Patents

Literature

144results about How to "Improve liquid carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

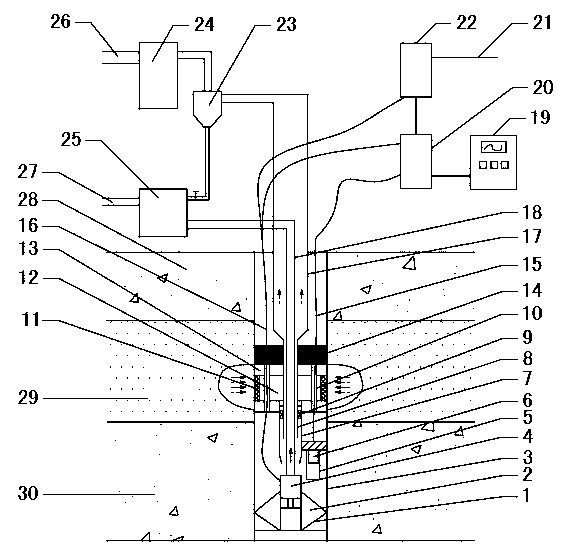

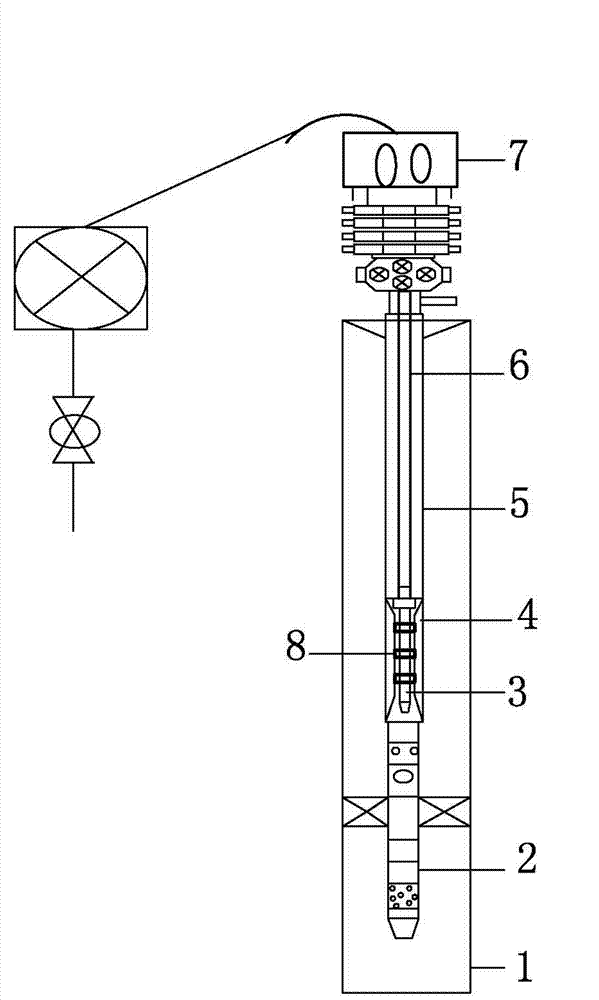

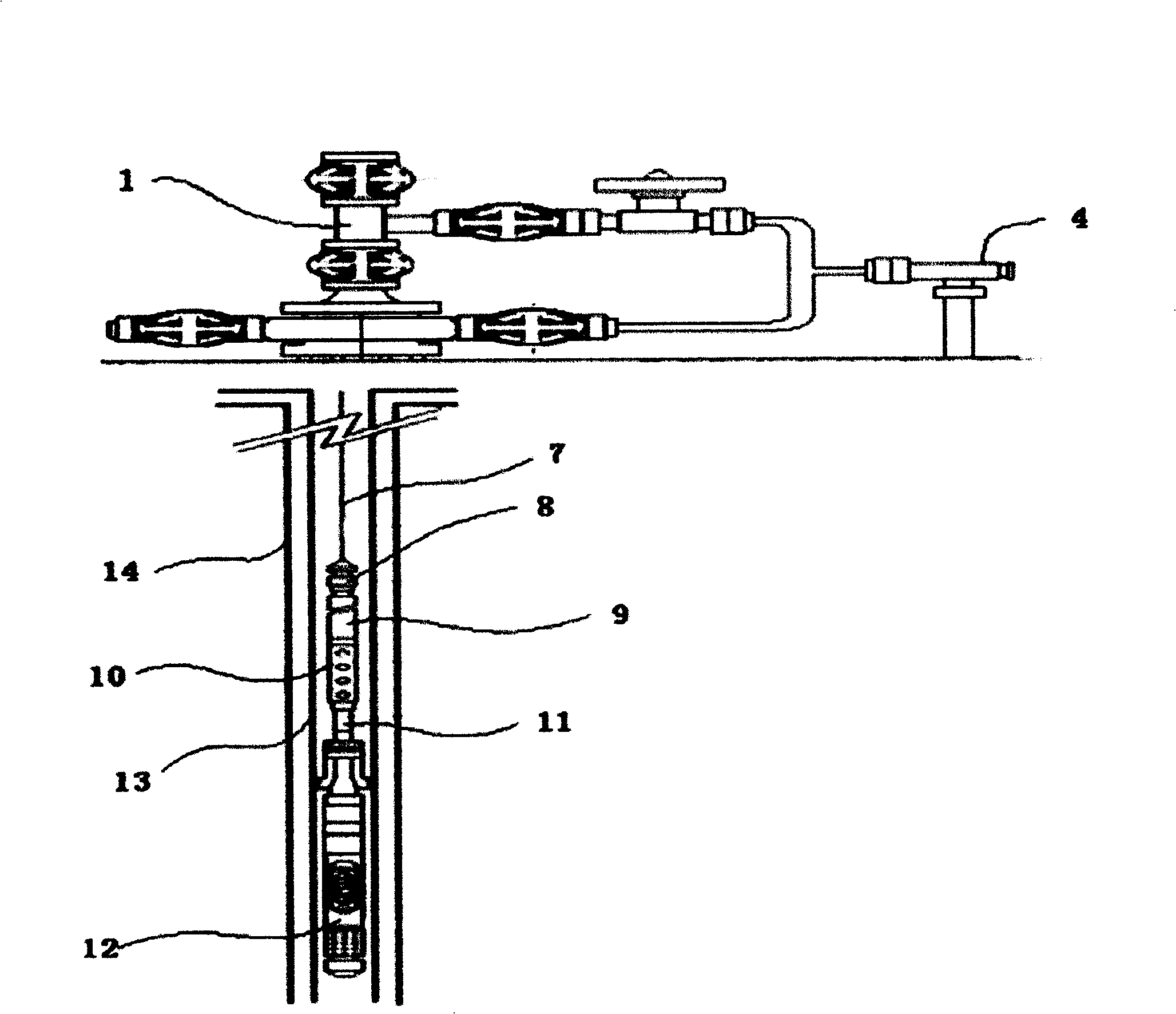

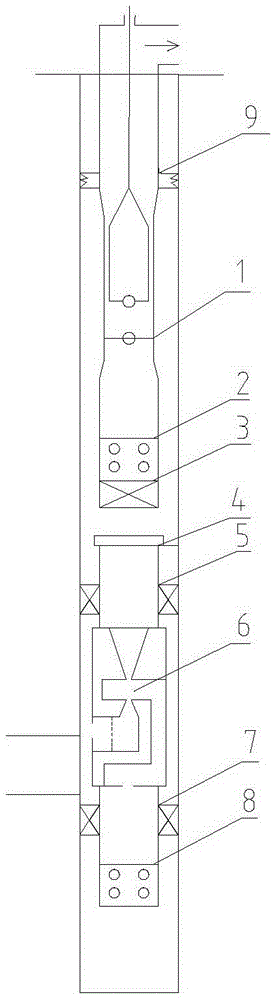

Natural gas hydrate water discharge gas production exploitation device and exploitation method of natural gas hydrate water discharge gas production exploitation device

ActiveCN103410488ASpeed up decompositionReduce moisture contentConstructionsFluid removalElectricityVapor–liquid separator

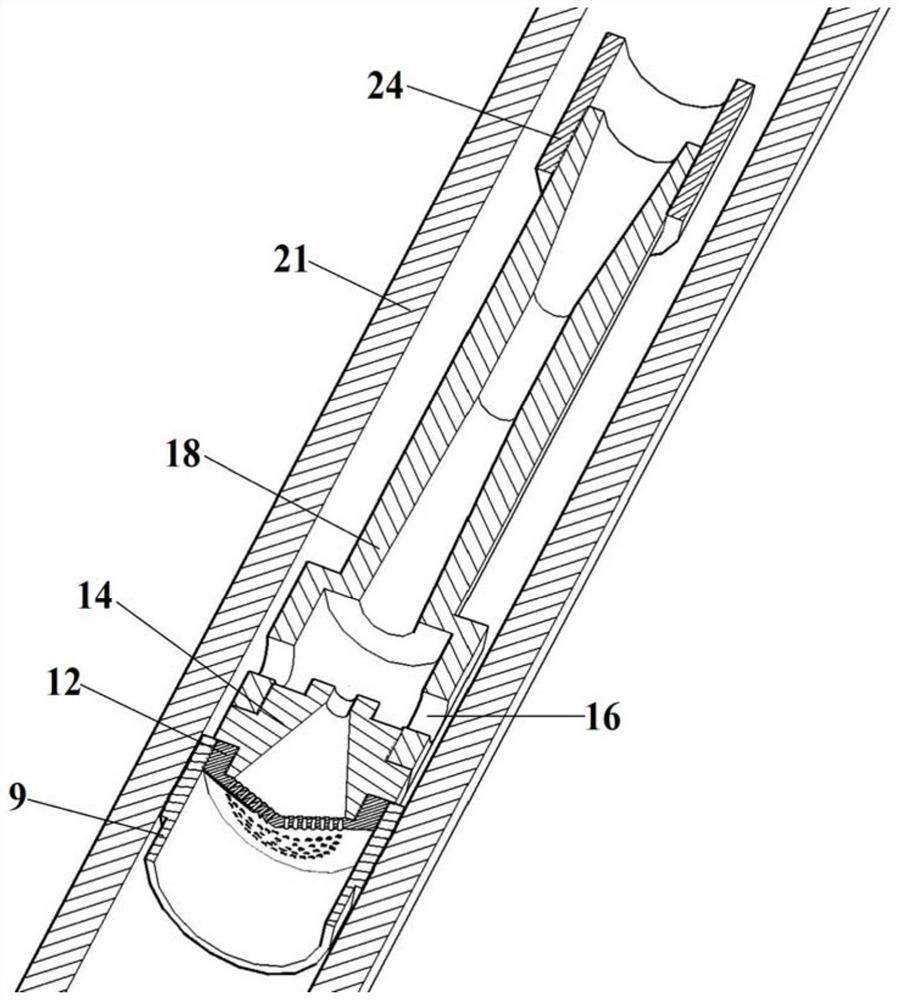

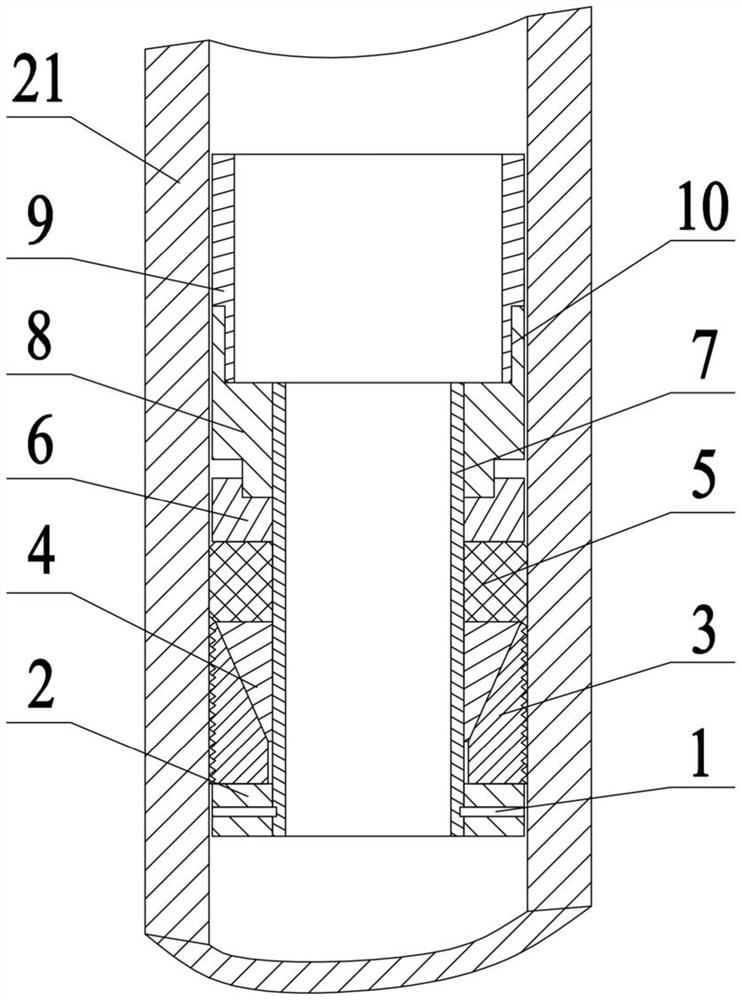

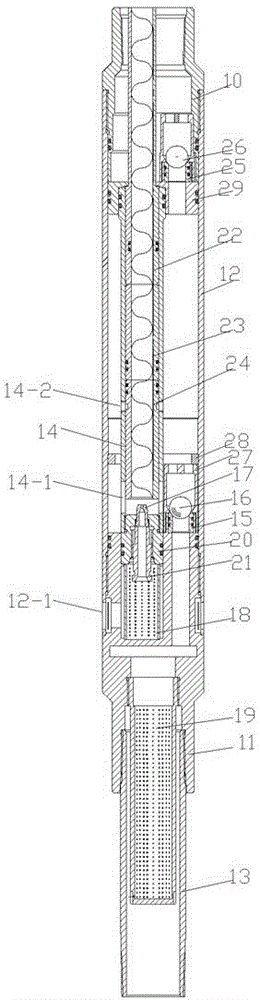

The invention provides a natural gas hydrate water discharge gas production exploitation device and an exploitation method of the natural gas hydrate water discharge gas production exploitation device, and belongs to the technical field of natural gas hydrate exploitation. A feeding cavity (12) communicated with a natural gas hydrate layer (29) is connected with an in-well gas-liquid separator (7), an exhaust cavity (8) of the in-well gas-liquid separator (7) is communicated with a gas production sleeve pipe (17), and a water discharge opening of the in-well gas-liquid separator (7) is communicated with a liquid storage cavity (2) arranged at the lower part. According to the exploitation method adopting the device, the natural gas hydrate layer (29) is firstly heated, the in-well gas-liquid separator (7) is utilized for separating gas-water mixture generated in the natural gas hydrate decomposition process, meanwhile, a liquid level monitoring device is utilized for regulating the water discharge speed of an electric submersible pump (4), and the decomposition speed of the natural gas hydrate is controlled. The device and the method have the advantages that the natural gas hydrate exploitation well liquid accumulation can be effectively prevented, the gas production efficiency is improved, the work is safe and reliable, the environment is protected, the service life is long, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Oil-resistant mineralization-degree-resistant solid foam-scrubbing agent and preparation method thereof

