Production method of preset small-diameter pipe for sidetracking well and slim hole well

A technology of small-diameter pipes and production methods, which is applied in wellbore/well components, earth-moving drilling, and fluid production, etc., can solve the problems of short life and large reservoir damage, and achieve extended extension distance, prolong gas well life, and improve The effect of liquid-carrying capacity in gas wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

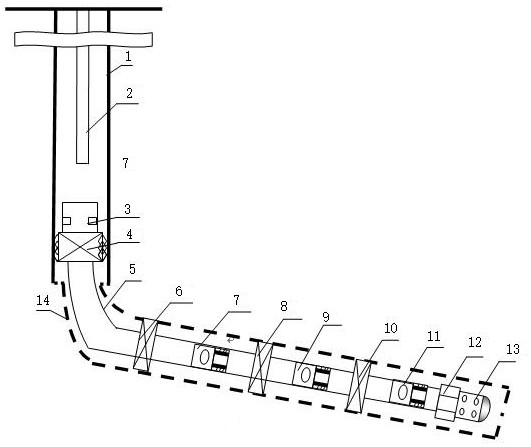

[0029] In order to overcome the problems of short service life of existing gas wells and great damage to reservoirs, the present invention provides such as figure 1 and figure 2 Shown is a production method of preset small-diameter pipes for sidetracking and slimhole wells. Before the fracturing reconstruction of the present invention, the small-diameter pipes are lowered into the casing, which avoids the downhole small-diameter pipes being suppressed during the production process, and can reduce storage capacity. layer damage and prolong the life of the gas well. The invention adopts a small-diameter tube instead of a coiled tubing as a velocity string to run into the wellbore, so as to improve the liquid-carrying capacity of the gas well, prolong the production period of the gas well, and greatly reduce the production cost of the gas well.

[0030] A method for producing a preset small-diameter pipe for sidetracking and slimhole wells, the specific steps are:

[0031] Ste...

Embodiment 2

[0041] Based on Example 1, in this example, preferably, in Step 1, the fracturing strings produced by using open hole packers for sidetracked wells and slimhole wells and presetting small-diameter pipes include lost Hand back barrel 3, casing packer 4, tubing 5, multiple reservoir packers, multiple sand blasters, floating hoop 12 and guide screen 13, reservoir packers and sand blasters alternately Setting, the lower end of the throw-back sleeve 3 is connected to the casing packer 4, the casing packer 4 is set at the inner lower part of the casing 1, and the lower end of the casing 1 is an open hole section 14, The open hole section 14 is arranged obliquely; the plurality of reservoir packers are distributed in the open hole section 14 from top to bottom, and each reservoir packer is provided with a sand blaster at the lower end. The uppermost reservoir packer is connected to the lower end of the casing packer 4 through the tubing 5 .

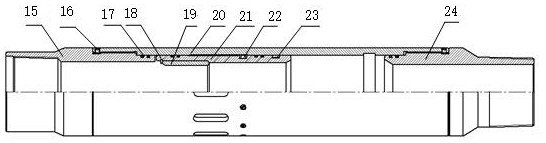

[0042] Preferably, the sand blaster incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com