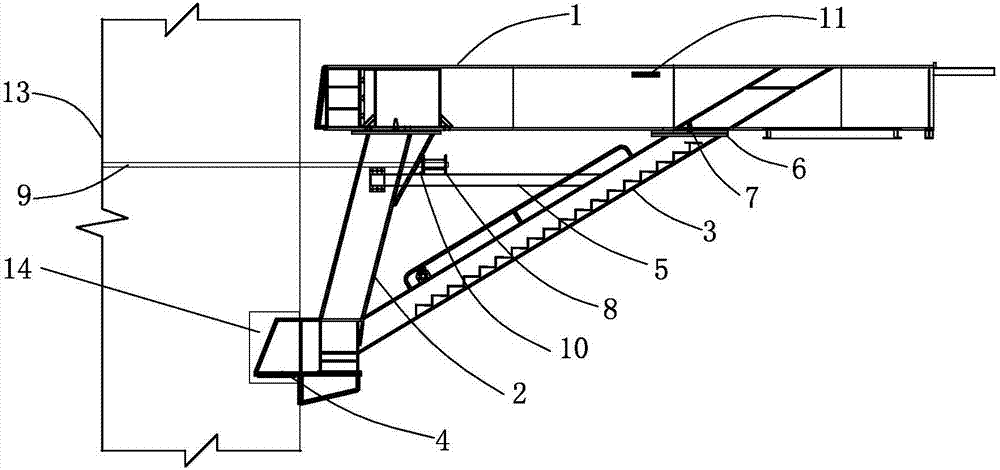

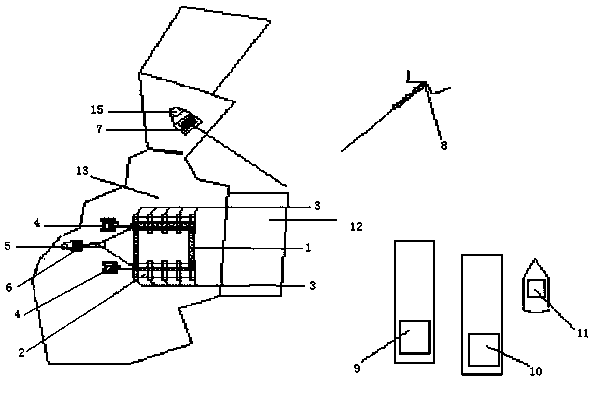

Separated dismantling and hoisting method for large-scale corbels used for high pier construction

ActiveCN106522100ASmall construction machineryAccelerate Construction Progress GoalsBridge structural detailsBridge erection/assemblySUSPENDING VEHICLECorbel

The invention provides a separated dismantling and hoisting method for large-scale corbels used for high pier construction. During separated dismounting, firstly, an opposite-pull beam is welded to the interchanges of vertical supports and connecting beams of the corbels, and the pair of corbels are oppositely pulled through pull rods; then connection between cross beams and supports of the corbels is dismantled, and the cross beams are hoisted to the ground through cranes; and the corbel supports on the two sides of a pier body are lifted through the two cranes at the same time, the pull rods are dismantled, and the corbel supports are hoisted to the ground. During corbel mounting, firstly, the supports of the pair of corbels are separately hoisted to the two sides of the pier body through the two cranes to be mounted and oppositely pulled through the pull rods; and then the corbel cross beams are hoisted, and the pull rods are tensioned through hydraulic jacks.

