Composite medical biopolymer material and preparation method thereof

A biopolymer and macromolecule technology, applied in non-active ingredient medical preparations, pharmaceutical formulations, chemical instruments and methods, etc., can solve the problems of inaccurate control of the physical and chemical properties of polymer materials, price and preparation process. Does not have very good advantages, harsh reaction conditions and other problems, to achieve the effect of increasing the degradation half-life or dissolution time, excellent stability, and reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039]实施例一:

[0040]一种复合医用生物高分子材料的制备方法,其制备方法包括以下步骤:

[0041]第一步:称取可溶性甲壳素类高分子,氨基化透明质酸,去离子水,助溶剂按照按照一定比例放置在搅拌装置中形成混合溶液;

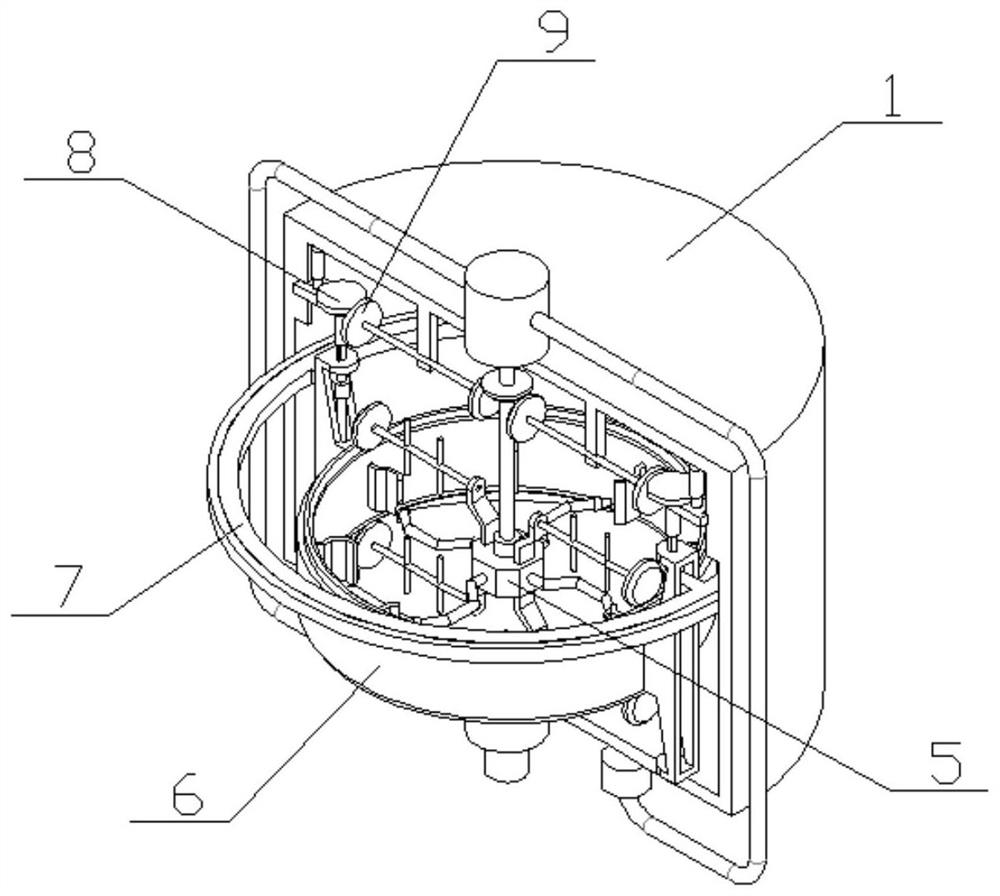

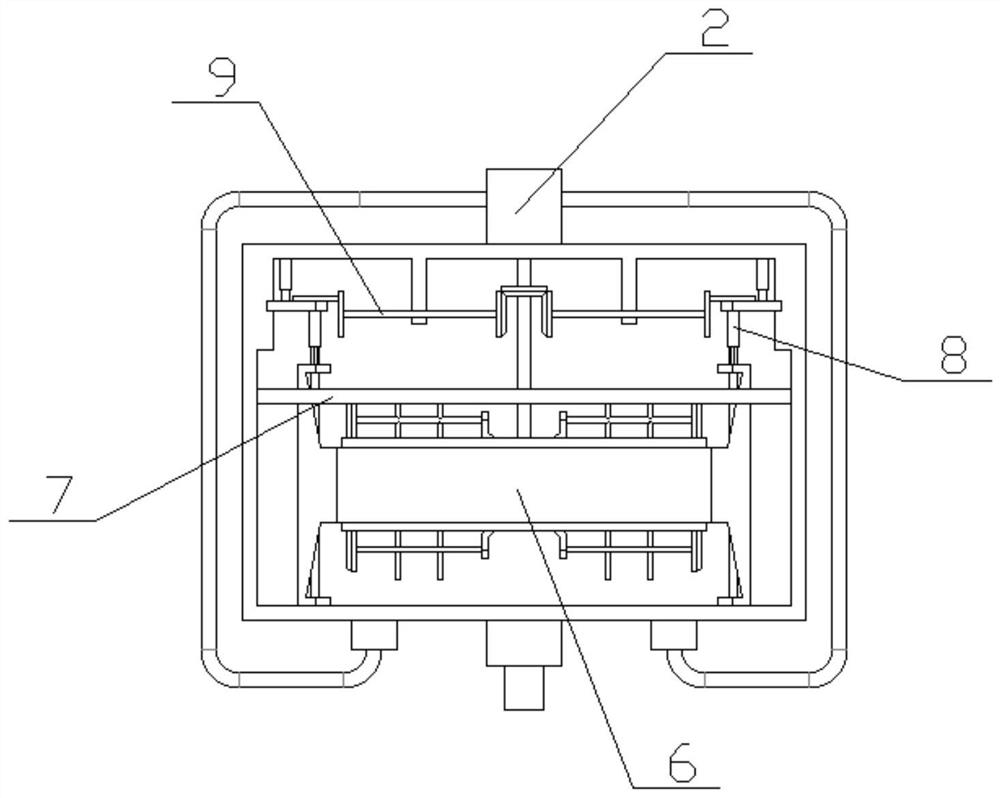

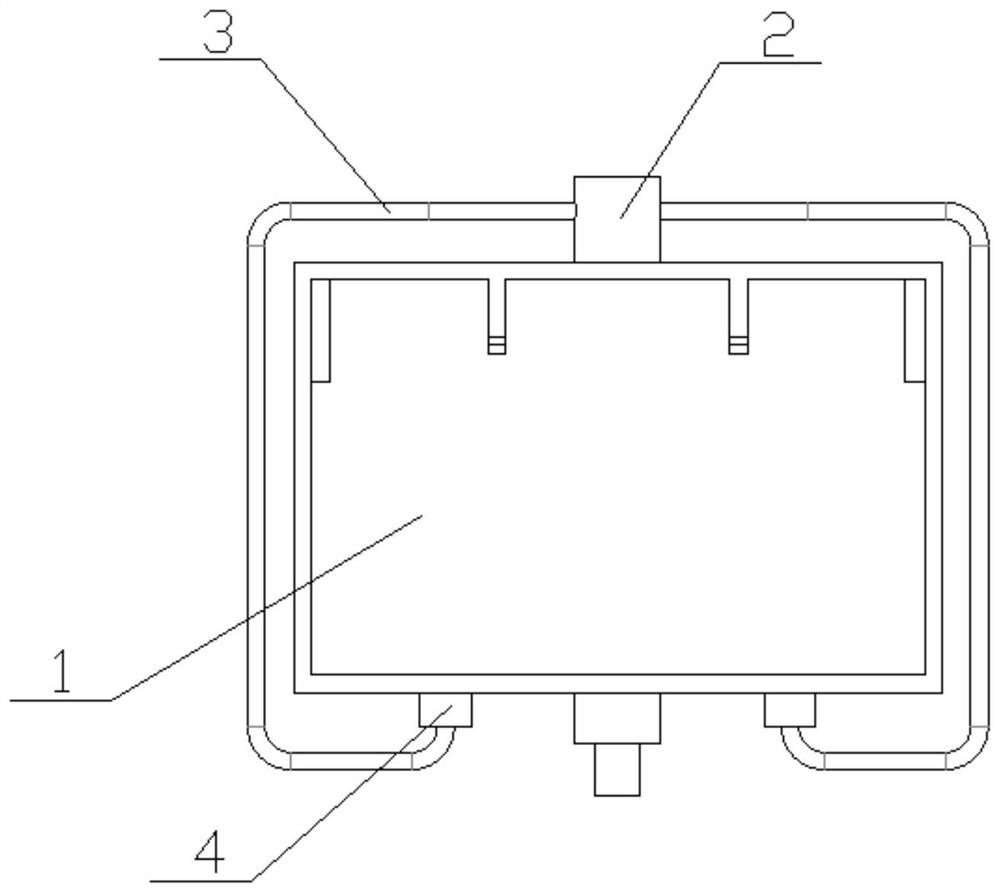

[0042]搅拌装置包括搅拌箱体,固定安装在所述搅拌箱体外部的输送泵,所述输送泵与所述搅拌箱体的底部之间通过导管相连通,每个所述导管与所述搅拌箱体的底部之间均设置有过滤网,所述搅拌箱体的内部同心设置有喷射机构及固定机构,所述固定机构与所述搅拌箱体之间固定连接,所述固定机构上还设置有刮板机构,所述喷射机构转动连接在所述搅拌箱体的内部,并且所述喷射机构的顶部与所述输送泵之间相连通,所述喷射机构与所述固定机构之间通过第一传动机构和第二传动机构之间传动连接;

[0043]第二步:通过驱动输送泵使搅拌装置中的混合溶液循环流动,利用混合溶液的流动冲击固定机构形成对喷射机构的反向推力带动所述喷射机构进行转,并在此过程中通过第一传动机构和第二传动机构的作用下推动刮板机构在搅拌装置的内部进行上下往复移动,充分搅拌后得到待加工产物;

[0044]所述固定机构包括固定连接在所述搅拌箱体内部的固定支架,所述固定支架的内表面均匀分布安装有弧形挡板,所述固定支架的两侧均转动连接有丝杆,所述固定支架上下滑动连接有刮板机构,两个所述丝杆均与所述刮板机构之间螺纹连接,所述固定支架的上下两侧均固定连接有斜齿环;

