Water acid-sensitivity deformation magnetic tracer function self-suspension propping agent and preparation method thereof

A proppant and self-suspension technology, which is applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problem of endangering the health of drilling workers and surrounding residents, the ability to carry sand cannot meet the demand for large-scale sand addition, and increase equipment Load and chemical consumption and other issues, to achieve a wide range of application prospects and research value, improve the effective seepage capacity, optimize the effect of the effective fracture area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

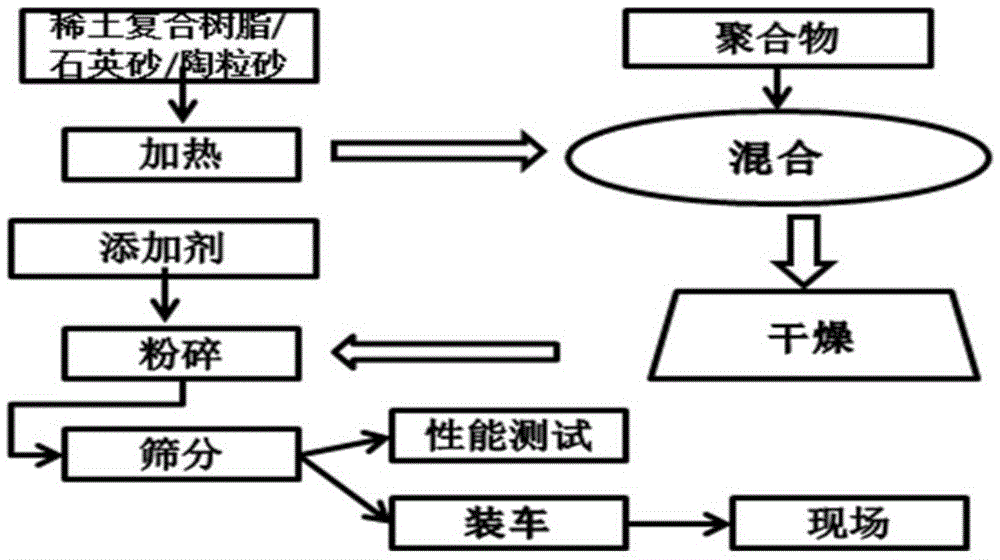

Method used

Image

Examples

Embodiment 1

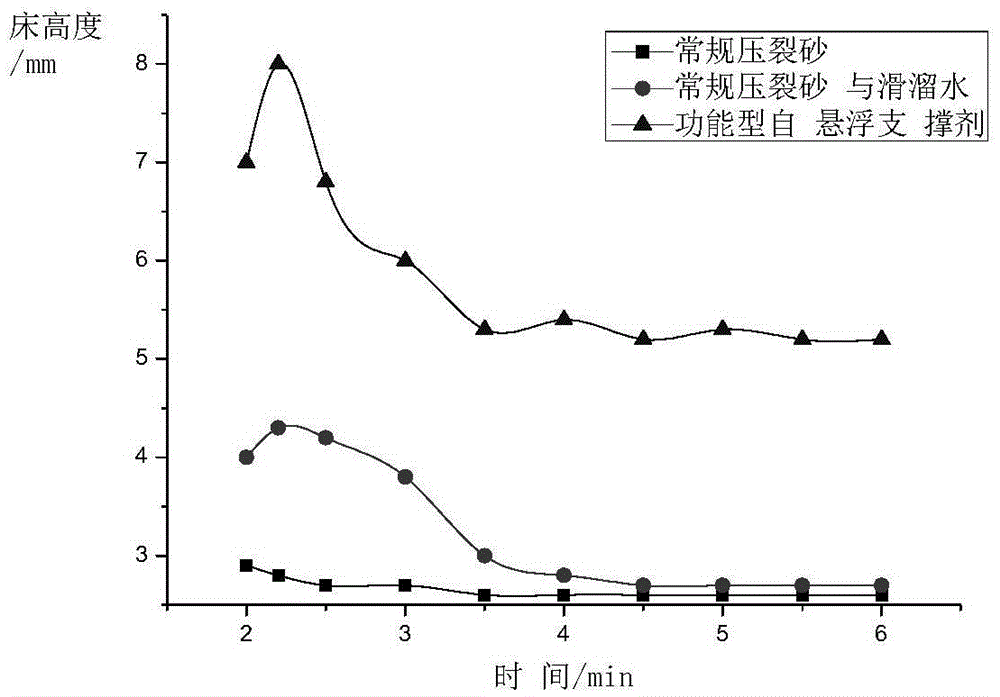

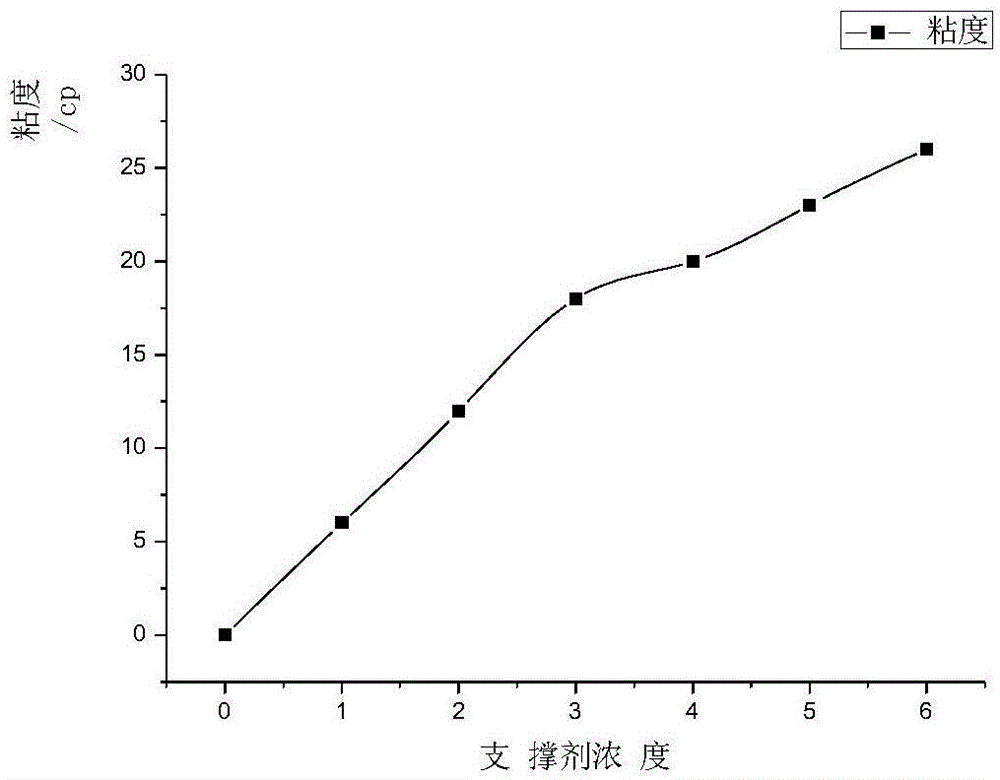

[0021] The self-suspending proppant with water acid-sensitive deformation magnetic tracer function described in this embodiment is composed of aggregate (i.e. traditional proppant), cationic polymer layer, anionic polymer layer, and anti-caking agent layer. Swelling, increasing the particle volume, thereby reducing the bulk density, reducing the proppant settling velocity, the anionic polymer layer can form a entangled network structure after expansion, with strength and elasticity, and better roundness than ceramsite and quartz sand. The frictional resistance is smaller, and the proppant can be completely suspended in low-viscosity