Launching construction method of steel cofferdam suitable for shallow water area

A construction method and technology for steel cofferdams, which are applied in infrastructure engineering, construction, caisson, etc., can solve the problems of unsuitable draft depth of cofferdams, many hidden dangers in construction safety, and lack of flexibility. Short cycle and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

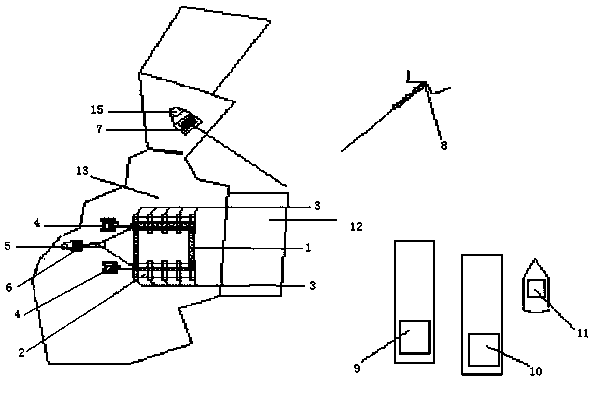

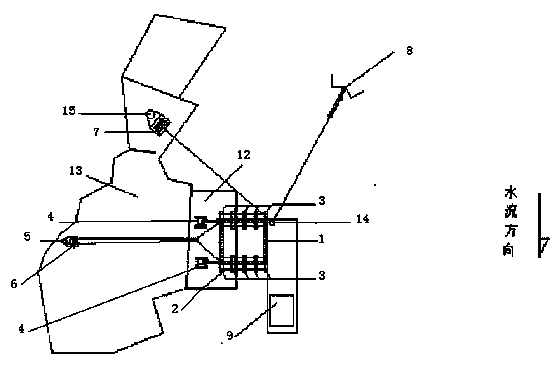

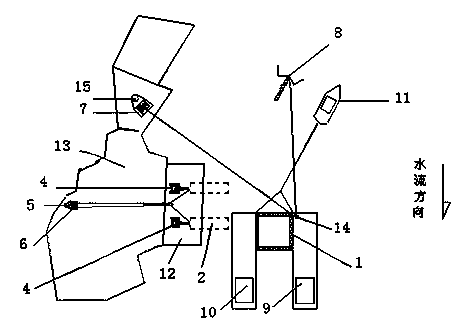

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] see Figure 1 to Figure 5 , a steel cofferdam launching construction method suitable for shallow water areas, the steps of which are as follows:

[0030] The first step is to level the steel cofferdam assembling yard; on the shore, a site inclined to the river is leveled as the steel cofferdam assembling yard 13, and the slope of the steel cofferdam assembling yard is 5%;

[0031] The second step is to build a steel cofferdam launching slope; build a steel cofferdam launching slope 12 on the side of the steel cofferdam assembly site near the river and slope to the river. The slope of the steel cofferdam launching slope is 20% ;

[0032] The third step is to set up temporary buttresses and ground anchors; set up temporary buttresses on the steel cofferdam assembly field for installing brackets; set the bank side ground anchor 5 in the middle of the side away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com