Ribbed rockfill retaining wall structure with compound foundation and construction method thereof

A technology of composite foundation and construction method, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of masonry structures such as bulky, unstable damage, and complicated procedures, so as to improve integrity and resistance Deformation capacity, reduced bearing capacity requirements, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, but are only examples; at the same time, the advantages of the present invention will become clearer and easier to understand through description.

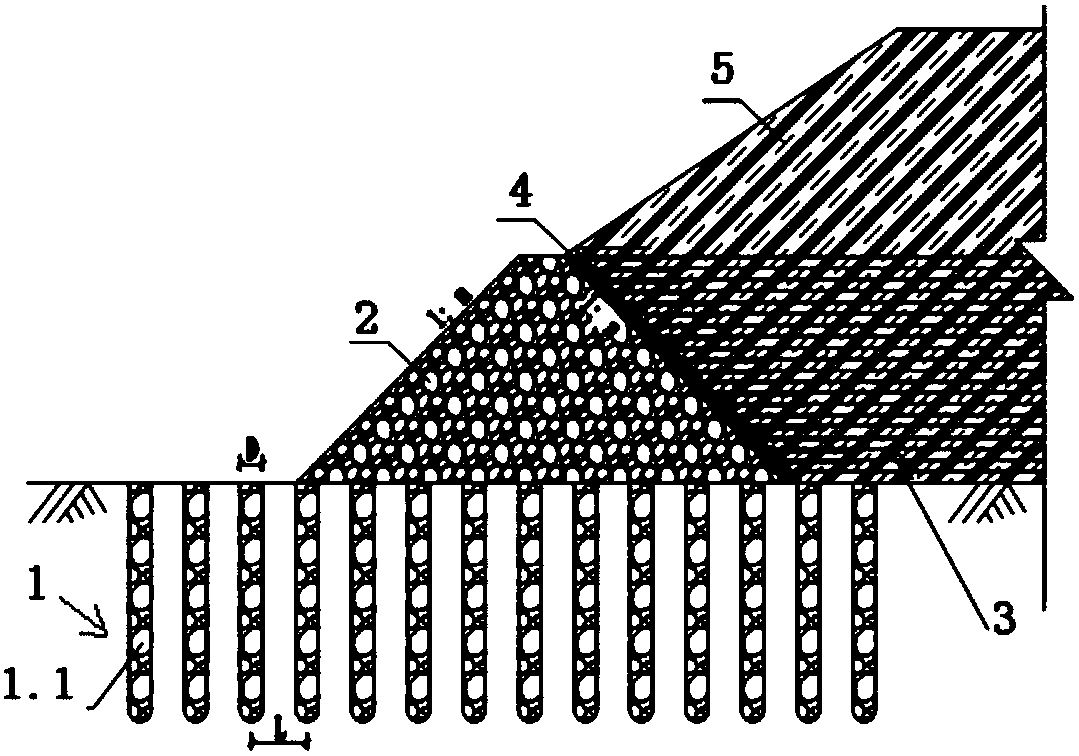

[0026] refer to Figure 1-2 Shown: Composite foundation reinforced rockfill retaining wall structure, which is mainly composed of composite foundation 1, rockfill retaining wall 2, geogrid 3, filter layer 4 and filling body 5.

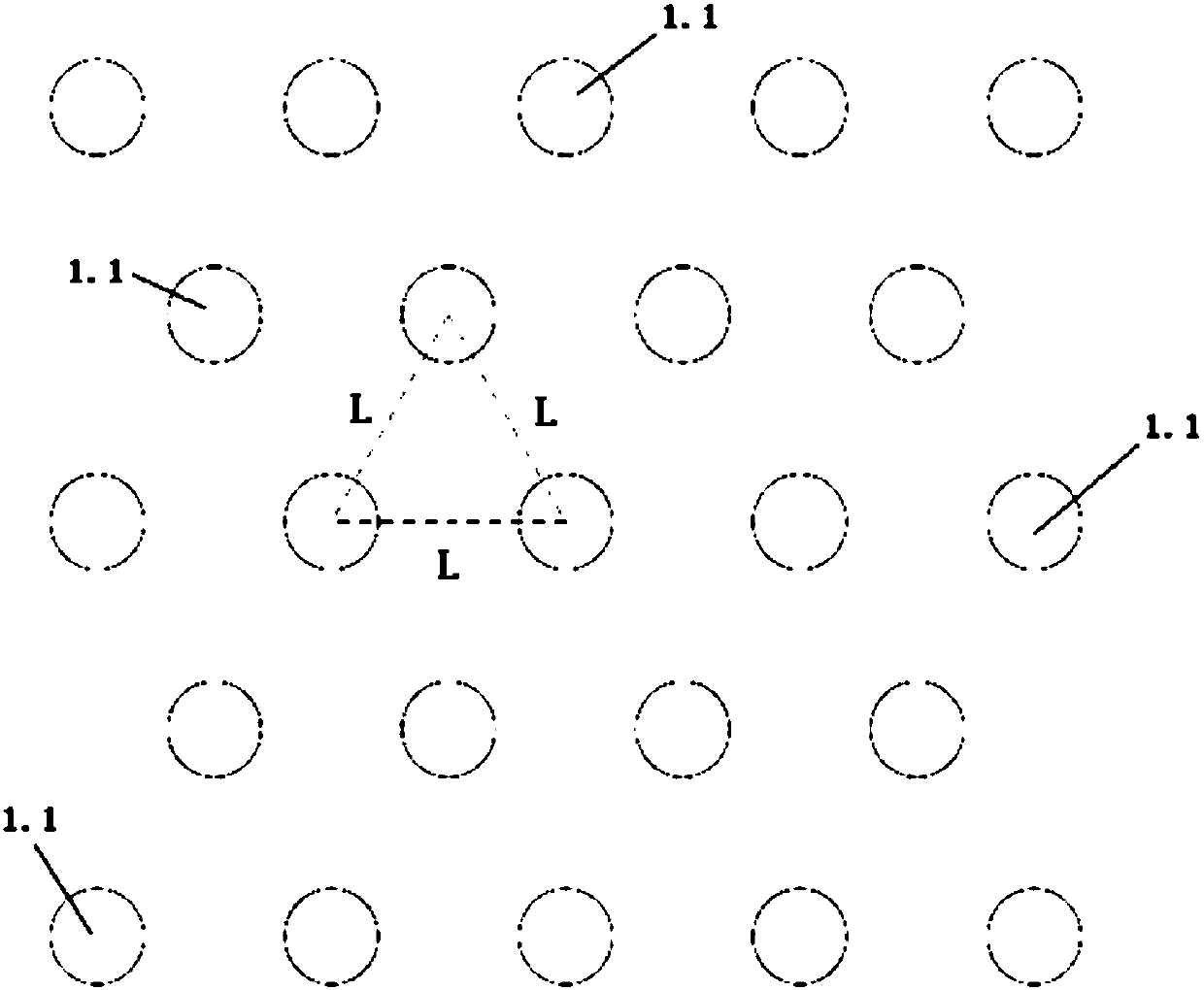

[0027] Composite foundation 1 is the composite foundation 1 of vibro-vibration gravel pile 1.1 after the original soft soil foundation or deep overburden foundation has been treated by vibro-replacement method, and its bearing capacity should meet the requirements of the retaining wall against slipping and overturning. Bearing capacity R of composite foundation reinforced by vibrating gravel piles 1.1 sp =[1+mn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com