Composite foundation reinforced cantilever retaining wall structure and construction method thereof

A composite foundation and cantilever-type technology, which is applied in the direction of foundation structure engineering, underwater structures, artificial islands, etc., can solve the problems of high bearing capacity of the foundation, increase in the amount of steel and concrete, instability and damage, etc., to improve the resistance Deformation ability, increase in applicable wall height, effect of ensuring connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

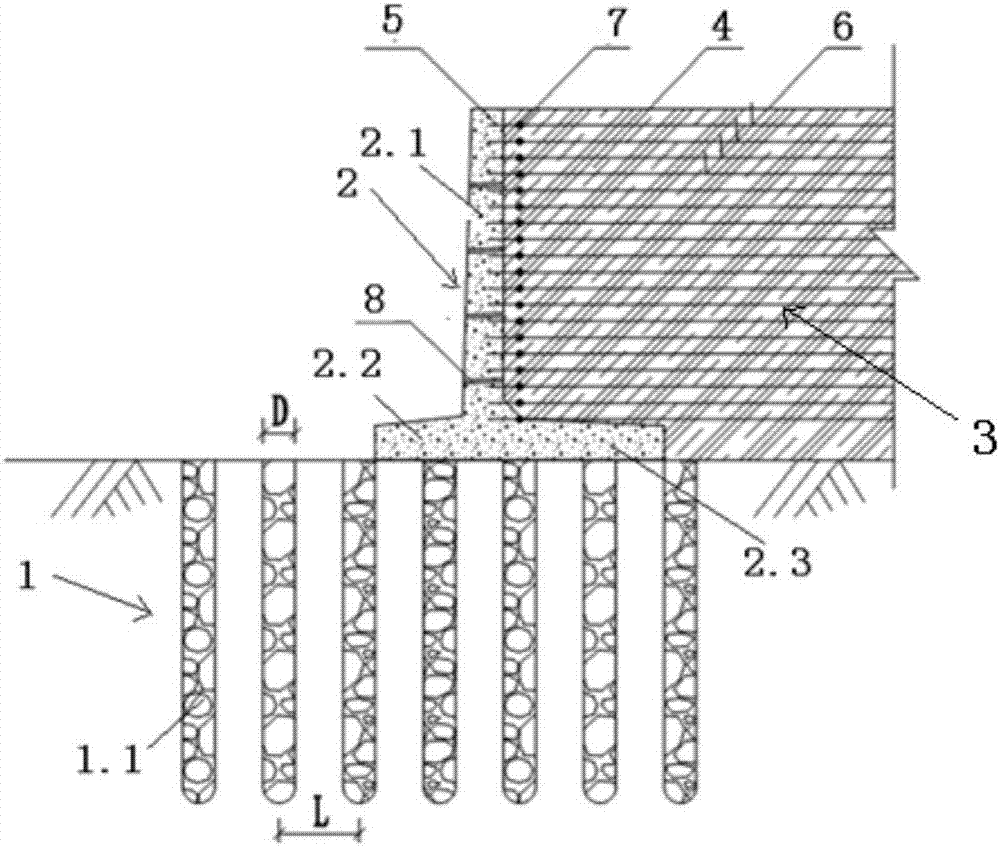

[0022] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, and are merely examples; at the same time, the advantages of the present invention will become clearer and easier to understand through the description.

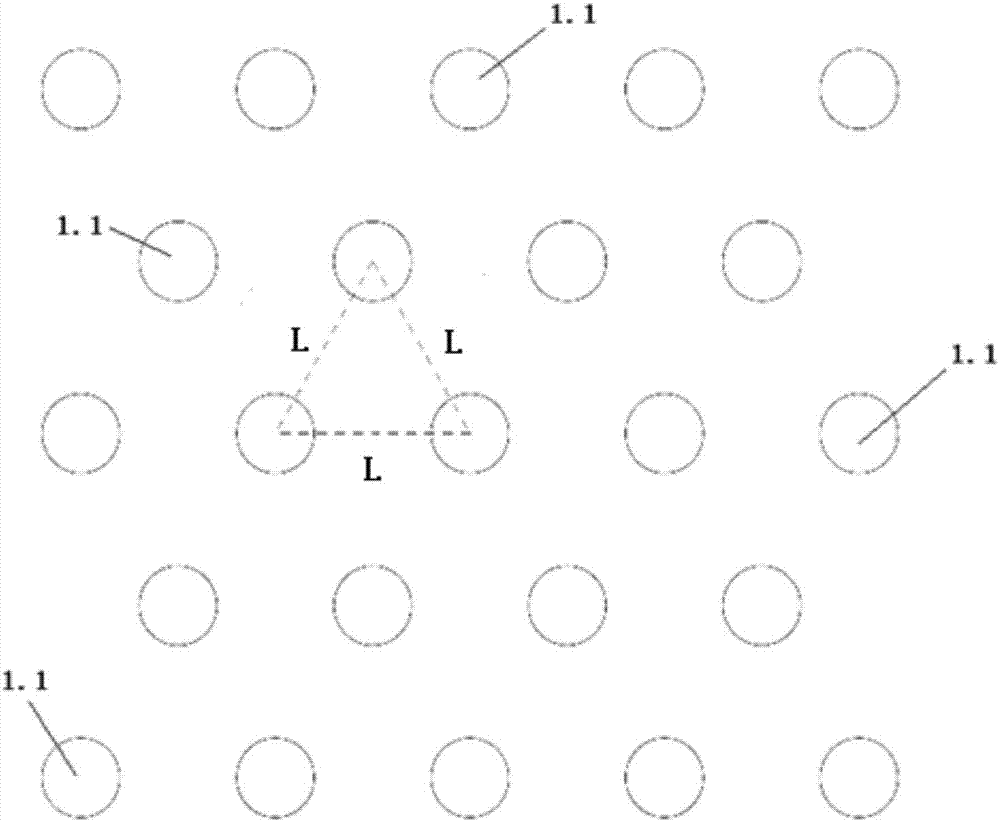

[0023] The composite foundation 1 is a composite foundation 1 formed by vibro-penetrating gravel piles 1.1 after the original soft soil foundation or deep overburden foundation is treated by the vibro-impact replacement method, and its bearing capacity should meet the anti-sliding and anti-sliding resistance of the retaining wall. Overturning requirements. The composite foundation 1 bearing capacity R sp =[1+m(n-1)]×R s , R s Is the bearing capacity of the original foundation; m is the replacement rate of gravel piles, m=A P / A s , A P Is the cross-sectional area of the gravel pile, A s Is the area of the composite foundation; n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com