Conveying belt change method for conveyor

A replacement method and conveyor belt technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of long time consumption, large investment of manpower and material resources, low construction safety factor, etc., and achieve simple construction process, few construction links, and obvious feasibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

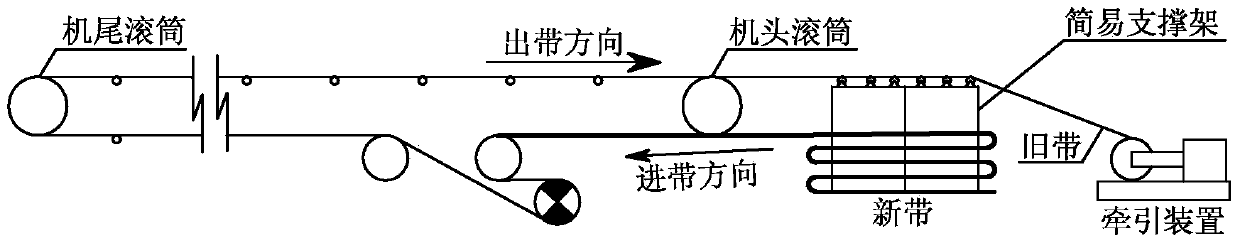

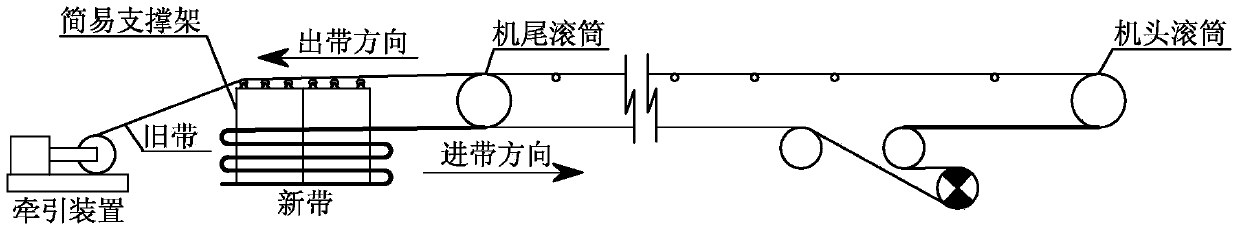

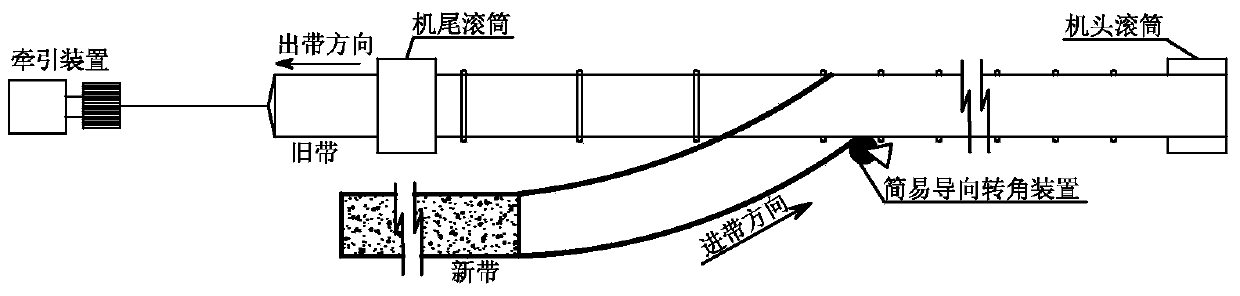

[0026] In a nutshell, when replacing the conveyor belt of a belt conveyor, the connection between the old and new conveyor belts should be completed in advance, one end of the new conveyor belt should be connected to one end of the old conveyor belt in advance, and the other end of the old conveyor belt should be connected to the traction device. The device pulls the old conveyor belt out of the conveyor. During this process, the new conveyor belt is gradually laid on the conveyor under the pull of the old conveyor belt, thus completing the replacement of the old and new conveyor belts.

[0027] According to the actual environment and construction conditions of the site and the transportation mode of the conveyor, when replacing the conveyor belt, you can choose different positions on the conveyor where the new conveyor belt enters and the old conveyor belt outputs. In the following, four conveyor belt replacement methods will be described according to the difference between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com