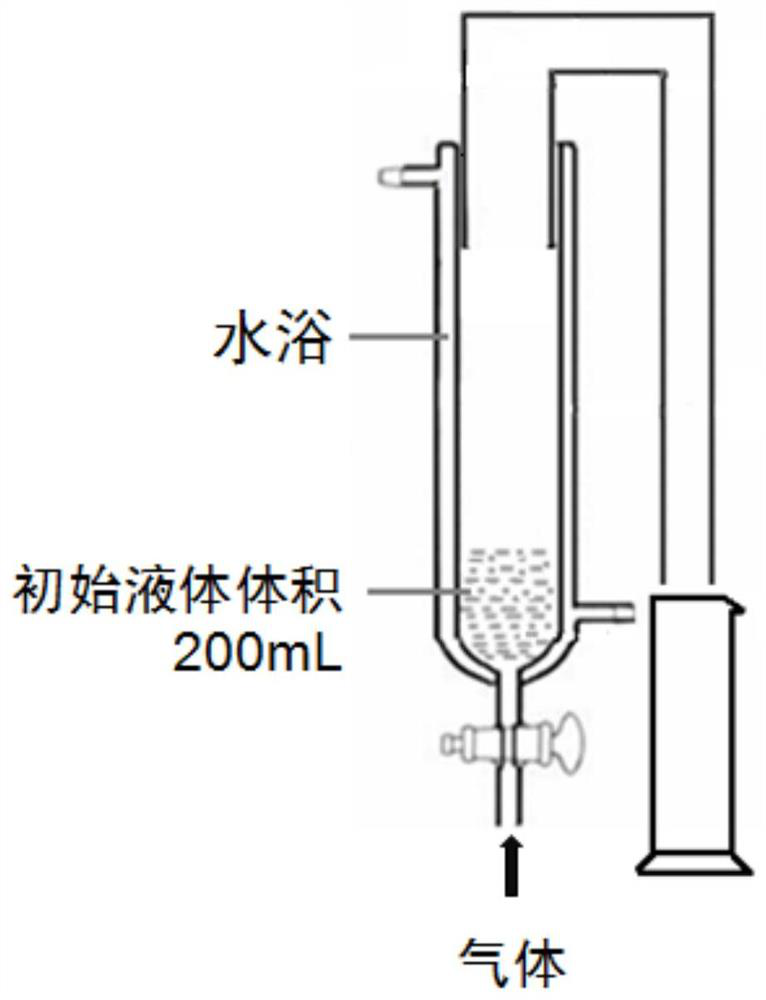

InactiveCN104531122AImprove liquid carrying capacityLow costDrilling compositionWater bathsParaffin wax

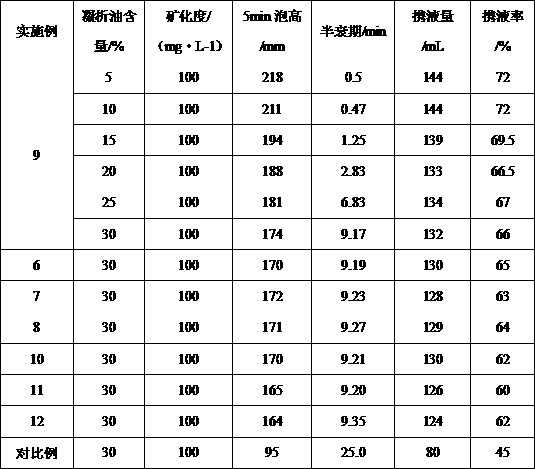

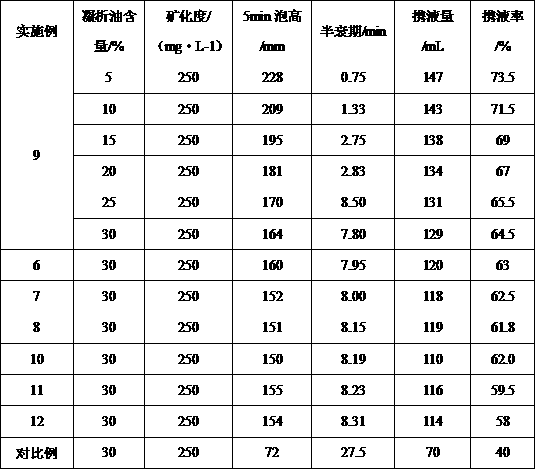

The invention relates to an oil-resistant mineralization-degree-resistant solid foam-scrubbing agent and a preparation method thereof. The foam-scrubbing agent is prepared from the following raw materials in percentage by mass: 20-40% of AES, 5-20% of OP-10, 0.1-0.5% of polyacrylamide, 0-20% of thiourea and 40-60% of paraffin. The preparation method comprises the following specific steps: adding AES and OP-10 into a beaker, uniformly stirring, adding polyacrylamide and paraffin, stirring and mixing again, heating raw materials in a water bath until the raw materials are molten, uniformly stirring, cooling the raw materials to room temperature, pouring the raw materials into a grinding device and carrying out extrusion molding to obtain the oil-resistant mineralization-degree-resistant solid foam-scrubbing agent finished product. The foam-scrubbing agent has the beneficial effects of low cost, new ingredients, long efficacy time, safety and no toxicity, and is easy to carry and after the solid foam-scrubbing agent is subjected to performance test, the solid foam-scrubbing agent is found to have better liquid carrying capacity in various water profiles.

Owner:NINGXIA ZHONGKE KANGYU CHEM

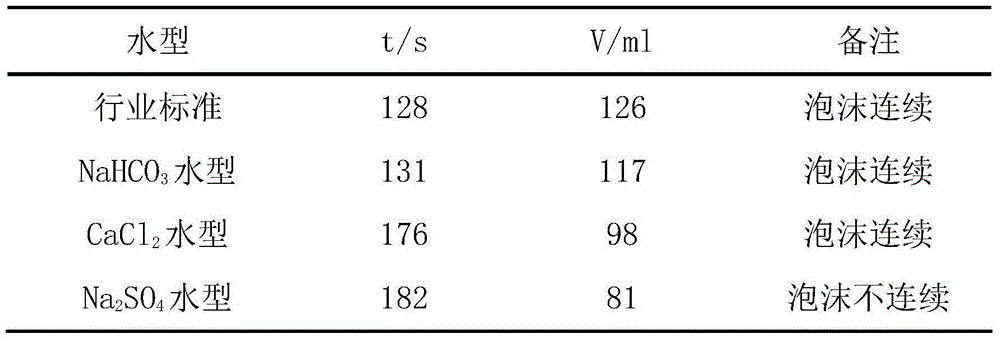

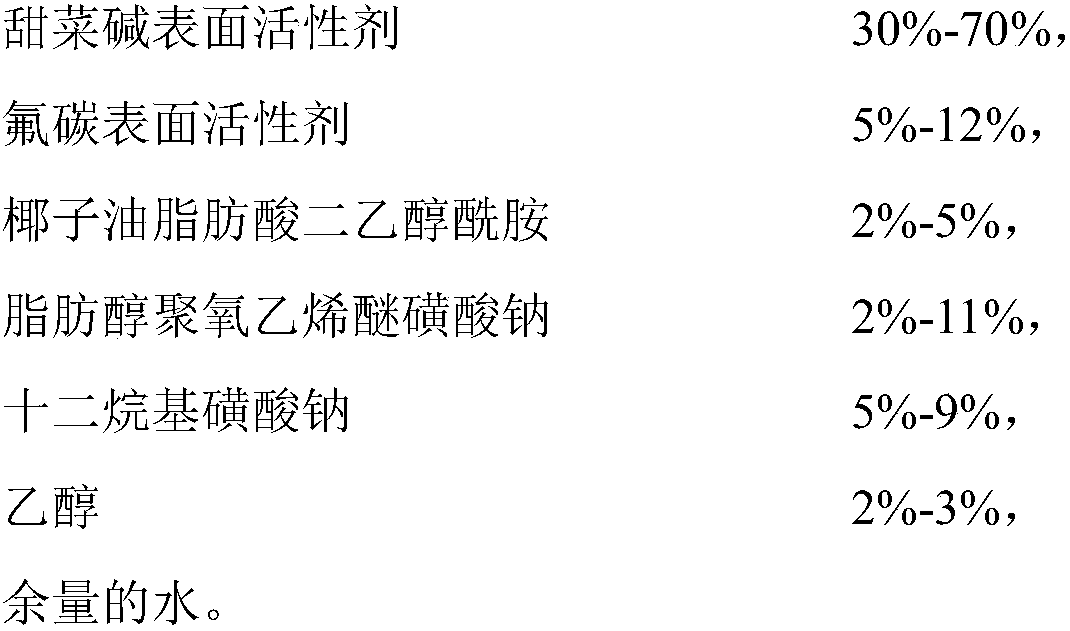

Condensate-oil-resistant foam discharging agent, preparation method thereof and application of foam discharging agent

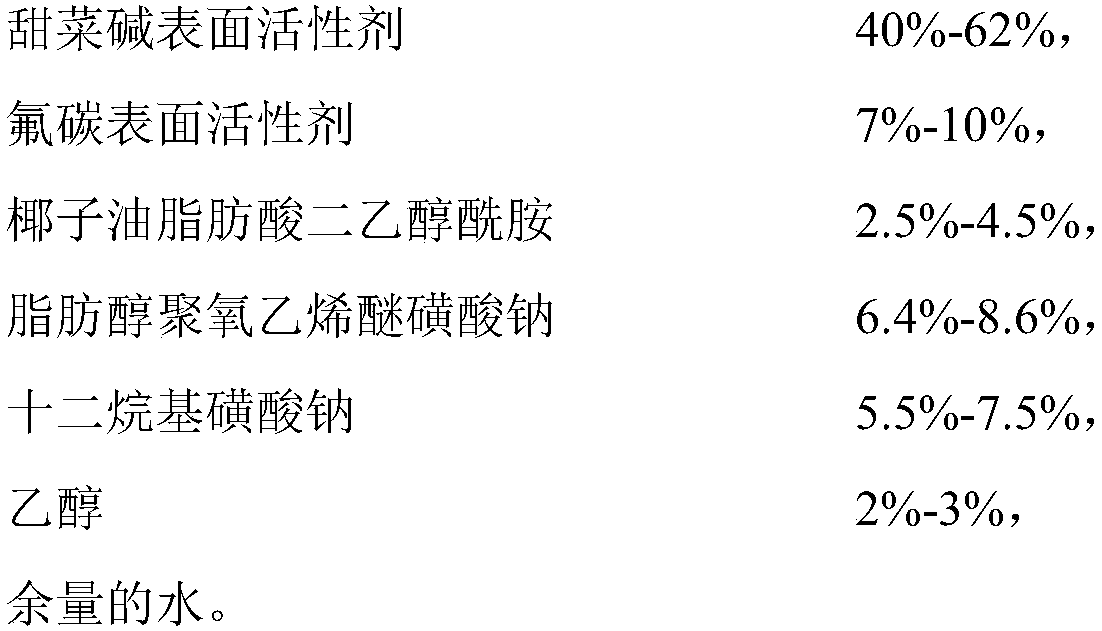

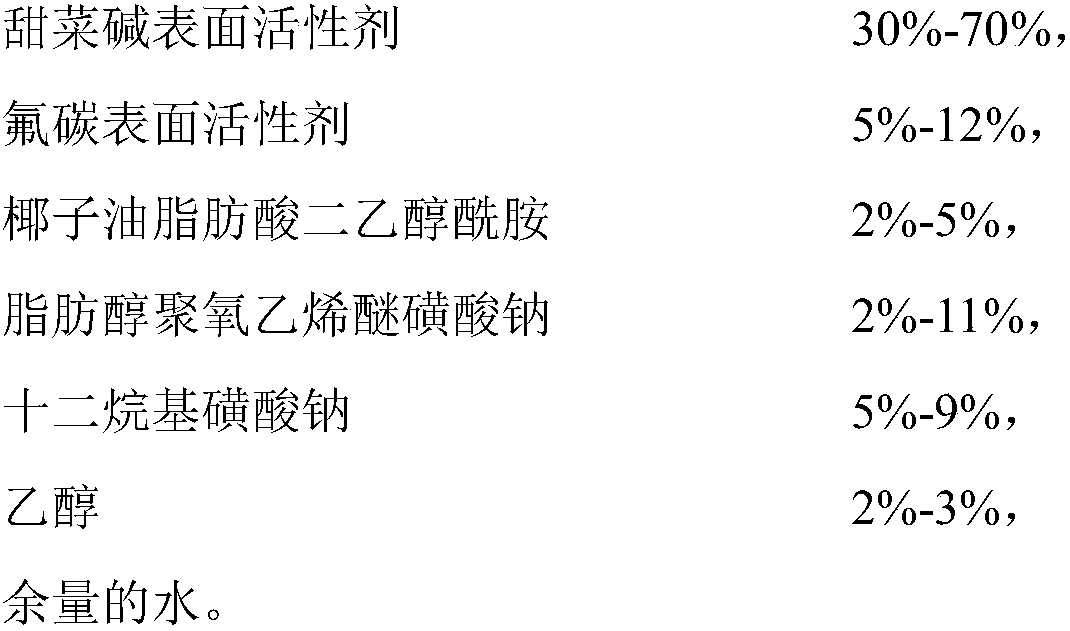

ActiveCN107652961AMeet the technical requirements of liquid drainage and gas recoveryEasy to scale applicationDrilling compositionSulfonateAlcohol