Owner:ROAD & BRIDGE INT +1

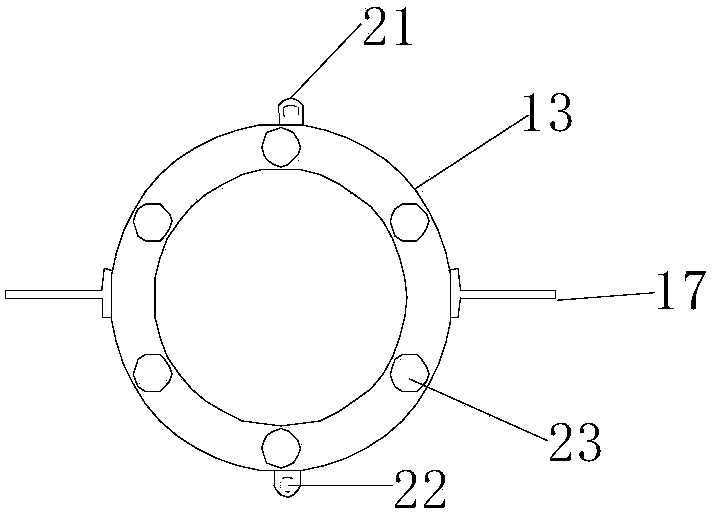

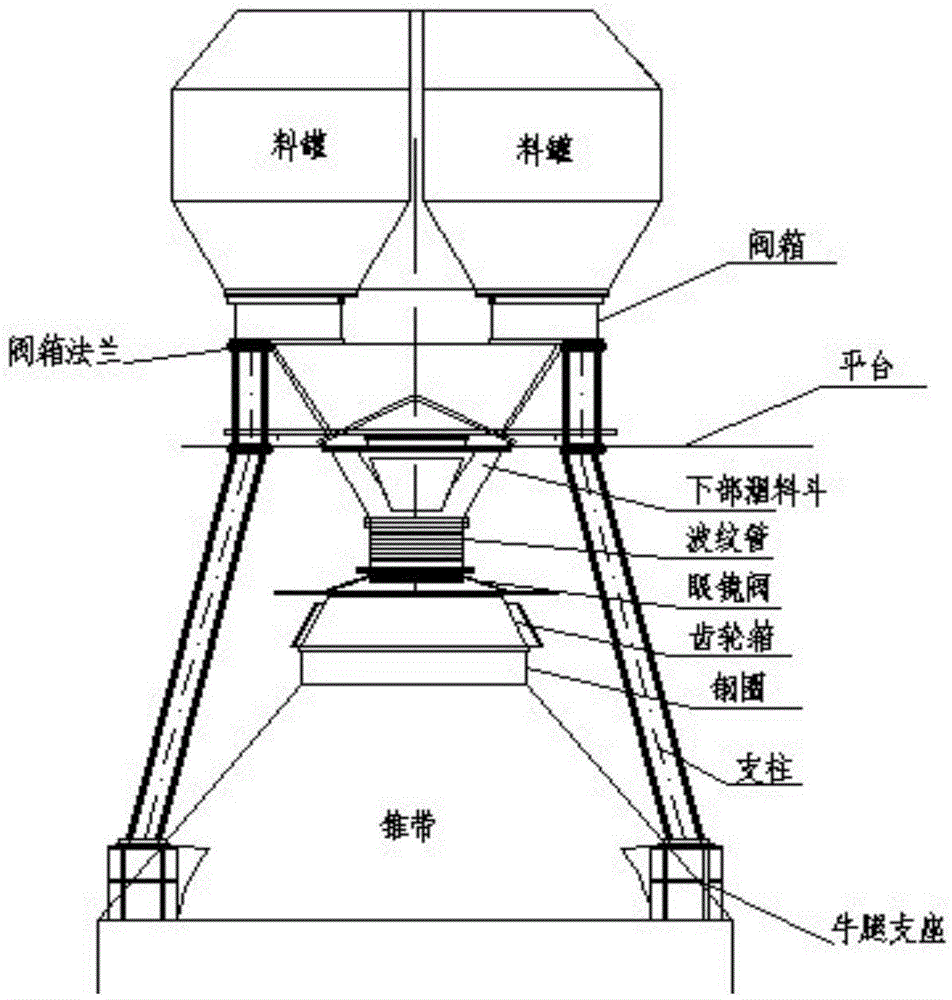

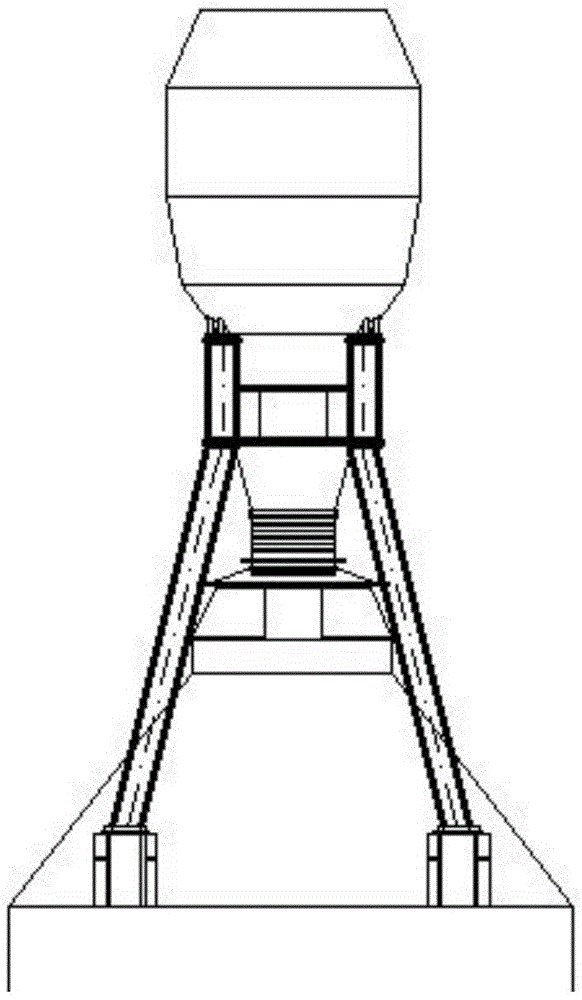

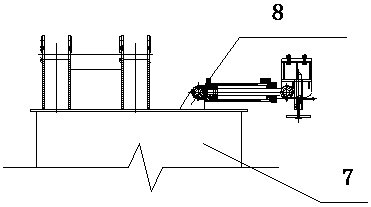

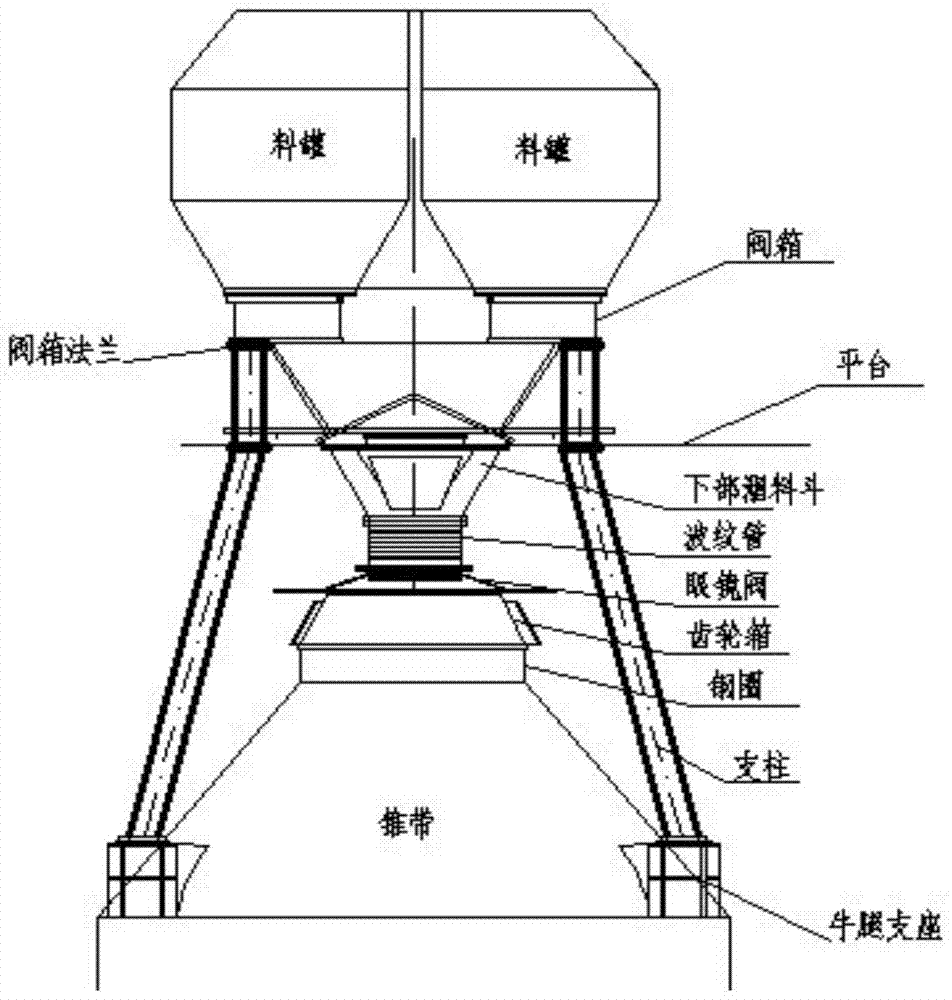

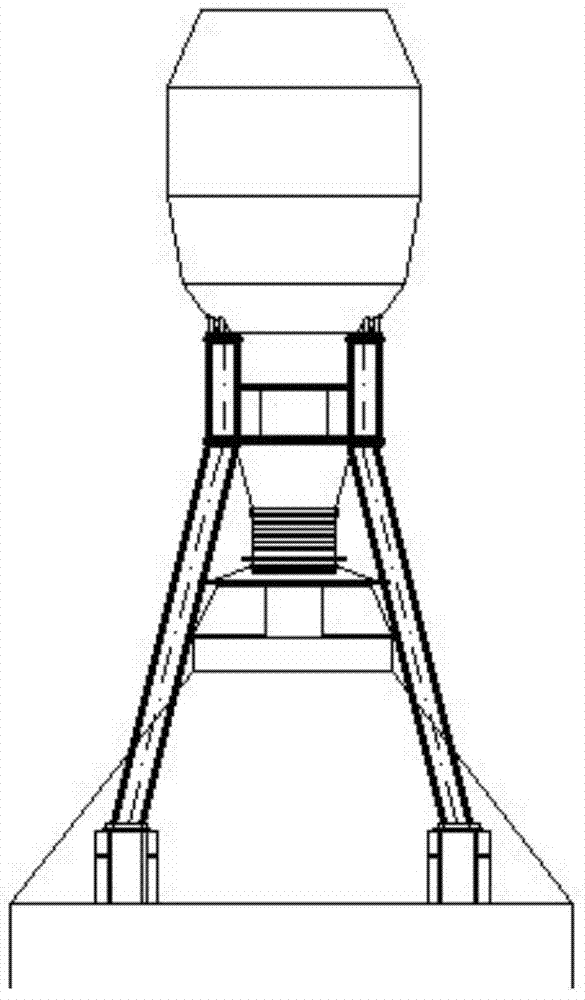

Installing construction method for large blast furnace top valve box

ActiveCN105483302AImprove accuracyImprove installation accuracyBell-and-hopper arrangementBlast furnace detailsEngineeringFlange

