Condensate-oil-resistant foam discharging agent, preparation method thereof and application of foam discharging agent

A technology of anti-condensate oil and foam discharge agent, which is applied in chemical instruments and methods, compositions of drilling holes, etc., can solve the problems of insufficient foaming, foam-stabilizing performance and liquid-carrying ability, achieve excellent foaming, facilitate the The effect of large-scale applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

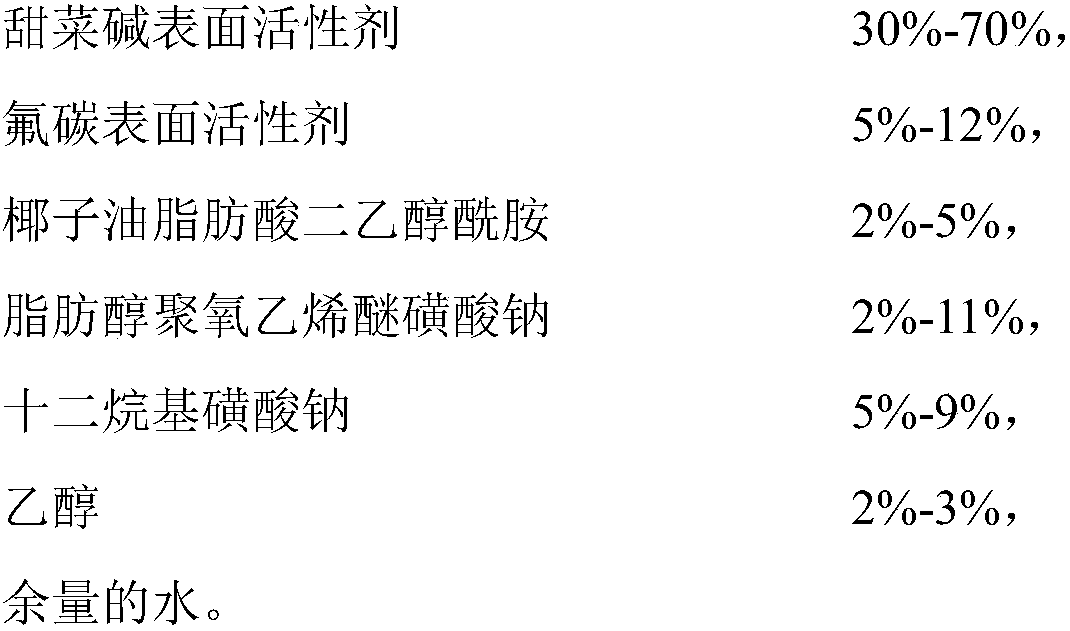

[0028] This embodiment provides an anti-condensate oil foaming agent, the raw material composition of the anti-condensate oil foaming agent includes:

[0029]

[0030]

[0031] This embodiment also provides the preparation method of the above-mentioned anti-condensate oil foaming agent, which includes the following steps:

[0032] Step 1: Weigh the raw materials according to the composition of the above raw materials, add water into the reaction kettle and heat up to 75°C, then add sodium dodecylsulfonate and sodium fatty alcohol polyoxyethylene ether sulfonate with a main chain length of C20-24 , start the reactor and fully stir for 2.5 hours until the system is uniform to obtain solution A;

[0033] Step 2, after the reactor is cooled to 50°C, add ethanol, dodecyl betaine, perfluorooctane sulfonic acid surfactant, coconut oil fatty acid diethanolamide (Ninal 6501) and main chain to solution A Sodium fatty alcohol polyoxyethylene ether sulfonate with a length of C14-18...