The invention provides a condensate-oil-resistant foam discharging agent, a preparation method thereof and an application of the foam discharging agent. The condensate-oil-resistant foam discharging agent comprises, in weight percent of 100%, 30%-70% of betaine surfactants, 5%-12% of fluorocarbon surfactants, 2%-5% of cocoanut fatty acid diethanolamide, 2%-11% of sodium fatty alcohol polyoxyethylene ether sulfonate, 5%-9% of sodium dodecylsulphate, 2%-3% of ethyl alcohol and the balance water. The condensate oil content of the foam discharging agent in accumulated liquid of a condensate gas well is within the range of the volume ratio of 0-90%, high temperature resistance of the foam discharging agent reaches 120 DEG C, highest mineralization resistance of the foam discharging agent reaches 30000mg / L, condensate oil resistance of the foam discharging agent reaches 90%, the foam discharging agent has excellent foaming capacity, can meet requirements of a gas recovery by liquid discharging process of the condensate gas well and is applicable to condensate gas wells with high condensate oil production fluids, and large-scale application of on-site gas wells is facilitated.

Owner:PETROCHINA CO LTD

Diamond fret saw and production technology thereof

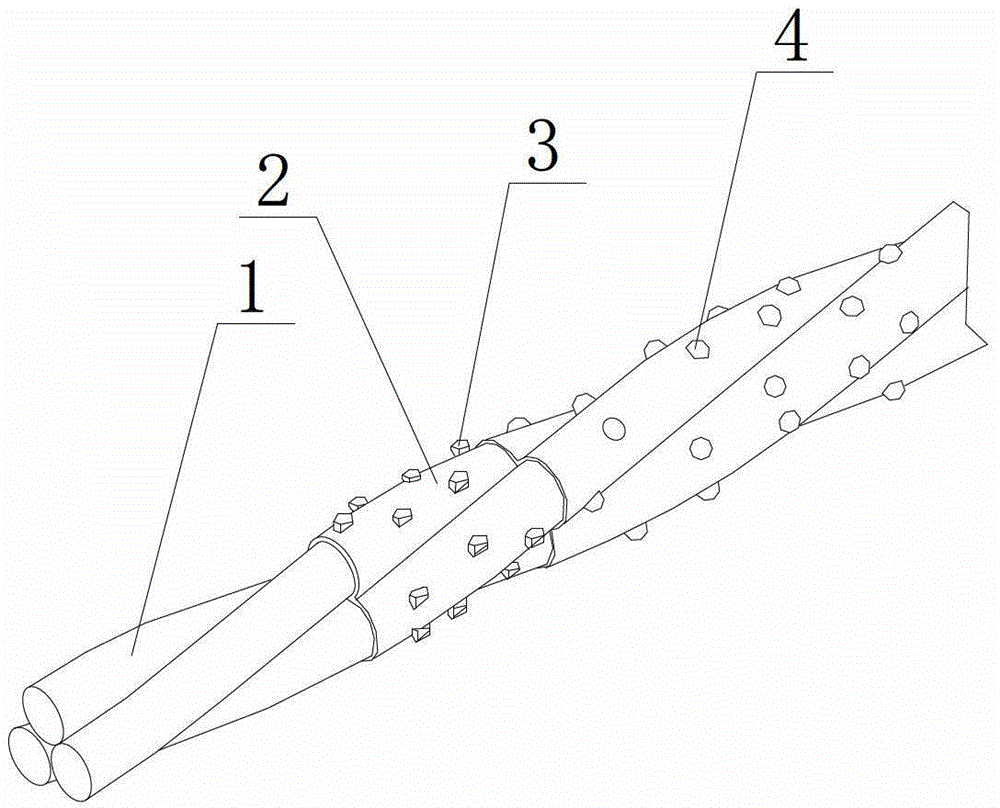

ActiveCN103144209AEnhanced liquid carrying capacityGood cooling effectElectrolytic coatingsMetal sawing toolsWear resistantContinuous production

The invention relates to a diamond fret saw, which comprises a fret saw inner core, wherein the fret saw inner core is formed by mutually twisting more than two strands of metal wires; a metal layer is plated on the surface of the fret saw inner core; the surface of the metal layer is fixedly provided with abrasive grains; and the abrasive grains are diamond particles, other wear-resistant material particles, or mixture of diamond particles and other wear-resistant material particles. The continuous production technology of the diamond fret saw provided by the invention has the advantages of being reasonable in flow, high in yield and the like, and the diamond fret saw can be continuously produced.

Owner:盛利维尔(常州)金属材料有限公司

Environmental-friendly type foam water-draining agent and preparation method thereof

ActiveCN106244127AEasy to operateGood drainageDrilling compositionCocamidopropyl dimethylamineBetaine

The invention discloses an environmental-friendly type foam water-draining agent and a preparation method thereof. The environmental-friendly type foam water-draining agent adopts a biodegradable material; and the foam water drainage refers to discharging liquid accumulated at the bottom of a well out of the well by utilizing the water containing performance of foam and the own capability of the well bottom so as to realize the purpose of increasing the yield of the natural gas well. In a field experiment, the foam water-draining agent disclosed by the invention has the advantages that the foam water drainage gas producing process can be met by good foaming capability, foam stabilizing capability and liquid carrying capability, and the foam water-draining effect can be achieved. The environmental-friendly type foam water-draining agent is characterized by comprising the following components of: cocamidopropyl dimethylamine hydroxysultaine, dodecyl dimethyl betaine, alkyl glycoside, cocamidopropyl betaine, lauramidopropyl betaine, dodecyl dimethyl ammonium oxide, hexadecyl trimethyl ammonium chloride, fatty alcohol polyoxyethylene ether, urea and water.

Owner:北京众博达石油科技有限公司

Environmental-friendly foam drainage bar, and preparation method thereof

ActiveCN106244128AEasy to carrySimple filling processDrilling compositionSodium bicarbonatePolyethyleneglycol stearate

The invention discloses an environmental-friendly foam drainage bar, and a preparation method thereof. The environmental protection performance of the environmental-friendly foam drainage bar is used for referring that the environmental-friendly foam drainage bar is prepared from biodegradable raw materials. Foam drainage is used for referring discharging of well bottom accumulated water or accumulated liquid out of wells via utilization of water-containing or fluid-carrying capability of foam, so that gas recovery factor of gas wells is increased fully. The environmental-friendly foam drainage bar is capable of satisfying requirements of foam draining gas recovery and achieving excellent foam draining effect in field tests because of the excellent foaming ability, foam stabilizing ability, and liquid carrying capacity of the environmental-friendly foam drainage bar. The environmental-friendly foam drainage bar comprises following raw materials: cocamidopropyl betaine, sodium lauryl oxyethyl sulfonate, sodium lauroyl glutamate, fatty alcohol polyoxyethylene ether, polyethylene glycol monostearate, urea, citric acid, sodium bicarbonate, and sodium carbonate.

Owner:北京众博达石油科技有限公司

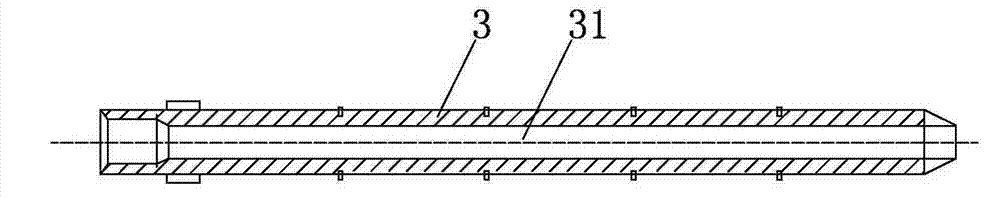

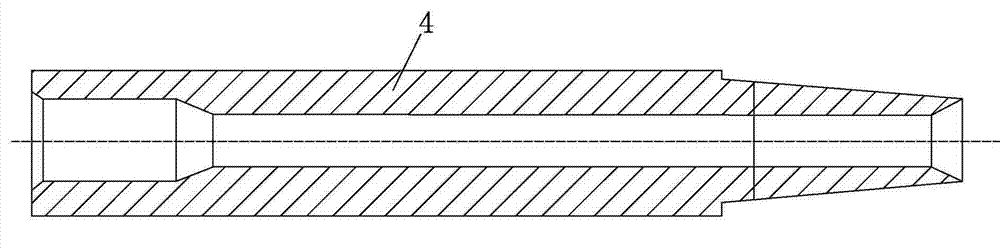

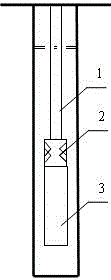

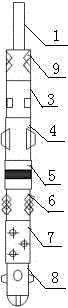

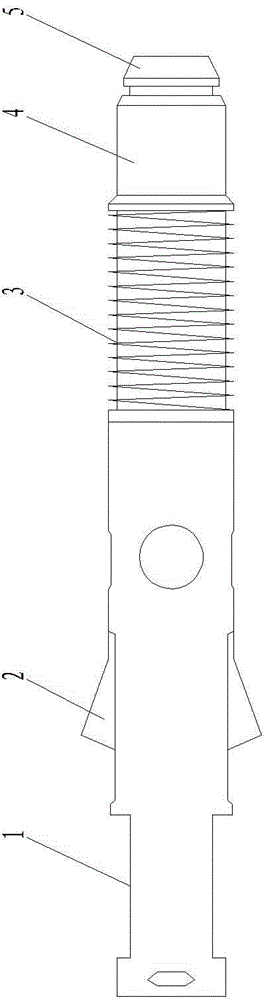

Plug-in coiled tubing induced-spraying device

InactiveCN102733787AAchieve multiple functionsSolve the problem of unsatisfactory liquid carrying effectFluid removalSealing/packingCoiled tubingEngineering

The invention discloses a plug-in coiled tubing induced-spraying device, which comprises an outer tubular column, a coiled tubing and a coiled tubing injector, wherein the coiled tubing is fed inside the outer tubular column through the coiled tubing injector; a locating seal working barrel is arranged in the outer tubular column; the periphery of the locating seal working barrel is matched with an inner periphery of the outer tubular column in a sealing way; an inserted sealing rod is arranged at the lower end of the coiled tubing; the inserted sealing rod is provided with a through hole communicated with the coiled tubing along the axial direction; and the inserted sealing rod is inserted into the seal work barrel when the coiled tubing injector feeds the coiled tubing downwards to a preset position in the outer tubular column, and the periphery of the inserted sealing rod is matched with the inner periphery of the locating seal working barrel in the sealing way. According to the device, the problems that water seepages at the stratum and the liquid carrying effect of a large-diameter tubular column is not ideal in a gas well test can be solved, and common gas lift induced spraying, production seeking and testing also can be carried out, so as to achieve the multifunctional purpose of the tubular column.

