Construction method for underbridge

A construction method and technology of bottom plate, which are applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of poor construction environment, deep piles, using many materials, and unsatisfactory construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the invention will be described below in conjunction with specific embodiments.

[0031] In the construction method of the underpass bridge of the present invention, the prefabricated construction process of the bridge slab remains unchanged. Using the existing construction method, the part below the bridge slab is divided into the bottom slab and the vertical wall. What the present invention solves is the construction of the bottom slab and the vertical wall, including the following step:

[0032] (a) Clear, level and compact the concrete pavement or asphalt pavement and other parts that are not easy to be excavated by excavators in the ground area where the underpass bridge is planned to be built;

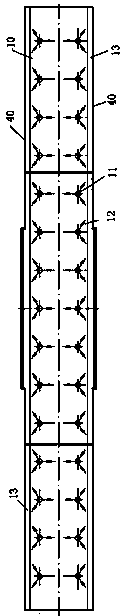

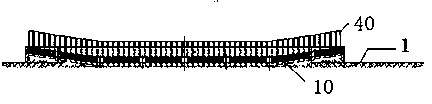

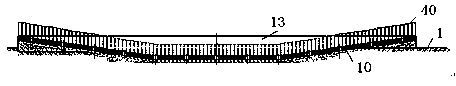

[0033] (b) See also figure 1 , Figure 2a to Figure 2d , Figure 3a to Figure 3e On the leveled and compacted ground 1, pour the bottom plate 10 of the underpass bridge and the first section of vertical wall 13 located outside the two long sides of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com