Installing construction method for large blast furnace top valve box

A construction method and valve box technology, applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as low safety, large labor costs, and long installation time, and achieve the goals of improving installation accuracy, high safety, and overcoming errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

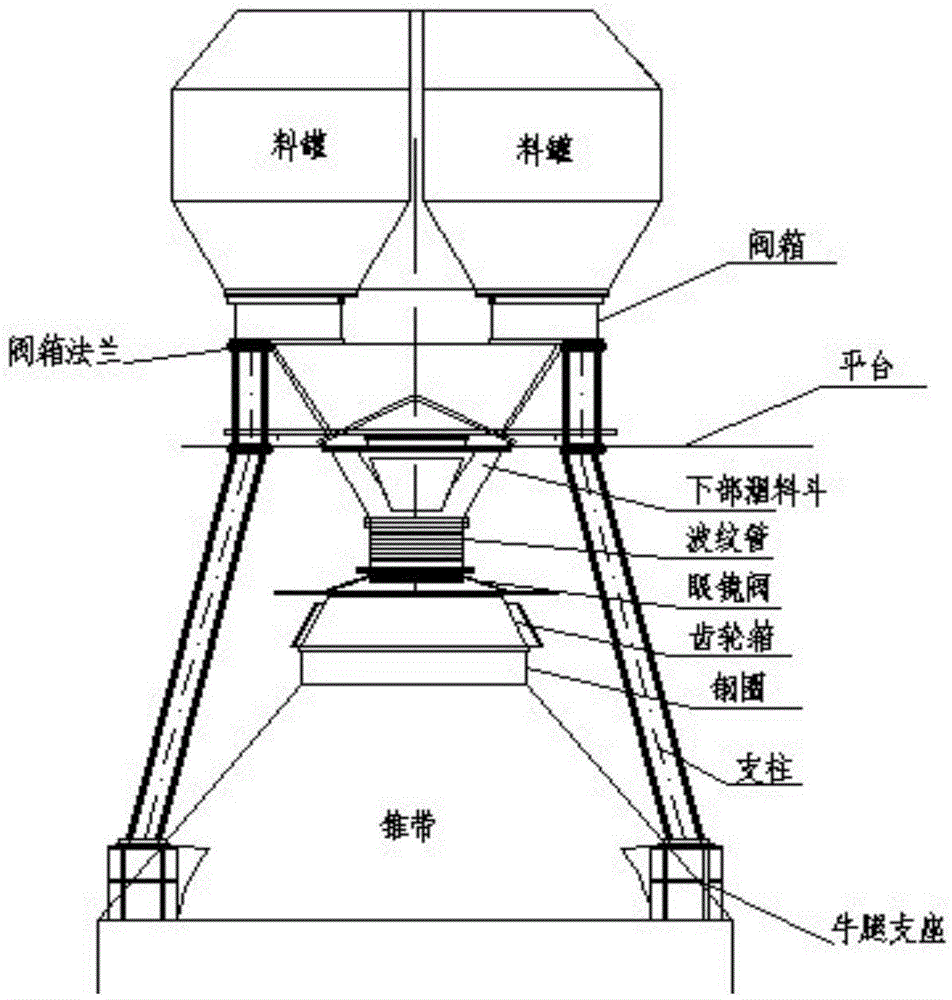

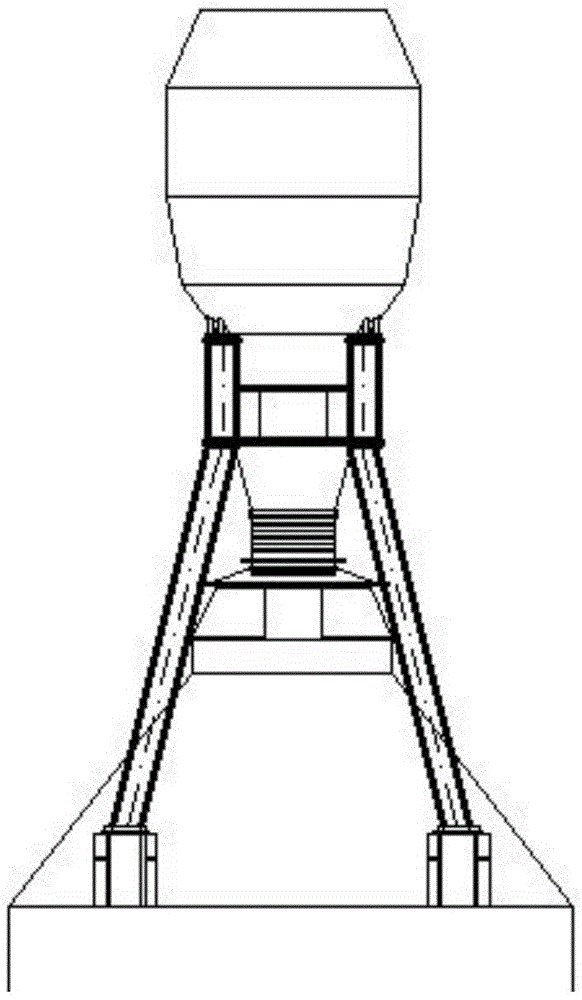

[0043] For a better understanding of the present invention, the inventive method will be further described below in conjunction with the accompanying drawings, see Figure 1 to Figure 11 , the installation and construction method of the large-scale blast furnace roof valve box of the present invention, comprising the following steps:

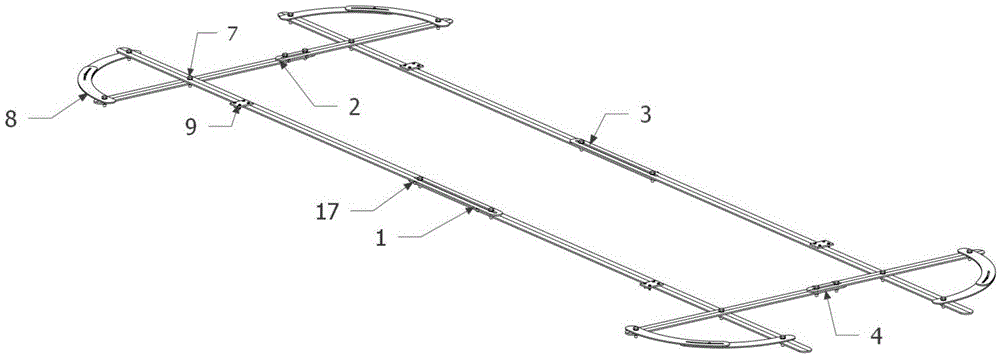

[0044] (1) Prepare the pillar quick positioning device: see image 3 , the device is a steel structure, mainly composed of two sets of straight horizontal bars 1, two sets of straight vertical bars 2, and four sets of arc-shaped holding parts 8 connected by bolts; two sets of horizontal bars 1 and two sets of vertical bars 2 is fixed in the shape of a well, and the two ends of each of the four sets of holding parts 8 are respectively fixed on the ends of the adjacent horizontal bar 1 and the end of the vertical bar 2; two sets of horizontal bars 1 and two sets of vertical bars 2 can be straight The length of the telescopic adjustment rod, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com