The invention provides an installing construction method for a large blast furnace top valve box. Valve box supporting column installation is assisted through a rapid supporting column positioning device. Two sets of cross rods and two sets of vertical rods of the rapid supporting column positioning device can linearly stretch and contract for rod length adjustment, and four sets of clamping pieces of the rapid supporting column positioning device can stretch and contract through curves for clamping piece arc length adjustment. Supporting column top blind flange installing is assisted through a valve box supporting column top blind flange alignment device, and the valve box supporting column top blind flange alignment device is mainly formed by connecting an upper annular detachable steel structure and a lower annular detachable steel structure, and in other words, the valve box supporting column top blind flange alignment device is formed by connecting an upper adjusting end and a lower fixing end through a horizontal adjusting high-strength screw. According to the installing construction method, the installing and positioning accuracy of valve box supporting columns and blind flanges is improved, the installing precision of a furnace top valve box is improved, the error of the equipment manufacturing and installing process is effectively overcome, and the installing construction method has the advantages that time and labor are saved, the installing construction method is more convenient and more rapid, accuracy is high, safety is good, and cost is saved.

Owner:CHINA FIRST METALLURGICAL GROUP

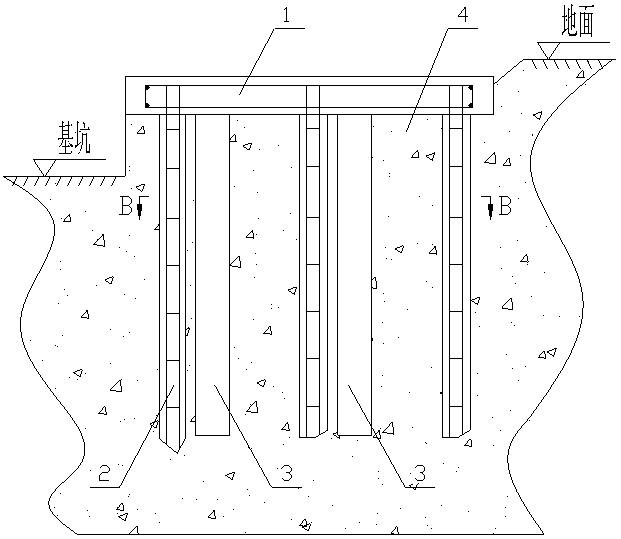

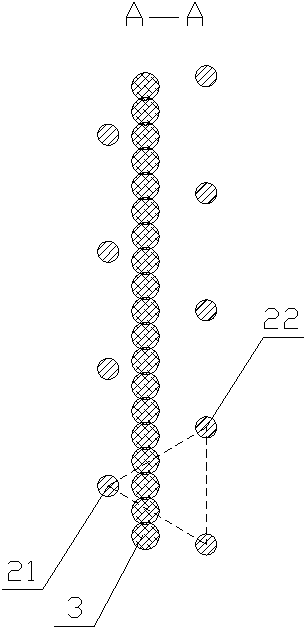

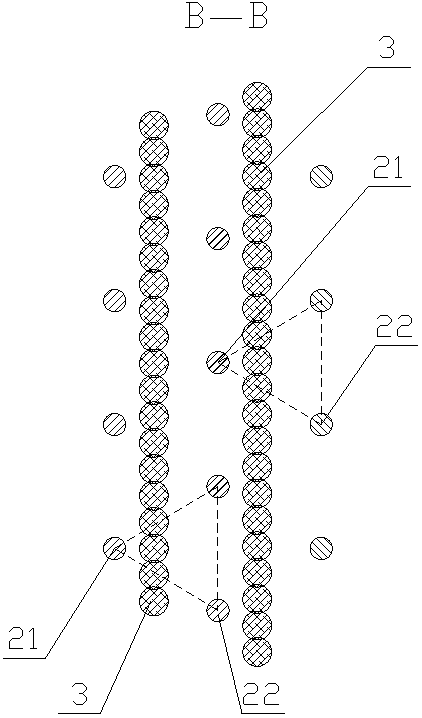

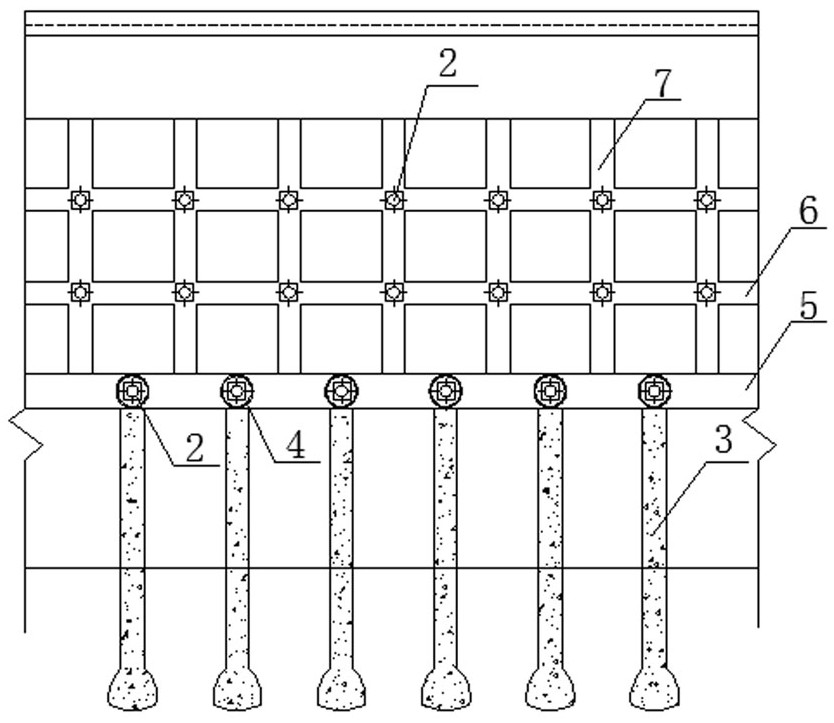

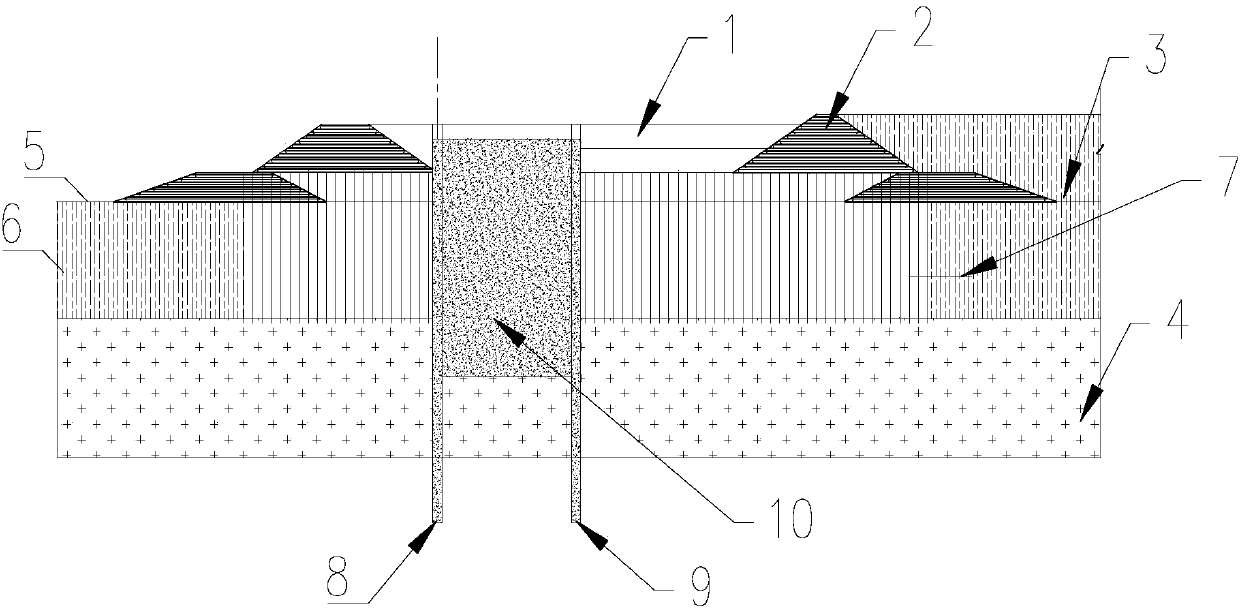

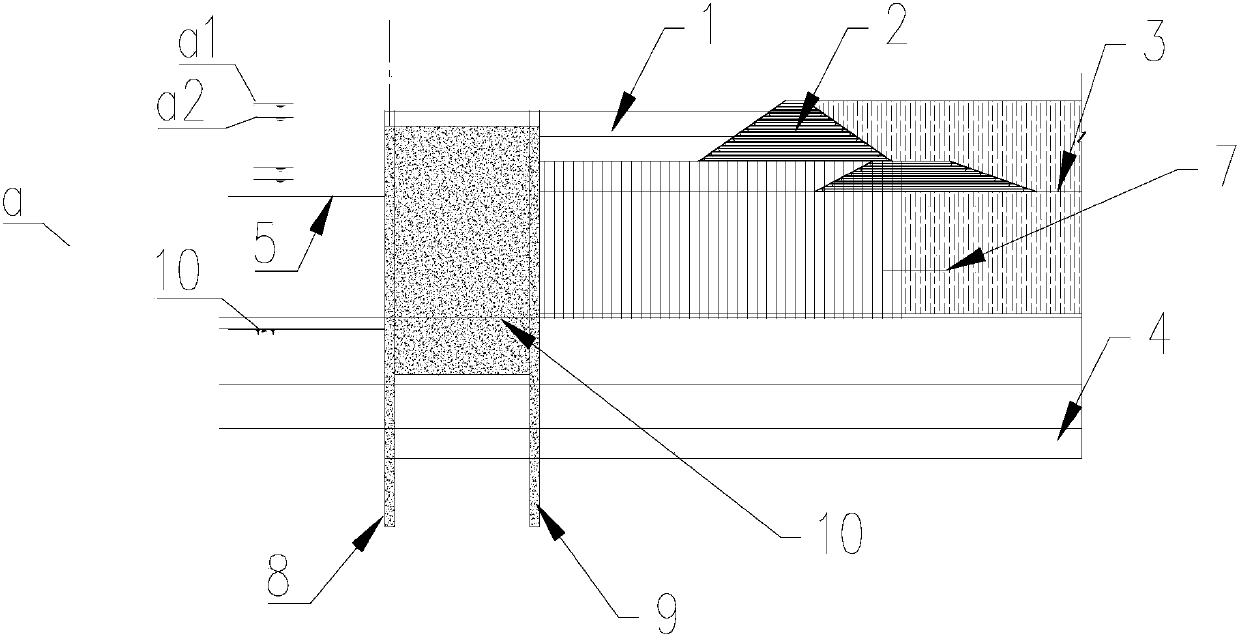

Multi-row mini-pile enclosing structure for blocking soil and construction process