[0045]所述喷射机构包括转动连接在所述搅拌箱体上的导料管,所述导料管上固定连接有第一斜齿轮,所述导料管的下端固定连接有喷射支架,所述喷射支架的圆周方向上设置有喷射头,所述喷射头的喷射方向与所述导料管的径向方向之间具有夹角,所述喷射支架上下两端的两侧均转动连接有搅拌支架,每个所述搅拌支架在远离所述导料管的一端均固定连接有第二斜齿轮,所述第二斜齿轮与所述斜齿环之间传动连接;

[0046]所述第一传动机构包括转动连接在所述搅拌箱体上的传动转轴,所述传动转轴的两侧分别固定连接有第一传动轮与第三斜齿轮,所述第三斜齿轮与所述第一斜齿轮之间啮合连接;

[0047]所述第二传动机构包括滑动连接在所述搅拌箱体侧面的传动支架,所述传动支架与所述搅拌箱体之间设置有气缸,所述传动支架上转动连接有传动套筒,所述传动套筒套设在延伸出所述固定支架上端的所述丝杆上并与所述丝杆之间传动连接,所述传动套筒上固定连...

Example Embodiment

[0049]实施例二:

[0050]一种复合医用生物高分子材料的制备方法,基于实施例一,不同的是在第一步;

[0051]称取可溶性甲壳素类高分子,阳离子透明质酸,去离子水,助溶剂按照按照一定比例放置在搅拌装置中形成混合溶液;

[0052]经过充分搅拌及烘干机烘干后,最终得到高分子生物膜。

Example Embodiment

[0053]实施例三:

[0054]一种复合医用生物高分子材料的制备方法,基于实施例一,不同的是在第三步;

[0055]经过充分搅拌及冷冻干燥干后,最终得到高分子生物海绵。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com