fluid or clear water, so that the proppant migration performance is better, and the sedimentation speed is low, the dust is less, and the width of the sand pile is increased, so that the flow conductivity decreases. Slow down, the proppant can reduce the viscosity demand of the fracturing fluid, avoid the problem of large fluid loss in the fracturin...

Embodiment 2

[0059] In this example, 500g of 40 / 70 mesh fracturing sand was added to the drum of the mixer and heated to 120°C; 200g of tap water and 4g of 1% PDAC solution were added to the sand, vibrated for 5 minutes, vacuum filtered, and dried at 80°C; 20g of EM533 and glycerin Add to the sand at a ratio of 9:1; add 3.3g of fumed silica to the sample and mix again for 30 seconds; turn on the mixer to mix the sand and polymer for 7 minutes, and dry the sample at 85°C for 1 hour; remove from the drying oven Remove the sample and sieve.

Embodiment 3

[0061] In this example, add 500g of 40 / 70 mesh fracturing sand into the drum of the mixer and heat it to 120°C; add 200g of tap water and 0.4g of 1% PDAC solution to the sand, vibrate for 5 minutes, vacuum filter, and dry at 80°C; mix 20g of EM533 and Glycerin was added to the sand at a ratio of 9:1; 3.3g of fumed silica was added to the sample and mixed again for 30 seconds; the mixer was turned on to mix the sand and polymer for 7 minutes, and the sample was dried at 85°C for 1 hour; Remove the sample and sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com