Owner:CHINA NAT OFFSHORE OIL CORP +1

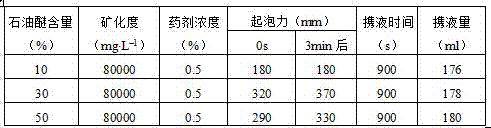

Efficient foam dehydrant composition and preparation method and application thereof

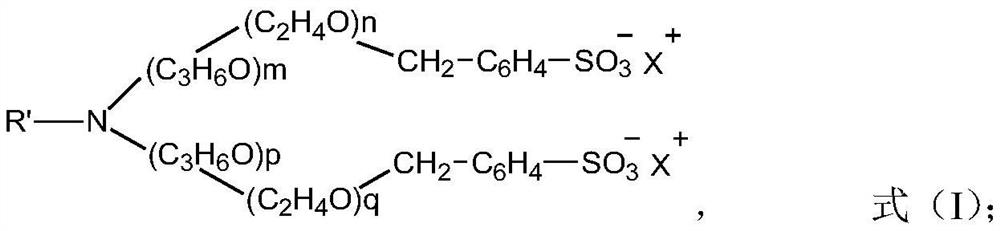

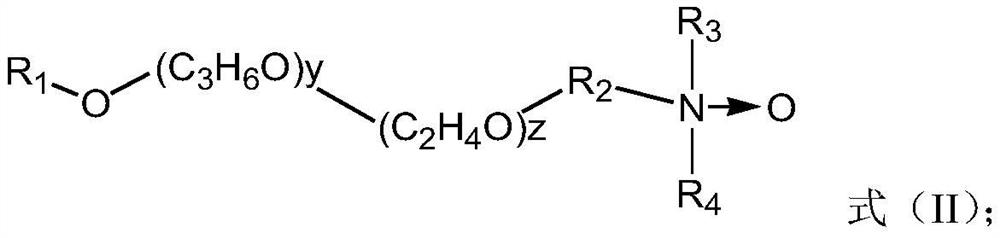

ActiveCN107603581AIncreased fluid carrying capacitySlow downDrilling compositionFoaming agentNitrogen

The invention relates to a foam dehydrant composition and a preparation method and application thereof, and belongs to the technical field of petrochemical industry. The efficient foam dehydrant composition provided by the invention is prepared from the following ingredients in parts by mass: 1 part of alkylamine polyether benzene sulfonate and 0.1-50 parts of long-chain polyether nitrogen containing compound. By adopting the technical scheme of the invention, proven by test on foam performance of a foam dehydrant according to SY / T 6465-2000 evaluation method of foaming agent for foam water drainage and gas production, in brine with the degree of mineralization of 0mg / L to 200,000mg / L, the foaming height is greater than 200mm, the liquid carrying amount is greater than 150mL, and after aging at the high temperature of 180 DEG C for 24h, the foam foaming height and drainage performance change rate are smaller than 5%, so that the efficient foam dehydrant composition has good temperatureresistance, salt tolerance, foaming performance and liquid carrying capability, and a relatively good technical effect is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +2

Foam scrubbing agent with gas condensate resistance and salt resistance and preparation method of foam scrubbing agent

ActiveCN107338038AEnhance the strength of the liquid filmFine foamDrilling compositionSalt resistanceBetaine

The invention discloses a foam scrubbing agent with gas condensate resistance and salt resistance and a preparation method of the foam scrubbing agent and belongs to the technical field of gas well exploitation materials in the oil and gas field. The foam scrubbing agent is prepared from raw materials in percentage by mass as follows: 20%-30% of cocamido propyl hydroxy sulfobetaine, 10%-20% of erucylamide propyl betaine, 10%-20% of lauramidopropylamine oxide, 2%-5% of sodium dodecyl sulfate, 1%-2% of a foam stabilizer, 1%-2% of sodium salt and the balance of water. The foam scrubbing agent is applicable to well gas exploitation and has good gas condensate resistance and salt resistance capability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid foaming drainage agent composition as well as preparation method and application thereof

ActiveCN107573917AIncreased fluid carrying capacitySlow downDrilling compositionAdhesivePetrochemical

The invention relates to a solid foaming drainage agent composition as well as a preparation method and application thereof and belongs to the technical field of petrochemical engineering. The solid foaming drainage agent composition disclosed by the invention comprises the following components in parts by mass: 1 part of alkylamine polyether benzene sulfonate, 0.1-50 parts of long-chain polyethernitrogen-containing compounds, 0.2-100 parts of solid fillers and 0-0.5 part of an adhesive. By virtue of the technical scheme in the invention, the solid foaming drainage agent is subjected to foaming performance test according to SY / T 6465-2000 Foaming Agent Evaluation Method for Foaming Drainage Gas Recovery, the foaming height is more than 200mm in 0-200000 mg / L of salinity brine, the liquorcarrying capacity is more than 150mL, and when aged at a high temperature of 180 DEG C for 24 hours, the change ratio of the foaming height and drainage performance of the foam is less than 5%. The solid foaming drainage agent composition has excellent temperature resistance, salt resistance, foaming performance and liquor carrying capacity, and excellent technical effects are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +2

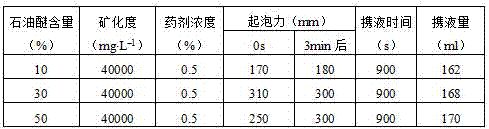

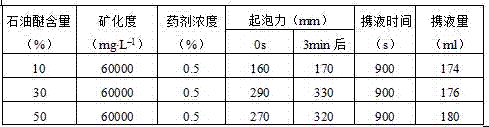

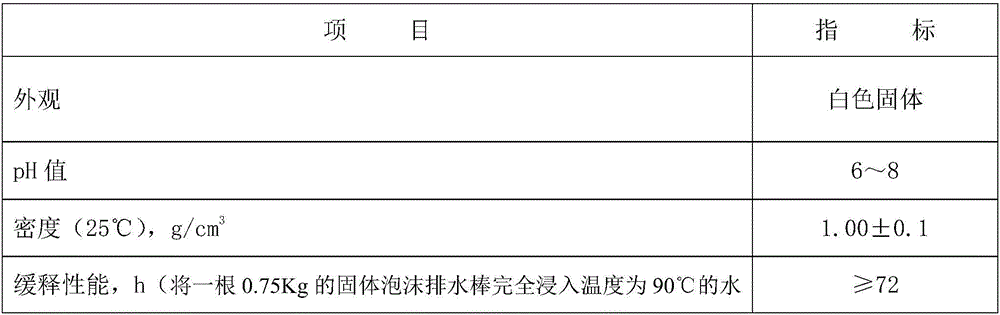

Oil-proof sustained-release solid foaming drainage agent used for gas wells, and preparation method and applications thereof

The invention discloses an oil-proof sustained-release solid foaming drainage agent used for gas wells, and a preparation method and applications thereof. The oil-proof sustained-release solid foaming drainage agent is mainly used for solving problems of conventional solid foaming drainage agents that high local concentration and waste are caused because of high dissolving speed, and preferable application is different to realize when gas well output water is high in gas condensate content, high in mineralization degree, and high in temperature. The dissolving time of the oil-proof sustained-release solid foaming drainage agent at 90 DEG C formation water condition is longer than 72h, and agent effect lasting time is long; the oil-proof sustained-release solid foaming drainage agent is capable of resisting gas condensate of 50% or higher, temperature of 120 DEG C or higher, and mineralization degree of 250000ppm; the foaming power is equal to or larger than 140mm; foam stabilizing time is long; and compatibility with agents such as methyl alcohol, corrosion inhibitors, and scale inhibitors is high. The preparation method is simple; no environment pollution is caused; no chemical reaction of products with gas and liquid ingredients is caused; equipment or pipeline corrosion is not caused; the prominent problems of gas wells are solved; and the oil-proof sustained-release solid foaming drainage agent is suitable for a plurality of water-producing gas wells.

Owner:四川锦盛油田技术服务有限公司

Self-perturbing capsule-type solid foam scrubbing agent

ActiveCN106978155ASolve the problem of low foaming abilityIncrease reaction rateDrilling compositionSodium bicarbonateCarrying capacity

The invention relates to a self-perturbing capsule-type solid foam scrubbing agent for oil and gas field gas production. The self-perturbing capsule-type solid foam scrubbing agent realizes full mixing with water in the well bottom so that drainage and gas recovery efficiency of the horizontal well is improved. The solid foam scrubbing agent is processed to form a capsule-type capsule shell, the capsule has the outer surface comprising two halves of capsule shell parts with sealing interlayers, two sides of the capsule shell are provided with two small symmetrical holes, the capsule shell is prepared from the solid foam scrubbing agent, the sealing interlayers of the capsule shell are filled with a liquid foam scrubbing agent, the center in the capsule shell is divided into two parts through a water-soluble diaphragm, the upper part is filled with ammonium chloride solids, the lower part is filled with sodium bicarbonate solids, and the two halves of the capsule are connected by the water-soluble diaphragm. The solid foam scrubbing agent is used in the drainage and gas recovery processes, is simple, convenient and economic, solves the problem that the foam scrubbing agent in a gas well has poor foaming ability under the condition of no bubble, effectively improves a reaction rate and a foam liquid-carrying capacity, has high drainage and gas recovery efficiency and saves a cost.

Owner:SOUTHWEST PETROLEUM UNIV

Anti-freezing foam drainage agent and preparation method thereof

InactiveCN106433594AImprove liquidityPerformance unchangedDrilling compositionAnti freezingFoaming agent

Provided is an anti-freezing foam drainage agent and a preparation method thereof. The anti-freezing property means the foam drainage agent has the anti-freezing performance or the low-temperature-resistance. The anti-freezing property is beneficial to the foam drainage agent to get adapted to the low temperature environment during the winter in Northern China, and avoid the liquid foam drainage agent to freeze, thus guaranteeing the normal operation of foam scrubbing of gas well in winter. The agent is characterized in that the agent comprises foaming agent and anti-freezing agent which form a mixture solution. The foaming agent accounts for 60-90% of the weight of the mixture agent, and the anti-freezing agent accounts for 10-40% of the weight of the mixture agent.

Owner:北京众博达石油科技有限公司

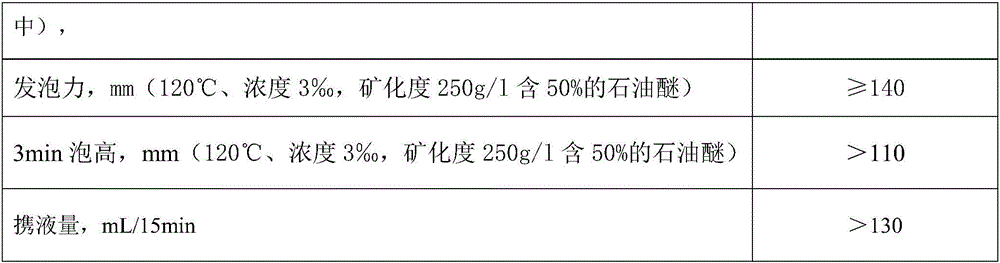

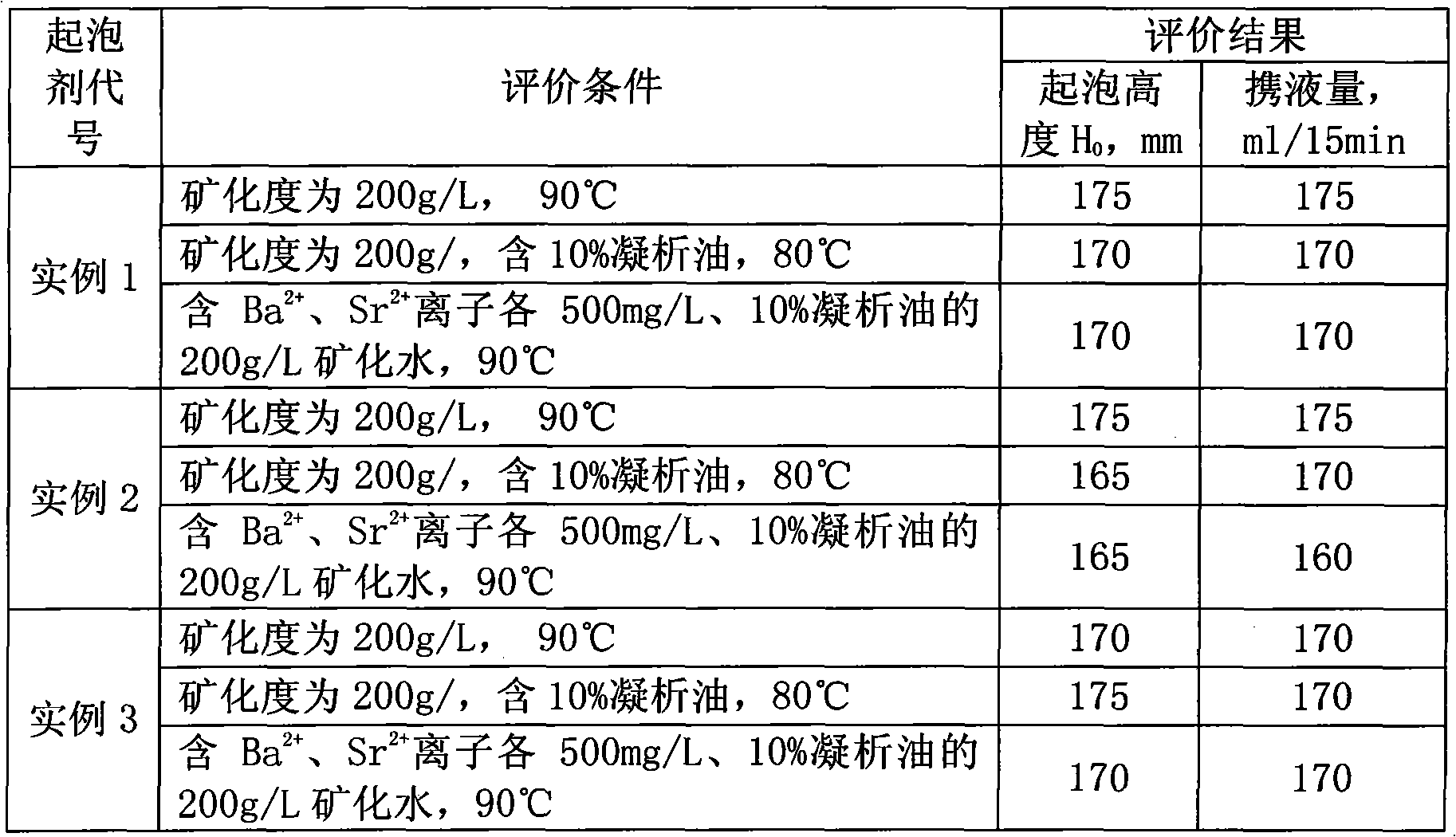

Foaming agent for highly mineralized water containing barium-strontium ions and gas condensate and preparation method thereof

InactiveCN102031099AExcellent foaming performance and liquid carrying capacityAvoid dischargeDrilling compositionSolventFormation water

The invention discloses a foaming agent for highly mineralized water containing barium-strontium ions and gas condensate and a preparation method thereof. The foaming agent contains the following components in mass percentage: 40%-50% of amphoteric surfactants, 10%-20% of nonionic surfactants, 5%-10% of barium-strontium ion inhibitors, 3%-5% of pH regulators and 15%-42% of solvents. The preparation method comprises the following steps of: A, adding the amphoteric surfactants and the nonionic surfactants into a stainless steel reactor by the proportions in a formula, heating to 50-60 DEG C, and then stirring for 20 min-50 min; B, adding the solvents and stirring for 20 min-30 min; and C, finally adding the barium-strontium ion inhibitors and the pH regulators, and continuously stirring for20 min-30 min. The foaming agent can have good foaming performance and liquid-carrying capacity in a formation water medium which contains 1000 mg / L-3000 mg / L of barium-strontium ions and has the gascondensate of not more than 30% and the total mineralization degree of not more than 250 g / L. In experiments, when the addition amount of the foaming agent is 3 g / L, the foaming height is greater than 150 mm, and the liquid-carrying amount is greater than 150 ml / 15 min.