The invention relates to the field of foundation bases and discloses a multi-row mini-pile enclosing structure for blocking soil and a construction process. The multi-row mini-pile enclosing structure for blocking soil comprises a top beam (2) and more than two rows of mini piles (2), the mini piles (2) comprise front-row piles (21) and rear-row piles (22), cement stirring piles (3) are arranged between the front-row piles and the rear-row piles (22), and the top ends of the mini piles (2) are connected together by the top beam (1). The construction process comprises the steps of digging grooves, positioning pile heads, drilling, grouting, casting and the like. The multi-row piles have the advantages that the whole performance is good, the anti-bending rigidity is high, the lateral deformation of a foundation pit and the surface subsidence of the periphery of the foundation pit can be effectively controlled by an inner support or an anti-pulling anchor rod, the construction time can be saved well and the construction cost is reduced.

Owner:ZHEJIANG SCI-TECH UNIV

A cable groove body assembly

ActiveCN107276002BEasy maintenanceEasy to replaceElectrical apparatusMechanical engineeringCable line

The invention discloses a cable trench assembly which includes at least two cable trenches and a base plate assembly. The adjacent cable trenches are horizontally and detachably fixed together by means of butt joint sealing. The base plate assembly is detachably fixed to the ground or a mounting surface. The lower part of each cable trench is detachably fixed to the upper part of the base plate assembly by means of sealing and inserting. Each cable trench has a trench opening at the bottom. The upper middle part of the base plate assembly is disposed in the trench openings. The cable trench assembly of the invention is simple in structure, convenient to install and disassemble and easy to transport, and is installed by means of splicing on an installation site. The cable trench assembly can be used in renovation of old cable channels or old cable lines. The cable trench assembly can be directly used in a channel with unmovable equipment, and can be installed without moving the original equipment. Thus, time is saved. The cable trench assembly is inclusive. There is no need to reinstall the original cable and other lines.

