Shield head system capable of effectively reducing surrounding rock disturbance

A shield head and surrounding rock technology, applied in the shield head system field, can solve problems such as low efficiency and surface subsidence, and achieve the effects of protecting the ecological environment, improving soil strength, and reducing disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below.

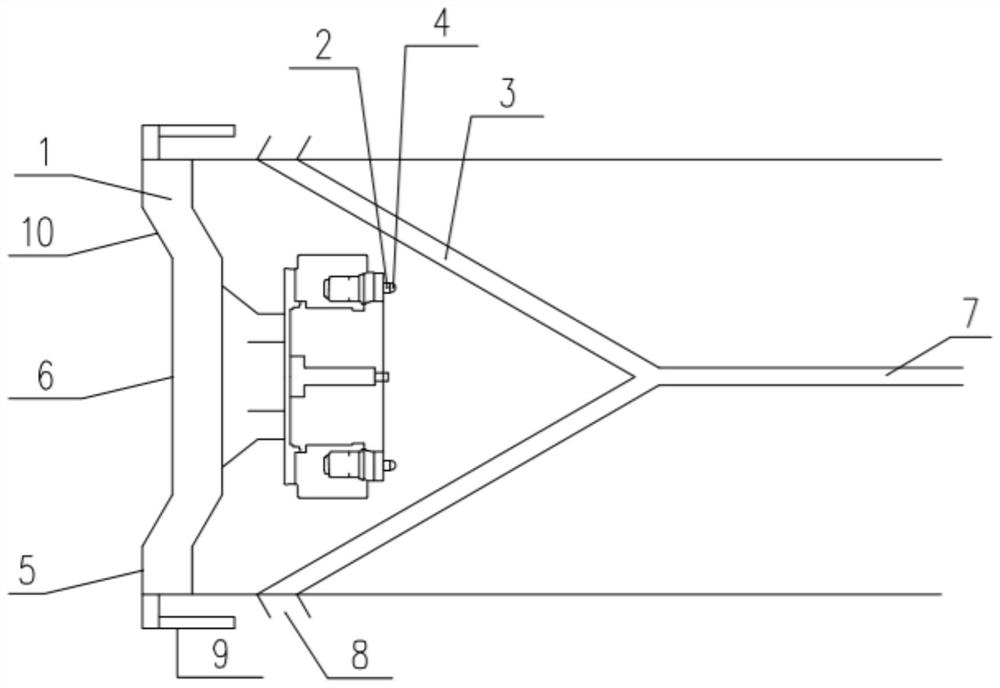

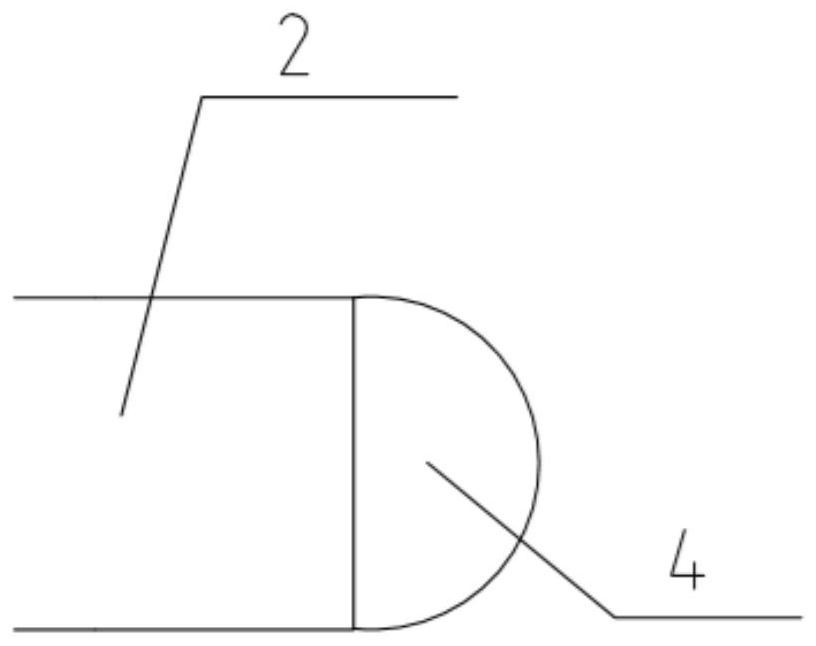

[0018] Such as figure 1 and figure 2 As shown, the present invention includes a cutter head overall 1, a shield shell I, a shield shell II, a grouting pipe 3 outside the shell, a pressure detection device and a conveying main pipe 7. The cutter head overall 1 is installed on the front end of the shield shell I, and the shield shell The rear end of I is coaxially fixedly connected with the front end of shield shell II;

[0019] Described cutter head overall 1 comprises primary excavation surface 5, cutting surface 10 and secondary excavation surface 6, and described primary excavation surface 5 and secondary excavation surface 6 are parallel to each other, primary excavation surface 5 and secondary excavation surface Excavation surface 6 is annular, and the annulus external diameter of secondary excavation surface 6 is less than the annulus internal diameter of excavation surface 5; The soil mouth 9 is outside ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com