Owner:SUINING HUANING CHEM

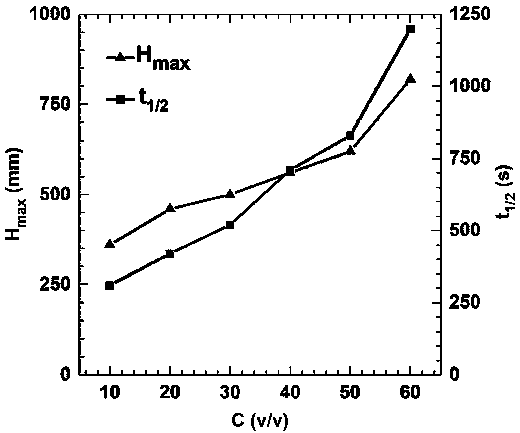

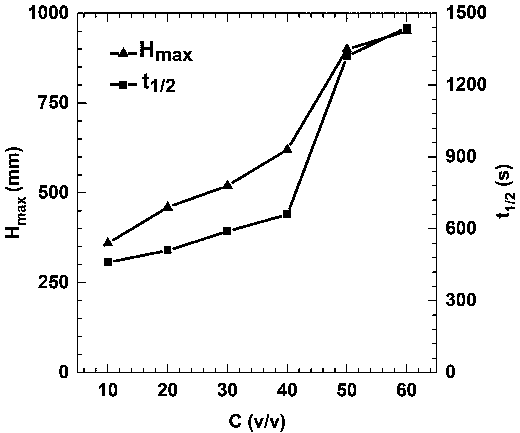

Gas well foaming agent composition as well as preparation method and application thereof

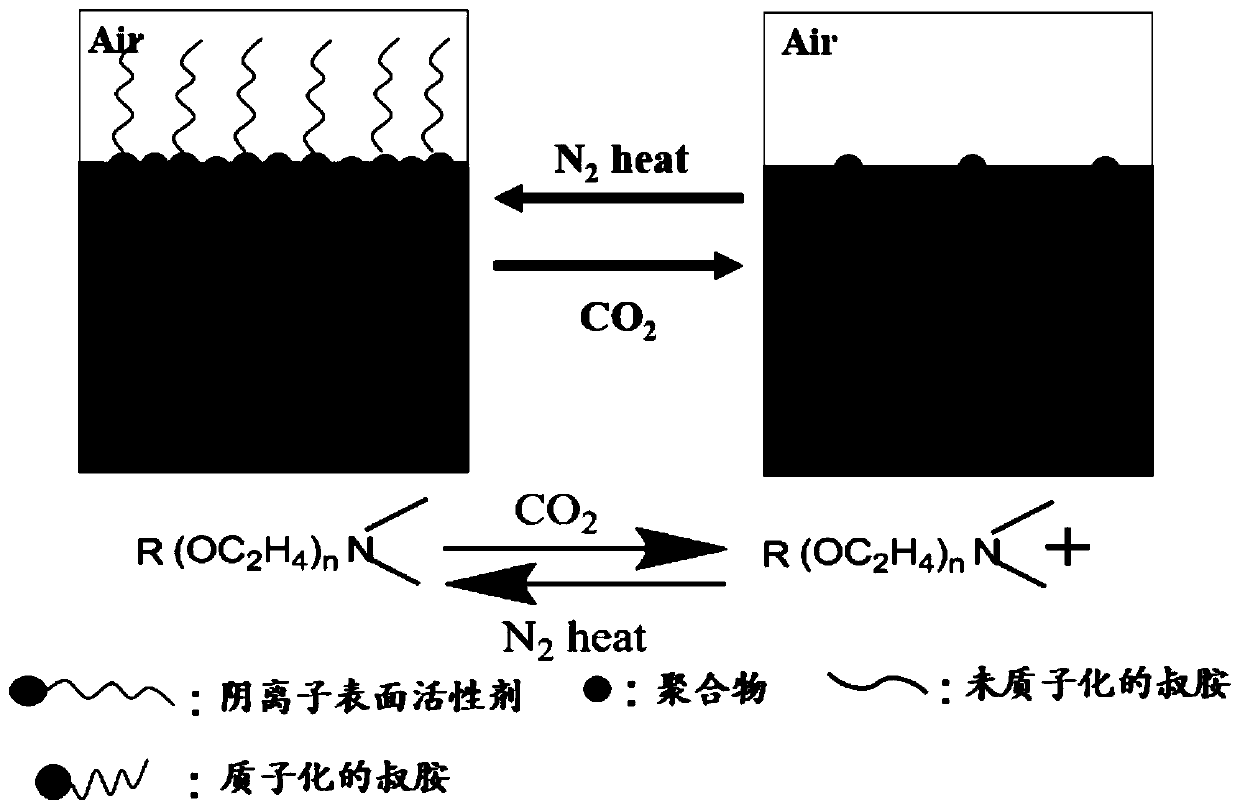

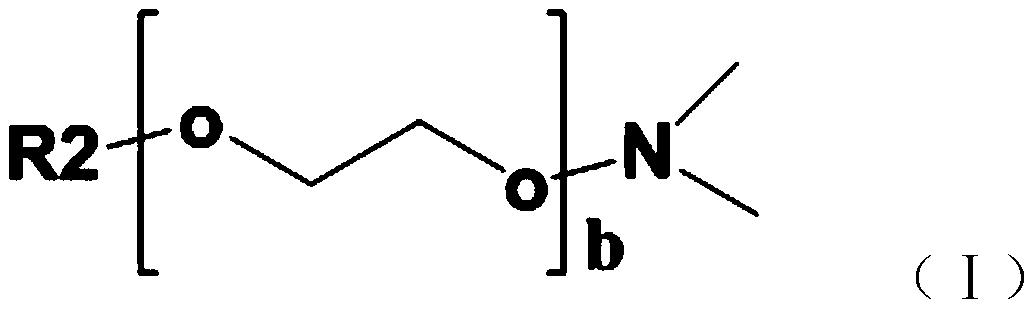

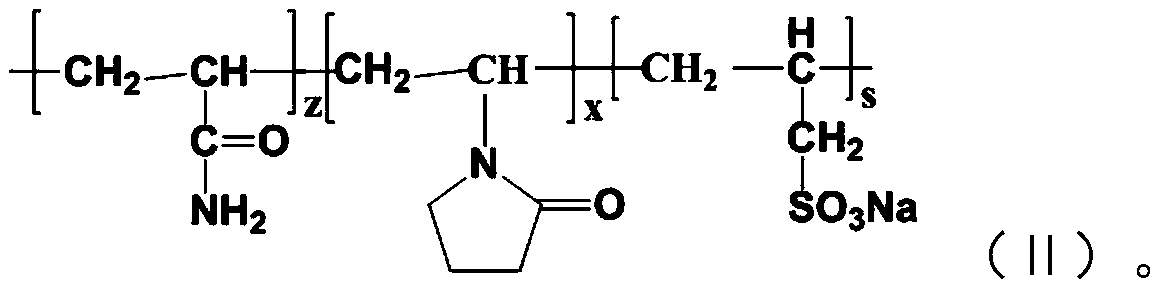

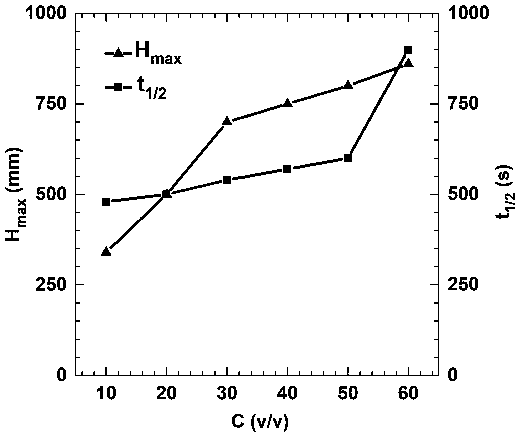

ActiveCN110791273AImprove switching performanceImprove salt toleranceDrilling compositionFoaming agentActive agent

The invention discloses a gas well foaming agent composition as well as a preparation method and application thereof, and belongs to the technical field of oil and gas field chemical agents. The technical problems that in the prior art, a foaming agent is poor in foam stability, water carrying capacity and the like in the drainage gas recovery process under the conditions of high temperature, highsalinity and high salinity are mainly solved. The composition comprises the following components: an anionic surfactant with the mass fraction of 40%; a self-made CO2 / N2 switch salt-tolerant responsetype tertiary amine the mass fraction of which is 45%; a self-made polymer AM-NVP-AS with a mass fraction of 10%; a foam stabilizer with a mass fraction of 5% and ethanol. The foaming agent disclosedby the invention has responsiveness in high-temperature high-salinity formation water; the foaming agent has the advantages of good foaming performance, long half-life period, high liquid carrying capacity and the like, and well solves the drainage gas recovery problem of high-temperature high-salt gas wells. Raw materials are low in price, easy to obtain, low in toxicity and irritation, and thecomposition is simple to produce and prepare, and can be applied to the drainage gas recovery industry of the gas well.

Owner:DONGYING SPRING PETROLEUM ENG TECH +1

Foam drainage agent with resistance to high-content gas condensate and resistance to high mineralization and preparation method of foam drainage agent

ActiveCN110819327AGood foam stabilityImprove liquid carrying capacityDrilling compositionActive agentFluorocarbon

The invention discloses a foam drainage agent with resistance to high-content gas condensate and resistance to high mineralization and a preparation method of the foam drainage agent, and belongs to the technical field of materials for gas well mining in oil-gas fields. The foam drainage agent includes the following raw material components: in percent by mass, 20-35% of a zwitterionic surfactant,1-5% of a fluorocarbon surfactant, 1-5% of an anionic surfactant, 1-5% of cocinic acid monoethanolamide and the balance water. The preparation method comprises the steps: performing weighing, stirring, mixing and heating, and performing dissolution so as to obtain the foam drainage agent finished product. Through arrangement of the specific raw materials and the ratios, good resistance to high-content gas condensate and resistance to high mineralization are achieved, and it is ensured that the foam drainage agent can have excellent capacity of foam generation, foam stabilization and liquid carrying under the conditions of high-content gas condensate and high mineralization; and meanwhile, the foam drainage agent has a wide range of raw material sources, low price, a simple production technology, low requirements of equipment and environments and large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

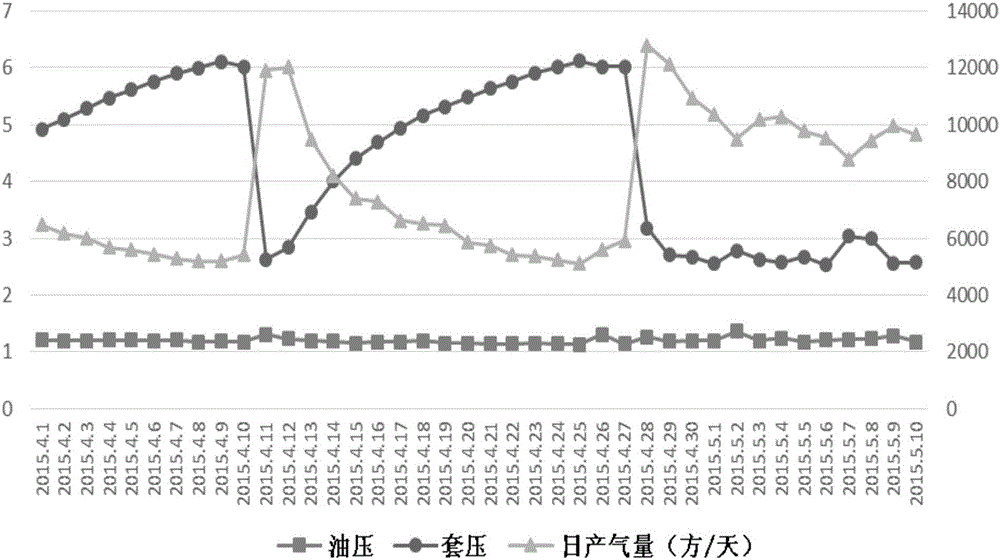

Coiled tube fracturing and well completion integration technological method for vertical gas well

ActiveCN104481489AReduce construction riskShorten the gas testing cycleDrilling rodsFluid removalCoiled tubingProduction string

The invention belongs to the technical field of vertical well fracturing in gas fields, and particularly relates to a coiled tube fracturing and well completion integration technological method for a vertical gas well. The coiled tube fracturing and well completion integration technological method for the vertical gas well includes following steps: 1) lowering a tool string into the vertical well; 2) perforating and fracturing each segment of the tool string; 3) throwing soluble balls into the vertical well from a wellhead, achieving releasing through a hydraulic releasing tool, and dropping the fractured tool string to the artificial bottom of the vertical well; 4) using a coiled tube as a production string and leaving the production string in a shaft of the vertical well after the soluble balls are completely dissolved; 5) dismantling the fractured wellhead, installing a coiled tube hanger and a gas recovery tree, and performing draining and production; 6) fishing the fractured tool string out of the shaft according to needs at the production tail. The coiled tube fracturing and well completion integration technological method for the vertical gas well reduces construction risk of the production string under pressure, shortens a gas testing task cycle, and simultaneously can observably improve fluid carrying capability of the vertical gas well, timely drains formation water out of the shaft, and prolongs a gas well production cycle.