Owner:宁夏众力管廊科技有限公司

An unloadable pile-anchor multi-stage support structure and construction method

The invention discloses an unloading piled anchor multi-stage support structure and a construction method, and belongs to the technical field of geotechnical engineering anchoring. The unloading piledanchor multi-stage support structure comprises a framed anchor and a piled anchor combination structure. The framed anchor is composed of a frame and anchor rods, and the anchor rods are anchored tothe frame by anchorage devices. The piled anchor combination structure is composed of anchor rods, cast-in-situ bored piles, unloading grouting bearing steel pipes and a crown beam. Enlarge heads arepoured at the bottoms of the cast-in-situ bored piles, and the crown beam is poured at the tops of the cast-in-situ bored piles. The unloading grouting bearing steel pipes penetrate through a reservedpassage on the crown beam to drive into a stable soil body. The ends, penetrating through the unloading grouting bearing steel pipes, of the anchor rods are anchored in the stable soil body, and theother ends of the anchor rods are fixed to the crown beam. Stand columns on the lower portion of the framed anchor are poured on the crown beam. The unloading piled anchor multi-stage support structure and the construction method can fully utilize the lifting action of the unloading grouting bearing steel pipes and the free sections of the anchor rods between an unstable soil body and piles for unloading, the soil pressure acting on pile bodies is reduced, and the problems of the embedded depth, diameter and reinforcement of support piles in row and the length of the anchor rods working with the frame are solved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Construction method for underbridge

InactiveCN102505707BSmall construction machineryArtificial islandsUnderwater structuresUltimate tensile strengthRetaining wall

The invention relates to a construction method for an underbridge. The construction method comprises the following steps of: firstly pouring a middle-part base plate and a vertical wall on ground, and reserving a steel pipe pile inserting hole on the base plate, wherein retaining wall guide rails are arranged on two side surfaces of the exterior of the base plate and the retaining wall guide rails and the base plate are poured together; after the concretion degree of the base plate is up to the concretion strength requirement, driving a retaining wall from two sides of the base plate to a place which is 0.5-1m below the lower surface of the base plate along the retaining wall guide rails, and inserting a steel pipe pile and applying pressure to the followed reduced place which is 0.5-1m below the lower surface of the base plate after drilling and taking out soil in the steel pipe pile inserting hole reserved on the base plate; arranging a jack at the top of the steel pipe pile by taking the steel pipe pile as a support, lifting up the base plate by use of the jack, taking out soil below the base plate and sinking the poured base plate and the vertical wall; and pouring the externally extended base plate and vertical wall again, repeating such steps till finishing the sinking process, taking out the steel pipe piles and the retaining walls, and mounting a beam plate. The construction method for the underbridge, disclosed by the invention, has the advantages of rather fewer machines used in the process of construction, small occupied area and smaller influence on surrounding environment.

Owner:张 云祥

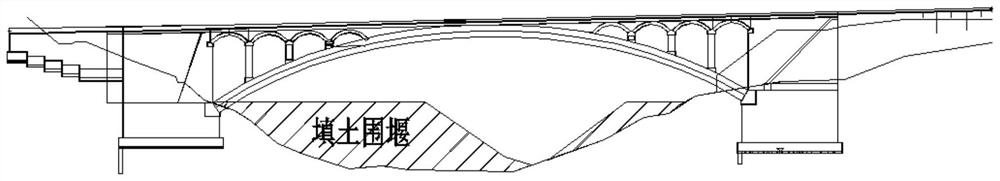

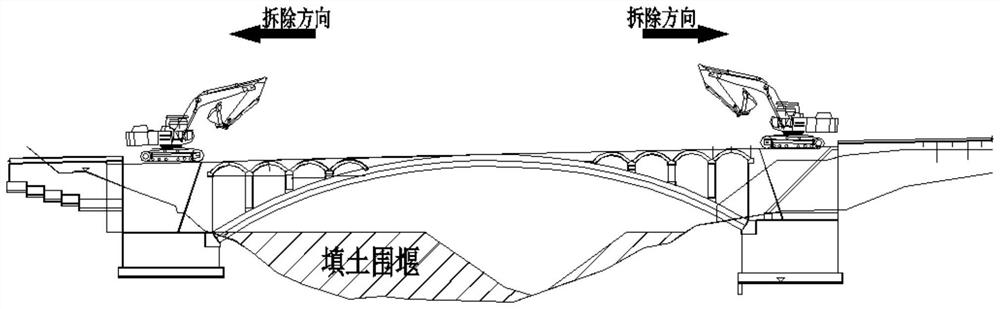

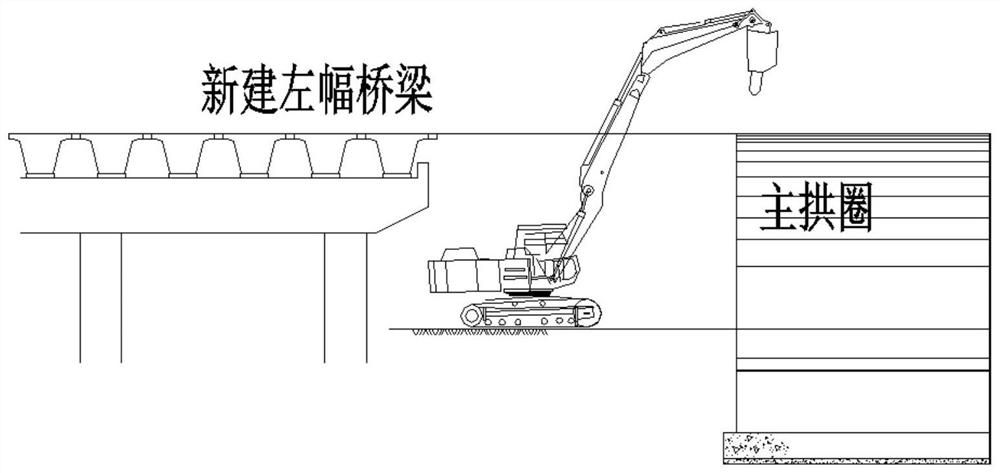

Arch bridge dismantling method

PendingCN113944113AReduce riskSmall construction machineryBuilding repairsBridge strengtheningArchitectural engineeringCofferdam

The invention relates to an arch bridge dismantling method which comprises the steps that at least one side of an arch bridge is filled with soil to form a cofferdam; a bridge deck is milled from one end to the other end of the arch bridge; guardrails on the two sides of the arch bridge are dismantled; two excavators are adopted to dismantle arch filling and web arch rings from the middle to the two ends of the bridge deck of the arch bridge; the excavators are stopped on the soil cofferdam, vault strip stones of the main arch ring are dismantled till the vault is broken to the soil cofferdam and the riverbed from the dismantling position, and dismantling continues to be conducted from the main arch position to the bridge abutment; and the two excavators are adopted to stop on the road surfaces at the two ends of the arch bridge to dismantle bridge abutments at the two ends of the arch bridge. By the adoption of the arch bridge dismantling method, arch bridge dismantling construction can be completed two days earlier than that of a direct impact crushing method, the aim of quickening the construction progress while construction machinery is saved is achieved, the construction efficiency is greatly improved, and meanwhile the danger of high-altitude operation is reduced.