Embodiment 2

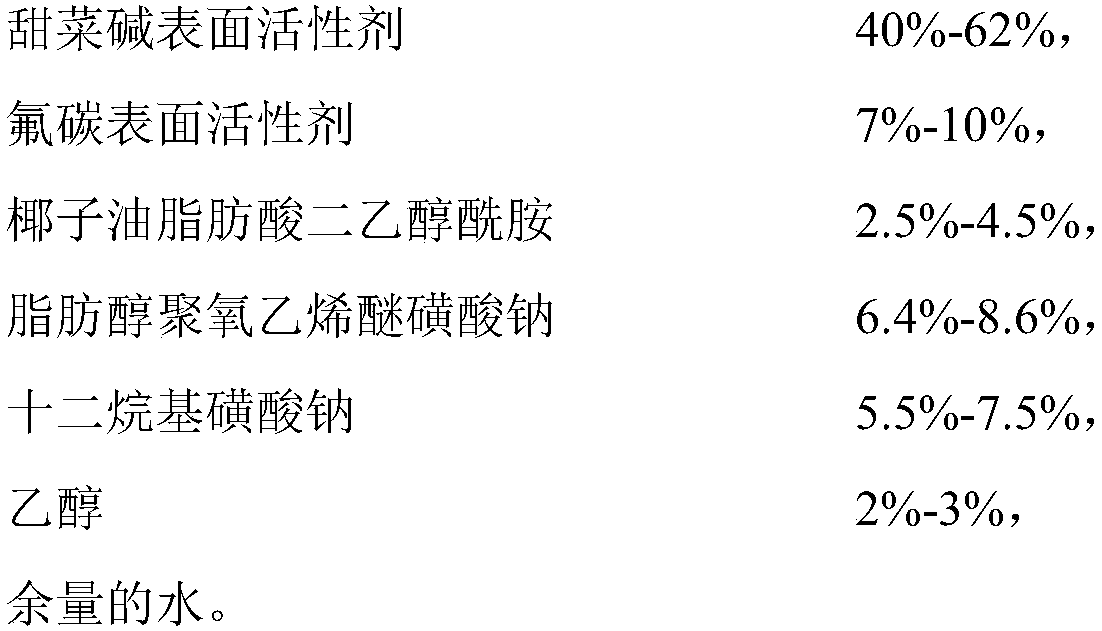

[0035] This embodiment provides an anti-condensate oil foaming agent, the raw material composition of the anti-condensate oil foaming agent includes:

[0036]

[0037] This embodiment also provides the preparation method of the above-mentioned anti-condensate oil foaming agent, which includes the following steps:

[0038] Step 1: Weigh the raw materials according to the composition of the above raw materials, add water into the reaction kettle and heat up to 75°C, then add sodium dodecylsulfonate and sodium fatty alcohol polyoxyethylene ether sulfonate with a main chain length of C20-24 , start the reactor and fully stir for 2.5 hours until the system is uniform to obtain solution A;

[0039]Step 2, after the reactor is cooled to 50°C, add ethanol, dodecyl betaine, perfluorooctane sulfonate surfactant, coconut oil fatty acid diethanolamide (Ninal 6501) and main Sodium fatty alcohol polyoxyethylene ether sulfonate with a chain length of C14-18, start the reactor again and s...

Embodiment 3

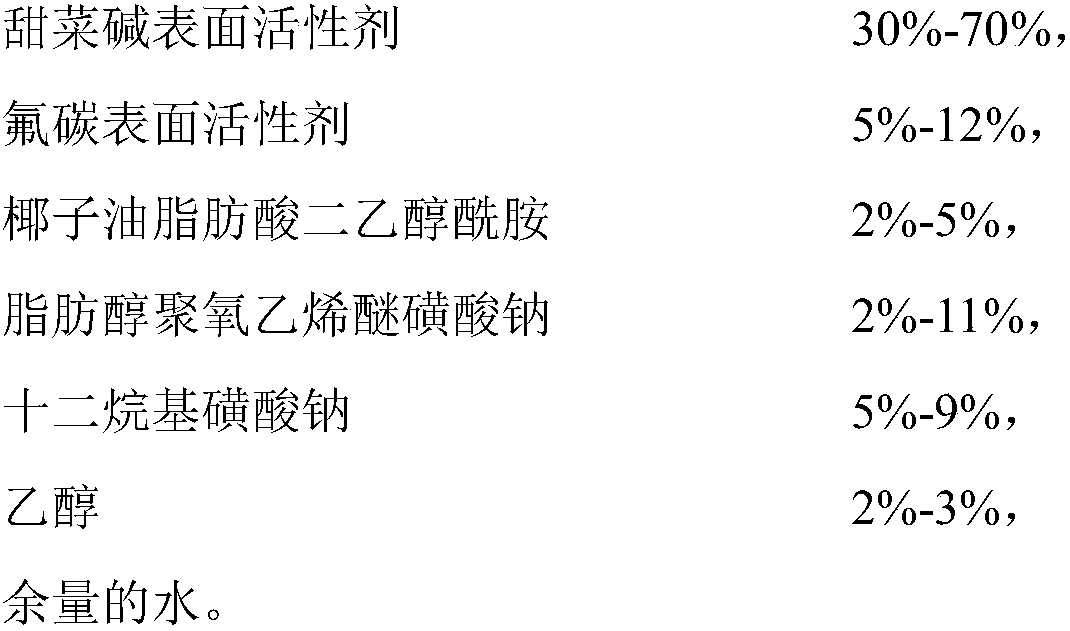

[0041] This embodiment provides an anti-condensate oil foaming agent, the raw material composition of the anti-condensate oil foaming agent includes:

[0042]

[0043] This embodiment also provides the preparation method of the above-mentioned anti-condensate oil foaming agent, which includes the following steps:

[0044] Step 1: Weigh the raw materials according to the composition of the above raw materials, add water into the reaction kettle and heat up to 75°C, then add sodium dodecylsulfonate and sodium fatty alcohol polyoxyethylene ether sulfonate with a main chain length of C20-24 , start the reactor and fully stir for 2.5 hours until the system is uniform to obtain solution A;

[0045] Step 2, after the reactor is cooled to 50°C, add ethanol, dodecyl betaine, perfluorooctane sulfonate surfactant, coconut oil fatty acid diethanolamide (Ninal 6501) and main Sodium fatty alcohol polyoxyethylene ether sulfonate with a chain length of C14-18, start the reactor again and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com