Owner:PETROCHINA CO LTD

Oil-resistant foaming agent and preparation method thereof

ActiveCN104449632AStrong foaming abilityGood foam stabilityDrilling compositionChemistryCarrying capacity

The invention belongs to the technical field of oil and gas field chemical engineering, and particularly relates to an oil-resistant foaming agent. The oil-resistant foaming agent comprises, in percentage by weight, 50-70% of alkyl propyl betaine, 5-15% of an anionic surfactant, 10-20% of cetyl trimethyl ammonium bromide and 10-20% of water. The oil-resistant foaming agent is high in foaming capacity and high in foam stability after added to water-producing gas wells, still high in liquid carrying capacity for gas-condensate-producing gas wells, and applicable to gas-condensate-containing water-producing gas wells with moderate mineralization degrees.

Owner:PETROCHINA CO LTD

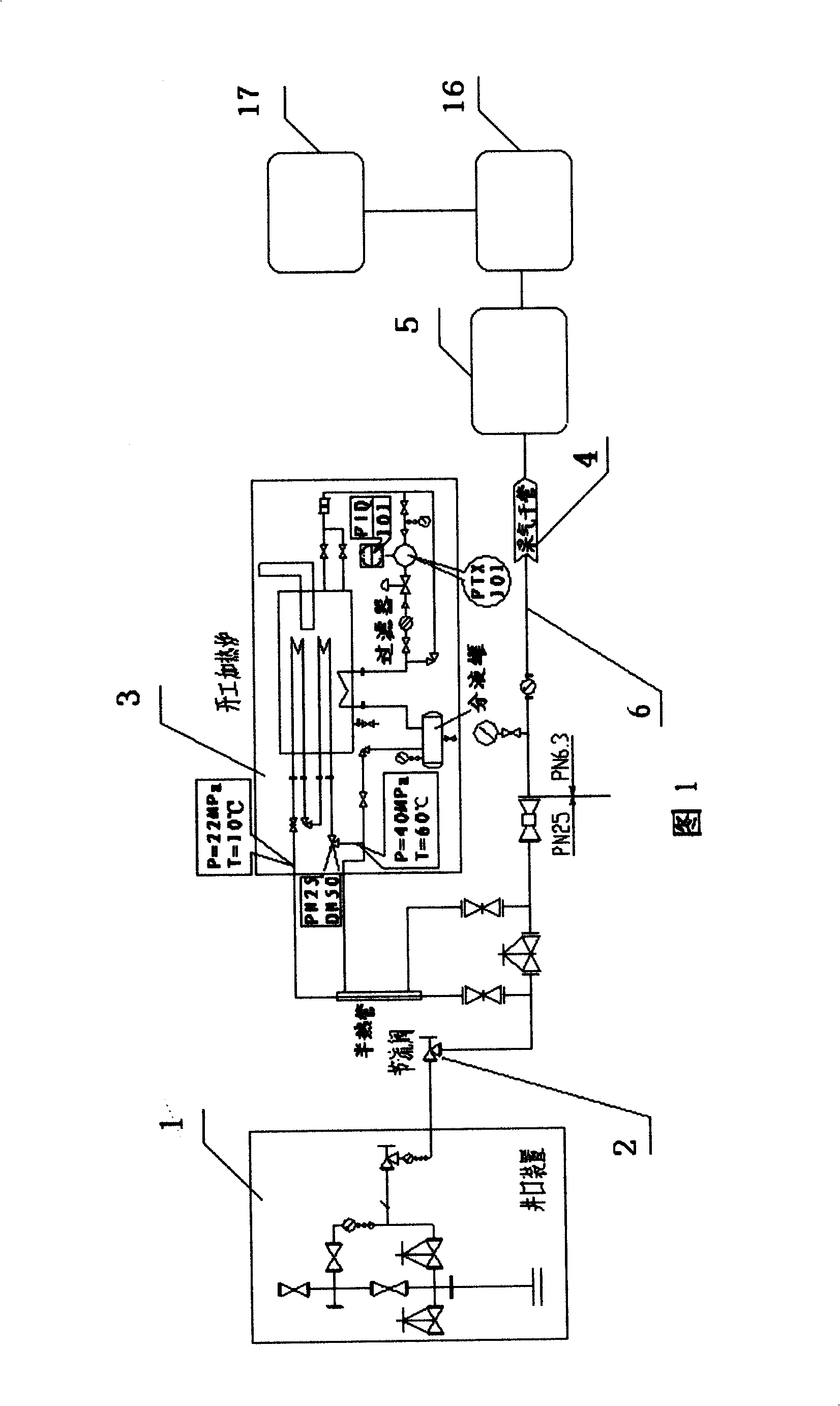

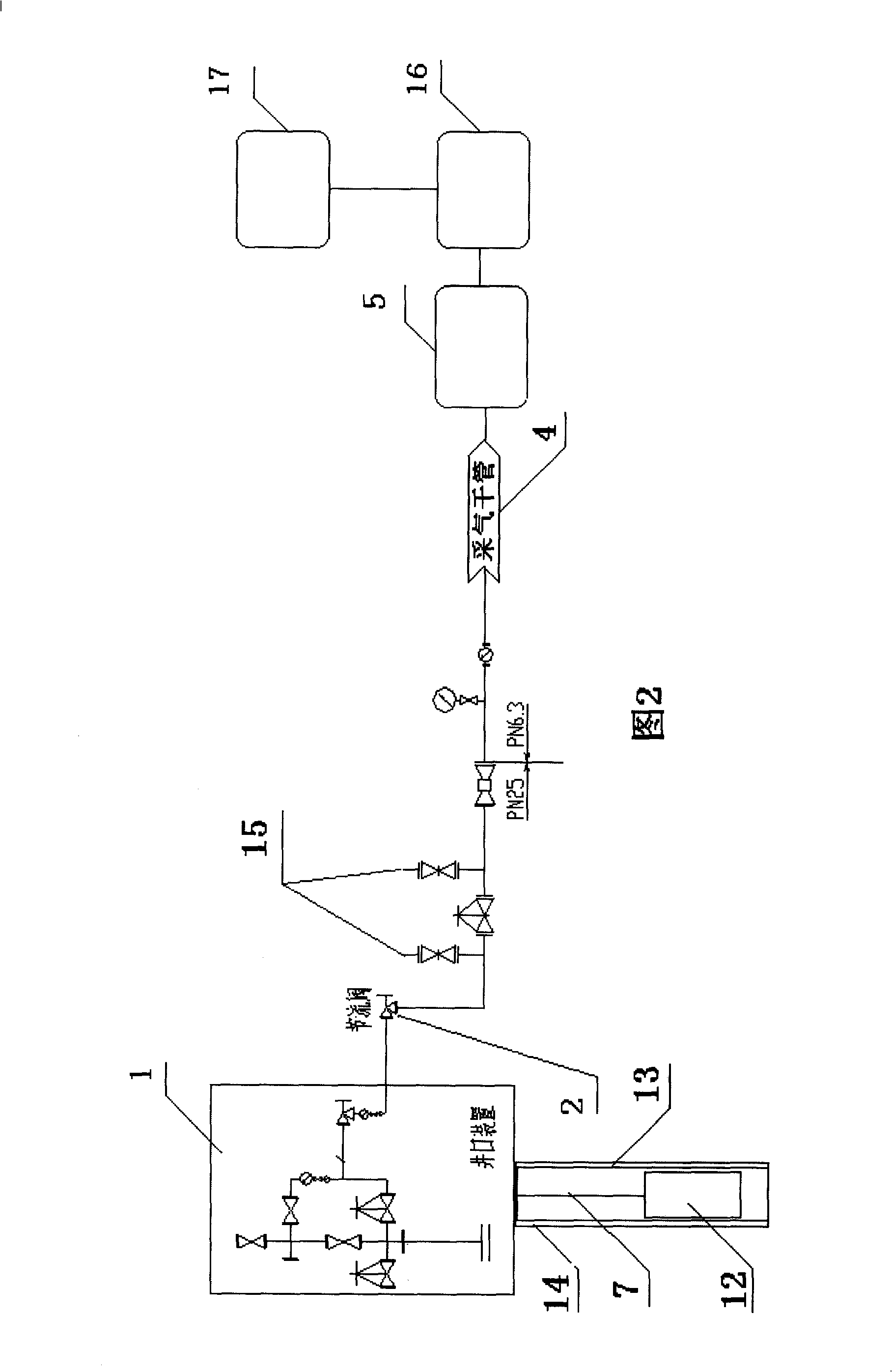

Middle-low pressure gas collection technique

InactiveCN101250995AReduce operating pressureReduce the chance of cloggingFluid removalSealing/packingLine tubingEngineering

The invention relates to a gas transmission device for a gas field, in particular to a method for a middle and low pressure gas collecting process, comprising a gas well, a wellhead device (1), a gas transmission pipeline, a gas collecting station (5) and a central processing plant. The invention is characterized in that the pressure of a wellhead is reduced to a middle pressure or a low pressure through an underground throttleer (12), is directly subject to a gas-liquid separation and a gas supercharging through a gas collecting pipeline (4) being connected to the gas collecting station (5), and is transmitted to a central processing mechanism (17) for deoiling and dewatering through a gas collecting branch trunk (16). The method for the middle and low pressure gas collecting process achieves aims of reducing blockage probability of hydrate in a pitshaft, increasing the property of liquid carrying, reducing the operating pressure of the pipeline and protecting a reservoir through underground throttling.

Owner:XIAN CHANGQING TECH ENG

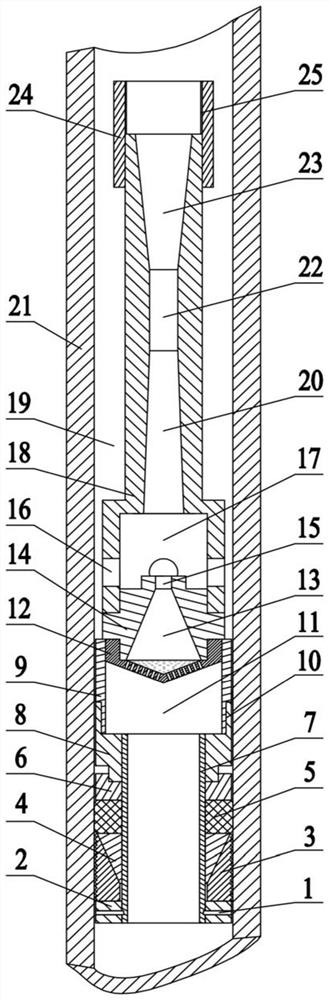

Foam atomizer and wellbore structure for bubble exhaust and gas production of natural gas well and gas production method

ActiveCN111701740AImprove atomization efficiencySimple structureFluid removalLiquid spraying apparatusEngineeringNozzle throat

The invention discloses a foam atomizer and wellbore structure for bubble exhaust and gas production of a natural gas well and a gas production method. The foam atomizer comprises a porous cone plate,a nozzle barrel and an atomizer vortex section barrel, wherein the nozzle barrel is provided with a nozzle inlet, the nozzle inlet extends from one end of the nozzle barrel to the other end of the nozzle barrel, the nozzle inlet is a linear tapered cone pipe, a nozzle throat is arranged on the portion, at the tail end of the small end of the nozzle inlet, of the nozzle barrel, and the porous coneplate is arranged on one side of the big end of the nozzle inlet and is connected with the nozzle barrel; the conical surface of the porous cone plate is uniformly provided with atomizing holes, theaxis of the atomizing holes is parallel to the wall surface of the nozzle inlet, and the sum of the cross-sectional areas of the atomizing holes is not larger than the cross-sectional area of the nozzle throat; and the atomizer vortex section barrel is arranged on one side of the small end of the nozzle inlet and is connected to the nozzle barrel. The foam atomizer and a bubble exhaust and gas extraction process are used in combination so that accumulated liquid in the natural gas well can be more effectively discharged out of a wellbore.