Owner:CHINA COMM NORTH ROAD & BRIDGE +2

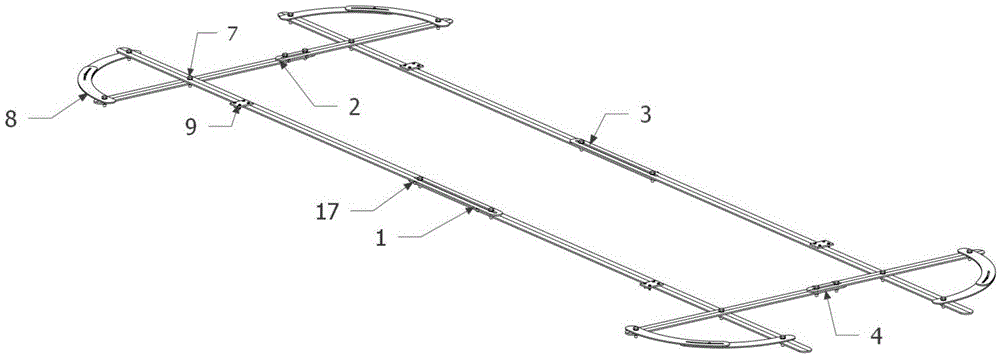

The whole continuous retreat method of the mobile formwork beam surface

ActiveCN106522113BReduce riskSmall construction machineryBridge erection/assemblyEngineeringMechanical equipment

The invention relates to an integrally continuous backing method for a moving formwork on a girder face. The integrally continuous backing method comprises the following steps that (A), a rail and jack supporting positions are arranged on the girder face, and a first backing girder is lifted and downwards placed on jacks; (B), a second backing girder is arranged, and a connector of the second backing girder is aligned with the first backing girder; (C), horizontally moving suspension girders and a horizontally moving jack system are arranged; (D), a main girder is connected with a backing upper suspension girder; (E), the backing upper suspension girder and anchor holes of the horizontally moving suspension girders are fixed on preformed holes of a frange plate by suspension rods; (F), according to the mounting steps, a back horizontal girder is connected with the main girder; (G), opposite-pulling finish-rolled deformed steel bars for brackets are removed, and the brackets are horizontally moved out of holes; (H), the formwork is integrally and horizontally moved to a designated position, and a vertical stabilizer rod is arranged; and (I), all suspension rods of the preformed holes of the frange plate are relieved, the backing upper suspension girder and a vertical pushing device on a rail of the back horizontal girder are synchronously operated, and the moving formwork is subjected to continuous backing travel till backing construction is finished. According to the integrally continuous backing method, the backing construction period of the moving mould frame is shortened, the input of mechanical equipment is reduced, construction cost is saved, and the construction safety risk is lowered.

Owner:ROAD & BRIDGE INT +1

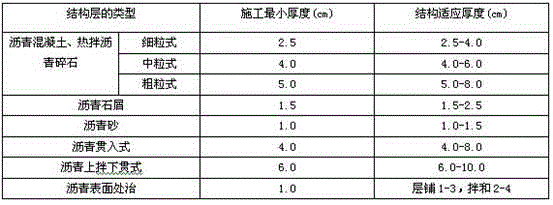

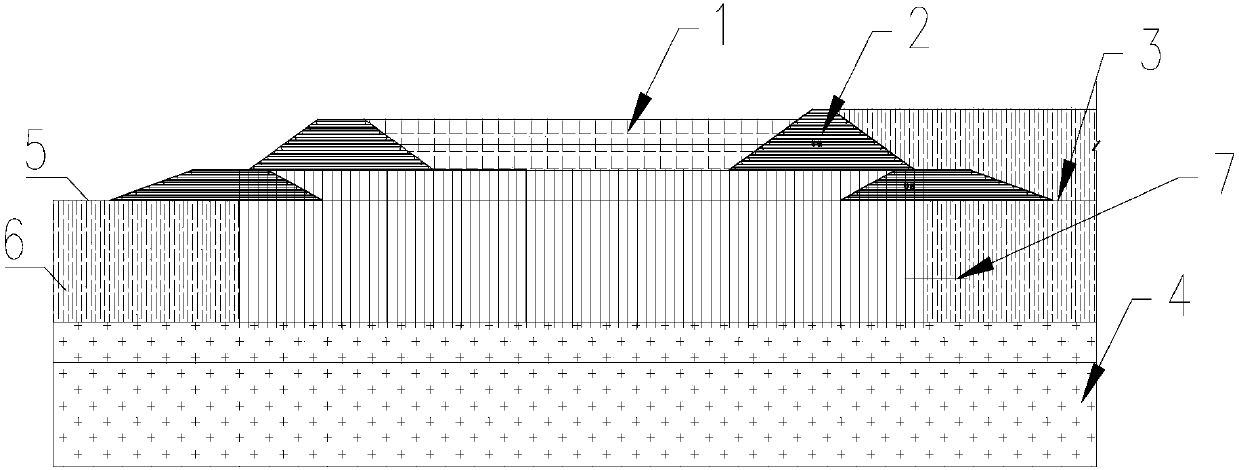

High-viscosity modified asphalt pavement with prefabricated coil (plate) structure

ActiveCN102839581BMass productionHighly integratedSingle unit pavingsClimate change adaptationGlass fiberProduction line

The invention discloses a high-viscosity modified asphalt thin layer road surface for an assembled coil (plate) structure. A method for forming the high-viscosity modified asphalt thin layer road surface comprises the following steps of: preparing a substrate (non-woven geotextile), a cementing agent (high-viscosity modified asphalt), a reinforced material (glass fiber), rough aggregate (smashed stone), fine aggregate (sand and stone chips), a filler (mineral powder), a pigment (coloring matter) and an additive (viscosity depressant) according to the requirements of service environments such as hot regions, warm regions and cold regions; designing mixtures of different mixture ratios; paving non-woven geotextile serving as a substrate on a production line; paving a high-viscosity modified asphalt warmly-mixed mixture formed by stirring on the substrate; pressing into a coil (plate) road thin layer road surface by using a pressure machine; coiling coils into cylinders by adopting a cylindrical roller support; and packing plates in a supporting way. In the invention, the road asphalt thin layer road surface is integrated into industrial production and assembled construction, so that the high-viscosity modified asphalt thin layer road surface has the characteristics of high integration, quick construction, reliable quality, superior performance, saving in energy, environment friendliness, attractiveness, practicability, wide application and the like.

Owner:江苏省淮安市公路管理处

A wharf structure suitable for muddy coast and its construction method

ActiveCN105672199BIncrease land areaSave engineering investmentBreakwatersQuaysFront edgeCoupling beam

The invention discloses a wharf structure suitable for a silt coast. A direction which is close to the sea is used as a front direction, and a direction which is relatively away from the sea is used as a rear direction. The wharf structure comprises a causeway, a front diaphragm wall, a rear diaphragm wall, a partition, a plurality of coupling beams and a wharf upper part structure, wherein the front diaphragm wall, the rear diaphragm wall and the partition form a cylindrical caisson structure; the coupling beams are connected with the rear diaphragm wall and a pile foundation; and the wharf upper part structure covers the front diaphragm wall, the rear diaphragm wall, the partition and the pile foundation. By the structure, construction difficulty and engineering investment costs are reduced effectively. A construction method comprises the following steps: (1) constructing the causeway by bagged sand quilts; (2) reinforcing the causeway and silt filled at the rear of the causeway in a blowing manner, reinforcing new silt filled in the blowing manner, and constructing the front diaphragm wall, the rear diaphragm wall and the partition to form the cylindrical caisson structure when the bearing capacity of foundation soil reaches 5 tons at least; (3) excavating causeway remaining earthwork in front of the front diaphragm wall and earthwork under a natural silt surface, and enabling the front edge of a wharf to reach designed water depth; and (4) constructing the pile foundation and the coupling beams, and then constructing the wharf upper part structure. The construction method is simple.

