Fracturing and completion integrated method adopting coiled tubing and production tubing combined tubing string

A technology for producing oil pipes and composite pipes, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve problems such as large construction risks, polluted intervals, failure to achieve continuous liquid carrying, etc., and reduce reservoir formation. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The purpose of the present invention is to provide an integrated method of fracturing and well completion for the combination of coiled tubing and production tubing, so as to simplify the construction process and reduce the damage to the reservoir caused by well killing.

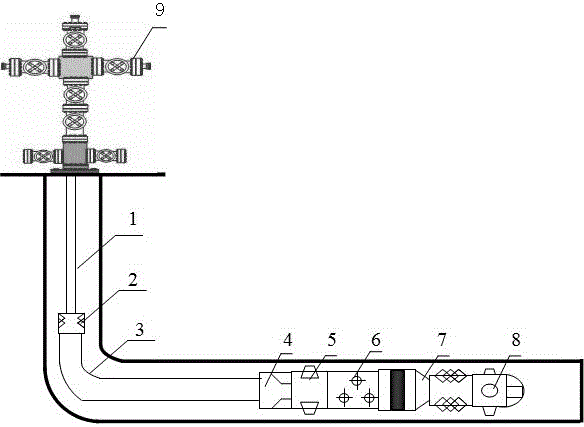

[0025] This embodiment provides a figure 1 The combined coiled tubing and production tubing string fracturing and well completion integration method includes the following steps:

[0026] Step 1) Run in the combined tubing string: through the lower end of the coiled tubing 1, the connector 2, the production tubing 3, the hydraulic release 4, the mechanical casing collar positioner 5, the injector 6, the Y241 packer, and the guide The check valve 8 is combined into a combined pipe string, which is lowered into the wellbore;

[0027] Step 2) Setting the first layer: Position the casing collar locator, align the injector 6 with the designed perforation position of the first section, set the Y241 packer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com