Owner:XI AN JIAOTONG UNIV

Condensate-oil-resistant, salt-resistant and temperature-resistant foam scrubbing agent and preparation method thereof

InactiveCN111139050AHigh fluid carrying capacityIncrease the lengthDrilling compositionChloroacetic acidsErucyl amide

The invention discloses a condensate-oil-resistant, salt-resistant and temperature-resistant foam scrubbing agent and a preparation method thereof. The condensate-oil-resistant, salt-resistant and temperature-resistant foam scrubbing agent is composed of the following components in percentages by weight: 8%-22% of cocamidopropyl dimethyl tertiary amine, 3%-12% of oleamide propyl dimethyl tertiaryamine, 3%-15% of erucyl amide propyl dimethyl tertiary amine, 3%-18% of chloroacetic acid, 8%-22% of liquid caustic soda and 6%-20% of organic solution, with the balance being water. According to theinvention, through selection and specific proportion design of raw materials, the liquid carrying capacity of the foam scrubbing agent is still high under the condition of high condensate oil content;meanwhile, the liquid carrying capacity cannot be reduced along with increase of the condensate oil content; and the problem that a conventional foam scrubbing agent cannot simultaneously meet the requirements for high temperature resistance, salt resistance and condensate oil resistance is solved.

Owner:PETROCHINA CO LTD

Underground oil and gas nozzle

InactiveCN102913188AReduce production pressureReduced minimum unloading flowWell/borehole valve arrangementsSealing/packingCarrying capacityDischarge rate

The invention provides an underground oil and gas nozzle and relates to a high-pressure oil and gas well throttling device working under the ground. The underground oil and gas nozzle comprises a hollow cylindrical main body; an oil nozzle is formed at one end of the main body and is a hollow cone; and lock blocks are also obliquely arranged on the main body. The underground oil and gas nozzle has the benefits that the production pressure is reduced, the wellhead temperature is improved, the generation conditions of hydrates are damaged, and the hydrates can be effectively prevented; and in addition, the minimum discharge rate of a wellhead of a gas well is reduced, and the liquid-carrying capacity of the gas well self is enhanced, so that the production of the gas well with lower liquid yield tends to be more stable.

Owner:SHAANXI QIYUAN TECH DEV

Method for water drainage and gas recovery of ultra-deep gas well by adopting solid foam water drainage agent composition

ActiveCN109679637AGood temperature and salt resistanceFine foamDrilling compositionSalt resistanceAdhesive

Owner:CHINA PETROLEUM & CHEM CORP +1

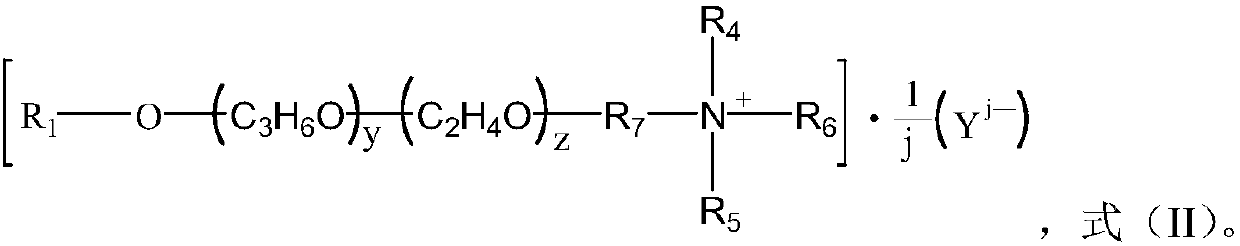

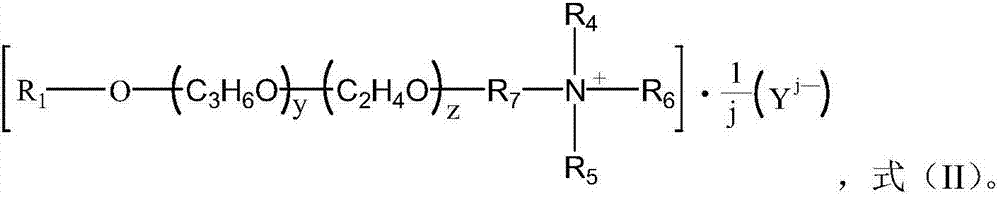

Method for liquid drainage and gas recovery using oil-foam-resistant drainage agent composition

ActiveCN109681176BImprove salt toleranceFine foamFluid removalDrilling compositionBenzenesulfonatesBenzenesulfonic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

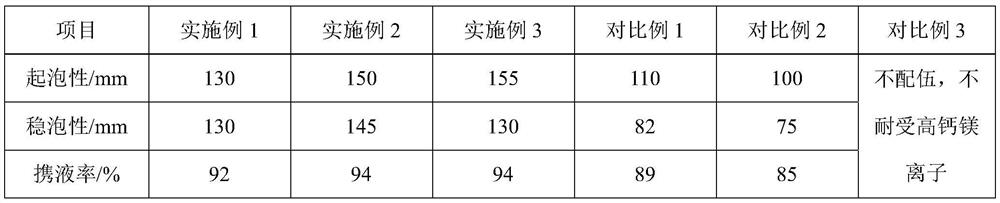

Salt-resistant foaming agent as well as preparation method and application thereof

The invention relates to a salt-resistant foaming agent as well as a preparation method and application thereof. The salt-resistant foaming agent is mainly prepared from cocamidopropyl betaine, dodecyl dimethyl betaine, cocamidopropyl amine oxide and water. The total mass of cocamidopropyl betaine and dodecyl dimethyl betaine accounts for 9-15% of the mass of the salt-resistant foaming agent, andthe mass ratio of cocamidopropyl betaine to dodecyl dimethyl betaine is (1-2.4): 1; the cocamidopropyl amine oxide accounts for 21-35% of the mass of the salt-resistant foaming agent. The salt-resistant foaming agent provided by the invention has the characteristics of low concentration and high efficiency after the components are combined, still has good foamability and foam stability when the mass percent of the total effective components is as low as 30%, has strong liquid carrying capacity, and has good applicability to a foam drainage gas recovery process of a gas well with high mineralization degree and high calcium and magnesium ion content.

Owner:CHINA PETROLEUM & CHEM CORP +1

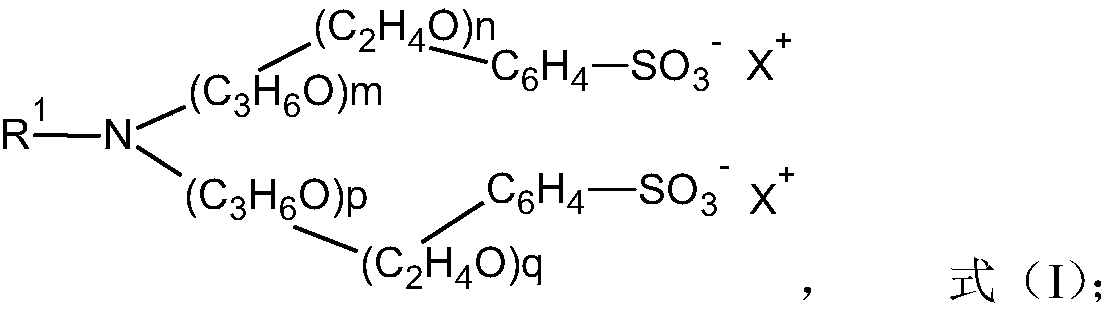

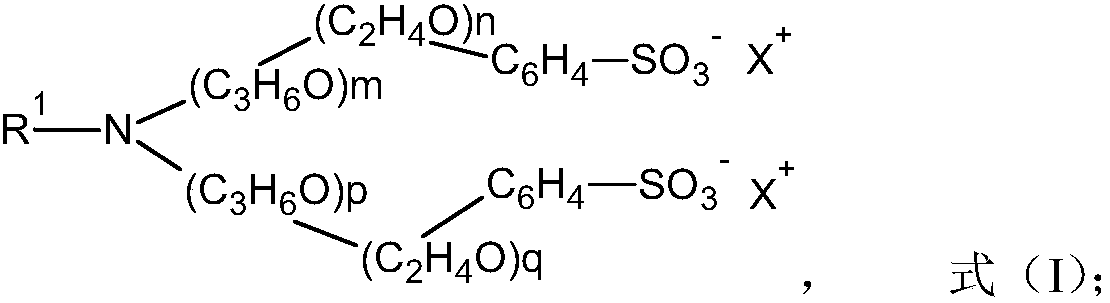

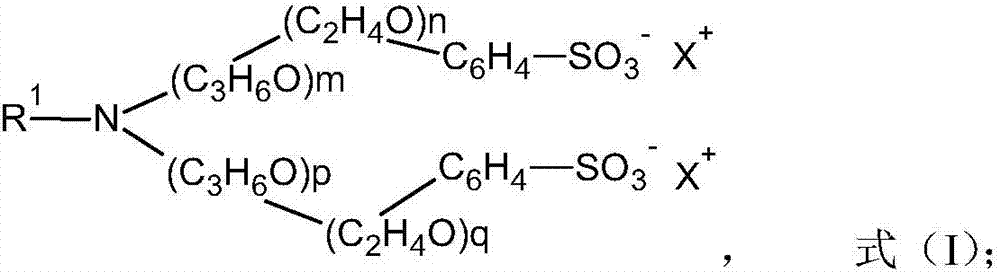

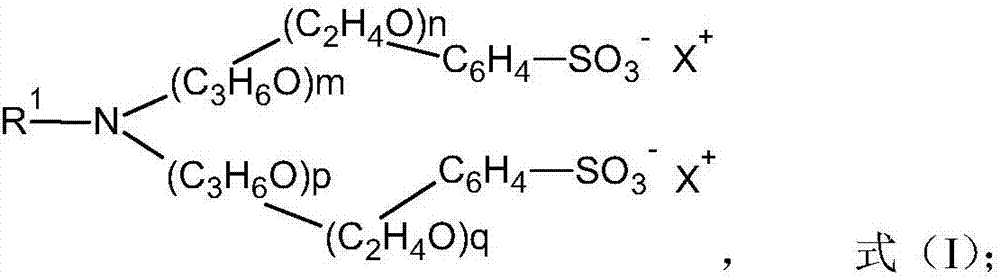

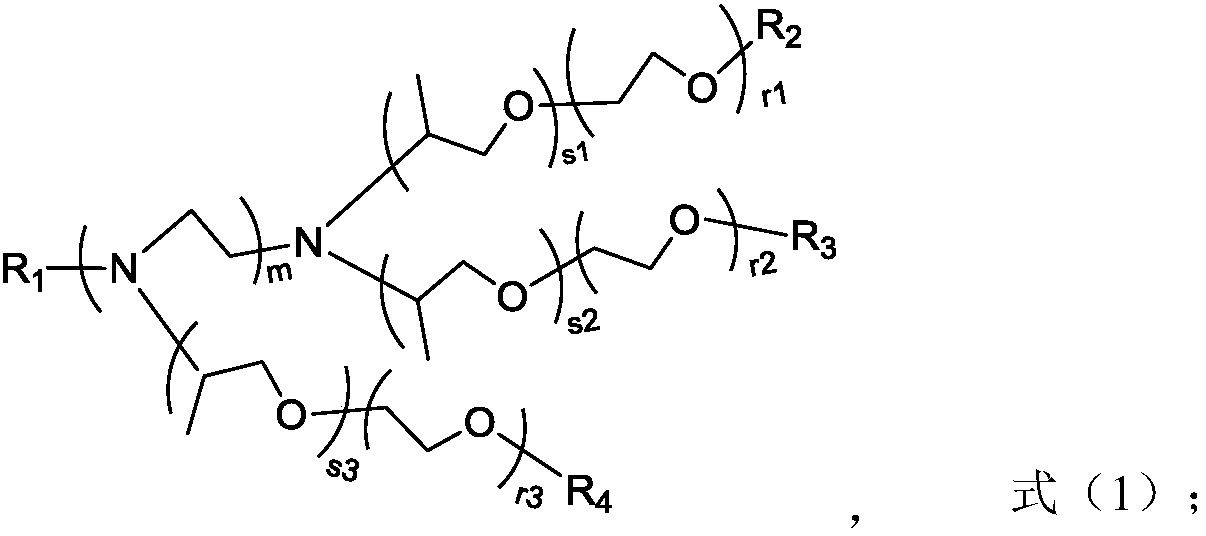

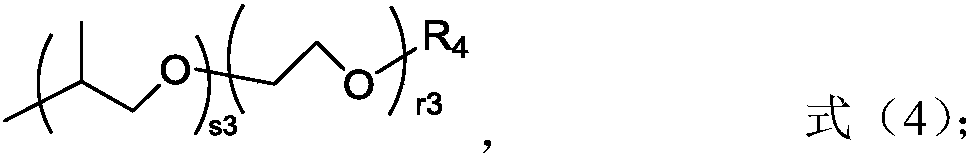

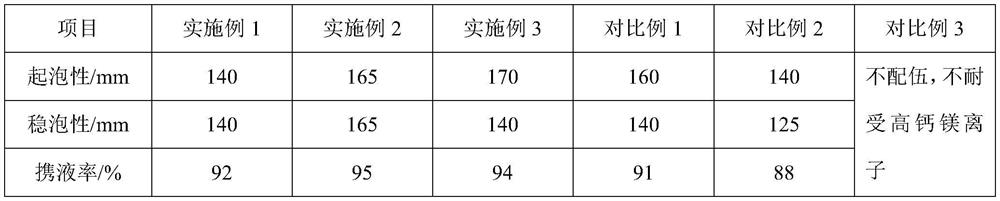

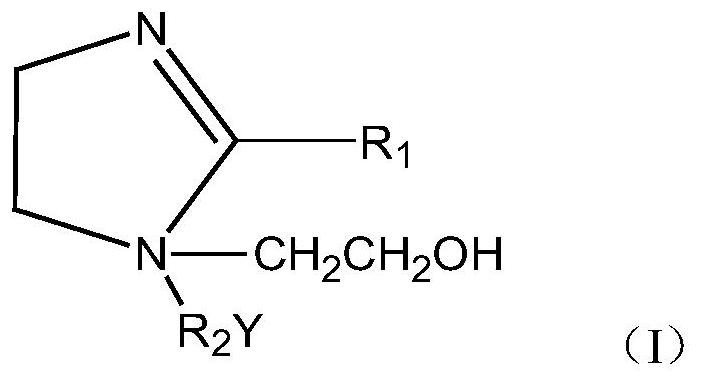

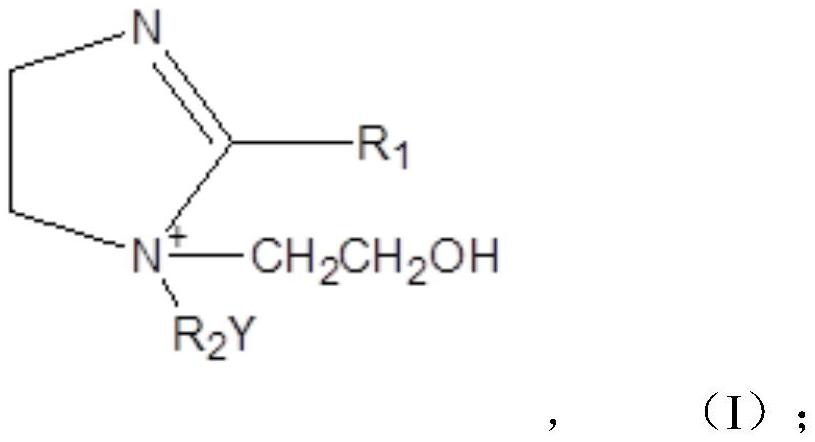

Salt-resistant acid-resistant drainage foam discharge agent composition for gas recovery and its preparation method and application