Owner:CCCC THIRD HARBOR CONSULTANTS

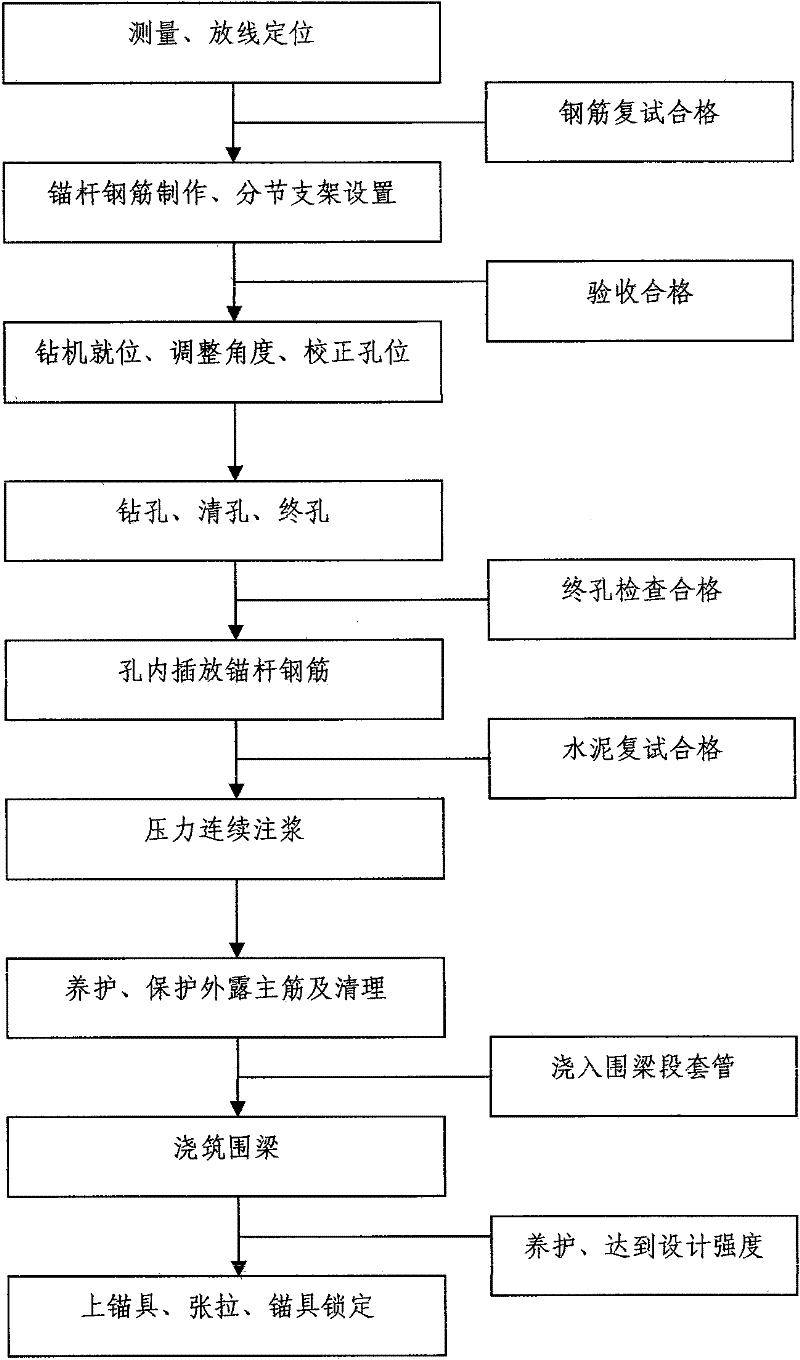

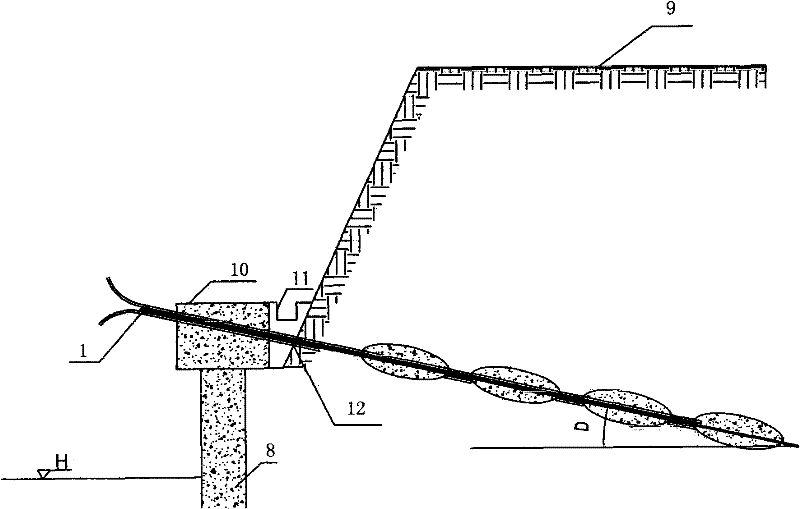

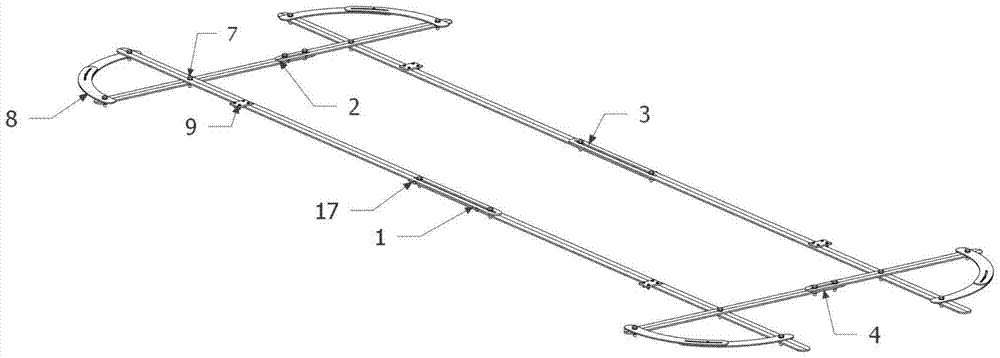

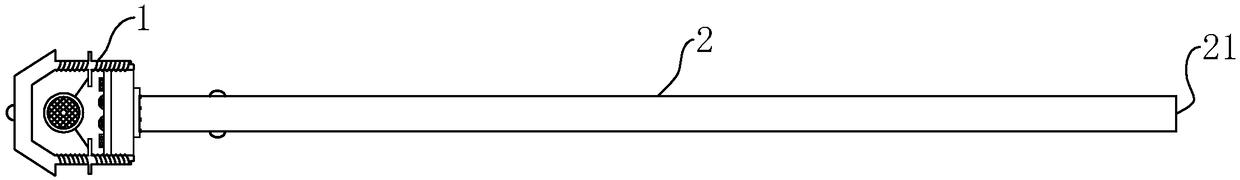

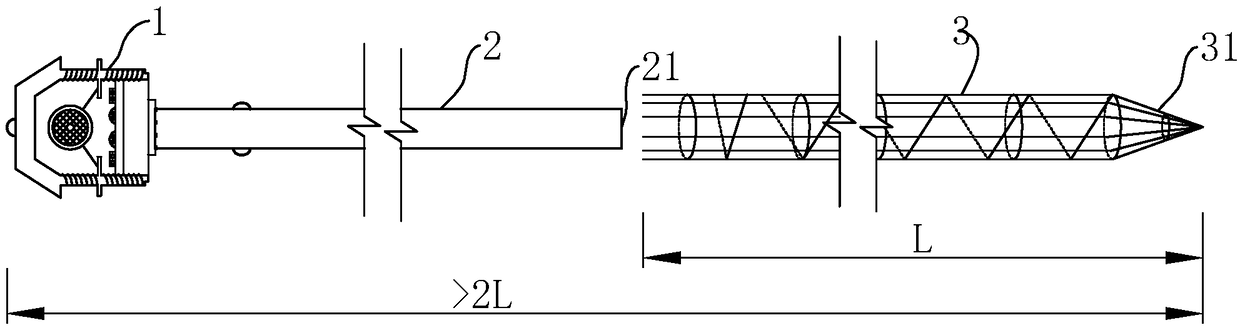

Support construction process of lotus root-shaped segmental expanded soil anchor rod

InactiveCN101929163BControl pull-out resistanceImprove tensile propertiesExcavationsBulkheads/pilesSludgeEngineering

The invention discloses a support construction process of a lotus root-shaped segmental expanded soil anchor rod, which comprises the following steps: drilling a hole in the ground or the wall surface of a deeply-excavated basement or the vertical wall of an unexcavated foundation pit to a certain designed depth, flushing by using a slurry wall protection method to form a columnar hole, placing aprefabricated anchor rod steel bar wrapped by a woven tubular bag in the hole, injecting a cement paste or a chemical grout through a pre-embedded injection pipe, carrying out segmental expansion andextrusion on sludge soil in the hole wall, using a pre-arranged plastic short hose and a paste complement tube as ventilation tubes, and discharging air in the hole to fully expand the wrapped woven tubular bag to be tightly combined with the soil so as to form a lotus root-shaped anchor rod. By using the anchor rod support construction method according to local conditions, the invention can greatly reduce the construction cost of foundation pit support, shorten the construction period, lower the construction difficulty, save energy and materials, and has the characteristics of portable construction machinery and simple operation.

Owner:浙江中联建设集团有限公司

Construction Method for Installing the Top Valve Box of Large Blast Furnace

ActiveCN105483302BImprove accuracyImprove installation accuracyBell-and-hopper arrangementBlast furnace detailsEngineeringFlange

The invention provides an installing construction method for a large blast furnace top valve box. Valve box supporting column installation is assisted through a rapid supporting column positioning device. Two sets of cross rods and two sets of vertical rods of the rapid supporting column positioning device can linearly stretch and contract for rod length adjustment, and four sets of clamping pieces of the rapid supporting column positioning device can stretch and contract through curves for clamping piece arc length adjustment. Supporting column top blind flange installing is assisted through a valve box supporting column top blind flange alignment device, and the valve box supporting column top blind flange alignment device is mainly formed by connecting an upper annular detachable steel structure and a lower annular detachable steel structure, and in other words, the valve box supporting column top blind flange alignment device is formed by connecting an upper adjusting end and a lower fixing end through a horizontal adjusting high-strength screw. According to the installing construction method, the installing and positioning accuracy of valve box supporting columns and blind flanges is improved, the installing precision of a furnace top valve box is improved, the error of the equipment manufacturing and installing process is effectively overcome, and the installing construction method has the advantages that time and labor are saved, the installing construction method is more convenient and more rapid, accuracy is high, safety is good, and cost is saved.

