Construction technology of section assembled box girder erection based on descending bridge erecting machine

A construction technology and bridge erecting machine technology, applied in bridge construction, bridge, erection/assembly of bridges, etc., can solve the problems of high pier body structure requirements, poor visibility, low stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

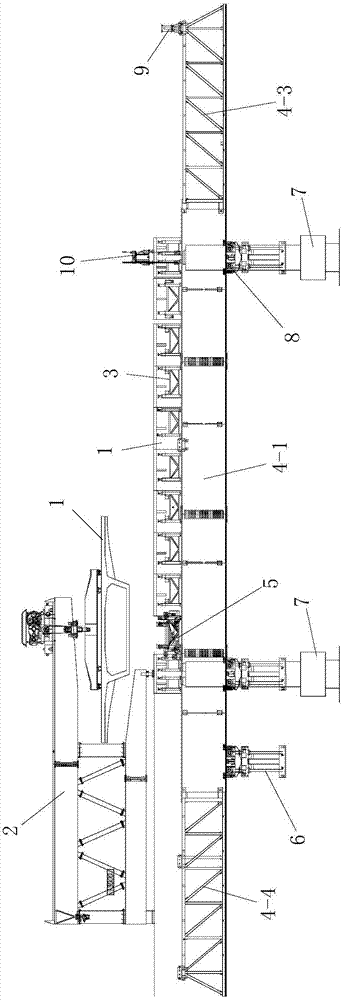

[0123] Such as Figure 17 The construction process of segmental assembled box girder erection based on the down-going bridge erecting machine is shown. The down-going bridge erecting machine is used to erect the constructed box girder. A plurality of box girder segments 1 are assembled from the back to the front, and each hole beam of the constructed box girder is supported by two front and rear piers 7, that is, the front and rear ends of each hole beam are respectively supported by a bridge pier 7;

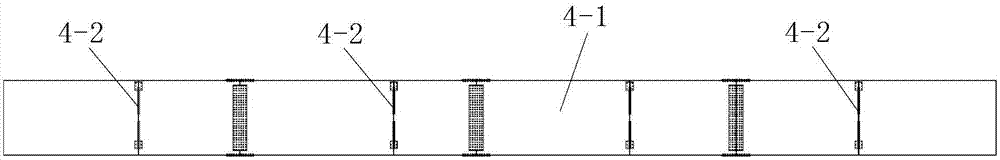

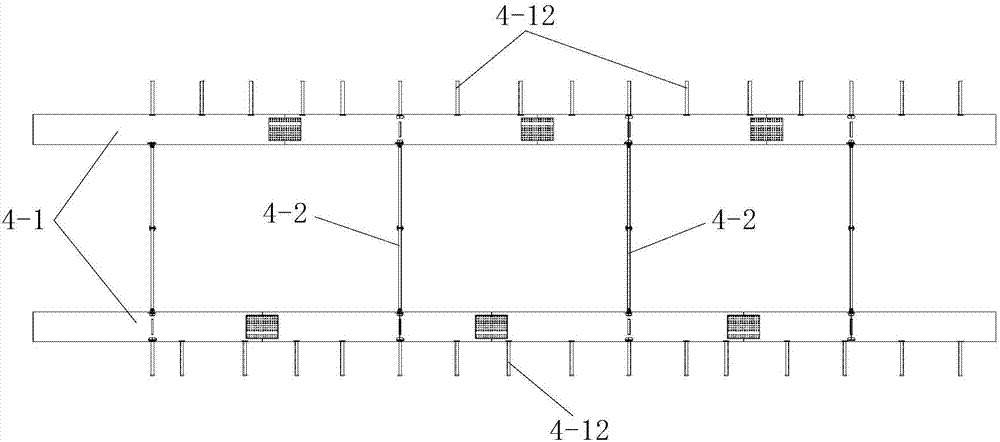

[0124] Such as figure 1 As shown, the descending bridge erecting machine includes a bottom horizontal support system, a main girder system installed on the bottom horizontal support system, a longitudinal movement system for moving the main girder system longitudinally, and a box girder section Section 1 is hoisted to the cantilever crane 2 on the main girder system, an assembly frame 3 for assembling the multiple box girder segments 1 hoisted on the main girder system, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com