Oil-proof sustained-release solid foaming drainage agent used for gas wells, and preparation method and applications thereof

A foam drainage agent and technology of drainage agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of high local concentration of foam drainage agent, waste of chemicals, etc. The effect of long and simple operation of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The medicament formula and synthesis process involved in the invention can produce a high-condensate oil-resistant, high-salinity-resistant, high-temperature-resistant slow-release solid foam drainage agent for gas wells. Now set forth the preparation method of the foam drainage agent, the specific steps are as follows.

[0028] 1. Prepare

[0029] 1) Preparation of raw materials.

[0030] 2) Check whether there are foreign objects in the reactor, and if there are foreign objects, remove them in time.

[0031] 3) Start the mixer and observe whether it is working normally, if not, carry out corresponding maintenance.

[0032] 4) Calibrate scales:

[0033] a) Zero adjustment.

[0034] b) Calibrate the instrument with a 500g standard weight.

[0035] 2. Production:

[0036] 1) Depending on the size of the reaction kettle, fully mix fatty amidopropyl hydroxysultaine, lauryl amidopropyl betaine, and cocodiethanolamine according to the ratio (mass percentage: 40% to 20%...

Embodiment 1

[0046] (1) Configuration of foaming ingredients

[0047] Weigh each component according to the following mass ratio: 20kg fatty amidopropyl hydroxysultaine, 40kg lauryl amidopropyl betaine, 40kg cocodiethanolamine, stir for 30 minutes, and mix the components evenly to obtain the foaming component .

[0048] (2) Configure drainage agent

[0049] Weigh each component according to the following mass ratio: 30kg of foaming component, 20kg of polyethylene glycol, 35kg of acrylic resin, and 15kg of sodium sulfate, and mix the weighed components evenly to obtain the product.

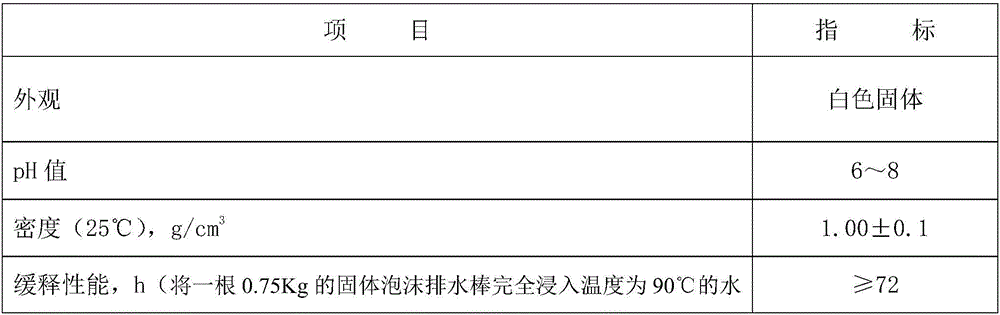

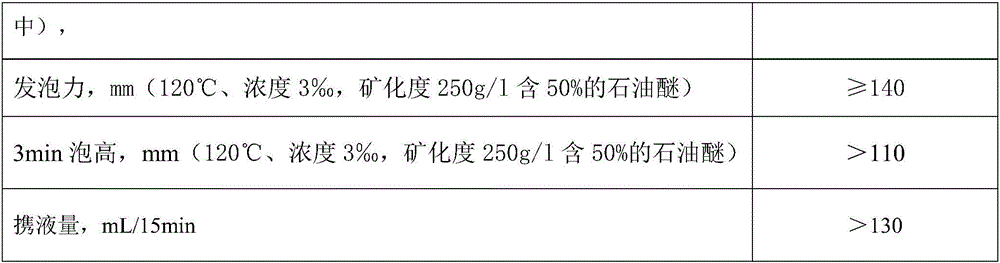

[0050] It has been determined that the product prepared in this example has a dissolution time of more than 72 hours in 90°C water; the anti-condensate oil ability is 65%; the temperature resistance ability is ≥ 120°C, and the high salinity resistance reaches 250,000ppm; the foam drainage agent foams Capacity is 162mm.

Embodiment 2

[0052] (1) Configuration of foaming ingredients

[0053] Weigh each component according to the following mass ratio: 35kg fatty amidopropyl hydroxysultaine, 35kg lauryl amidopropyl betaine, 30kg cocodiethanolamine, stir for 45 minutes, and mix the components evenly to obtain the foaming component .

[0054] (2) Configure drainage agent

[0055] Weigh each component according to the following mass ratio: 40kg of foaming component, 15kg of polyethylene glycol, 30kg of acrylic resin, and 15kg of sodium sulfate, and mix the weighed components evenly to obtain the product.

[0056] It has been determined that the product prepared in this example has a dissolution time of more than 72 hours in 90°C water; the anti-condensate oil ability is 58%; the temperature resistance ability is ≥ 120°C, and the high salinity resistance reaches 250,000ppm; the foam drainage agent foams Capacity is 155mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com