Flue gas resource utilizing system of oil field stream-injecting boiler based on steam injection and application thereof

A steam injection boiler and resource utilization technology, applied in the fields of utilization and storage, thermal oil recovery and flue gas capture, can solve problems such as endangering site construction safety, complex process equipment, and increased production costs, so as to protect the environment and save energy Investment cost, the effect of solving the requirements of process treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

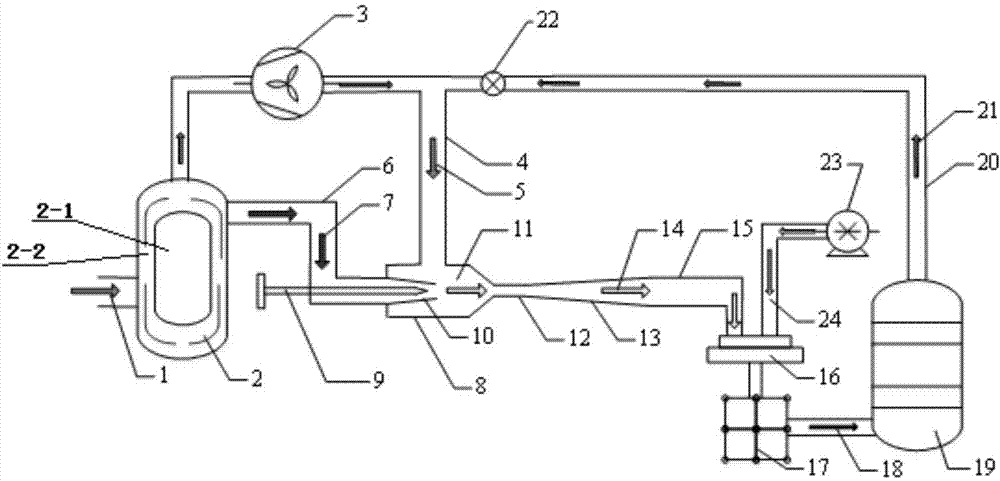

[0036] Such as figure 1 shown.

[0037] A steam injection boiler flue gas resource utilization system in oilfields based on steam injection, including: steam injection system, steam injection boiler system, heavy oil recovery system, production fluid separation system and foam generation system;

[0038]The steam injection boiler system and the steam injection system are arranged in series closed-loop; the steam injection system, the heavy oil production system and the production fluid separation system are arranged in series closed-loop, and the heavy oil production system is provided with a foam generator system.

[0039] The steam ejection system includes a steam ejector 8, a steam inlet, a smoke inlet and a steam-smoke mixed fluid delivery pipeline 15, and a valve stem 9 is also arranged at the steam inlet.

[0040] The steam injection boiler system includes a boiler 2, the boiler 2 includes a furnace 2-1 and a drum 2-2; the steam ejector 8 passes through the steam inlet...

Embodiment 2

[0046] A kind of application method of system as described in embodiment 1, comprises steps as follows:

[0047] (1) According to the production needs of the heavy oil well group 17, inject steam, flue gas mixed fluid 14 and high-temperature foaming agent solution 24 therein;

[0048] (2) Through the steam ejector 8, the boiler 2 is used to generate steam and introduced into the mixing chamber 12; the smoke in the suction chamber 10 is introduced into the mixing chamber 12 to form a steam-smoke mixed fluid 14;

[0049] (3) adjusting the valve rod 9 to realize the adjustment of the pressure and flow of the steam-smoke mixed fluid 14;

[0050] (4) The steam-flue gas mixed fluid 14 is injected into the heavy oil well group 17 through the steam-flue gas mixed fluid delivery pipeline 15 and the wellhead control 16 to assist heavy oil recovery;

[0051] (5) The crude oil production fluid enters the gas-liquid separator 19, and the separated flue gas enters the suction chamber 10 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com