Agroforestrial biomass gasification furnace adapted to multiple raw materials

A gasifier and biomass technology, applied in the field of agricultural and forestry biomass energy, can solve the problems of difficult bridging, overhead, local sintering, etc., and achieve the effect of increasing the gas production of a single furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

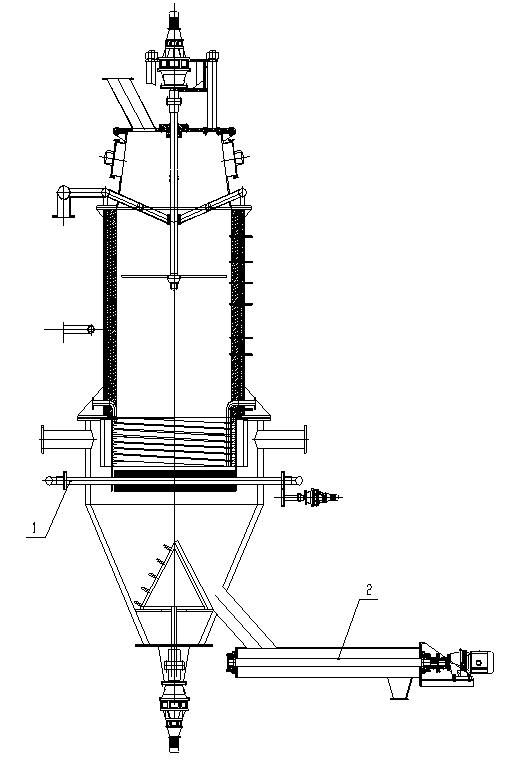

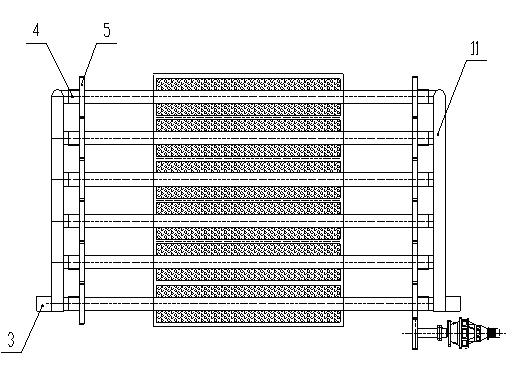

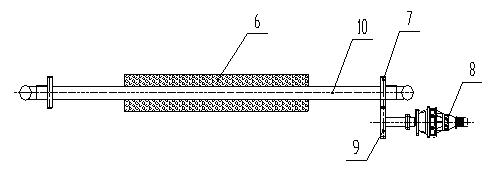

[0011] Control attached figure 1 , its structure is that the top of the gasification furnace is equipped with a rotary feeder driven by a motor reducer, a hydraulic feed lifter and a feed inlet, wherein the rotary feeder is connected to the hydraulic feed lifter; in the gasification There is a gasification reaction chamber in the gasification furnace cavity in the middle of the furnace. The gasification reaction chamber is divided into a preheating drying chamber, an oxidation reaction chamber, and a reduction reaction chamber from top to bottom. The preheating drying chamber communicates with the primary air inlet pipe. The oxidation reaction chamber is communicated with the secondary air inlet pipe, and the lower end of the reduction reaction chamber is provided with a gas-solid separation chamber; the outer wall of the gasification furnace chamber is provided with an insulation layer; Below the rotating grate (the bottom of the gasifier) is a continuous rotary charcoal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com