ActiveCN109401743BImprove liquid carrying capacityImprove foam stabilization performanceDrilling compositionSulfonateNanoparticle

The invention relates to a salt-resistant and acid-resistant drainage foaming agent composition for gas recovery, a preparation method and application thereof. It mainly solves the problem of excessive liquid accumulation in the development process of existing gas wells, which leads to the reduction of production or even the suspension of blowout of gas wells. Including the following components by mass fraction: (1) 1 part of imidazoline type amphoteric surfactant; (2) 0.2 to 20 parts of α-olefin sulfonate; (3) 0-10 parts of nanoparticles; wherein The imidazoline type amphoteric surfactant has molecular general formula shown in formula (I), described R 1 for C 8 ~C 30 fat base; R 2 for C 1 ~C 5 Any one of the alkylene or substituted alkylene; Y is the technical scheme of the anionic group that makes the molecules shown in formula (I) be electrically neutral, which solves this problem better, and can be applied to high salt content Drainage and gas recovery in sour gas fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly foam preparation and preparation method thereof

InactiveCN110935393ABiodegradableHigh temperature resistanceTransportation and packagingMixingAlkylphenolEnvironmental engineering

The invention belongs to the technical field of environment-friendly product preparation, and provides an environment-friendly foam preparation. The environment-friendly foam preparation is prepared from the following raw materials in percentage by weight: 5-15% of lauryl sodium sulfate, 2-6% of octaphenyl polyoxyethyiene, 2-6% of alkylphenol ethoxylate, 4-10% of a foam stabilizer, 0.2-2% of a preservative, 0.2-1% of a stabilizer, 0.2-2% of a foam aid and the balance of water. All the raw materials are green and environmentally friendly and have biodegradability. The environment-friendly foampreparation has high temperature resistance, the highest temperature can reach 150 DEG C, the high salinity resistance is achieved, the highest salinity can reach 300 g / L, the high oil resistance is achieved, and the highest condensate oil content can reach 30%. Good foaming capability, foam stabilizing capability and liquid carrying capability are achieved. The environment-friendly shield foamingagent disclosed by the invention is stable in quality and good in corrosion resistance, is not influenced by the storage temperature and storage time, and has a relatively long shelf life. The preparation method is simple to operate, easy to prepare and suitable for large-scale production.

Owner:陕西速源节能科技有限公司

Oil well gas prevention system

InactiveCN106567695AControl gas productionIncrease fluid productionFluid removalCarrying capacitySpray nozzle

The invention discloses an oil well gas prevention system and a using method. The oil well gas prevention system comprises an oil well casing and a gas prevention pump. The lower end of the gas prevention pump 1 is sequentially connected with an upper filter screen pipe and an upper screwed plug. A release sub located below the gas prevention pump 1 is arranged in the oil well casing. The release sub is located in the oil well casing through an upper packer arranged on the periphery of the release sub. The lower end of the release sub is connected with a gas prevention lifting pump. The gas prevention lifting pump is located and installed in the oil well casing through a lower packer. The lower end of the gas prevention lifting pump is connected with a lower filter screen pipe. A lower oil layer liquid inlet is formed below the gas prevention lifting pump. An upper oil layer liquid inlet is formed in one side of the gas prevention lifting pump. The oil well gas prevention system has the following advantages that the production pressure difference of the low-pressure oil layer is increased, the liquid production amoung of the low-pressure layer is increased, interlayer interference is avoided, the function of changing the motion direction of liquid and the acceleration function are achieved, the liquid carrying capacity of gas is improved, and the liquid production capacity of the low-pressure layer is improved; and secondary filter of well liquid is achieved, and a spray nozzle is effectively prevented from being blocked.

Owner:CHINA PETROLEUM & CHEM CORP

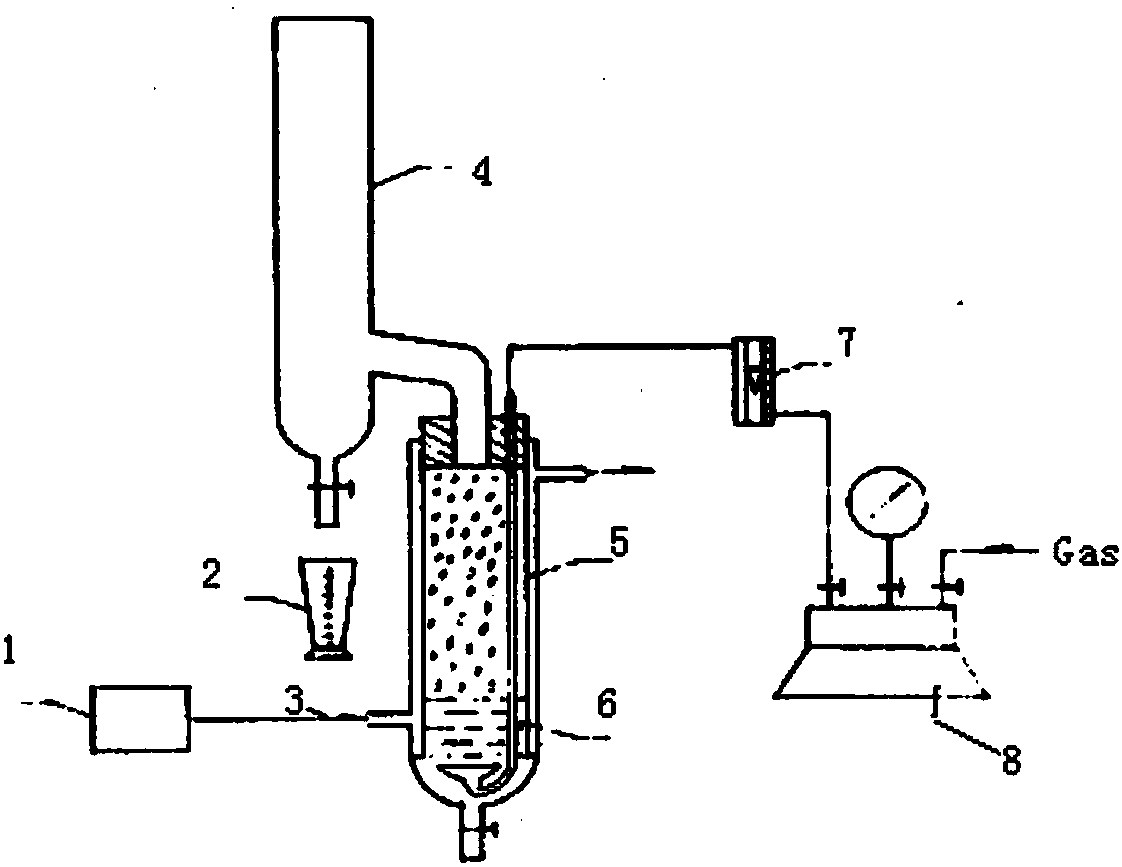

Compressor extraction system for natural gas well

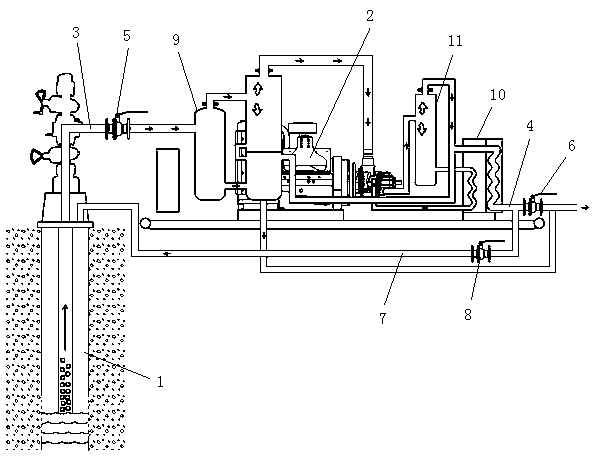

InactiveCN104234672AIncrease pressureImprove air flow carrying capacityFluid removalProduction rateProcess engineering

The invention discloses a compressor extraction system for a natural gas well, relates to the technical field of natural gas extraction, and solves the technical problems of low gas production rate and short life cycle of the gas well. The system comprises a compressor, a gas inlet pipe, a gas outlet pipe and a vent valve; a medium inlet of the compressor is connected with the natural gas well through the gas inlet pipe; a medium outlet of the compressor is connected to the inlet of the vent valve through the gas outlet pipe; the gas inlet pipe is provided with an inlet valve used for controlling the on or off of the gas inlet pipe. The compressor extraction system is characterized in that the medium outlet of the compressor is connected to the natural gas well through a reinjection pipe, and the reinjection pipe is provided with a reinjection valve used for controlling the on or off of the reinjection pipe. The system provided by the invention is suitable for extraction of the natural gas well.

Owner:汉纬尔机械(上海)有限公司

Foaming agent with corrosion inhibiting function for acidic gas field, preparation and applications thereof

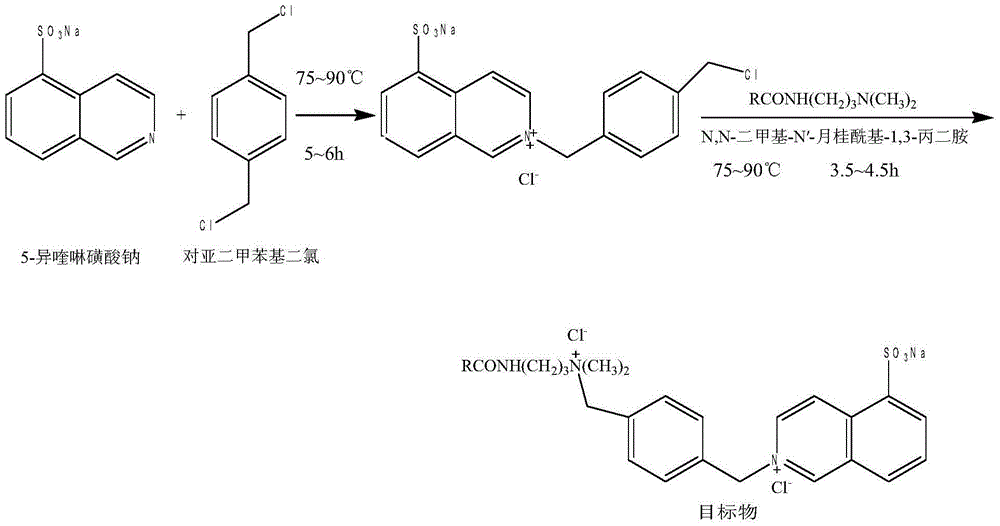

ActiveCN104629702AActs as corrosion protectionGood foaming powerOrganic chemistryDrilling compositionSulfonateXylylene

The invention relates to a foaming agent with a corrosion inhibiting function for acidic gas field, preparation and applications thereof. The preparation method comprises the following steps: preparing the following components: sodium 5-isoquinoline sulfonate, p-xylylene dichlorine, and N,N-dimethyl-N'-lauroyl-1,3-propane diamine according to a mole ratio of 1.0-1.2:1.0:1.0-1.2; carrying out reactions between 5-isoquinoline sulfonate and p-xylylene dichlorine for 5 to 6 hours at a temperature of 75 to 90 DEG C; then adding N,N-dimethyl-N'-lauroyl-1,3-propane diamine, carrying out reactions for 3.5 to 4.5 hours at a temperature of 75 to 90 DEG C; and adding deionized water so as to obtain a foaming agent water solution with a content of 30 to 40%. The foaming ability of the foaming agent is 108 to 255 mm, the stability is 22 to 55 mm, the liquid carrying amount is 130 to 148 mL / 15min, and the corrosion speed is not more than 0.076 mm / a.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com