Construction method of mudstone-filled embankment

A construction method, mudstone technology, applied to roads, roads, buildings, etc., can solve problems such as uneconomical, high cost, and long construction time, and achieve the effects of saving engineering costs, good engineering quality, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 : construction method of embankment filled with mudstone

[0024] 1. Detection of rock composition and mechanical characteristics of filled roadbed:

[0025] In order to understand the Jishao Expressway project and understand the rock composition and mechanical characteristics of the filled roadbed, samples were taken from the JSTJ-07 contract section where the test road section is located, and rock chemical composition and physical and mechanical tests were carried out on typical samples.

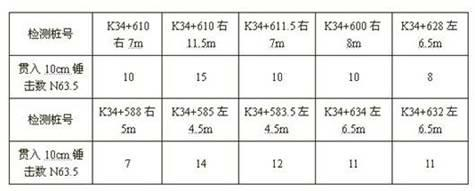

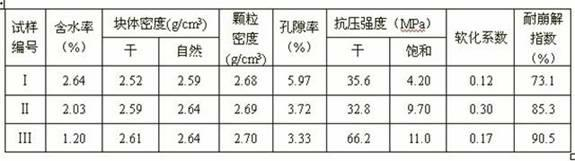

[0026] Table 1: Physical and mechanical test data table of indoor rock

[0027]

[0028] Rock ore identification results are as follows (% by weight):

[0029] Sample Ⅰ: reddish calcium-containing mudstone (or shale), clay mineral content > 70%, calcite (calcite) content 10% ~ 20%, iron content 5% ~ 10%, quartz (debris) content < 5% %.

[0030] Sample II: reddish silty calcareous mudstone, with clay mineral content >60%, calcite (calcite) content 10%~20%, iron cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com