Assembly type overhead platform and construction method thereof

An assembled and platform technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as delay in construction period, unfavorable vehicle traffic, and long time-consuming temporary roads, so as to reduce occupation, save manpower and material resources, and facilitate construction. Quick and easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

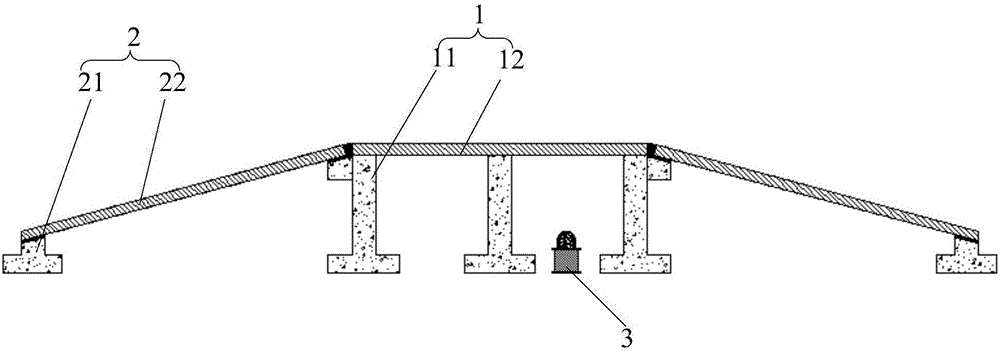

[0029] Such as figure 1 As shown, the present invention provides an assembled elevated platform, which is erected above the ground and includes a horizontal section 1 and slope sections 2 arranged at both ends of the horizontal section 1. One end is erected on the ground, the horizontal section 1 includes a first support column 11 and a horizontal road slab 12 arranged above the first support column 11, and the slope section 2 includes a second support column 21 and two ends are respectively erected For the slope road surface 22 on the first support column 11 and the second support column 21 , the height of the first support column 11 is greater than the height of the second support column 21 . The assembled elevated platform in this embodiment is aimed at super-high concrete pumping projects. The height of the first support column 11 is 0.8-1.0m, and the height of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com