Owner:CHINA FIRST METALLURGICAL GROUP

Construction method of air duct with machine-made glass-magnesium composite board

ActiveCN108591634BShorten the construction periodSmall construction machineryPipe laying and repairRigid pipesSmall footprintComposite slab

Owner:QINGDAO XINHUAYOU CONSTR GROUP

A separate demolition and hoisting method for large corbels used in high pier construction

ActiveCN106522100BReduce usageReduce riskBridge structural detailsBridge erection/assemblySUSPENDING VEHICLECorbel

Owner:ROAD & BRIDGE INT +1

Launching construction method of steel cofferdam suitable for shallow water area

The invention relates to a launching construction method of a steel cofferdam suitable for a shallow water area. The method includes flatting a steel cofferdam assembly yard; building a steel cofferdam launching slope; arranging temporary buttress and ground anchor; assembling the steel cofferdam; filling in air bags; aerating the air bags and removing the temporary buttress; pushing an excavator in position; arranging a water leading anchor; arranging a guide pulley; pushing the steel cofferdam to a first machine barge; the steel cofferdam is bound with the first machine barge; the steel cofferdam is bound with another machine barge; and floating the steel cofferdam. The method can enable the steel cofferdam to launch in the shallow water area once without stranding, the process is simple, safe and reliable, and time is saved.

Owner:THE 8TH GRP OF CHINA RAILWAY 1ST ENG CO LTD

A method for efficiently inserting vibrating pipes into cast-in-place piles after long helical drilling

The invention discloses a method for effectively inserting a long spiral bored pile with a post-inserted cage into a vibration pipe. According to the key points of the technical scheme, the method comprises the following construction steps that a, an assembly hole with the diameter larger than the diameter of a steel reinforcement cage is drilled in the ground; b, the steel reinforcement cage is vertically hoisted into the assembly hole; c, the vibration pipe is hoisted into the steel reinforcement cage in the assembly hole, wherein the bottom of the vibration pipe is made to abut against the conical portion of the steel reinforcement cage; and d, a vibration hammer, the vibration pipe and the steel reinforcement cage are hoisted to the upper portion of a concrete pile to be subjected to cage insertion, and insertion of the steel reinforcement cage into the concrete pile begins. By means of the method, pipe penetration operation which is originally carried out on the ground is changed to be carried out in the special assembly hole, the pipe penetration operation is changed to be in the vertical direction from the horizontal direction, original manual pipe penetration is changed to mechanical pipe penetration, the high requirements on construction sites and the arm length of a crane are lowered, and the construction efficiency is greatly improved.

Owner:BEIJING ZHONGRUN BAOCHENG ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com