A separate demolition and hoisting method for large corbels used in high pier construction

A hoisting method and separate technology, applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., to achieve the effect of reducing the risk, saving construction machinery, and speeding up the construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

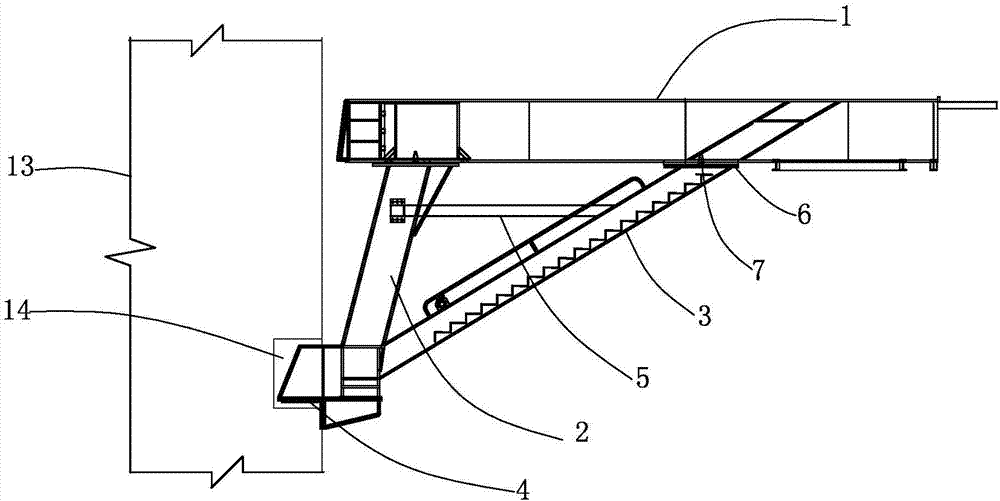

[0024] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

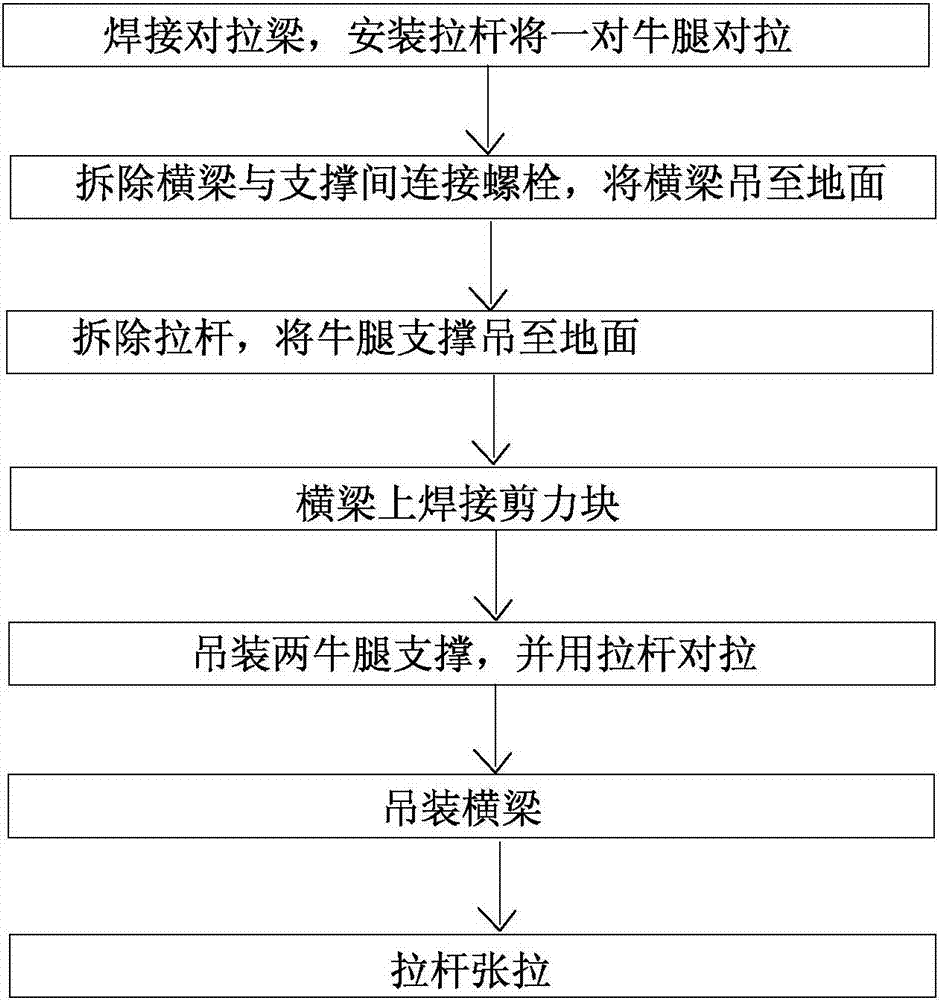

[0025] figure 2 Shown is the flow chart of the method of the present invention. The specific process is as follows:

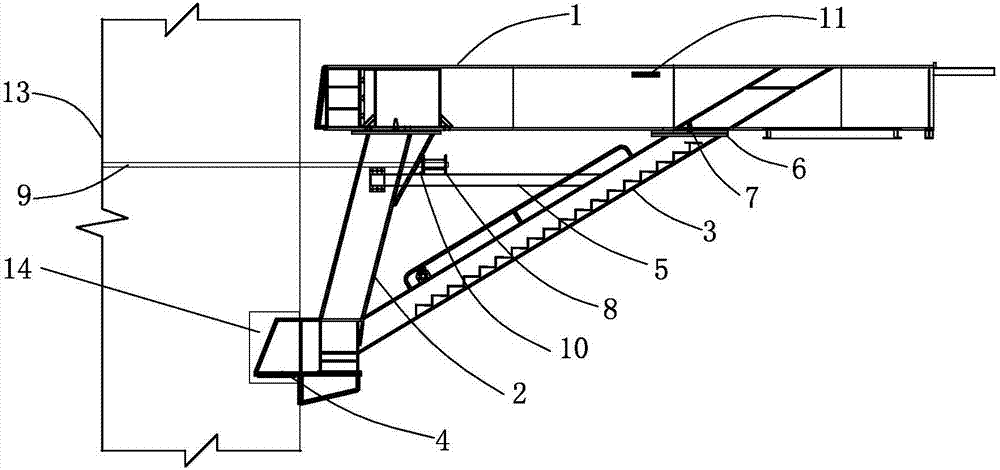

[0026] Such as image 3 As shown, before the separate disassembly of the corbel, a pair of tie beams 8 perpendicular to the tie beam are welded horizontally at the intersection of the vertical brace 2 of the corbel and the tie beam 5, and the two ends of the tie beam 8 protrude from the tie beam. Outside the two sides of the leg; use two pull rods 9 to connect the two ends of the tension beam on the two corbels respectively, and pull the pair of corbels on both sides of the high pier to each other;

[0027] When welding the tie beam at the junction of the vertical brace and the tie beam, if there is a gap between the tie beam 8 and the vertical brace 2 and the tie beam 5, then fill and weld the stiffener 10 in the gap.

[0028] Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com